ASTM D1412-02a

(Test Method)Standard Test Method for Equilibrium Moisture of Coal at 96 to 97 Percent Relative Humidity and 30°C

Standard Test Method for Equilibrium Moisture of Coal at 96 to 97 Percent Relative Humidity and 30°C

SCOPE

1.1 This test method covers determination of the equilibrium moisture of coal in an atmosphere over a saturated solution of potassium sulfate at 30°C.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1412 – 02a

Standard Test Method for

Equilibrium Moisture of Coal at 96 to 97 Percent Relative

1

Humidity and 30°C

This standard is issued under the fixed designation D 1412; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope moisture of either coal that is wet and shows visible surface

2

moisture or coal that may have lost some moisture. It may be

1.1 This test method covers determination of the equilib-

used for estimating the surface, or extraneous moisture of wet

rium moisture of coal in an atmosphere over a saturated

coal, such moisture being the difference between the total

solution of potassium sulfate at 30°C.

moisture as determined by Test Method D 3302 and the

1.2 This standard does not purport to address all of the

equilibrium moisture.

safety concerns, if any, associated with its use. It is the

3.2 When samples are collected in conformity with Classi-

responsibility of the user of this standard to establish appro-

fication D 388, the equilibrium moisture is considered to be

priate safety and health practices and determine the applica-

equal to bed moisture with the exception of some low rank

bility of regulatory limitations prior to use.

coals that yield equilibrium moisture values below bed mois-

2. Referenced Documents ture.

2.1 ASTM Standards:

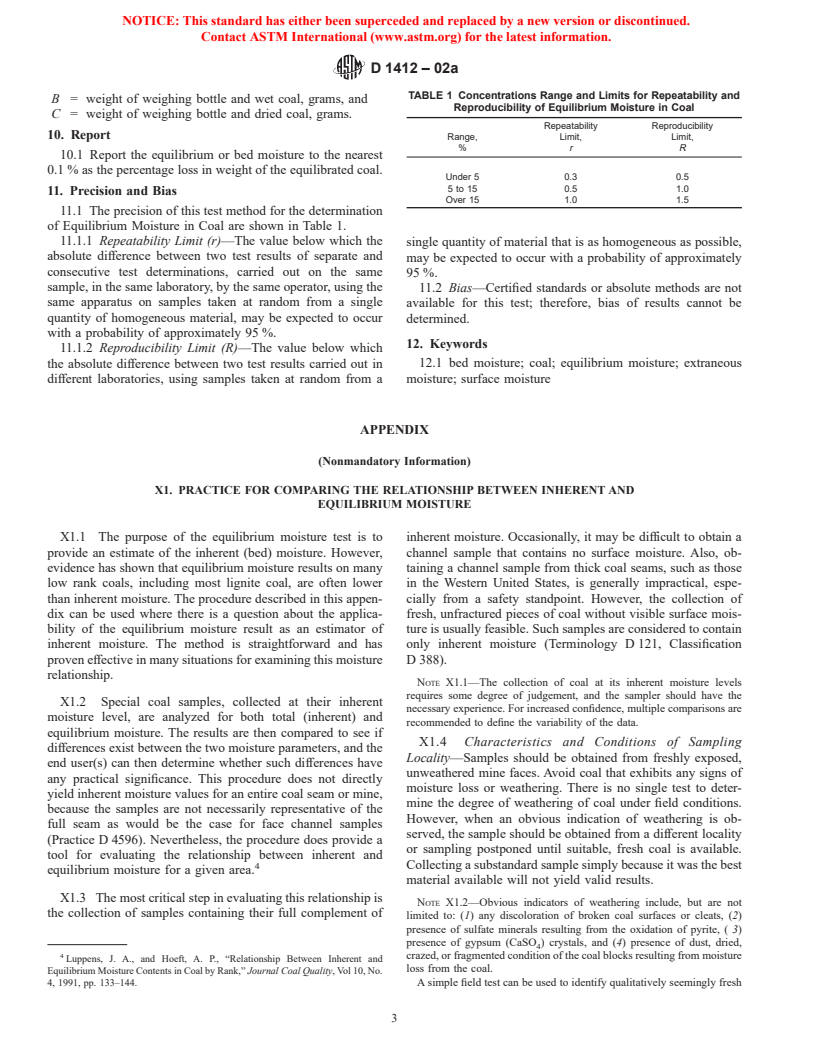

4. Apparatus

3

D 121 Terminology of Coal and Coke

3

4.1 Water Bath or Insulated Air Cabinet—The bath or

D 388 Classification of Coals by Rank

3 cabinet shall be of sufficient size to accommodate several

D 2013 Practice for Preparing Coal Samples for Analysis

3

vacuum-type desiccators, and shall be provided with a tem-

D 2234 Practice for Collection of a Gross Sample of Coal

3 perature regulator to maintain a uniform temperature of 30.0 6

D 3172 Practice for Proximate Analysis of Coal and Coke

0.2°C.

D 3173 Test Method for Moisture in the Analysis Sample of

3 4.2 Moisture Oven—The oven shall be so constructed as to

Coal and Coke

3

have a uniform temperature in all parts and a minimum of air

D 3302 Test Method for Total Moisture in Coal

space. It may be of the type shown in the Apparatus section of

D 4596 Practice for Collection of Channel Samples of Coal

3

Test Method D 3173. Provision shall be made for renewing the

in the Mine

air (or, if desired, dry oxygen-free nitrogen for subbituminous

3. Significance and Use

and lignitic coals) in the oven at the rate of two times per

minute, with the air dried by passing it through H SO (sp gr

2 4

3.1 This test method affords a means of estimating the bed

1.84).

4.3 Mechanical Vacuum Pump.

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal

4.4 Crusher, laboratory, coffee-mill type.

and Coke and is the direct responsibility of Subcommittee D05.21 on Methods of

4.5 Sieve, 8-in. (203-mm) diameter, with 1.18-mm (No. 16)

Analysis.

Current edition approved September 10, 2002. Published October 2002. Origi-

openings.

nally published as D 1412 – 56 T. Last previous edition D 1412 – 02.

4.6 Shaking Machine.

2

For information concerning the experimental work on which this test method is

4.7 Desiccator—Small vacuum-type desiccator, 160 mm in

based, see the following papers:

diameter (see Fig. 1).

Stansfield, Edgar and Gilbart, K. C., “Moisture Determination for Coal Classi-

fication,” Transactions, American Institute of Mining and Metallurgical Engineers,

4.8 Weighing Bottles, glass, low-form, flat-bottom, cylindri-

Coal Division, TAMCA, Vol 101, 1932, pp. 125–43.

cal, 70 mm in diameter, with well-fitting covers.

Rees, O. W., Reed, F. H., and Land, G. W., “A Study of the Equilibration Method

4.9 Filter Pump, aspirator.

of Determining Moisture in Coal for Classification by Rank,” Report of Investiga-

1

tions No. 58, Illinois State Geological Survey, ILGIA, 1939, pp. 34. 4.10 Buchner-Type Funnel, approximately 2 ⁄2 in. (64 mm)

Krumin, Peter, “The Determination of Forms of Moisture in Coal,” No. 195,

in diameter.

Ohio State University, p. 92, 1963.

Kreulen, D. J. W., “The Adsorption Water of Coal,” Chemische en Pharma-

5. Technical Hazards

ceutische Techniek (Dordrecht), CHPHA, Vol 7, 1951, pp. 23–24.

Selvig, W. A., and Ode, W. H., “Determination of Moisture-Holding Capacity 5.1 In collecting, containing, handling, reducing, and divid-

(Bed Moisture) of Coal for Classification by Rank,” Report of Investigations No.

ing the gross moisture sample, all operations must be done

4968, U.S. Bureau of Mines, XMBUA 1953.

expeditiously and in a manner that attempts to preserve the

3

Annual Book of ASTM Standards, Vol 05.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C70

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.