ASTM F2811-10

(Test Method)Standard Test Methods for Evaluating Design and Performance Characteristics of Elliptical Trainers

Standard Test Methods for Evaluating Design and Performance Characteristics of Elliptical Trainers

SIGNIFICANCE AND USE

The purpose of these test methods is to provide reliable and repeatable test methods for the evaluation of elliptical trainers assembled and maintained according to the manufacturer’s specifications. Use of these test methods, in conjunction with Specification , is intended to ensure appropriate performance and reliability of an elliptical trainer and reduce the risk of serious injury from design deficiencies.

SCOPE

1.1 These test methods specify procedures and equipment used for testing and evaluating elliptical trainers for compliance to Specification . Both design and operational parameters will be evaluated. Where possible and applicable, accepted test methods from other recognized bodies will be used and referenced. In case of a conflict between this document and Specification , Specification takes precedence.

1.2 Requirements—An elliptical trainer is to be tested for all of the following parameters:

1.2.1 Endurance,

1.2.2 Static loading,

1.2.2.1 Handlebars

1.2.2.2 Foot supports

1.2.3 Adjustable guide systems,

1.2.4 Control panel,

1.2.5 Warnings, and

1.2.6 Documentation.

1.3 The values stated in SI units are to be regarded as the standard. The values in parenthesis are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2811 − 10 AnAmerican National Standard

Standard Test Methods for

Evaluating Design and Performance Characteristics of

Elliptical Trainers

This standard is issued under the fixed designation F2811; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The goal of these test methods is to provide reliable and repeatable methods for the evaluation of

elliptical trainers. The equipment user must recognize, however, that a standard alone will not

necessarily prevent injuries. Like other physical activities, exercise involving fitness equipment

involvestheriskofinjury,particularlyiftheequipmentisusedimproperlyornotproperlymaintained.

In addition, users with physical limitations should seek medical advice or instruction from the fitness

facility, or both, prior to using this equipment. Certain physical conditions or limitations may preclude

some persons from using this equipment properly and without increasing the risk of serious injury.

1. Scope 2. Referenced Documents

1.1 These test methods specify procedures and equipment 2.1 ASTM Standards:

used for testing and evaluating elliptical trainers for compli- F1749 Specification for Fitness Equipment and Fitness Fa-

ance to Specification F2810. Both design and operational cility Safety Signage and Labels

parameters will be evaluated. Where possible and applicable, F2276 Specification for Fitness Equipment

accepted test methods from other recognized bodies will be F2571 TestMethodsforEvaluatingDesignandPerformance

used and referenced. In case of a conflict between this Characteristics of Fitness Equipment

document and Specification F2810, Specification F2810 takes F2810 Specification for Elliptical Trainers

precedence.

3. Terminology

1.2 Requirements—An elliptical trainer is to be tested for all

3.1 Definitions—For definitions applicable to this standard,

of the following parameters:

see Specification F2810.

1.2.1 Endurance,

1.2.2 Static loading,

4. Significance and Use

1.2.2.1 Handlebars

1.2.2.2 Foot supports 4.1 The purpose of these test methods is to provide reliable

1.2.3 Adjustable guide systems, and repeatable test methods for the evaluation of elliptical

1.2.4 Control panel, trainers assembled and maintained according to the manufac-

1.2.5 Warnings, and turer’s specifications. Use of these test methods, in conjunction

1.2.6 Documentation. with Specification F2810, is intended to ensure appropriate

performance and reliability of an elliptical trainer and reduce

1.3 The values stated in SI units are to be regarded as the

the risk of serious injury from design deficiencies.

standard. The values in parenthesis are for information only.

1.4 This standard does not purport to address all of the

5. Sample Preparations

safety concerns, if any, associated with its use. It is the

5.1 Assembleandadjusttheellipticaltraineronahorizontal

responsibility of the user of this standard to establish appro-

surface according to the manufacturer’s instructions. On train-

priate safety and health practices and determine the applica-

ers that are fully assembled, verify according to the manufac-

bility of regulatory limitations prior to use.

turer’sinstructionsthatallcomponentsarefunctioningandthat

This specification is under the jurisdiction ofASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee F08.30 on Fitness Products. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2010. Published June 2010. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F2811-10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2811 − 10

theyhavebeenadjustedandalignedproperly.Unlessotherwise the elliptical trainer per the manufacturer’s instructions and

stated, the trainer must pass the following tests without observe the orientation of the end portion of the movable

adjustment from this initial condition. Apply power to, if handlebars with respect to the head of the evaluator throughout

required, or use the trainer and verify that the unit functions the range of travel of the movable handlebars.

properly. If the unit is equipped with a guide system, operate it 6.2.3.4 Pass/Fail Criteria—The dimension of the end por-

through its full range. tionofthemovablehandlebarshallbeatleast50mm(1.97in.)

in diameter. Alternately, if the end portion of the movable

5.2 The individual test methods will describe any variations

handlebars is always angled away from the user during

or modifications that are required to the test sample.

operation of the elliptical trainer then it shall be concluded that

5.3 Upon completion of the tests the equipment shall

the movable handlebars meet the requirements of the specifi-

function as intended by the manufacturer.

cations.

6.2.3.5 Precision and Bias:

6. Test Methods and Procedures

(1) Precision—The precision of this test method has not

been determined.

6.1 In addition to the tests specified in Test Methods F2571,

(2) Bias—Thebiasofthistestmethodincludesquantitative

elliptical trainers shall be evaluated as follows:

estimates of the uncertainties of the measuring devices, the

6.2 Exterior Design:

calibrations of testing equipment and the skill of the operators.

6.2.1 Foot Supports—The purpose of this test is to evaluate

At this time, the statements on bias should be limited to

the dimensions of the foot supports used on the sample.

documented performance of particular laboratories.

6.2.1.1 Apparatus and Set Up—The sample shall be set up

6.3 Endurance—The purpose of this test is to confirm the

as described in 5.1.

endurance of the main components of the elliptical trainer.

6.2.1.2 Calibration—Verify that the measurement device is

Load input to the elliptical trainer can be accomplished by

properly calibrated and has a resolution of 1 mm (0.04 in.).

securing weight to the foot pedals and lifting the weight using

6.2.1.3 Procedure—Measure the dimensions of the slip

pneumatic cylinders, or by pushing down with pneumatic

resistant area of the pedal. Measure the guard heights of the

cylinders (with or without weight). Regardless of how the load

pedal at the front and inside edge.

is input to the elliptical trainer under test, careful consideration

6.2.1.4 Pass/Fail Criteria—The dimensions of the slip re-

shallbegivenbythetestingfacilityastohowthetestapparatus

sistant surface of each pedal shall be at least 300 mm (11.8 in.)

is constructed. The testing facility shall communicate with the

longand100mm(3.9in.)wide.Theguardheightsofthepedal

manufacturer prior to commencing the test and verify that the

shallbeatleast30mm(1.2in.)alongthefrontand12mm(0.5

apparatus functions and loads the elliptical trainer in a manner

in.) along the inside edge.

similar to how a user would actually use and interface with the

6.2.1.5 Precision and Bias:

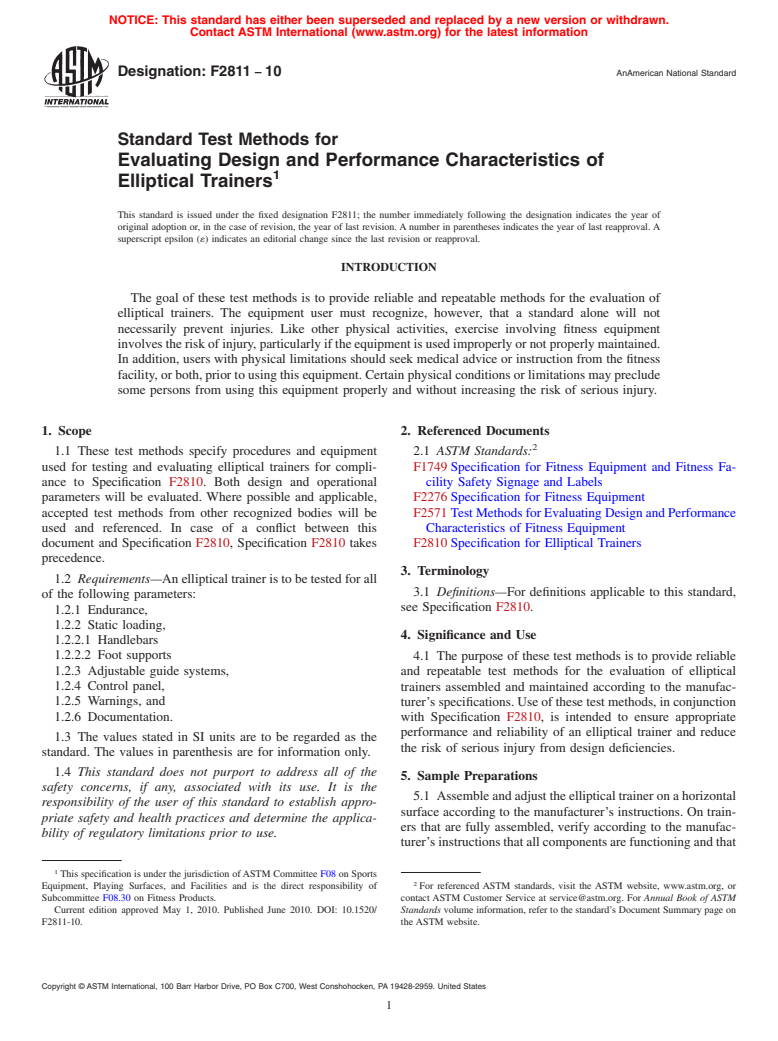

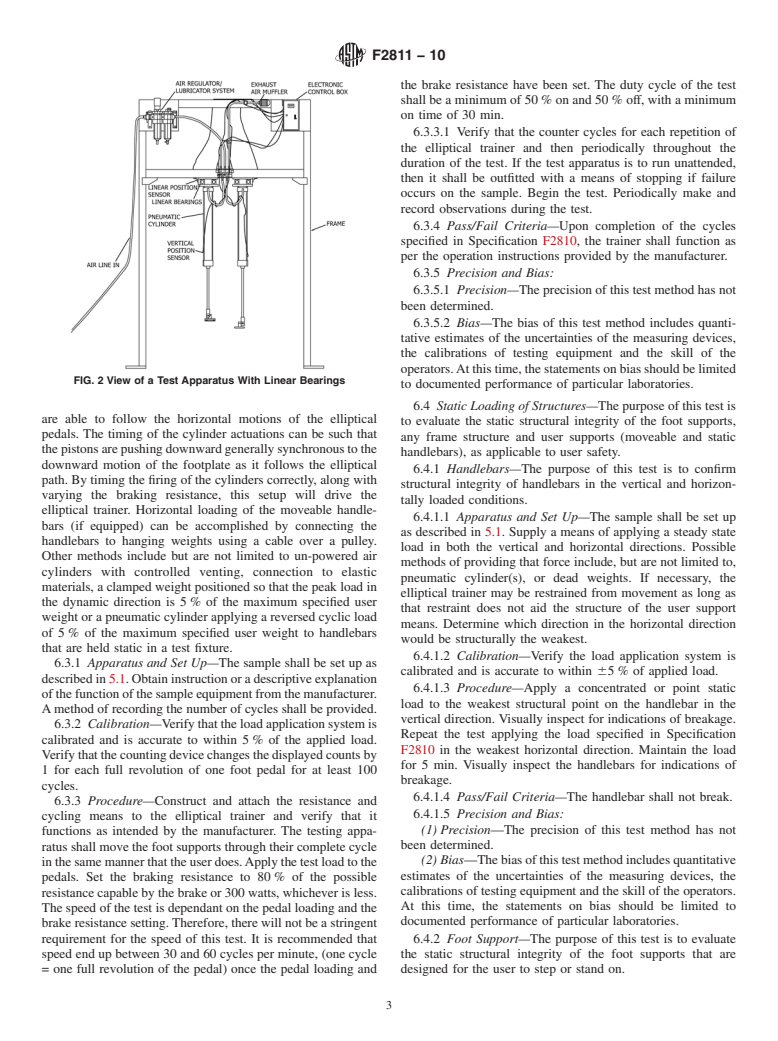

elliptical trainer. Figs. 1 and 2 illustrate pneumatic apparatuses

(1) Precision—The precision of this test method has not

that have been used successfully to conduct endurance testing.

been determined.

The elliptical trainer shown in Fig. 2 is driven by the two

(2) Bias—Thebiasofthistestmethodincludesquantitative

pneumatic cylinders which are attached to the footplates of the

estimates of the uncertainties of the measuring devices, the

device under test. The cylinders can be pivoted or mounted to

calibrations of testing equipment and the skill of the operators.

linear bearings on the test apparatus frame so that the cylinders

At this time, the statements on bias should be limited to

documented performance of particular laboratories.

6.2.2 Handlebars—The purpose of this test is to verify the

existence of the handlebar.

6.2.2.1 Apparatus and Set Up—The sample shall be set up

as described in 5.1.

6.2.2.2 Calibration—No calibration required.

6.2.2.3 Procedure—Visually verify the presence of a

handlebar.

6.2.2.4 Pass/Fail Criteria—The handlebar must be present.

6.2.2.5 Precision and Bias—No information is presented

abouteithertheprecisionorbiasofthistestsincethetestresult

is non-quantitative.

6.2.3 Movable Handlebar Design—The purpose of this test

is to evaluate the dimensions of the movable handlebars used

on the sample.

6.2.3.1 Apparatus and Set Up—The sample shall be set up

as described in 5.1.

6.2.3.2 Calibration—Verify that the measurement device is

properly calibrated and has a resolution of 1 mm (0.04 in.).

6.2.3.3 Procedure—Measure the dimensions of the end

portion of the movable handlebar. The evaluator shall also use FIG. 1 Isometric View of a Pivoting Test Apparatus

F2811 − 10

the brake resistance have been set. The duty cycle of the test

shall be a minimum of 50 % on and 50 % off, with a minimum

on time of 30 min.

6.3.3.1 Verify that the counter cycles for each repetition of

the elliptical trainer and then periodically throughout the

duration of the test. If the test apparatus is to run unattended,

then it shall be outfitted with a means of stopping if failure

occurs on the sample. Begin the test. Periodically make and

record observations during the test.

6.3.4 Pass/Fail Criteria—Upon completion of the cycles

specified in Specification F2810, the trainer shall function as

per the operation instructions provided by the manufacturer.

6.3.5 Precision and Bias:

6.3.5.1 Precision—The precision of this test method has not

been determined.

6.3.5.2 Bias—The bias of this test method includes quanti-

tative estimates of the uncertainties of the measuring devices,

the calibrations of testing equipment and the skill of the

operators.Atthistime,thestatementsonbiasshouldbelimited

FIG. 2 View of a Test Apparatus With Linear Bearings

to documented performance of particular laboratories.

6.4 Static Loading of Structures—The purpose of this test is

are able to follow the horizontal motions of the elliptical

to evaluate the static structural integrity of the foot supports,

pedals. The timing of the cylinder actuations can be such that

any frame structure and user supports (moveable and static

thepistonsarepushingdownwardgenerallysynchronoustothe

handlebars), as applicable to user safety.

downward motion of the footplate as it follows the elliptical

6.4.1 Handlebars—The purpose of this test is to confirm

path. By timing the firing of the cylinders correctly, along with

structural integrity of handlebars in the vertical and horizon-

varying the braking resistance, this setup will drive the

tally loaded conditions.

elliptical trainer. Horizontal loading of the moveable handle-

6.4.1.1 Apparatus and Set Up—The sample shall be set up

bars (if equipped) can be accomplished by connecting the

as described in 5.1. Supply a means of applying a steady state

handlebars to hanging weights using a cable over a pulley.

load in both the vertical and horizontal directions. Possible

Other methods include but are not limited to un-powered air

methods of providing that force include, but are not limited to,

cylinders with controlled venting, connection to elastic

pneumatic cylinder(s), or dead weights. If necessary, the

materials, a clamped weight positioned so that the peak load in

elliptical trainer may be restrained from movement as long as

the dynamic direction is 5 % of the maximum specified user

that restraint does not aid the structure of the user support

weight or a pneumatic cylinder applying a reversed cyclic load

means. Determine which direction in the horizontal direction

of 5 % of the maximum specified user weight to handlebars

would be structurally the weakest.

that are held static in a test fixture.

6.4.1.2 Calibration—Verify the load application system is

6.3.1 Apparatus and Set Up—The sample shall be set up as

calibrated and is accurate to within 65 % of applied load.

describedin5.1.Obtaininstructionoradescriptiveexplanation

6.4.1.3 Procedure—Apply a concentrated or point static

ofthefunctionofthesampleequipmentfromthemanufacturer.

load to the weakest structural point on the handlebar in the

Amethod of recording the number of cycles shall be provided.

vertical direction. Visually inspect for indications of breakage.

6.3.2 Calibration—Verifythattheloadapplicationsystemis

Repeat the test applying the load specified in Specification

calibrated and is accurate to within 5 % of the applied load.

F2810 in the weakest horizontal direction. Maintain the load

Verifythatthecountingdevicechangesthedisplayedcountsby

for 5 min. Visually inspect the handlebars for indications of

1 for each full revolution of one foot pedal for at least 100

breakage.

cycles.

6.4.1.4 Pass/Fail Criteria—The handlebar shall not break.

6.3.3 Procedure—Construct and attach the resistance and

6.4.1.5 Precision and Bias:

cycling means to the elliptical trainer and verify that it

(1) Precision—The precision of this test method has not

functions as intended by the manufacturer. The testing appa-

been determined.

ratus shall move the foot supports through their complete cycle

(2) Bias—Thebiasofthistestmethodincludesquantitative

inthesamemannerthattheuserdoes.Applythetestloadtothe

estimates of the uncertainties of the measuring devices, the

pedals. Set the braking resistance to 80 % of the possible

calibrations of testing equipment and the skill of the operators.

resistance capable by the brake or 300 watts, whichever is less.

At this time, the statements on bias should be limited to

The speed of the test is dependant on the pedal loading and the

documented performance of particular laboratories.

brake resistance setting.Therefore, there will not be a stringent

requirement for the speed of this test. It is recommended that 6.4.2 Foot Support—The purpose of this test is to evaluate

speed end up between 30 and 60 cycles per minute, (one cycle the static structural integrity of the foot supports that are

= one full revolution of the pedal) once the pedal loading and designed for the user to step or stand on.

F2811 − 10

6.4.2.1 Apparatus and Set Up—Thesampleshallbesetupas 6.4.3.4 Pass/Fail Criteria—The maximum measured speed

described in 5.1. Supply a means of providing a steady state shall not exceed limits set in Specification F2810.

load (pneumatic cylinder(s) weights, etc.) on foot pedals or 6.4.3.5 Precision and Bias:

other foot support locations, capable of adjustment to apply (1) Precision—The precision of this test me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.