ASTM B407-96

(Specification)Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

SCOPE

1.1 This specification covers UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, and UNS N08890 in the form of cold-worked and hot-finished annealed seamless pipe and tube. Alloy UNS N08800 is normally employed in service temperatures up to and including 1100°F (593°C). Alloys UNS N08120, UNS N08810, UNS N08811, and UNS N08890 are normally employed in service temperatures above 1100°F (593°C) where resistance to creep and rupture is required, and they are annealed to develop controlled grain size for optimum properties in this temperature range.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section13 , of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: B 407 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

This standard is issued under the fixed designation B 407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

5

1. Scope nation of Nickel and Nickel Alloy Tubular Products

2

E 1473 Test Methods for Chemical Analysis of Nickel,

1.1 This specification covers UNS N08120, UNS N08800,

6

Cobalt, and High-Temperature Alloys

UNS N08801, UNS N08810, and UNS N08811 in the form of

cold-worked and hot-finished annealed seamless pipe and tube.

3. Terminology

Alloy UNS N08800 is normally employed in service tempera-

3.1 Definitions:

tures up to and including 1100°F (593°C). Alloys UNS

3.1.1 average diameter, , n—average of the maximum and

N08120, UNS N08810, and UNS N08811 are normally em-

minimum outside diameters, or the maximum and minimum

ployed in service temperatures above 1100°F (593°C) where

inside diameters, as determined at any one cross section of the

resistance to creep and rupture is required, and they are

tube.

annealed to develop controlled grain size for optimum proper-

3.1.2 pipe , n—seamless tube conforming to the particular

ties in this temperature range.

dimensions commercially known as standard pipe sizes (see

1.2 The values stated in inch-pound units are to be regarded

Table X3.1).

as the standard. The values given in parentheses are for

3.1.3 tube , n—hollow product of round or any other cross

information only.

section having a continuous periphery.

1.3 The following safety hazards caveat pertains only to the

test method portion, Section 13, of this specification. This

4. Ordering Information

standard does not purport to address all of the safety concerns,

4.1 Orders for material to this specification should include

if any, associated with its use. It is the responsibility of the user

information with respect to the following:

of this standard to establish appropriate safety and health

4.1.1 Alloy (Table 1).

practices and determine the applicability of regulatory limita-

4.1.2 Condition Temper (Table 2 and Table X3.1, and

tions prior to use.

Appendixes X2 and X3).

2. Referenced Documents

4.1.3 Finish (Table X1.1 and Table X3.2).

2.1 ASTM Standards: 4.1.4 Dimensions:

3

E 8 Test Methods for Tension Testing of Metallic Materials 4.1.4.1 Tube—May be specified in two dimensions only

E 18 Test Methods for Rockwell Hardness and Rockwell (length excepted) as follows: Outside diameter and average or

3

Superficial Hardness of Metallic Materials minimum wall, inside diameter and average wall, or outside

E 29 Practice for Using Significant Digits in Test Data to diameter and inside diameter.

4

Determine Conformance with Specifications

NOTE 1—Tube produced to outside diameter and minimum wall may be

E 112 Test Methods for Determining the Average Grain

furnished upon agreement between the manufacturer and the purchaser.

3

Size

4.1.4.2 Pipe—Standard pipe size and schedule (Table

3

E 140 Hardness Conversion Tables for Metals

X3.1).

E 426 Practice for Electromagnetic (Eddy-Current) Exami-

4.1.5 Fabrication Details—Not mandatory but helpful to

nation of Seamless and Welded Tubular Products, Austen-

the manufacturer:

5

itic Stainless Steel and Similar Alloys

4.1.5.1 Cold Bending or Coiling.

E 571 Practice for Electromagnetic (Eddy-Current) Exami-

4.1.5.2 Hot Forming.

4.1.5.3 Welding or Brazing—Process to be employed.

1

4.1.5.4 Pressure Requirements—Test pressure if other than

This specification is under the jurisdiction of ASTM Committee B-2 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

required by 7.3.

B02.07 on Refined Nickel and Cobalt, and Alloys Containing Nickel or Cobalt or

4.1.5.5 Machining—Indicate finished size and length in

Both as Principal Constituents. Current edition approved May 10, 1996. Published

which to be machined and whether to be chucked to outside

June 1996. Originally published as B 407 – 57 T. Last previous edition B 407 – 95.

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

diameter or inside diameter.

cation SB-407 in Section II of that Code.

3

Annual Book of ASTM Standards, Vol 03.01.

4

Annual Book of ASTM Standards, Vol 14.02.

5 6

Annual Book of ASTM Standards, Vol 03.03. Annual Book of ASTM Standards, Vol 03.06.

1

---------------------- Page: 1 ----------------------

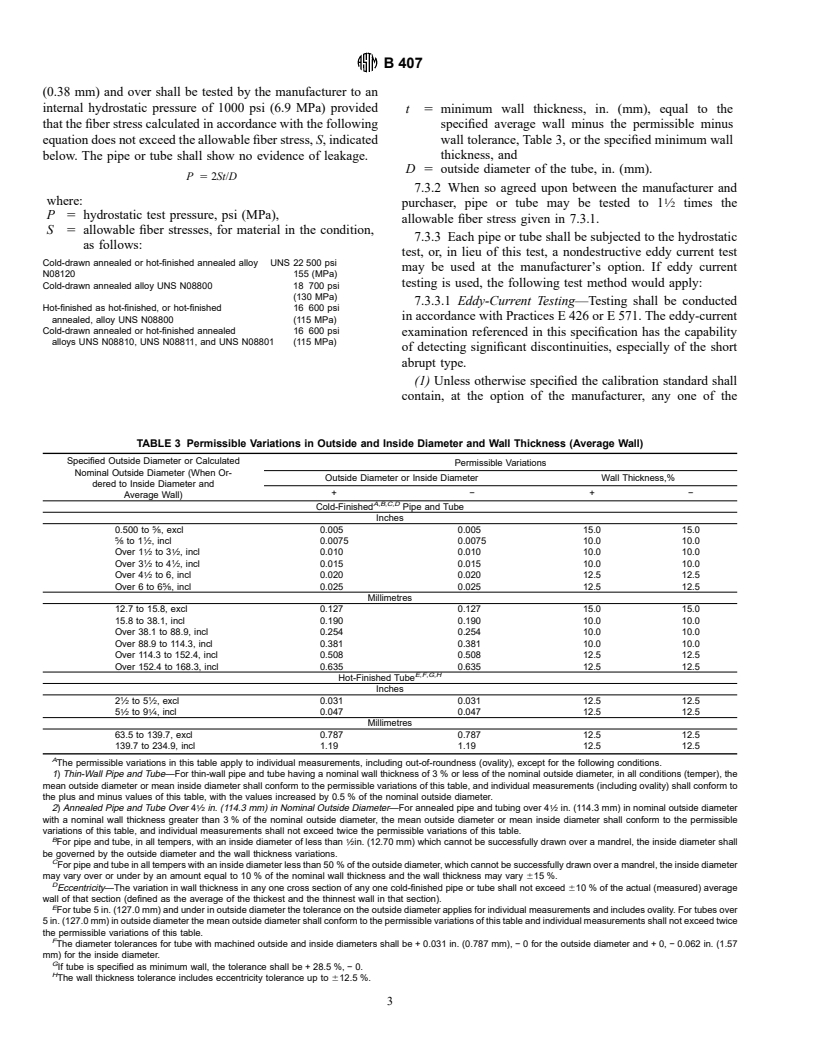

B 407

†

TABLE 1 Chemical Requirements

Product (Check) Analysis Variations,

Composition Limits, %

Under Min

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.