ASTM E1502-98(2003)e1

(Guide)Standard Guide for Use of Freezing-Point Cells for Reference Temperatures

Standard Guide for Use of Freezing-Point Cells for Reference Temperatures

SCOPE

1.1 This guide describes the essential features of freezing-point cells and auxiliary apparatus, and the techniques required to realize freezing points in the temperature range from 29 to 1085 °C.

1.2 Detailed design and construction are not addressed in this guide.

1.3 This guide is intended to describe good practice and establish uniform procedures for the realization of freezing points.

1.4 This guide emphasizes principles. The emphasis on principles is intended to aid the user in evaluating cells, in improving technique for using cells, and in establishing procedures for specific applications.

1.5 For the purposes of this guide, the use of freezing-point cells for the accurate calibration of thermometers is restricted to immersion-type thermometers that, when inserted into the reentrant well of the cell, (1) indicate the temperature only of the isothermal region of the well, and (2) do not significantly alter the temperature of the isothermal region of the well by heat transfer.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1502 – 98 (Reapproved 2003)

Standard Guide for

Use of Freezing-Point Cells for Reference Temperatures

This standard is issued under the fixed designation E1502; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Updated caution note in Section 7.2.2 in November 2003.

INTRODUCTION

During freezing, pure material transforms from the liquid state to the solid state at a constant

temperature known as the freezing point. The freezing points of highly purified materials can serve as

reference temperatures, and in fact, the International Temperature Scale of 1990 (ITS-90) relies on

the freezing points of some highly purified metals as defining fixed points. Freezing points can be

realized in commercially available systems incorporating freezing-point cells. When the cells are

properly made and used, they establish useful reference temperatures for the calibration of

thermometers and for other industrial and laboratory purposes; with care, the freezing points of highly

purified materials can be realized with an uncertainty of a few millikelvins or less.

1. Scope 1.6 This guide does not address all of the details of

thermometer calibration.

1.1 This guide describes the essential features of freezing-

1.7 This guide is intended to complement special operating

point cells and auxiliary apparatus, and the techniques required

instructions supplied by manufacturers of freezing-point appa-

to realize freezing points in the temperature range from 29 to

3 ratus.

1085 °C.

1.8 The following hazard caveat pertains only to the test

1.2 Detailed design and construction are not addressed in

methodportion,Section7,ofthisguide. This standard does not

this guide.

purport to address all of the safety concerns, if any, associated

1.3 This guide is intended to describe good practice and

with its use. It is the responsibility of the user of this standard

establish uniform procedures for the realization of freezing

to establish appropriate safety and health practices and

points.

determine the applicability of regulatory limitations prior to

1.4 This guide emphasizes principles. The emphasis on

use.

principles is intended to aid the user in evaluating cells, in

improving technique for using cells, and in establishing pro-

2. Referenced Documents

cedures for specific applications.

2.1 ASTM Standards:

1.5 For the purposes of this guide, the use of freezing-point

E344 Terminology Relating to Thermometry and Hydrom-

cells for the accurate calibration of thermometers is restricted

etry

to immersion-type thermometers that, when inserted into the

E644 Test Methods for Testing Industrial Resistance Ther-

reentrant well of the cell, (1) indicate the temperature only of

mometers

the isothermal region of the well, and (2) do not significantly

alter the temperature of the isothermal region of the well by

3. Terminology

heat transfer.

3.1 Definitions:

3.1.1 reference temperature, n—a fixed, reproducible tem-

perature, to which a value is assigned, that can be used for the

This guide is under the jurisdiction of ASTM Committee E20 on Temperature

calibration of thermometers or other purposes.

Measurement and is the direct responsibility of Subcommittee E20.07 on Funda-

3.1.2 Additional terms used in this guide are defined in

mentals in Thermometry.

Current edition approved Nov. 1, 2003. Published November 2003. Originally Terminology E344.

approved in 1992. Last previous edition aprpoved in 1998 as E1502 – 98. DOI:

10.1520/E1502-98R03E01.

Preston-Thomas, H., “The International Temperature Scale of 1990 (ITS-90),”

Metrologia, Vol 27, No. 1, 1990, pp. 3–10. For errata see ibid, Vol 27, No. 2, 1990, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

p. 107. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Inthisguidetemperatureintervalsareexpressedinkelvins(K)andmillikelvins Standards volume information, refer to the standard’s Document Summary page on

(mK). Values of temperature are expressed in degrees Celsius (°C), ITS-90. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

E1502 – 98 (2003)

3.2 Definitions of Terms Specific to This Standard:

3.2.1 first cryoscopic constant, A, n—a constant of propor-

tionality between the freezing point depression of, and concen-

tration of impurities in, a sample of reference material, given

by the ratio of the molar heat of fusion of the pure material, L,

to the product of the molar gas constant, R, and the square of

the thermodynamic temperature of fusion, T, of the pure

material (freezing point):

L

A 5 (1)

RT

3.2.2 freeze, n—an experiment or test run conducted with a

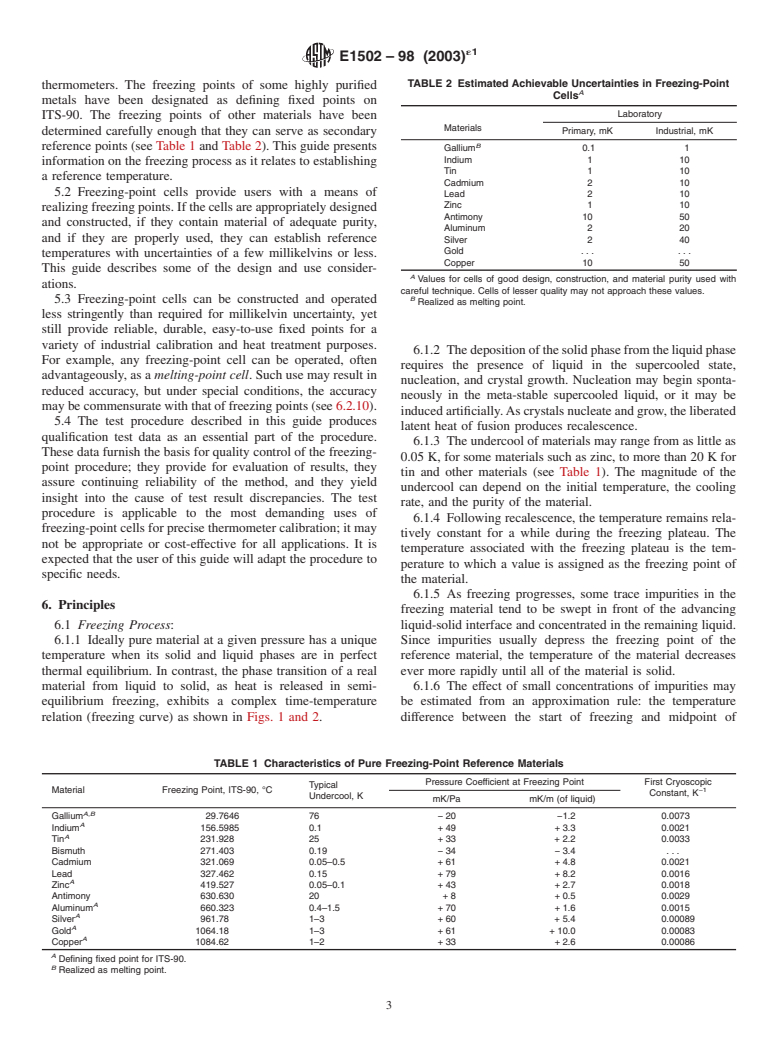

FIG. 2 Freezing Curve of a Sample of Highly Purified Tin

freezing-point cell while the reference material in the cell

solidifies.

3.2.3 freezing curve, n—theentiretime-temperaturerelation

and crystal growth, due to the release of latent heat of fusion of

of the reference material in a freezing-point cell during

the reference material.

freezing, including initial cooling, undercool, recalescence,

3.2.9 reference material, n—the material in a freezing-point

freezing plateau, and final cooling to complete solidification.

cell that melts and freezes during use, the freezing point of

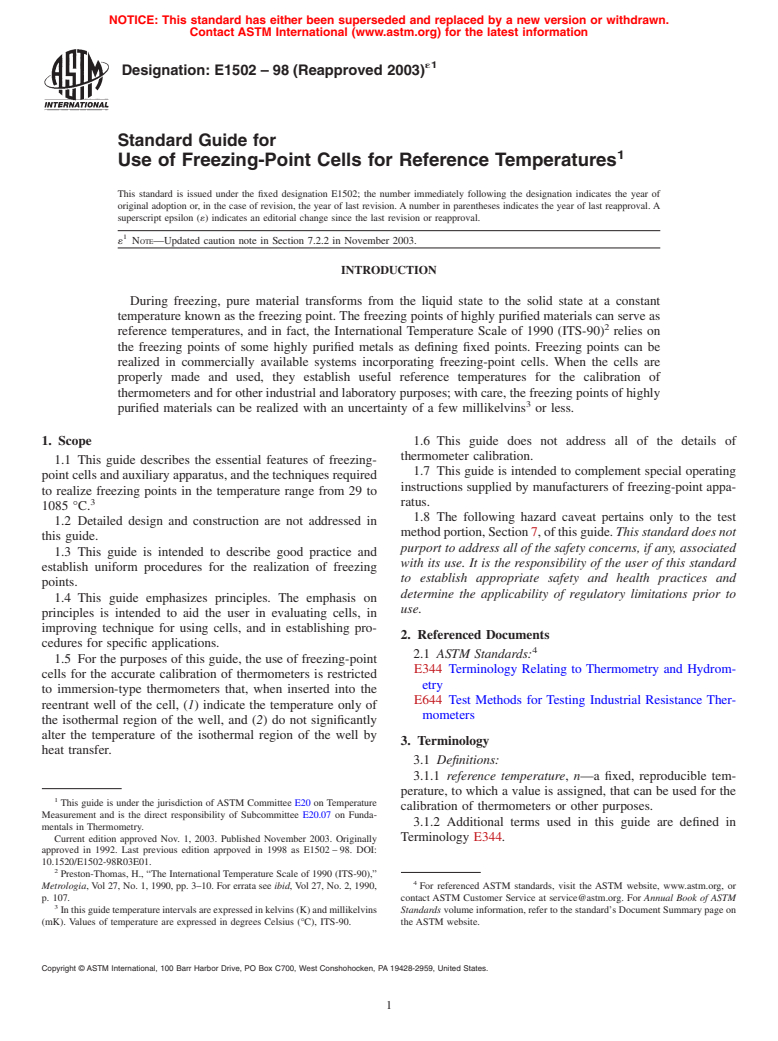

3.2.3.1 Discussion—Graphic representations of freezing

which can establish a reference temperature.

curves are shown in Fig. 1 and Fig. 2.

3.2.10 supercooled state, n—the meta-stable state of refer-

3.2.4 freezing plateau, n—the period during freezing in

ence material in which the temperature of the liquid phase is

which the temperature does not change significantly.

below the freezing point.

3.2.5 freezing-point cell, n—a device that contains and

3.2.11 undercool, n—the temperature depression below the

protects a sample of reference material in such a manner that

freezing point of reference material in the supercooled state.

the freezing point of the material can establish a reference

temperature. 4. Summary of Guide

3.2.6 freezing range, n—the range of temperature over

4.1 Afreezing-point cell is used for thermometer calibration

which most of the reference material in a freezing-point cell

by establishing and sustaining a reference material at the

solidifies.

freezing point, to which a value of temperature has been

3.2.6.1 Discussion—The freezing range is indicated graphi-

assigned. The thermometer to be calibrated is inserted into a

cally in Fig. 1.

reentrant well in the cell; the well itself is surrounded by the

3.2.7 nucleation, n—theformationofcrystalnucleiinliquid

freezing reference material.

in the supercooled state.

4.2 The cell is heated to melt the reference material. The

3.2.8 recalescence, n—the sudden increase in temperature

temperature of the surrounding environment is then reduced to

of reference material in the supercooled state upon nucleation

about 1 K below the freezing point so that the reference

material cools. Following the undercool, nucleation, and re-

calescence, the well temperature becomes constant during the

freezing plateau. After a time, depending on the rate of heat

loss from the cell, the amount of reference material, and the

purity of the reference material, the temperature starts to

decrease and eventually all of the material becomes solidified.

4.3 Since the temperature in the reentrant well remains

constant during the freezing plateau, one or more test ther-

mometers may be calibrated by inserting them singly into the

well. In some cases the plateau can be sustained for many

hours, and even under routine industrial conditions, the plateau

may be readily sustained long enough to test several thermom-

eters. The duration of the plateau may be lengthened by

preheating the test thermometers.

4.4 Measurements are made also during each freeze with a

A = Stabilized temperature of cell before freezing, typically about 1 K above

freezing point.

dedicated monitoring thermometer. These measurements, to-

B = Freezing point of cell.

gether with other special test measurements, provide qualifi-

C = Temperature of cell surroundings during freezing, typically about 1 K

cation test data (see 6.4 and 7.5).

below freezing point.

D = Maximum undercool.

E = Onset of recalescence.

5. Significance and Use

F = Freezing plateau.

5.1 A pure material has a well-defined freezing behavior,

G = Total freezing time.

H = Freezing range.

and its freezing point, a characteristic of the material, can serve

FIG. 1 Structure of a Typical Freezing Curve as a reproducible reference temperature for the calibration of

´1

E1502 – 98 (2003)

TABLE 2 Estimated Achievable Uncertainties in Freezing-Point

thermometers. The freezing points of some highly purified

A

Cells

metals have been designated as defining fixed points on

Laboratory

ITS-90. The freezing points of other materials have been

Materials

Primary, mK Industrial, mK

determined carefully enough that they can serve as secondary

B

reference points (see Table 1 and Table 2). This guide presents

Gallium 0.1 1

Indium 1 10

information on the freezing process as it relates to establishing

Tin 1 10

a reference temperature.

Cadmium 2 10

5.2 Freezing-point cells provide users with a means of

Lead 2 10

Zinc 1 10

realizing freezing points. If the cells are appropriately designed

Antimony 10 50

and constructed, if they contain material of adequate purity,

Aluminum 2 20

and if they are properly used, they can establish reference

Silver 2 40

Gold . .

temperatures with uncertainties of a few millikelvins or less.

Copper 10 50

This guide describes some of the design and use consider-

A

Values for cells of good design, construction, and material purity used with

ations.

careful technique. Cells of lesser quality may not approach these values.

B

5.3 Freezing-point cells can be constructed and operated

Realized as melting point.

less stringently than required for millikelvin uncertainty, yet

still provide reliable, durable, easy-to-use fixed points for a

variety of industrial calibration and heat treatment purposes.

6.1.2 Thedepositionofthesolidphasefromtheliquidphase

For example, any freezing-point cell can be operated, often

requires the presence of liquid in the supercooled state,

advantageously, as a melting-point cell. Such use may result in

nucleation, and crystal growth. Nucleation may begin sponta-

reduced accuracy, but under special conditions, the accuracy

neously in the meta-stable supercooled liquid, or it may be

may be commensurate with that of freezing points (see 6.2.10).

induced artificially.As crystals nucleate and grow, the liberated

5.4 The test procedure described in this guide produces

latent heat of fusion produces recalescence.

qualification test data as an essential part of the procedure.

6.1.3 The undercool of materials may range from as little as

These data furnish the basis for quality control of the freezing-

0.05 K, for some materials such as zinc, to more than 20 K for

point procedure; they provide for evaluation of results, they

tin and other materials (see Table 1). The magnitude of the

assure continuing reliability of the method, and they yield

undercool can depend on the initial temperature, the cooling

insight into the cause of test result discrepancies. The test

rate, and the purity of the material.

procedure is applicable to the most demanding uses of

6.1.4 Following recalescence, the temperature remains rela-

freezing-point cells for precise thermometer calibration; it may

tively constant for a while during the freezing plateau. The

not be appropriate or cost-effective for all applications. It is

temperature associated with the freezing plateau is the tem-

expected that the user of this guide will adapt the procedure to

perature to which a value is assigned as the freezing point of

specific needs.

the material.

6.1.5 As freezing progresses, some trace impurities in the

6. Principles

freezing material tend to be swept in front of the advancing

6.1 Freezing Process: liquid-solid interface and concentrated in the remaining liquid.

6.1.1 Ideally pure material at a given pressure has a unique Since impurities usually depress the freezing point of the

temperature when its solid and liquid phases are in perfect reference material, the temperature of the material decreases

thermal equilibrium. In contrast, the phase transition of a real ever more rapidly until all of the material is solid.

material from liquid to solid, as heat is released in semi- 6.1.6 The effect of small concentrations of impurities may

equilibrium freezing, exhibits a complex time-temperature be estimated from an approximation rule: the temperature

difference between the start of freezing and midpoint of

relation (freezing curve) as shown in Figs. 1 and 2.

TABLE 1 Characteristics of Pure Freezing-Point Reference Materials

Pressure Coefficient at Freezing Point First Cryoscopic

Typical

−1

Material Freezing Point, ITS-90, °C

Constant, K

Undercool, K

mK/Pa mK/m (of liquid)

A,B

Gallium 29.7646 76 − 20 −1.2 0.0073

A

Indium 156.5985 0.1 + 49 + 3.3 0.0021

A

Tin 231.928 25 + 33 + 2.2 0.0033

Bismuth 271.403 0.19 − 34 − 3.4 . . .

Cadmium 321.069 0.05–0.5 + 61 + 4.8 0.0021

Lead 327.462 0.15 + 79 + 8.2 0.0016

A

Zinc 419.527 0.05–0.1 + 43 + 2.7 0.0018

Antimony 630.630 20 + 8 + 0.5 0.0029

A

Aluminum 660.323 0.4–1.5 + 70 + 1.6 0.0015

A

Silver 961.78 1–3 + 60 + 5.4 0.00089

A

Gold 1064.18 1–3 + 61 + 10.0 0.00083

A

Copper 1084.62 1–2 + 33 + 2.6 0.00086

A

Defining fixed point for ITS-90.

B

Realized as melting point.

´1

E1502 – 98 (2003)

freezing (when half the material is solid) equals the tempera-

ture difference between the freezing point of the ideally pure

material and the freezing point (at the start of freezing) of the

real reference material (see 8.6.2). The product of this tem-

perature difference and the first cryoscopic constant gives an

estimate of the mole fraction impurity concentration in the

reference material. Conversely, if the impurity concentration is

known, then the temperature difference can be estimated.

6.1.7 The change in temperature during the freezing plateau

due to a change in pressure is generally less than 0.1 µK/Pa

(Table 1). Thus, normal changes in atmospheric pressure have

little effect on the freezing point, but the effect of the pressure

of a head of dense liquid reference material may be significant.

Thefreezingpointisusuallytakentobethetemperatureduring

the freezing plateau at a pressure of 101 325 Pa.

6.2 Fr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.