ASTM B5-00

(Specification)Standard Specification for High Conductivity Tough-Pitch Copper Refinery Shapes

Standard Specification for High Conductivity Tough-Pitch Copper Refinery Shapes

SCOPE

1.1 This specification establishes the requirements for high conductivity tough-pitch copper wire bars, cakes, slabs, billets, ingots, and ingot bars.

1.2 Copper under this specification corresponds to the designations "ETP" (UNS C11000) and "FRHC" (UNS C11020) as shown in Classification B224. These coppers may also be used to produce coppers corresponding to the following: Copper UNS No. Classification B 224 Designation C11300, C11400, C11500 ∧ C11600 STP C12000 DLP C12200 DHP C12300 DHPS C14500 DPTE

1.3 Although this specification includes certain UNS designations as described in Practice E527, these designations are for cross reference only and are not specification requirements. Therefore in case of conflict, this ASTM specification shall govern.

1.4 In this specification inch-pound units are the standard except for electrical resistivity which is expressed in SI units. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B5–00

Standard Specification for

High Conductivity Tough-Pitch Copper Refinery Shapes

This standard is issued under the fixed designation B 5; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * loyed Copper by Gravimetry

E 255 Practice for Sampling Copper and CopperAlloys for

1.1 This specification establishes the requirements for high

Determination of Chemical Composition

conductivity, tough-pitch, copper wire bars, cakes, slabs, bil-

E 478 Test Methods for Chemical Analysis of Copper

lets, ingots, and ingot bars.

Alloys

1.2 Copper under this specification corresponds to the

E 527 Practice for Numbering Metals and Alloys (UNS)

designations “ETP” (UNS C11000) and “FRHC” (UNS

C11020) as shown in Classification B 224. These coppers may

3. Terminology

also be used to produce coppers corresponding to the follow-

3.1 For definitions of terms related to this specification,

ing:

refer to Classification B 224 and Terminology B 846.

Copper UNS No. Classification B 224 Designation

4. Ordering Information

C11300, C11400, C11500, and C11600 STP

C12000 DLP

4.1 Include the following information, as applicable:

C12200 DHP

4.1.1 ASTM Specification Designation and year of issue,

C12300 DHPS

C14500 DPTE

4.1.2 Copper UNS No. Designation,

4.1.3 Quantity, shape, and dimension of each piece, and

1.3 Although this specification includes certain UNS desig-

weight,

nations as described in Practice E 527, these designations are

4.1.4 Should cakes, slabs, or billets be ordered for electrical

for cross reference only and are not specification requirements.

use, it must be stated in the contract or purchase order, and

Therefore, in case of conflict, this ASTM specification shall

4.1.5 Silver content in silver-bearing shapes when required,

govern.

in troy oz per short ton.

1.4 Units—The values stated in inch-pound units are the

standard, except for electrical resistivity, which is expressed in

5. Chemical Composition

SI units. The values given in parentheses are mathematical

5.1 The copper in all shapes shall meet the minimum

conversions to SI units, which are provided for information

requirement for copper, including silver, of 99.90 %.

only, and are not considered the standard.

5.1.1 These composition limits do not preclude the presence

2. Referenced Documents of other elements. Limits for unnamed elements may be

established, and analysis required, by agreement between the

2.1 ASTM Standards:

supplier and the purchaser.

B 193 Test Method for Resistivity of Electrical Conductor

2 5.2 For the STP (silver-bearing) coppers, the addition of

Materials

silver up to an average of 30 troy oz per short ton (0.10 %) will

B 224 Classification of Coppers

3 beconsideredwithinthespecification,withnoindividualsilver

B 846 Terminology for Copper and Copper Alloys

analysis to exceed 35 troy oz per short ton (0.12 %).

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

6. Physical Property Requirements

E 53 Test Method for Determination of Copper in Unal-

6.1 Electrical Resistivity:

6.1.1 The maximum mass resistivity for wire bars, cakes,

1 slabs, and billets for electrical use shall be 0.153 28 V·g/

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

m (conductivity 100.0 % minimum, International Annealed

and Copper Alloys and is the direct responsibility of Subcommittee B05.07 on

Refined Copper.

Copper Standard, (IACS)), at 68°F (20°C), annealed.

Current edition approved March 10, 2000. Published April 2000. Originally

published asB5–11. Last previous editionB5–95.

Annual Book of ASTM Standards, Vol 02.03.

3 5

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 03.05.

4 6

Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B5

6.1.2 The maximum mass resistivity for other uses shall be specification, may be supplied by agreement between manu-

0.156 94 V·g/m (conductivity 97.66 % minimum IACS), at facturer and the purchaser.

68°F (20°C), annealed. 7.2 Permissible Variations in Weight and Dimensions—A

6.1.3 The maximum mass resistivity for ingots and ingot permissible variation of 65 % in weight or 6 ⁄4 in. (6.3 mm)

bars shall be 0.156 94 V·g/m (conductivity 97.66 % minimum in any dimension from the manufacturer’s published list or the

IACS), at 68°F (20°C), annealed. purchaser’s specified size shall be considered good delivery;

provided, however, that wire bars may vary in length 61%

7. Dimensions, Mass, and Permissible Variations

from the listed or specified length, and cakes may vary 63%

7.1 Standard Sizes and Shapes of Wire Bars: from the listed or specified size in any dimension greater than

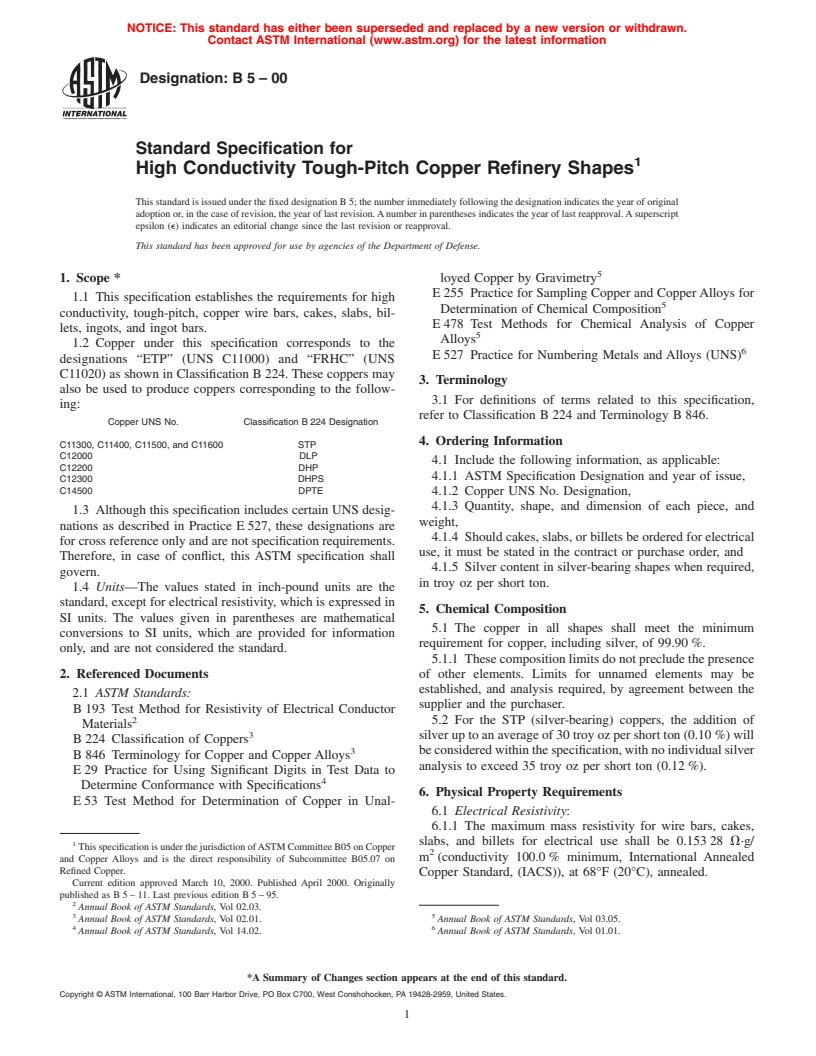

7.1.1 One size of mold shall be used for casting 200- to

8in.(203.2mm).Theweightofcopperiningotsandingotbars

230-lb (91- to 104-kg) wire bars, the bottom width of these shall not exceed that specified by more than 10 %, but

bars to be 3 ⁄2 in. (89 mm), the listed weights being 200 and

otherwise its variation is not important.

225 lbs (91 to 102 kg) (Fig. 1).

8. Workmanship, Finish, and Appearance

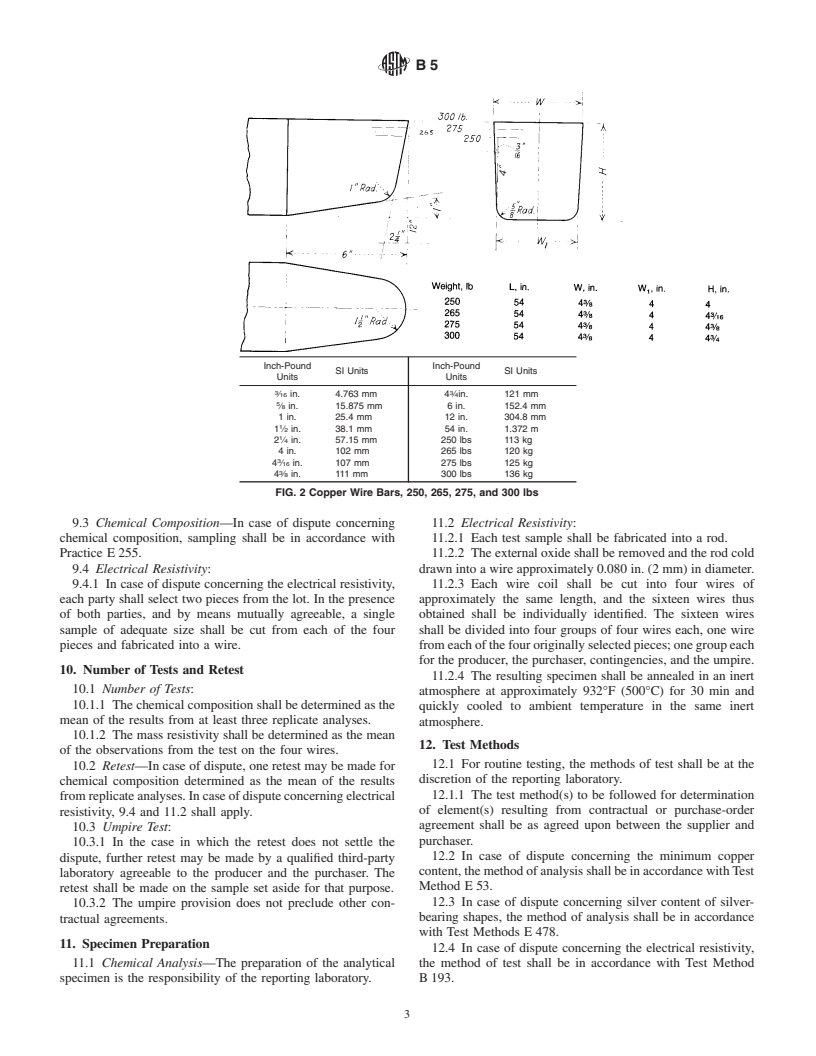

7.1.2 One size of mold shall be used for casting 240- to

300-lb (109- to 136-kg) wire bars, the bottom width of these 8.1 Wire bars, cakes, slabs, and billets shall be substantially

bars to be 4 in. (102 mm), the listed weights being 250, 265, free of shrink holes, cold sets, pits, sloppy edges, concave tops,

275, and 300 lbs (113, 120, 125, and 136 kg) (Fig. 2). and similar defects in set or casting. This requirement shall not

7.1.3 All bars shall be 54 in. (1.372 m) in length. The side apply to ingots or ingot bars, in which physical defects are of

3 3

draft or taper shall be ⁄8in. (9.5 mm) in 4 in. ( ⁄16 in. (4.8 mm) no consequence.

in 4 in. on each side of the bar).The radius of the corners at the 8.2 Blemishes of a nature that do not interfere with the

bottom of the bars shall be ⁄8in. (15.9 mm). The end taper at intended application are acceptable.

the bottom shall be 6 in. (152.4 mm) in overall length and

9. Sampling

approximately 2 in. (50.8 mm)/ft (304.8 mm).The end taper of

the side shall be approximately 2 ⁄4in. (57.1 mm)/ft and the end 9.1 For routine sampling, the sampling practice shall be at

of the bar shall be approximately 3 ⁄8 in. (85.7 mm) in depth at the discretion of the sampler.

the point. 9.2 In case of dispute, a lot shall consist of all pieces the

7.1.4 Wire bars not conforming to the requirements of Fig. same shape and size bearing a common single identifying

1 or Fig. 2, but otherwise meeting the requirements of this number.

Inch-Pound Inch-Pound

SI Units SI Units

Units Units

3 7

⁄16 in. 4.763 mm 3 ⁄8in. 98 mm

⁄8 in. 15.875 mm 4 in. 102 mm

1 in. 25.4 mm 6 in. 152.4 mm

1 ⁄2 in. 38.1 mm 12 in. 304.8 mm

2 ⁄4 in. 57.15 mm 54 in. 1.372 m

3 ⁄2 in. 89 mm 200 lbs 91 kg

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.