ASTM D2116-16

(Specification)Standard Specification for FEP Resin Molding and Extrusion Materials

Standard Specification for FEP Resin Molding and Extrusion Materials

ABSTRACT

This specification covers melt-processible molding and extrusion materials of FEP-fluorocarbon resin, which is a copolymer of tetrafluoroethylene and hexafluoropropylene or a modified FEP-fluorocarbon resin containing not more than 2% by weight of other fluoromonomers. Four types of FEP-fluorocarbon resin are included in this specification which shall be supplied in pellet form and shall be of uniform composition and free of foreign matters. Tests shall be conducted on the molded test specimens wherein the average test result of the lot shall conform to the melt flow rate, specific gravity, melting point, tensile strength, elongation, dielectric constant, and dissipation factor requirements.

SCOPE

1.1 This specification covers melt processable molding and extrusion materials of FEP resin. This specification does not cover recycled FEP materials. These FEP resins are copolymers of tetrafluoroethylene and hexafluoropropylene or modified FEP resins containing no more than 2 % by weight of other fluoromonomers.

1.2 The values stated in SI units as detailed in IEEE/ASTM SI-10 are to be regarded as the standard. The values given in parentheses are for information only.

Note 1: Although this specification and ISO 12086-1 and ISO 12086-2 differ in approach or detail, data obtained using either are technically equivalent.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2116 −16

Standard Specification for

1

FEP Resin Molding and Extrusion Materials

This standard is issued under the fixed designation D2116; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

1.1 This specification covers melt processable molding and

D1708TestMethodforTensilePropertiesofPlasticsbyUse

extrusion materials of FEP resin. This specification does not

of Microtensile Specimens

cover recycled FEP materials. These FEP resins are copoly-

D3892Practice for Packaging/Packing of Plastics

mers of tetrafluoroethylene and hexafluoropropylene or modi-

D4591Test Method for Determining Temperatures and

fiedFEPresinscontainingnomorethan2%byweightofother

Heats of Transitions of Fluoropolymers by Differential

fluoromonomers.

Scanning Calorimetry

1.2 The values stated in SI units as detailed in IEEE/

E691Practice for Conducting an Interlaboratory Study to

ASTMSI-10 are to be regarded as the standard. The values

Determine the Precision of a Test Method

given in parentheses are for information only.

IEEE/ASTMSI-10Use of the International System of Units

(SI): The Modern Metric System

NOTE 1—Although this specification and ISO 12086-1 and

3

ISO12086-2 differ in approach or detail, data obtained using either are

2.2 ISO Standards:

technically equivalent.

ISO 12086-1 Plastics—Fluoropolymer Dispersions and

1.3 The following precautionary caveat pertains only to the

Moulding and Extrusion Materials—Part 1

test methods portion, Section 11, of this specification. This ISO 12086-2 Plastics—Fluoropolymer Dispersions and

standard does not purport to address all of the safety concerns,

Moulding and Extrusion Materials—Part 2

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

3.1 Definitions:

tions prior to use.

3.1.1 General—The definitions given in Terminology D883

are applicable to this specification.

2. Referenced Documents

3.1.2 lot, n—one production run or a uniform blend of two

2

2.1 ASTM Standards:

or more production runs.

D150Test Methods forAC Loss Characteristics and Permit-

3.2 Abbreviated Terms:

tivity (Dielectric Constant) of Solid Electrical Insulation

3.2.1 General—The abbreviated terms given in Terminol-

D618Practice for Conditioning Plastics for Testing

ogy D1600 are applicable to this specification.

D638Test Method for Tensile Properties of Plastics

D792Test Methods for Density and Specific Gravity (Rela-

4. Classification

tive Density) of Plastics by Displacement

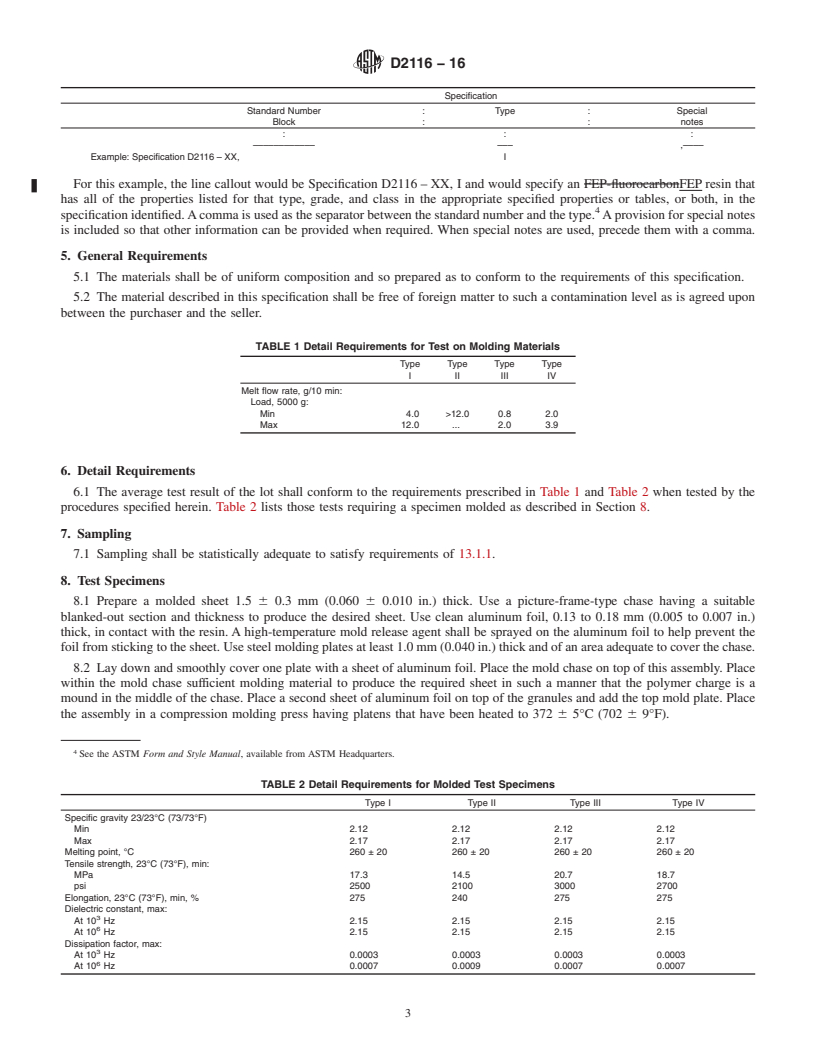

4.1 This specification covers four types of FEP resin sup-

D883Terminology Relating to Plastics

plied in pellet form classified according to their melt flow rate.

D1238Test Method for Melt Flow Rates of Thermoplastics

4.2 A one-line system shall be used to specify materials

by Extrusion Plastometer

covered by this specification.The system uses predefined cells

to refer to specific aspects of this specification, illustrated as

1

This specification is under the jurisdiction of ASTM Committee D20 on

follows:

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved Sept. 1, 2016. Published September 2016. Originally

approved in 1962. Last previous edition approved in 2012 as D2116–07(2012).

DOI: 10.1520/D2116-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2116−16

8. Test Specimens

Specification

Standard Number : Type : Special

8.1 Prepare a molded sheet 1.5 6 0.3 mm (0.060 6 0.010

Block : : notes

in.) thick. Use a picture-frame-type chase having a suitable

:: :

blanked-outsectionandthicknesstoproducethedesiredsheet.

–––––––––––– ––– ,––––

Example: Specification D2116 – XX, I

Use clean aluminum foil, 0.13 to 0.18 mm (0.005 to 0.007 in.)

thick, in contact with the resin. A high-temperature mold

For this example, the line callout would

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2116 − 07 (Reapproved 2012) D2116 − 16

Standard Specification for

FEP-Fluorocarbon FEP Resin Molding and Extrusion

1

Materials

This standard is issued under the fixed designation D2116; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 This specification covers melt processable molding and extrusion materials of FEP-fluorocarbonFEP resin. This

specification does not cover recycled FEP materials. These FEP resins are copolymers of tetrafluoroethylene and hexafluoropro-

pylene or modified FEP-fluorocarbonFEP resins containing notno more than 2 % by weight of other fluoromonomers.

1.2 The values stated in SI units as detailed in IEEE/ASTM SI-10 are to be regarded as the standard. The values given in

parentheses are for information only.

NOTE 1—Although this specification and ISO 12086-1 and ISO 12086-2 differ in approach or detail, data obtained using either are technically

equivalent.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification.This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1600 Terminology for Abbreviated Terms Relating to Plastics

D3295 Specification for PTFE Tubing, Miniature Beading and Spiral Cut Tubing

D3418D1708 Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential

Scanning CalorimetryTensile Properties of Plastics by Use of Microtensile Specimens

D3892 Practice for Packaging/Packing of Plastics

D4591 Test Method for Determining Temperatures and Heats of Transitions of Fluoropolymers by Differential Scanning

Calorimetry

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

IEEE/ASTM SI-10 Use of the International System of Units (SI): The Modern Metric System

3

2.2 ISO Standards:

ISO 12086-1 Plastics—Fluoropolymer Dispersions and Moulding and Extrusion Materials—Part 1

ISO 12086-2 Plastics—Fluoropolymer Dispersions and Moulding and Extrusion Materials—Part 2

3. Terminology

3.1 Definitions:

3.1.1 General—The definitions given in Terminology D883 are applicable to this specification.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved April 1, 2012Sept. 1, 2016. Published June 2012September 2016. Originally approved in 1962. Last previous edition approved in 20072012 as

D2116 – 07.D2116 – 07(2012). DOI: 10.1520/D2116-07R12.10.1520/D2116-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2116 − 16

3.1.2 lot, n—one production run or a uniform blend of two or more production runs.

3.2 Abbreviated Terms:

3.2.1 General—The abbreviated terms given in Terminology D1600 are applicable to this specification.

4. Classification

4.1 This specification covers four types of FEP-fluorocarbonFEP resin supplied in pellet form classified according to their melt

flow rate.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.