ASTM C667-09(2014)

(Specification)Standard Specification for Prefabricated Reflective Insulation Systems for Equipment and Pipe Operating at Temperatures above Ambient Air

Standard Specification for Prefabricated Reflective Insulation Systems for Equipment and Pipe Operating at Temperatures above Ambient Air

ABSTRACT

This specification covers the standard for all metal prefabricated, reflective insulation systems for equipment and piping operating at temperatures above ambient in air proposed for use in nuclear power-generating plants and industrial plants. The insulation unit is a rigid, self-contained, prefabricated metal construction made of an inner and outer casing arranged to form a rigid assembly with separated air spaces between the inner and outer casing and the individual reflective liners. The reflective insulation described herein is limited to systems of insulating units, designed to fit the equipment or piping to be insulated. The units shall be manufactured from metals that are in accordance with the thermal, physical, and chemical requirements not only of the insulation as unit, but also as an assembly of units forming the insulation system.

SCOPE

1.1 This specification covers the requirements for all metal prefabricated, reflective insulation systems for equipment and piping operating in air at temperatures above ambient. Typical applications are in nuclear power-generating plants and industrial plants.

1.2 Reflective insulation is thermal insulation that reduces radiant heat transfer across spaces by the use of surfaces of high reflectance and low emittance.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C667 −09 (Reapproved 2014)

Standard Specification for

Prefabricated Reflective Insulation Systems for Equipment

and Pipe Operating at Temperatures above Ambient Air

This standard is issued under the fixed designation C667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1045 Practice for Calculating Thermal Transmission Prop-

erties Under Steady-State Conditions

1.1 This specification covers the requirements for all metal

C1058 Practice for Selecting Temperatures for Evaluating

prefabricated, reflective insulation systems for equipment and

and Reporting Thermal Properties of Thermal Insulation

piping operating in air at temperatures above ambient. Typical

C1061 Test Method for Thermal Transmission Properties of

applications are in nuclear power-generating plants and indus-

Non-Homogeneous Insulation Panels Installed Vertically

trial plants.

(Withdrawn 1995)

1.2 Reflective insulation is thermal insulation that reduces

C1371 Test Method for Determination of Emittance of

radiant heat transfer across spaces by the use of surfaces of

Materials Near Room Temperature Using Portable Emis-

high reflectance and low emittance.

someters

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions:

and are not considered standard.

3.1.1 Terms relating to thermal insulation materials and

1.4 This standard does not purport to address all of the

testing are in accordance with Terminology C168.

safety concerns, if any, associated with its use. It is the

3.2 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

3.2.1 convection stops—seals used to reduce convection

priate safety and health practices and determine the applica-

losses.

bility of regulatory limitations prior to use.

3.2.2 end supports—structural members placed at the end of

a unit of insulation and fastened to both the inner and outer

2. Referenced Documents

case.

2.1 ASTM Standards:

3.2.2.1 Discussion—The primary purpose of the end sup-

C168 Terminology Relating to Thermal Insulation

ports is to increase the structural integrity of the unit.

C335 Test Method for Steady-State Heat Transfer Properties

3.2.3 inner case—the innermost sheet of the unit of insula-

of Pipe Insulation

tion (closest to the hot surface).

C411 Test Method for Hot-Surface Performance of High-

3.2.3.1 Discussion— The inner case may perform structural

Temperature Thermal Insulation

functions in addition to its thermal functions.

C835 Test Method for Total Hemispherical Emittance of

3.2.4 insulation assembly—an assembly of insulation units

Surfaces up to 1400°C

arranged and secured together in a prescribed order that

C854 Test Method for Resistance to External Loads on

comprises the complete insulation for a vessel, pump, pipeline,

Metal Reflective Pipe Insulation (Withdrawn 1997)

or other component for a single design objective.

3.2.5 insulation system—a collection of insulation

This specification is under the jurisdiction of ASTM Committee C16 on

assemblies, that when secured together in a prescribed order,

Thermal Insulation and is the direct responsibility of Subcommittee C16.40 on

comprises the complete insulation for a vessel, pump, pipeline,

Insulation Systems.

Current edition approved Feb. 1, 2014. Published March 2014. Originally or other component for a single design objective.

approved in 1992. Last previous edition approved in 2009 as C667-09. DOI:

3.2.6 lap straps—strips that overlap a longitudinal or cir-

10.1520/C0667-09R14.

cumferential joint in the insulation which aligns adjacent

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

insulation units and may also serve to restrict air infiltration

Standards volume information, refer to the standard’s Document Summary page on

and convection losses and to shed external falling water.

the ASTM website.

3.2.6.1 Discussion—The lap straps may be integral with one

The last approved version of this historical standard is referenced on

www.astm.org. piece of the outer case or separate strips secured to it.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C667−09 (2014)

3.2.7 outer case—the outermost sheet or the unit of insula- 4.1.7 Limits, if any, on size, maximum thickness, weight, or

tion (farthest from the hot surface). It usually performs number of insulation units requiring removal for inspection,

structural functions in addition to its thermal functions.

4.1.8 Location of components or maintenance, or both, and

systems requiring removal of units for inspections,

3.2.8 penetrations—openings in a unit of insulation from

the cold surface through to the hot surface.

4.1.9 Any unusual operating or test conditions, and

3.2.9 reflective liners—those reflective sheets or foil inter- 4.1.10 Cleanliness level required.

posed between the inner and outer case to reflect radiant

energy, to minimize emission of radiant energy, and to restrict

5. Materials and Manufacture

internal convection.

5.1 Each insulation unit is a rigid, self-contained, prefabri-

3.2.10 thickness—(see Fig. 1).

cated metal construction comprised of an inner casing and an

3.2.11 unit of insulation—a single structurally independent

outer casing, and if needed, one or more reflective liners

assembly of inner case, outer case, reflective liners, and end

supported and spaced so as to minimize internal convection

supports (if required).

and conduction. These parts are arranged to form a durable

rigid assembly with separated air spaces between the inner and

4. Ordering Information

outer casing and the individual reflective liners.

4.1 Ordering information shall include the following:

5.2 The reflective insulation described herein is limited to

4.1.1 Service requirements including operating hot surface

systems of insulating units, designed by the manufacturer to fit

temperature, expected ambient temperatures, and ambient air

the equipment or piping to be insulated, and engineered for the

velocities,

purchaser’s service requirements.

4.1.2 Expected service life and any special environmental

5.3 All parts of reflective insulation units be made of metals

exposures,

4.1.3 Permitted average heat loss per unit of cold surface or that meet the thermal, physical, and chemical requirements not

as otherwise specified, only of the insulation as a unit, but also as an assembly of units

4.1.4 Personnel exposure surface temperature limitations, forming the insulation system. The materials shall perform

4.1.5 Expected seismic, loading, and vibration exposures, their functions for the service life specified and be compatible

4.1.6 Purchaser’s systems and equipment drawings, with the environment in which they will be used.

FIG. 1 Illustration of Terms Relating to Prefabricated Reflective Insulation Systems

C667−09 (2014)

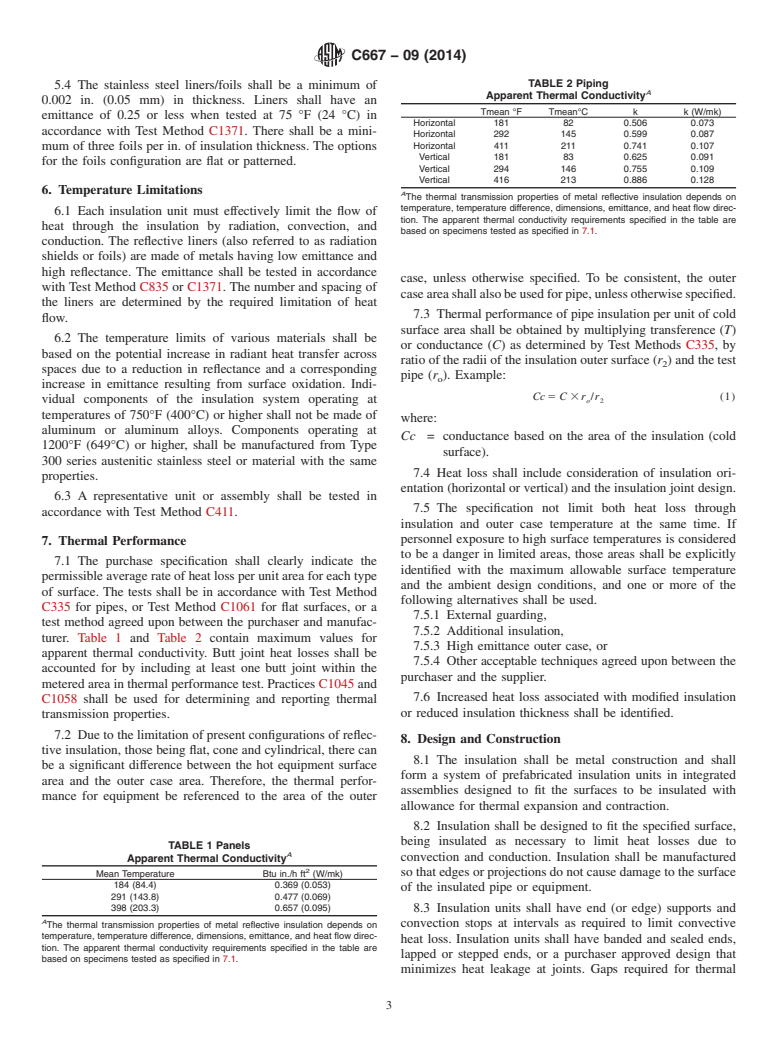

TABLE 2 Piping

5.4 The stainless steel liners/foils shall be a minimum of

A

Apparent Thermal Conductivity

0.002 in. (0.05 mm) in thickness. Liners shall have an

Tmean °F Tmean°C k k (W/mk)

emittance of 0.25 or less when tested at 75 °F (24 °C) in

Horizontal 181 82 0.506 0.073

accordance with Test Method C1371. There shall be a mini-

Horizontal 292 145 0.599 0.087

Horizontal 411 211 0.741 0.107

mum of three foils per in. of insulation thickness. The options

Vertical 181 83 0.625 0.091

for the foils configuration are flat or patterned.

Vertical 294 146 0.755 0.109

Vertical 416 213 0.886 0.128

6. Temperature Limitations

A

The thermal transmission properties of metal reflective insulation depends on

temperature, temperature difference, dimensions, emittance, and heat flow direc-

6.1 Each insulation unit must effectively limit the flow of

tion. The apparent thermal conductivity requirements specified in the table are

heat through the insulation by radiation, convection, and

based on specimens tested as specified in 7.1.

conduction. The reflective liners (also referred to as radiation

shields or foils) are made of metals having low emittance and

high reflectance. The emittance shall be tested in accordance

case, unless otherwise specified. To be consistent, the outer

with Test Method C835 or C1371. The number and spacing of

caseareashallalsobeusedforpipe,unlessotherwisespecified.

the liners are determined by the required limitation of heat

7.3 Thermal performance of pipe insulation per unit of cold

flow.

surface area shall be obtained by multiplying transference (T)

6.2 The temperature limits of various materials shall be

or conductance (C) as determined by Test Methods C335,by

based on the potential increase in radiant heat transfer across

ratio of the radii of the insulation outer surface (r ) and the test

spaces due to a reduction in reflectance and a corresponding

pipe (r ). Example:

o

increase in emittance resulting from surface oxidation. Indi-

Cc 5 C 3r /r (1)

o 2

vidual components of the insulation system operating at

temperatures of 750°F (400°C) or higher shall not be made of

where:

aluminum or aluminum alloys. Components operating at

Cc = conductance based on the area of the insulation (cold

1200°F (649°C) or higher, shall be manufactured from Type

surface).

300 series austenitic stainless steel or material with the same

7.4 Heat loss shall include consideration of insulation ori-

properties.

entation (horizontal or vertical) and the insulation joint design.

6.3 A representative unit or assembly shall be tested in

7.5 The specification not limit both heat loss through

accordance with Test Method C411.

insulation and outer case temperature at the same time. If

personnel exposure to high surface temperatures is considered

7. Thermal Performance

to be a danger in limited areas, those areas shall be explicitly

7.1 The purchase specification shall clearly indicate the

identified with the maximum allowable surface temperature

permissible average rate of heat loss per unit area for each type

and the ambient design conditions, and one or more of the

of surface. The tests shall be in accordance with Test Method

following alternatives shall be used.

C335 for pipes, or Test Method C1061 for flat surfaces, or a

7.5.1 External guarding,

test method agreed upon between the purchaser and manufac-

7.5.2 Additional insulation,

turer. Table 1 and Table 2 contain maximum values for

7.5.3 High emittance outer case, or

apparent thermal conductivity. Butt joint heat losses shall be

7.5.4 Other acceptable techniques agreed upon between the

accounted for by including at least one butt joint within the

purchaser and the supplier.

metered area in thermal performance test. Practices C1045 and

7.6 Increased heat loss associated with modified insulation

C1058 shall be used for determining and reporting thermal

or reduced insulation thickness shall be identified.

transmission properties.

7.2 Due to the limitation of present configurations of reflec-

8. Design and Construction

tive insulation, those being flat, cone and cylindrical, there can

8.1 The insulation shall be metal construction and shall

be a significant difference between the hot equipment surface

form a system of prefabricated insulation units in integrated

area and the outer case area. Therefore, the thermal perfor-

assemblies designed to fit the surfaces to be insulated with

mance for equipment be referenced to the area of the outer

allowance for thermal expansion and contraction.

8.2 Insulation shall be designed to fit the specified surface,

being insulated as necessary to limit heat losses due to

TABLE 1 Panels

A

Apparent Thermal Conductivity convection and conduction. Insulation shall be manufactured

so that edges or projections do not cause damage to the surface

Mean Temperature Btu in./h ft (W/mk)

184 (84.4) 0.369 (0.053)

of the insulated pipe or equipment.

291 (143.8) 0.477 (0.069)

398 (203.3) 0.657 (0.095)

8.3 Insulation units shall have end (or edge) supports and

A

The thermal transmission properties of metal reflective insulation depends on convection stops at intervals as required to limit convective

temperature, temperature difference, dimensions, emittance, and heat flow direc-

heat loss. Insulation units shall have banded and sealed ends,

tion. The apparent thermal conductivity requirements specified in the table are

lapped or stepped ends, or a purchaser approved design that

based on specimens tested as specified in 7.1.

minimizes heat leakage at joints. Gaps required for thermal

C667−09 (2014)

expansion or for internal unit construction are permitted when 11. Installation and Inspection

approved by the purchaser.

11.1 Since prefabricated reflective insulations are custom-

made to fit the vessel or piping to which they are to be

8.4 Insulation units and assemblies shall have the strength

installed, with casing lapping required for slip joints, water-

and rigidity to withstand specified seismic forces, and the

shedding, and weather protection, they must be installed in

operational loading and vibration requirements. Each unit shall

proper sequence. The insulation manufacturer is expected to

have strength and rigidity to hold its internal parts in its spacial

provide installation diagrams or procedures, or both, to show

relationship without bunching or matting. Resistance to exter-

the proper sequence of installation.

nal loads shall be determined by the use of Test Method C854.

11.2 Normally, insulation modifications shall be referred to

8.5 Insulation units and assemblies shall have provisions to

the manufacturer. Field cutting or fitting shall be done in a

retard entrance of liquids and to drain condensate, moisture, or

workmanlike manner with cuts that are clean and neat and

other liquids from spill or other exposures specified in the

flashed to restrict air flow in or out of the insulation.

ordering information.

11.3 Unitsofinsulationshallbeinstalledinpropersequence

8.6 Units shall have provisions to prevent internal pressure

with ends closely butted and with lap straps arranged to shed

build-up.

water.

8.7 Attachments, fasteners, and interlocking construction

11.4 Fitting, flange, and valve covers shall be installed to

shall hold the insulation units firmly in place in the assemblies

mate with straight pipe insulations.

under all specified operating and test conditions. Locations of

11.5 Where

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.