ASTM D291-07e1

(Test Method)Standard Test Method for Cubic Foot Weight of Crushed Bituminous Coal

Standard Test Method for Cubic Foot Weight of Crushed Bituminous Coal

SIGNIFICANCE AND USE

This test method concerns the compaction of crushed coal to determine either its compacted or uncompacted weight, for purposes such as charging coke ovens.

SCOPE

1.1 This test method covers two procedures for determining the cubic foot weight of crushed coal less than 1 ½ in. (37 mm) in size, such as is charged into coke ovens, as follows:

1.1.1 Procedure A—The cone procedure for determining an uncompacted weight per cubic foot (cubic metre).

1.1.2 Procedure B—The dropped-coal procedure for determining a compacted weight per cubic foot (cubic metre), comparable to actual bulk densities attained in coke ovens.

1.2 This test method is not applicable to the testing of powdered coal as used in boiler plants, nor to the determination of weights per cubic foot of coal in storage piles.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. Mass may be expressed in metric values.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D291 − 07

StandardTest Method for

1

Cubic Foot Weight of Crushed Bituminous Coal

This standard is issued under the fixed designation D291; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—11.1.1 was editorially corrected in January 2011.

1. Scope Coal and Designating Coal Size

1.1 This test method covers two procedures for determining

3. Significance and Use

1

the cubic foot weight of crushed coal less than 1 ⁄2 in. (37 mm)

in size, such as is charged into coke ovens, as follows: 3.1 This test method concerns the compaction of crushed

coal to determine either its compacted or uncompacted weight,

1.1.1 Procedure A—The cone procedure for determining an

uncompacted weight per cubic foot (cubic metre). for purposes such as charging coke ovens.

1.1.2 Procedure B—The dropped-coal procedure for deter-

PROCEDURE A—CONE PROCEDURE FOR

mining a compacted weight per cubic foot (cubic metre),

UNCOMPACTED CUBIC FOOT (CUBIC METRE)

comparable to actual bulk densities attained in coke ovens.

WEIGHT

1.2 This test method is not applicable to the testing of

powderedcoalasusedinboilerplants,nortothedetermination

4. Apparatus

of weights per cubic foot of coal in storage piles.

4.1 Measuring Box, of rigid construction, having inside

1.3 The values stated in inch-pound units are to be regarded

dimensions of 12.0 by 12.0 by 12.0 in. (305 by 305 by 305

3 3 3

as standard. The values given in parentheses are mathematical

mm), and a volume of 1728 6 5 in. (0.0283 m 6 82 cm ).

conversions to SI units that are provided for information only

The exact volume of the box shall be determined by water

and are not considered standard. Mass may be expressed in

calibration.

metric values.

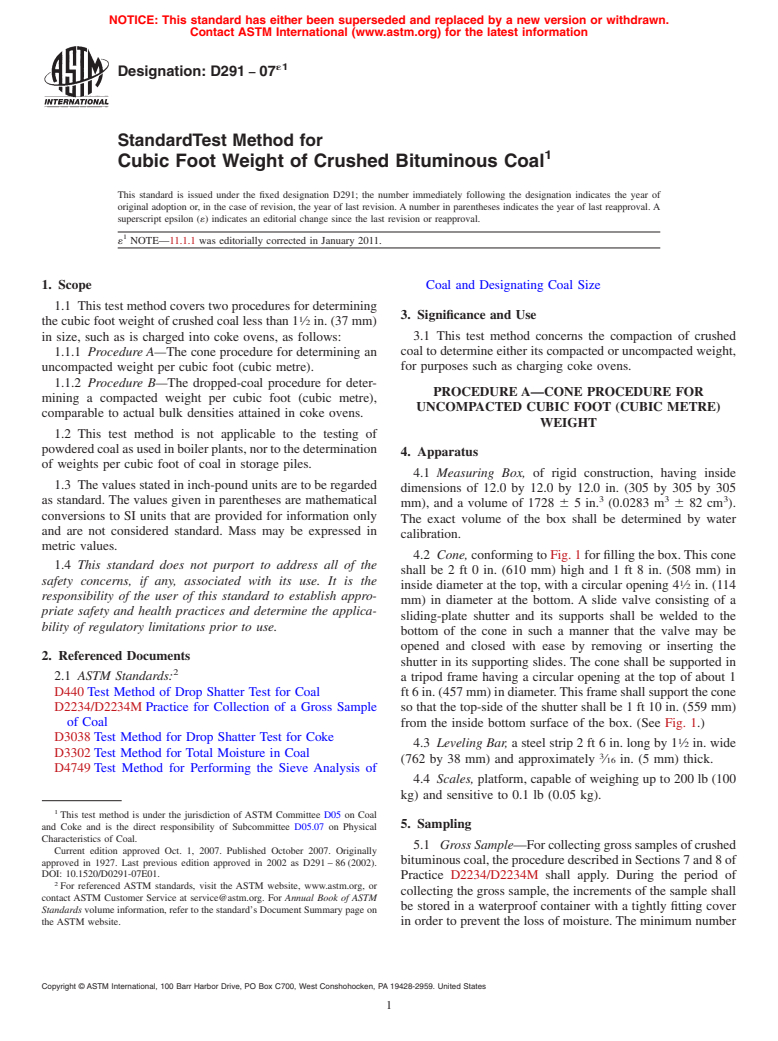

4.2 Cone, conforming to Fig. 1 for filling the box.This cone

1.4 This standard does not purport to address all of the

shall be 2 ft 0 in. (610 mm) high and 1 ft 8 in. (508 mm) in

safety concerns, if any, associated with its use. It is the 1

inside diameter at the top, with a circular opening 4 ⁄2 in. (114

responsibility of the user of this standard to establish appro-

mm) in diameter at the bottom. A slide valve consisting of a

priate safety and health practices and determine the applica-

sliding-plate shutter and its supports shall be welded to the

bility of regulatory limitations prior to use.

bottom of the cone in such a manner that the valve may be

opened and closed with ease by removing or inserting the

2. Referenced Documents

shutter in its supporting slides. The cone shall be supported in

2

2.1 ASTM Standards:

a tripod frame having a circular opening at the top of about 1

D440 Test Method of Drop Shatter Test for Coal ft6in.(457mm)indiameter.Thisframeshallsupportthecone

D2234/D2234M Practice for Collection of a Gross Sample

so that the top-side of the shutter shall be 1 ft 10 in. (559 mm)

of Coal from the inside bottom surface of the box. (See Fig. 1.)

D3038 Test Method for Drop Shatter Test for Coke

1

4.3 Leveling Bar, a steel strip 2 ft 6 in. long by 1 ⁄2 in. wide

D3302 Test Method for Total Moisture in Coal

3

(762 by 38 mm) and approximately ⁄16 in. (5 mm) thick.

D4749 Test Method for Performing the Sieve Analysis of

4.4 Scales, platform, capable of weighing up to 200 lb (100

kg) and sensitive to 0.1 lb (0.05 kg).

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal

5. Sampling

and Coke and is the direct responsibility of Subcommittee D05.07 on Physical

Characteristics of Coal.

5.1 GrossSample—Forcollectinggrosssamplesofcrushed

Current edition approved Oct. 1, 2007. Published October 2007. Originally

bituminouscoal,theproceduredescribedinSections7and8of

approved in 1927. Last previous edition approved in 2002 as D291 – 86 (2002).

DOI: 10.1520/D0291-07E01.

Practice D2234/D2234M shall apply. During the period of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

collecting the gross sample, the increments of the sample shall

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

be stored in a waterproof container with a tightly fitting cover

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in order to prevent the loss of moisture. The minimum number

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D291 − 07

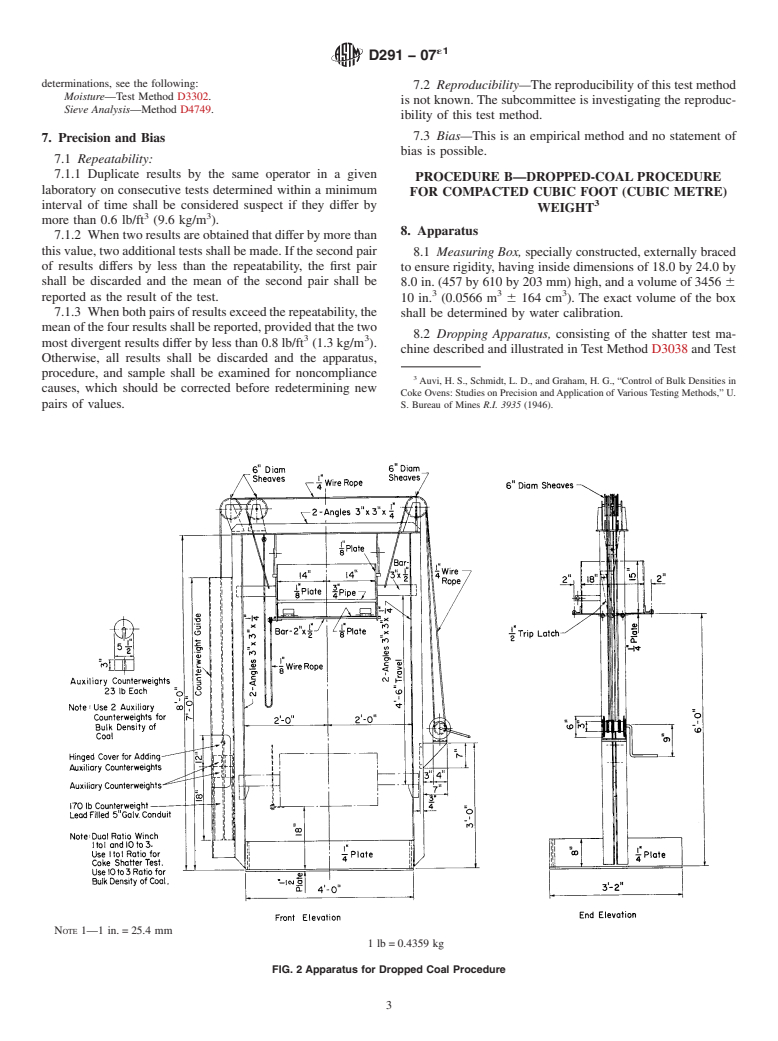

NOTE 1—1 in. = 25.4 mm

FIG. 1 Apparatus for Cone Procedure

and weights of increments collected shall be in accordance gationandpackingwhilethehopperisbeingfilled.Placeabout

with Tabl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.