ASTM D6438-05(2022)

(Test Method)Standard Test Method for Acetone, Methyl Acetate, and Parachlorobenzotrifluoride Content of Paints, and Coatings by Solid Phase Microextraction-Gas Chromatography

Standard Test Method for Acetone, Methyl Acetate, and Parachlorobenzotrifluoride Content of Paints, and Coatings by Solid Phase Microextraction-Gas Chromatography

SIGNIFICANCE AND USE

5.1 In order to calculate the volatile organic content (VOC) of paints containing EPA exempt solvents, it is necessary to know the acetone, methyl acetate, or parachlorobenzotrifluoride content. This gas chromatographic test method provides a simple and direct way for measuring these solvents. Each analyte is measured with respect to a unique internal standard. For acetone, the internal standard used is acetone-d6, for methyl acetate it is methyl acetate-d3, and for PCBTF it is metachlorobenzotrifluoride (MCBTF). These unique analyte/internal standard pairs behave very nearly as single solvents with respect to evaporation rate and adsorption rate onto a coated silica fiber (SPME) but are separable on a gas chromatograph (GC) capillary column. The only critical analytical technique required for successfully performing this test method is the ability of an analyst to weigh a paint sample and internal standard, corresponding to the analyte of interest, into a septum capped vial. After weighing, solvent evaporation has no effect on the final value of the determination. Since whole paint is not injected into the gas chromatograph, the analytical system is never compromised.

SCOPE

1.1 This test method is for the determination of acetone, methyl acetate, or parachlorobenzotrifluoride (PCBTF), or combination of any of the three, in paints and coatings, by solid phase microextraction (SPME) headspace sampling, and subsequent injection into a gas chromatograph. It has been evaluated for cellulose nitrate, acrylic, and urethane solvent-borne systems. The established working range of this test method is: acetone, 28 to 90 %; methyl acetate, 12 to 22 %; parachlorobenzotrifluoride, 10 to 17 %. There is no reason to believe that it will not work outside these ranges. A minor modification of this test method would make it suitable for the analysis of the same analytes in water-borne coatings (see Note 1).

Note 1: Water-borne paints are internally standardized and diluted with water followed by addition of solid sodium chloride.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6438 −05 (Reapproved 2022)

Standard Test Method for

Acetone, Methyl Acetate, and Parachlorobenzotrifluoride

Content of Paints, and Coatings by Solid Phase

1

Microextraction-Gas Chromatography

This standard is issued under the fixed designation D6438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method is for the determination of acetone, 2.1 ASTM Standards:

methyl acetate, or parachlorobenzotrifluoride (PCBTF), or D3925 Practice for Sampling Liquid Paints and Related

combinationofanyofthethree,inpaintsandcoatings,bysolid Pigmented Coatings

phase microextraction (SPME) headspace sampling, and sub- D6133 Test Method for Acetone, p-Chlorobenzotrifluoride,

sequent injection into a gas chromatograph. It has been Methyl Acetate or t-Butyl Acetate Content of Solvent-

evaluated for cellulose nitrate, acrylic, and urethane solvent- borne and Waterborne Paints, Coatings, Resins, and Raw

borne systems. The established working range of this test Materials by Direct Injection Into a Gas Chromatograph

method is: acetone, 28 to 90 %; methyl acetate, 12 to 22 %; E180 Practice for Determining the Precision of ASTM

parachlorobenzotrifluoride, 10 to 17 %. There is no reason to Methods for Analysis and Testing of Industrial and Spe-

3

believe that it will not work outside these ranges. A minor cialty Chemicals (Withdrawn 2009)

modification of this test method would make it suitable for the

3. Terminology

analysisofthesameanalytesinwater-bornecoatings(seeNote

1).

3.1 Abbreviations:

3.1.1 PCBTF—parachlorobenzotrifluoride

NOTE 1—Water-borne paints are internally standardized and diluted

(4-chlorobenzotrifluoride)

with water followed by addition of solid sodium chloride.

3.1.2 MCBTF—metachlorobenzotrifluoride

1.2 The values stated in SI units are to be regarded as

(3-chlorobenzotrifluoride)

standard. No other units of measurement are included in this

standard.

3.1.3 SPME—solid phase microextraction

1.3 This standard does not purport to address all of the

3.1.4 VOC—volatile organic compound

safety concerns, if any, associated with its use. It is the

3.1.5 PEG/DVB—polyethylene glycol/divinylbenzene

responsibility of the user of this standard to establish appro-

3.1.6 FID—flame ionization detector

priate safety, health, and environmental practices and deter-

3.1.7 MS—mass selective or mass spectral

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3.1.8 SIM—selected ion monitoring

dance with internationally recognized principles on standard-

3.1.9 GC—gas chromatograph

ization established in the Decision on Principles for the

3.1.10 Sr—repeatability standard deviations

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 3.1.11 SR—reproducibility standard deviations

Barriers to Trade (TBT) Committee.

3.1.12 r—repeatability, 95 % confidence limit

1 2

This test method is under the jurisdiction of ASTM Committee D01 on Paint For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Related Coatings, Materials, andApplications and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedJune1,2022.PublishedJuly2022.Originallyapproved the ASTM website.

3

in 1999. Last previous edition approved in 2015 as D6438 – 05 (2015). DOI: The last approved version of this historical standard is referenced on

10.1520/D6438-05R22. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6438 − 05 (2022)

3.1.13 R—reproducibility, 95 % confidence limit 6.2 Gas Chromatograph, FID Detection—Any capillary gas

chromatograph equipped with a flame ionization detector may

4. Summary of Test Method

be used. Temperature programming capability is desirable, but

4.1 A suitable aliquot of whole solvent-borne paint is

isothermal operations may be utilized.

internally standardized and diluted with dioctyl phthalate. The

6.2.1 For FID instrument conditions, see Table 1.

headspace of this solution is sampled with an SPME fiber,

6.2.2 Inlet Liner, 0.75-mm sh

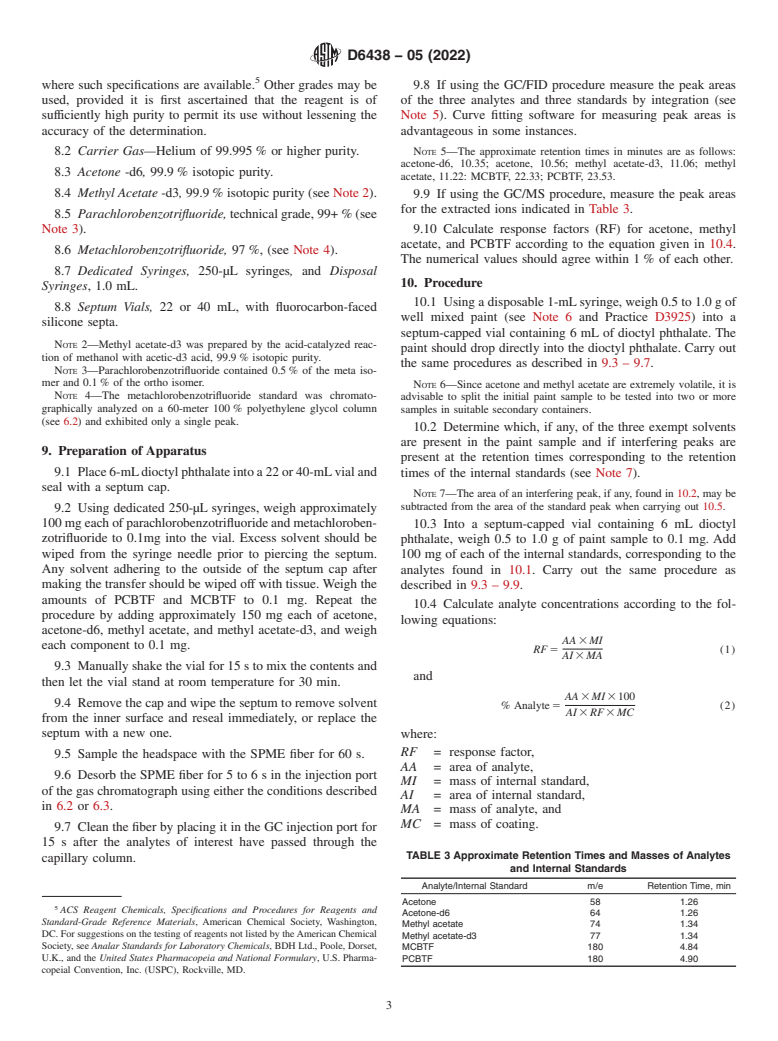

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.