ASTM D3759/D3759M-05(2011)

(Test Method)Standard Test Method for Breaking Strength and Elongation of Pressure-Sensitive Tape

Standard Test Method for Breaking Strength and Elongation of Pressure-Sensitive Tape

SIGNIFICANCE AND USE

This test method provides information that can be used in material specifications for product design and quality assurance applications. It can be used in comparing different products.

The use of this test method must be related to the purpose for which the test is performed. One purpose is for determining the relative strength of the tape in the size in which it is purchased or used. Another purpose is to identify or characterize a particular backing material.

The test may be performed on the tape as-received, that is, without cutting the material to a specimen width less than the as-received width. Usually tapes wider than 48 mm [2 in.] are not tested due principally to the limitations of equipment. Tapes as narrow as approximately 3 mm [0.125 in.] can be tested.

The test may be performed on a specimen cut from within the sample material boundaries using a sharp razor cutter, such as that defined in Section 6. This method is usually used for material characterization, determining quality of conformance, and for specification compliance.

Stretch characteristics of elongation at break or force to a specified elongation can be related to the tape's intended use or for identifying or characterizing a material.

SCOPE

1.1 This test method covers the measurement of tensile strength at break (breaking strength) and stretch properties (elongation) for pressure-sensitive tapes and labels. It includes procedures for machine direction and cross direction, for high-strength filament reinforced backings and for high stretch backings. It also includes a procedure for obtaining force (“F” value) in conjunction with a specified elongation. These procedures employ a constant-rate-of-extension (CRE)-type testing machine.

1.2 The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; conversions between measurement systems must be conducted carefully.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3759/D3759M − 05 (Reapproved 2011)

Standard Test Method for

Breaking Strength and Elongation of Pressure-Sensitive

1

Tape

This standard is issued under the fixed designation D3759/D3759M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D3715/D3715M Practice for QualityAssurance of Pressure-

Sensitive Tapes

1.1 This test method covers the measurement of tensile

D4332 Practice for Conditioning Containers, Packages, or

strength at break (breaking strength) and stretch properties

Packaging Components for Testing

(elongation) for pressure-sensitive tapes and labels. It includes

E4 Practices for Force Verification of Testing Machines

procedures for machine direction and cross direction, for

E122 Practice for Calculating Sample Size to Estimate,With

high-strength filament reinforced backings and for high stretch

Specified Precision, the Average for a Characteristic of a

backings. It also includes a procedure for obtaining force (“F”

Lot or Process

value) in conjunction with a specified elongation. These

2.2 AFERA Documents (Association Des Fabricants Eu-

procedures employ a constant-rate-of-extension (CRE)-type

ropeens De Reubans Auto-Adhesifs–Europe:

testing machine.

AFERA 4004 Self Adhesive Tapes—Measurement of

1.2 The values stated in either SI or inch-pound units are to

Breaking Strength

be regarded separately as standard. The values stated in each

AFERA4005 SelfAdhesive Tapes—Measurement of Elon-

system may not be exact equivalents; conversions between

gation

measurement systems must be conducted carefully.

2.3 European Norm (EN) Documents:

1.3 This standard does not purport to address all of the EN 1940 Self Adhesive Tapes—Measurement of Breaking

safety concerns, if any, associated with its use. It is the

Strength

responsibility of the user of this standard to establish appro- EN1941 SelfAdhesiveTapes—MeasurementofElongation

priate safety and health practices and determine the applica-

at Break

bility of regulatory limitations prior to use. 2.4 PSTC Documents (Pressure Sensitive Tape Council):

PSTC 131 Tensile Strength and Elongation of Pressure-

2. Referenced Documents

Sensitive Tapes

2

2.1 ASTM Standards:

3. Terminology

D828 Test Method for Tensile Properties of Paper and

3.1 Terminology found in Terminology D996 shall apply.

PaperboardUsingConstant-Rate-of-ElongationApparatus

3

(Withdrawn 2009)

4. Summary of Test Method

D882 Test Method for Tensile Properties of Thin Plastic

4.1 Procedure A–Machine Direction for Tapes with Elonga-

Sheeting

tion Under 200 %—A strip of tape is mounted between two

D996 Terminology of Packaging and Distribution Environ-

clamps aligned in a straight flat plane and force applied at a

ments

specified rate until breaking of the strip of tape occurs. Force

and elongation are determined at the moment of breakage.

1

This test method is under the jurisdiction of ASTM Committee D10 on

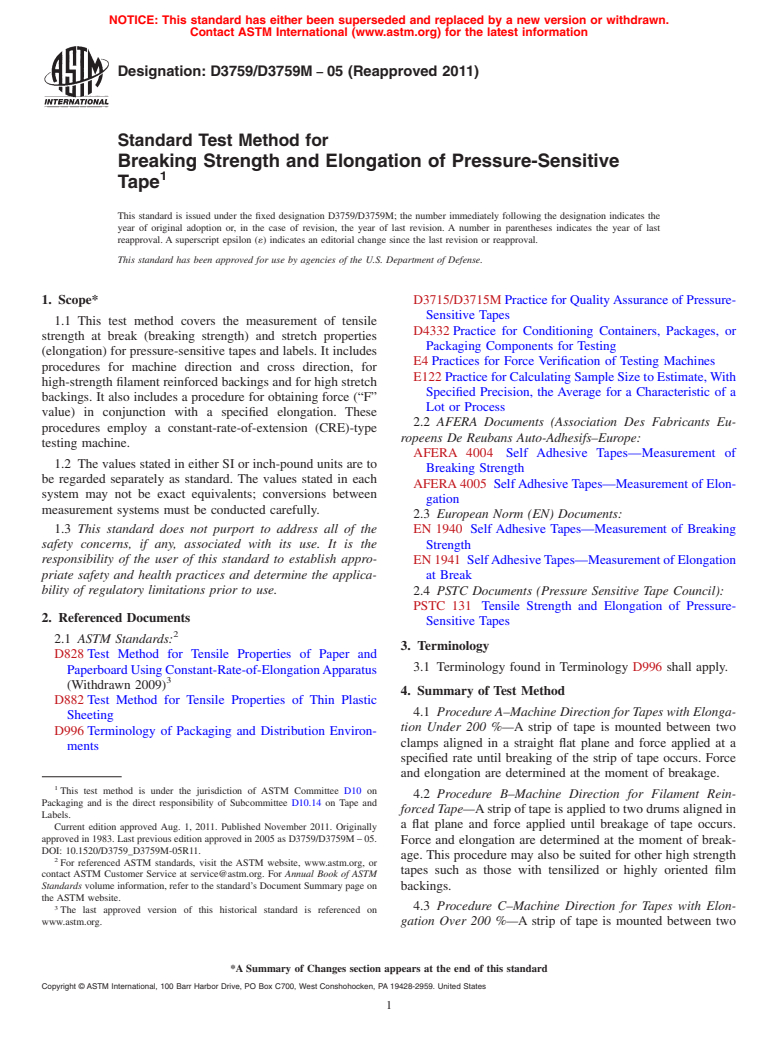

4.2 Procedure B–Machine Direction for Filament Rein-

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

forced Tape—Astrip of tape is applied to two drums aligned in

Labels.

a flat plane and force applied until breakage of tape occurs.

Current edition approved Aug. 1, 2011. Published November 2011. Originally

approved in 1983. Last previous edition approved in 2005 as D3759/D3759M – 05.

Force and elongation are determined at the moment of break-

DOI: 10.1520/D3759_D3759M-05R11.

age. This procedure may also be suited for other high strength

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tapes such as those with tensilized or highly oriented film

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on backings.

the ASTM website.

3

4.3 Procedure C–Machine Direction for Tapes with Elon-

The last approved version of this historical standard is referenced on

www.astm.org. gation Over 200 %—A strip of tape is mounted between two

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3759/D3759M − 05 (2011)

TABLE 1 Test Preparation and Specimen Dimensions

A

Gage Length, Cross Head Velocity, Specimen Length,

Specimen Width,

mm [in.] mm [in.]/min mm [in.] mm [in.]

A. Machine Direction

100 [4] 300 [12] 12–24 [0.5–1] 225 [9]

Elongation Under 200 %

B. Machine Direction

250

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.