ASTM D2593-93(2004)e1

(Test Method)Standard Test Method for Butadiene Purity and Hydrocarbon Impurities by Gas Chromatography

Standard Test Method for Butadiene Purity and Hydrocarbon Impurities by Gas Chromatography

SIGNIFICANCE AND USE

The trace hydrocarbon compounds listed can have an effect in the commercial use of butadiene. This test method is suitable for use in process quality control and in setting specifications.

SCOPE

1.1 This test method covers the determination of butadiene-1,3 purity and impurities such as propane, propylene, isobutane, n-butane, butene-1, isobutylene, propadiene, trans-butene-2, cis-butene-2, butadiene-1,2, pentadiene-1,4, and, methyl, dimethyl, ethyl, and vinyl acetylene in polymerization grade butadiene by gas chromatography. Impurities including butadiene dimer, carbonyls, inhibitor, and residue are measured by appropriate ASTM procedures and the results used to normalize the component distribution obtained by chromatography.

Note 1—Other impurities present in commercial butadiene must be calibrated and analyzed. Other impurities were not tested in the cooperative work on this test method.

Note 2—This test method can be used to check for pentadiene-1,4 and other C5s instead of Test Method D1088.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.1 and 9.3

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D2593–93 (Reapproved 2004)

Designation: 194/74(81)

Standard Test Method for

Butadiene Purity and Hydrocarbon Impurities by Gas

Chromatography

This standard is issued under the fixed designation D2593; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This test method was adopted as a joint ASTM-IP Standard in 1972.

´ NOTE—Warning notes were editorially moved into text in November 2004.

1. Scope D1088 Discontinued 1984; Method of Test for Boiling

Point Range of Polymerization-Grade Butadiene

1.1 This test method covers the determination of butadiene-

2.2 Energy Institute Standards:

1,3 purity and impurities such as propane, propylene, isobu-

Test Method IP 194, Analysis of Butadiene-1,3 Polymer-

tane, n-butane, butene-1, isobutylene, propadiene, trans-

ization Grade.

butene-2, cis-butene-2, butadiene-1,2, pentadiene-1,4, and,

methyl, dimethyl, ethyl, and vinyl acetylene in polymerization

3. Summary of Test Method

grade butadiene by gas chromatography. Impurities including

3.1 A representative sample is introduced into a gas-liquid

butadienedimer,carbonyls,inhibitor,andresiduearemeasured

partition column. The butadiene and other components are

by appropriate ASTM procedures and the results used to

separated as they are transported through the column by an

normalize the component distribution obtained by chromatog-

inert carrier gas. Their presence in the effluent is measured by

raphy.

adetectorandrecordedasachromatogram.Thechromatogram

NOTE 1—Other impurities present in commercial butadiene must be

of the sample is interpreted by applying component attenuation

calibrated and analyzed. Other impurities were not tested in the coopera-

and detector response factors to the peak areas or peak heights

tive work on this test method.

and the relative concentration determined by relating indi-

NOTE 2—This test method can be used to check for pentadiene-1,4 and

vidual peak response to total peak response. Impurities includ-

other C s instead of Test Method D1088.

ing butadiene dimer, carbonyls, inhibitor, and residue are

1.2 This standard does not purport to address all of the

measured by appropriate ASTM procedures and the results

safety concerns, if any, associated with its use. It is the

used to normalize the distribution obtained by gas chromatog-

responsibility of the user of this standard to establish appro-

raphy.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

4. Significance and Use

statements, see 6.1 and 9.3.

4.1 The trace hydrocarbon compounds listed can have an

effect in the commercial use of butadiene. This test method is

2. Referenced Documents

suitable for use in process quality control and in setting

2.1 ASTM Standards:

specifications.

5. Apparatus

This test method is under the jurisdiction of ASTM Committee D02 on 5.1 Chromatograph—Any chromatograph having either a

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

thermal-conductivity or flame ionization detector can be used

D02.D0 on Hydrocarbons for Chemical and Special Uses.

provided the system has sufficient sensitivity and stability to

Current edition approved Nov. 1, 2004. Published November 2004. Originally

approved in 1967. Last previous edition approved in 1998 as D2593 – 93 (1998).

DOI: 10.1520/D2593-93R04E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Withdrawn. The last approved version of this historical standard is referenced

Standards volume information, refer to the standard’s Document Summary page on on www.astm.org.

the ASTM website. Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

Withdrawn. U.K.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D2593–93 (2004)

obtain a recorder deflection of at least 2 mm at signal-to-noise 6.2 Column Materials:

ratio of at least 5:1 for 0.01 weight % of impurity. 6.2.1 Liquid Phase—The materials that have been used

5.2 Column—Any column can be used that is capable of

successfully in cooperative work as liquid phases are listed in

resolving the components listed in 1.1 with the exception of Table X1.1.

butene-1 and isobutylene, which can be eluted together. The

6.2.2 Solid Support—The support for use in the packed

componentsshouldberesolvedintodistinctpeakssuchthatthe column is usually crushed firebrick or diatomaceous earth.

ratio A/B will not be less than 0.5 where A is the depth of the

Sieve size will depend on the diameter of the column used and

valley on either side of peak B and B is the height above the liquid-phase loading, and should be such as would give

baseline of the smaller of any two adjacent peaks. In the case

optimum resolution and analysis time. Optimum size ranges

where the small component peak is adjacent to a large one, it cannot be predicted on purely theoretical grounds. For some

can be necessary to construct a baseline of the small peak

systems it has been found that a ratio of average particle

tangent to the curve as shown in Fig. 1. diameter to column inside diameter of 1:25 will result in

5.2.1 A description of columns that meet the requirements

minimum retention time and minimum band widths.

of this test method is tabulated in theAppendix. Persons using 6.2.3 Tubing Material—Copper, stainless steel, Monel, alu-

other column materials must establish that the column gives

minum, and various plastic materials have been found to be

results that meet the precision requirements of Section 11.

satisfactory for column tubing. The material must be nonreac-

5.3 Sample Inlet System—Means shall be provided for

tive with respect to substrate, sample, and carrier gas and of

introducing a measured quantity of representative sample into

uniform internal diameter.

the column. Pressure-sampling devices can be used to inject a

6.3 Hydrocarbons for Calibration and Identification—

small amount of liquid directly into the carrier gas. Introduc-

Hydrocarbon standards for all components present are needed

tion can also be accomplished by use of a gas valve to charge

for identification by retention time and for calibration for

the vaporized liquid.

quantitative measurements.

5.4 Recorder—A recording potentiometer with a full-scale

NOTE 4—Mixtures of hydrocarbons can be used provided there is no

deflection of 10 mV or less is suitable for obtaining the

uncertainty as to the identity or concentration of the compounds involved.

chromatographic data. Full-scale response time should be 2 s

or less, and with sufficient sensitivity to meet the requirements

7. Preparation of Apparatus

of 5.1.

7.1 Column Preparation—The technique used to prepare

NOTE 3—Othermethodsofrecordingdetectoroutputsuchascomputer-

the column is not critical as long as the finished column

teletype systems can be used instead of a recorder, provided precision

produces the desired separation. Preparation of the packing is

requirements of Section 11 are met.

not difficult once the support, partitioning liquid, and loading

level have been determined. The following general directions

6. Reagents and Materials

have been found to produce columns of acceptable character-

6.1 Carrier Gas—A carrier gas appropriate to the type of

istics.

detectorusedshouldbeemployed.Heliumorhydrogenmaybe

7.1.1 Weigh out the desired quantity of support, usually

used with thermal conductivity detectors. Nitrogen, helium, or

twice that required to fill the column.

argon may be used with ionization detectors. The minimum

7.1.2 Calculate and weigh out the required quantity of

purity of any carrier should be 99.95 mol %. (Warning—

partitioning agent. Dissolve the partitioning agent in a volume

Compressed gas. Hazardous pressure.) (Warning—Hydrogen

ofchemicallyinert,low-boilingsolventequaltoapproximately

flammable gas. Hazardous pressure.)

twice the volume of support.

6.1.1 Ifhydrogenisused,specialsafetyprecautionsmustbe

7.1.3 Graduallyaddthesupportmaterialtothesolutionwith

taken to ensure that the system is free from leaks and that the

gentle stirring.

effluent is properly vented.

7.1.4 Slowly evaporate the solvent while gently agitating

the mixture until the packing is nearly dry and no free liquid is

apparent.

7.1.4.1 Some stationary phases such as benzyl cyanide

silvernitratearesusceptibletooxidationandmustbeprotected

from excessive exposure to air during the evaporation and

drying steps.

7.1.5 Spread the packing in thin layers on a nonabsorbent

surface and air- or oven-dry as required to remove all traces of

solvent.

7.1.6 Resieve the packing to remove fines and agglomerates

produced in the impregnation step.

7.1.7 Fill the column tubing with packing by plugging one

end with glass wool and pouring the packing into the other end

throughasmallfunnel.Vibratethetubingcontinuouslyoverits

entirelengthwhilefilling.Whenthepackingceasestoflow,tap

FIG. 1 Illustration of A/B Ratio for Small-Component Peak the column gently on the floor or bench-top while vibrating is

´1

D2593–93 (2004)

continued. Add packing as necessary until no further settling

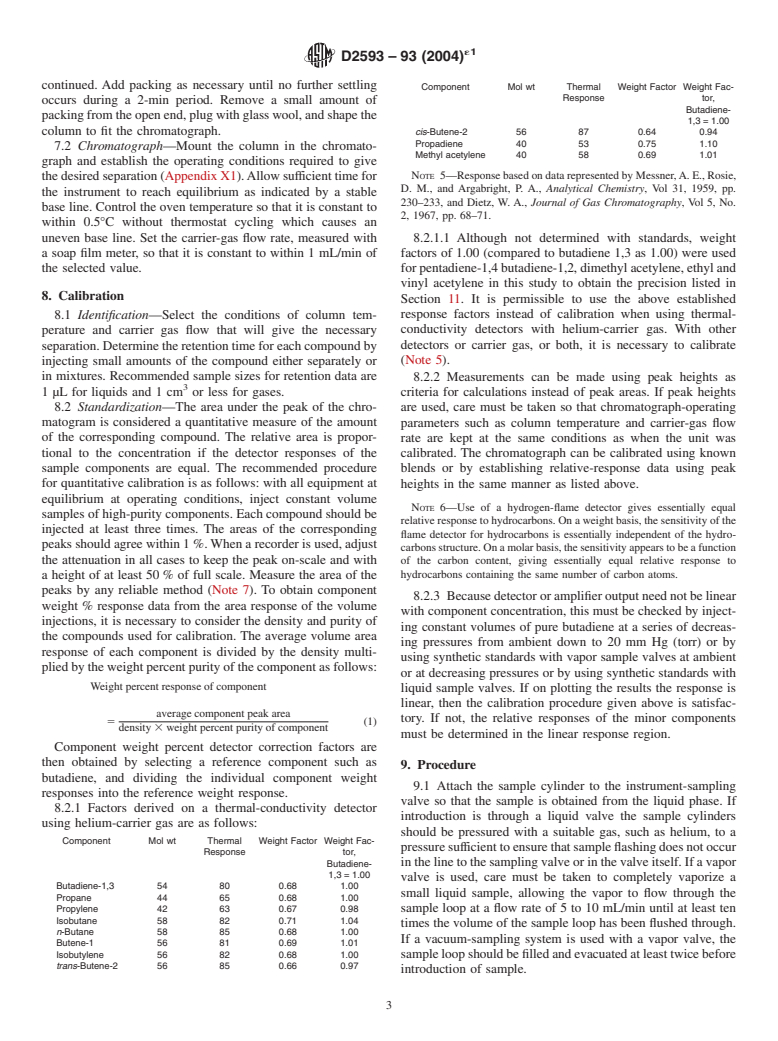

Component Mol wt Thermal Weight Factor Weight Fac-

Response tor,

occurs during a 2-min period. Remove a small amount of

Butadiene-

packingfromtheopenend,plugwithglasswool,andshapethe

1,3=1.00

column to fit the chromatograph. cis-Butene-2 56 87 0.64 0.94

Propadiene 40 53 0.75 1.10

7.2 Chromatograph—Mount the column in the chromato-

Methyl acetylene 40 58 0.69 1.01

graph and establish the operating conditions required to give

NOTE 5—ResponsebasedondatarepresentedbyMessner,A.E.,Rosie,

thedesiredseparation(AppendixX1).Allowsufficienttimefor

D. M., and Argabright, P. A., Analytical Chemistry, Vol 31, 1959, pp.

the instrument to reach equilibrium as indicated by a stable

230–233, and Dietz, W. A., Journal of Gas Chromatography, Vol 5, No.

base line. Control the oven temperature so that it is constant to

2, 1967, pp. 68–71.

within 0.5°C without thermostat cycling which causes an

uneven base line. Set the carrier-gas flow rate, measured with 8.2.1.1 Although not determined with standards, weight

a soap film meter, so that it is constant to within 1 mL/min of factors of 1.00 (compared to butadiene 1,3 as 1.00) were used

the selected value. forpentadiene-1,4butadiene-1,2,dimethylacetylene,ethyland

vinyl acetylene in this study to obtain the precision listed in

8. Calibration

Section 11. It is permissible to use the above established

response factors instead of calibration when using thermal-

8.1 Identification—Select the conditions of column tem-

conductivity detectors with helium-carrier gas. With other

perature and carrier gas flow that will give the necessary

detectors or carrier gas, or both, it is necessary to calibrate

separation.Determinetheretentiontimeforeachcompoundby

(Note 5).

injecting small amounts of the compound either separately or

in mixtures. Recommended sample sizes for retention data are 8.2.2 Measurements can be made using peak heights as

1 µL for liquids and 1 cm or less for gases. criteria for calculations instead of peak areas. If peak heights

8.2 Standardization—The area under the peak of the chro- are used, care must be taken so that chromatograph-operating

matogram is considered a quantitative measure of the amount parameters such as column temperature and carrier-gas flow

of the corresponding compound. The relative area is propor- rate are kept at the same conditions as when the unit was

tional to the concentration if the detector responses of the calibrated. The chromatograph can be calibrated using known

sample components are equal. The recommended procedure blends or by establishing relative-response data using peak

for quantitative calibration is as follows: with all equipment at

heights in the same manner as listed above.

equilibrium at operating conditions, inject constant volume

NOTE 6—Use of a hydrogen-flame detector gives essentially equal

samples of high-purity components. Each compound should be

relative response to hydrocarbons. On a weight basis, the sensitivity of the

injected at least three times. The areas of the corresponding

flame detector for hydrocarbons is essentially independent of the hydro-

peaks should agree within 1 %.When a recorder is used, adjust

carbonsstructure.Onamolarbasis,thesensitivityappearstobeafunction

the attenuation in all cases to keep the peak on-scale and with of the carbon content, giving essentially equal relative response to

hydrocarbons containing the same number of carbon atoms.

a height of at least 50 % of full scale. Measure the area of the

peaks by any reliable method (Note 7). To obtain component

8.2.3 Becausedetectororamplifieroutputneednotbelinear

weight % response data from the area response of the volume

with component concentration, this must be checked by inject-

injections, it is necessary to consider the density and purity of

ing constant volumes of pure butadiene at a series of decreas-

the compounds used for calibration. The average volume area

ing pressures from ambient down to 20 mm Hg (torr) or by

response of each component is divided by the density multi-

using synthetic standards with vapor sample valves at ambient

pliedbytheweightpercentpurityofthecomponentasfollows:

or at decreasing pressures or by using synthetic standards with

Weight percent response of component

liquid sample valves. If on plotting the results the response is

linear, then the calibration procedure given above is satisfac-

average component peak area

tory. If not, the relative responses of the minor components

5 (1)

density 3 weight percent purity of component

must be determined in the linear response region.

Component weight percent detector correction factors are

then obtained by selecting a reference component such as

9. Procedure

butadiene, and dividing the individual component weight

9.1 Attach the sample cylinder to the instrument-sampling

responses into the reference weight response.

valve so that the sample is obtained from the liquid phase. If

8.2.1 Factors derived on a thermal-conductivity detector

introduction is through a liquid valve the sample cylinders

using helium-carrier gas are as follows:

should be pressured with a suitable gas, such as helium, to a

Component Mol wt Thermal Weight Factor Weight Fac-

pressuresufficienttoensurethatsampleflashingdoesnotoccur

Response tor,

Butadiene- inthelinetothesamplingvalveorinthevalv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.