ASTM D2041-00

(Test Method)Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures

Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures

SCOPE

1.1 This test method covers the determination of the theoretical maximum specific gravity and density of uncompacted bituminous paving mixtures at 25oC (77oF).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2041 – 00

Standard Test Method for

Theoretical Maximum Specific Gravity and Density of

Bituminous Paving Mixtures

This standard is issued under the fixed designation D 2041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of the theo- 4.1 A weighed sample of oven-dry paving mixture in the

retical maximum specific gravity and density of uncompacted loose condition is placed in a tared vacuum vessel. Sufficient

bituminous paving mixtures at 25°C (77°F). water at a temperature of 25°C (77°F) is added to completely

1.2 This standard does not purport to address all of the submerge the sample. Vacuum is gradually applied to reduce

safety concerns, if any, associated with its use. It is the the residual pressure in the vacuum vessel to 4 kPa (30 mm of

responsibility of the user of this standard to establish appro- Hg) or less and then held for 15 6 2 min. At the end of the

priate safety and health practices and determine the applica- vacuum period, the vacuum is gradually released. The volume

bility of regulatory limitations prior to use. of the sample of paving mixture is obtained by immersing the

vacuum container with the sample in a water bath and

2. Referenced Documents

weighing or by filling the vacuum container level full of water

2.1 ASTM Standards: and weighing in air. Both the temperature and mass are

C 670 Practice for Preparing Precision and Bias Statements

measured at this time. From these mass and volume measure-

for Test Methods for Construction Materials ments, the specific gravity or density at 25°C is calculated.

D 979 Practice for Sampling Bituminous Paving Mixtures

5. Significance and Use

D 4753 Specification for Evaluating, Selecting, and Speci-

fying Balances and Scales for Use in Testing Soil, Rock, 5.1 The theoretical maximum specific gravities and densi-

and Related Construction Materials ties of bituminous paving mixtures are fundamental properties

E 1 Specification for ASTM Thermometers whose values are influenced by the composition of the mixture

E 12 Terminology Relating to Density and Specific Gravity in terms of types and amounts of aggregates and bituminous

of Solids, Liquids, and Gases materials.

5.1.1 Maximum specific gravity is used (1) in the calcula-

3. Terminology

tion of air voids in the compacted bituminous paving mixture,

3.1 The terms “specific gravity” and “density” used in this

(2) in calculating the amount of bitumen absorbed by the

test method are in accordance with Terminology E 12. aggregate, and (3) to provide target values for the compaction

3.2 Definitions of Terms Specific to This Standard:

of paving mixtures.

3.2.1 density, as determined by this test method— the mass

6. Apparatus

of a cubic metre of the material at 25°C (77°F) in SI units.

3.2.2 residual pressure, as employed by this test method— 6.1 Containers:

the pressure in a vacuum vessel when vacuum is applied. 6.1.1 Vacuum Bowls—Either a metal or plastic bowl with a

3.2.3 specific gravity, as determined by this test method— diameter of approximately 180 to 260 mm (7 to 10.25 in.) and

the ratio of a given mass of material at 25°C (77°F) to the mass a bowl height of at least 160 mm (6.3 in.) shall be equipped

of an equal volume of water at the same temperature. with a transparent cover fitted with a rubber gasket and a

connection for the vacuum line. Both the bowl and cover

should be sufficiently stiff to withstand the applied vacuum

This test method is under the jurisdiction of ASTM Committee D04 on Road

pressure without visibly deforming. The hose connection shall

and Paving Materials and is the direct responsibility of Subcommittee D04.21 on

Specific Gravity and Density of Bituminous Mixtures.

be covered with a small piece of fine wire mesh to minimize

Current edition approved Aug. 10, 2000. Published October 2000. Originally

the loss of any fine material.

published as D 2041 – 64 T. Last previous edition D 2041 – 95.

Annual Book of ASTM Standards, Vol 04.02.

NOTE 1—The transparent cover allows observation of the release of air

Annual Book of ASTM Standards, Vol 04.03.

bubbles.

Annual Book of ASTM Standards, Vol 04.08.

Annual Book of ASTM Standards, Vol 14.03.

6.1.2 Vacuum Flask for Weighing in Air Only, a thick-walled

Discontinued; see 1995 Annual Book of ASTM Standards, Vol 15.05. Replaced

volumetric glass flask with a capacity of approximately 4000

by Terminology E 1547.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

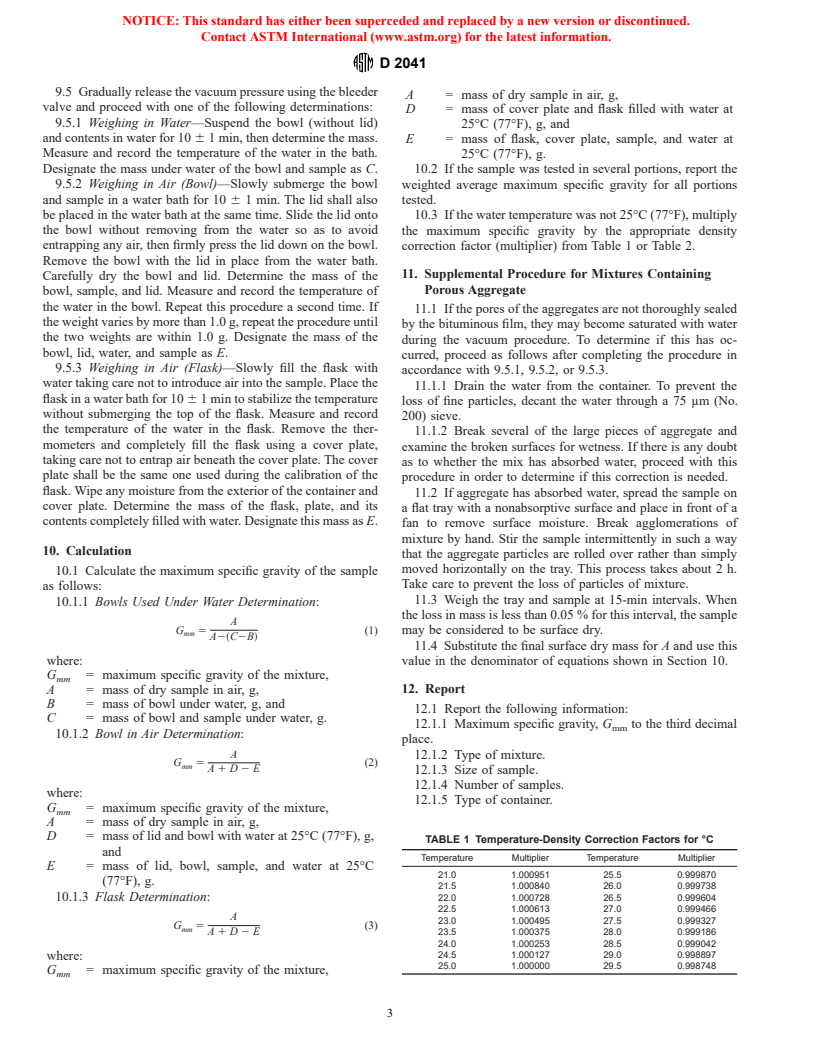

D 2041

mL, fitted with a rubber stopper with a connection for the 6.10 Oven, capable of maintaining a temperature of 110 6

vacuum line. The hose connection in the flask should be 5°C (230 6 9°F). This oven is needed when samples other than

covered with a small piece of fine wire mesh to minimize the laboratory prepared mixtures using oven-dry aggregate are

loss of any fine material tested.

6.2 Balance, capable of being read to the nearest 0.1 g and

7. Sampling

conforming to the requirements of Specification D 4753, Class

GP2. If underwater measurements will be taken, then the 7.1 Obtain the sample in accordance with Practice D 979.

balance shall be equipped with a suitable suspension apparatus 7.2 The size of sample shall be as follows:

and holder to permit weighing the sample while suspended

Nominal Maximum Aggregate Size, mm Minimum Sample Size, g

37.5 or greater 5000

from the center of the scale.

19 to 25 2500

6.3 Vacuum Pump or Water Aspirator, capable of evacuat-

12.5 or smaller 1500

ing air from the vacuum container to a residual pressure of 4.0

7.3 Sample sizes greater than about two thirds of the volume

kPa (30 mm of Hg) or less.

of the container shall be tested in portions with none of the

6.3.1 When a vacuum pump is used, a suitable trap shall be

portions tested being less than 1250 g.

installed between the vacuum vessel and vacuum source to

reduce the amount of water vapor entering the vacuum pump.

8. Calibration of Containers

6.4 Residual Pressure Manometer or Calibrated Absolute

8.1 Bowls—Calibrate the container by accurately determin-

Pressure Gage—This manometer or calibrated absolute pres-

ing the mass of the container immersed in water at 25 6 0.5°C

sure gage shall be used to confirm the specified pressure is

(77 6 0.9°F). Designate this mass as B.

applied to the container and shall be capable of measuring

8.1.1 If the bowl is used for weighing in air, place the

residual pressure to 4.0 kPa (30 mm of Hg) or less. It is to be

volumetric lid on the bowl while under water. Remove the

connected at the end of the vacuum line using an appropriate

water-filled bowl with the lid in place and dry prior to

tube and either a “T” connector on the top of the container or

determining the combined mass of the bowl, lid, and water.

by using a separate opening (from the vacuum line) in the top

Repeat three times and average the results. Designate the

of the container to attach the hose. To avoid damage, the

average mass as D.

manometer or gage itself is not to be situated on top of the

8.2 Flasks—Calibrate the volumetric flask by accurately

vessel but adjacent to it.

determining the mass of the flask filled with water at a

NOTE 2—Residual pressure in the vacuum vessel in millimetres of

temperature of 25 6 0.5°C (77 6 0.9°F). Designate this mass

mercury is the difference in the height of mercury.

as D. Accurate filling of the flask shall be ensured by the use of

a glass cover plate or similar smooth, flat transparent plate.

6.5 Manometer or Vacuum Gage, suitable for measuring the

vacuum being applied at the source of the vacuum. This device

9. Procedure

can be connected directly to the vacuum source or be in the

9.1 If the paving mixture has been prepared in a laboratory

vacuum line close to the source.

using oven-dry aggregates, proceed to 9.2. Any other sample

NOTE 3—The vacuum leg of a residual pressure manometer occasion-

needs to be dried to a constant mass (mass repeats within 0.1 %

ally acquires one or more air bubbles that introduce error into the residual

for consecutive 15-min weighings) at a temperature of 105 6

pressure reading. The additional vacuum gage or manometer provides a

5°C (2216 9°F).

means to quickly detect differences between the two vacuum measure-

ments. 9.2 Once the sample is dry and while it is still warm,

separate the particles of the sample of paving mixture by hand,

6.6 Thermometers—Calibrated liquid-in-glass thermom-

taking care to avoid fracturing the aggregate, so that the

eters of suitable range with subdivisions and maximum scale

particles of the fine aggregate portion are not larger than about

error of 0.5°C (0.9°F), or any other thermometric device of

6 mm. Cool the sample to room temperature. Additional

equal accuracy, precision, and sensitivity shall be used. Ther-

separation of the mixture is needed so that the particles of the

mometers shall conform to the requirements of Specification

fine aggregate portion are not larger than about 6 mm. Place the

E1.

sample directly into the tared bowl or volumetric flask. Do not

6.7 Water Bath, capable of maintaining by any means, a

use a container within a container. Weig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.