ASTM A1033-10(2015)

(Practice)Standard Practice for Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase Transformations

Standard Practice for Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase Transformations

SIGNIFICANCE AND USE

5.1 This practice is used to provide steel phase transformation data required for use in numerical models for the prediction of microstructures, properties, and distortion during steel manufacturing, forging, casting, heat treatment, and welding. Alternatively, the practice provides end users of steel and fabricated steel products the phase transformation data required for selecting steel grades for a given application by determining the microstructure resulting from a prescribed thermal cycle.

5.1.1 There are available several computer models designed to predict the microstructures, mechanical properties, and distortion of steels as a function of thermal processing cycle. Their use is predicated on the availability of accurate and consistent thermal and transformation strain data. Strain, both thermal and transformation, developed during thermal cycling is the parameter used in predicting both microstructure and properties, and for estimating distortion. It should be noted that these models are undergoing continued development. This process is aimed, among other things, at establishing a direct link between discrete values of strain and specific microstructure constituents in steels. This practice describes a standardized method for measuring strain during a defined thermal cycle.

5.1.2 This practice is suitable for providing data for computer models used in the control of steel manufacturing, forging, casting, heat-treating, and welding processes. It is also useful in providing data for the prediction of microstructures and properties to assist in steel alloy selection for end-use applications.

5.1.3 This practice is suitable for providing the data needed for the construction of transformation diagrams that depict the microstructures developed during the thermal processing of steels as functions of time and temperature. Such diagrams provide a qualitative assessment of the effects of changes in thermal cycle on steel microstructure. Appendix X2 describes ...

SCOPE

1.1 This practice covers the determination of hypoeutectoid steel phase transformation behavior by using high-speed dilatometry techniques for measuring linear dimensional change as a function of time and temperature, and reporting the results as linear strain in either a numerical or graphical format.

1.2 The practice is applicable to high-speed dilatometry equipment capable of programmable thermal profiles and with digital data storage and output capability.

1.3 This practice is applicable to the determination of steel phase transformation behavior under both isothermal and continuous cooling conditions.

1.4 This practice includes requirements for obtaining metallographic information to be used as a supplement to the dilatometry measurements.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A1033 − 10 (Reapproved 2015)

Standard Practice for

Quantitative Measurement and Reporting of Hypoeutectoid

1

Carbon and Low-Alloy Steel Phase Transformations

This standard is issued under the fixed designation A1033; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

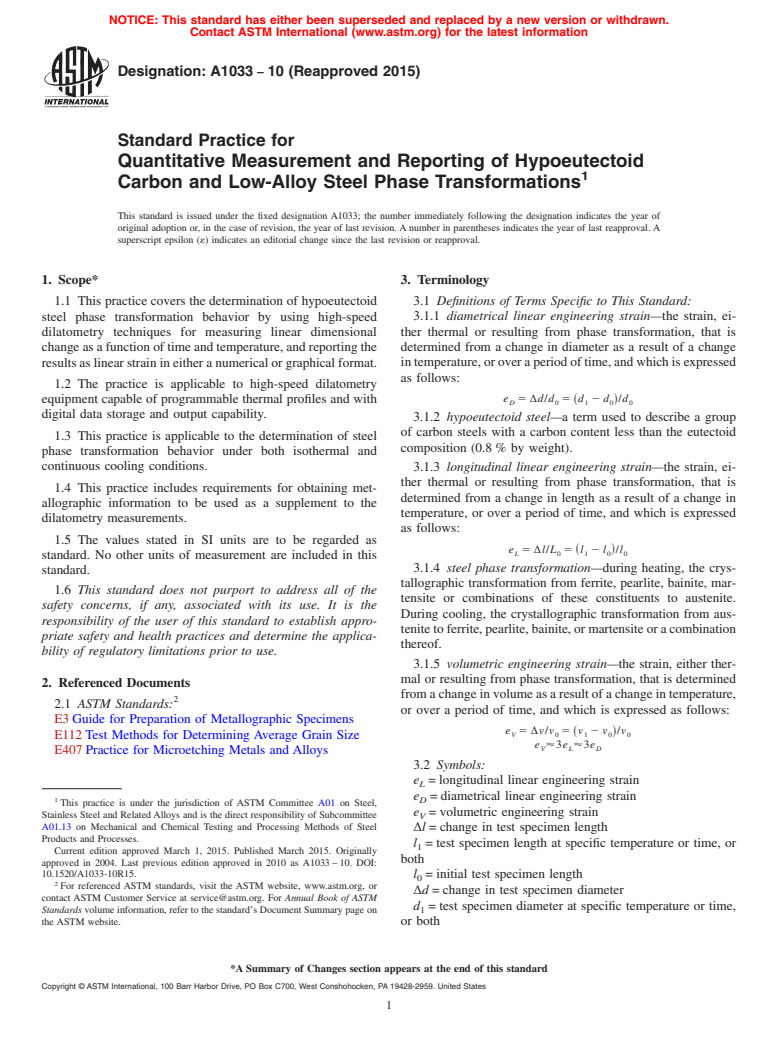

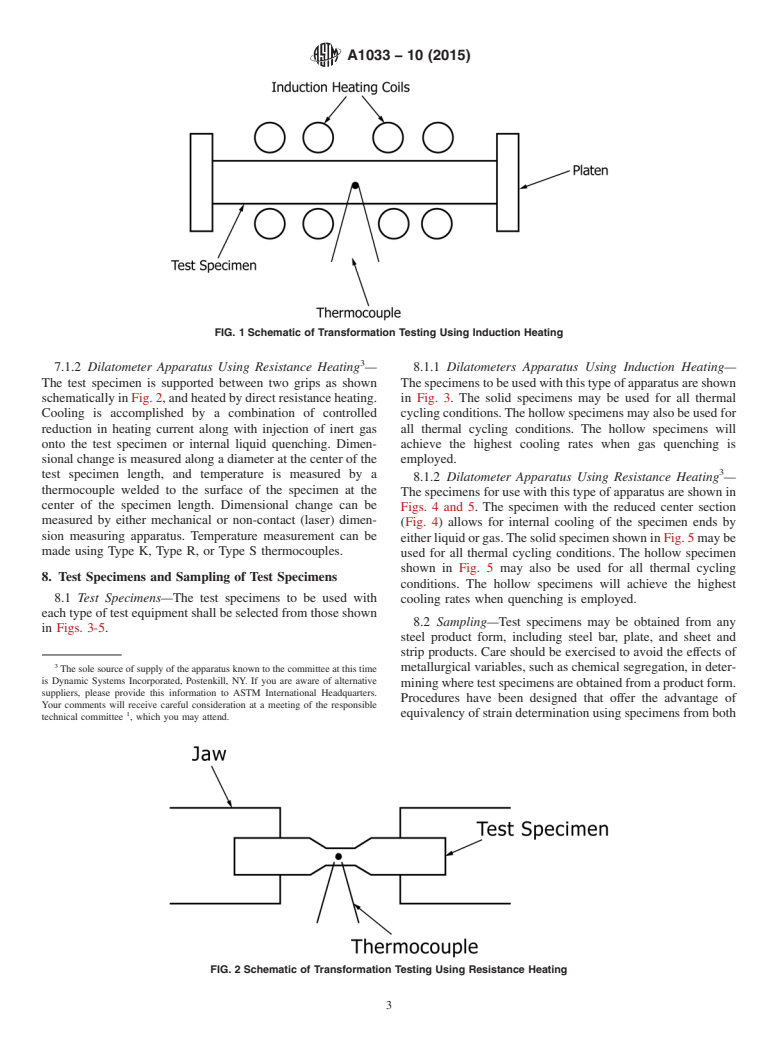

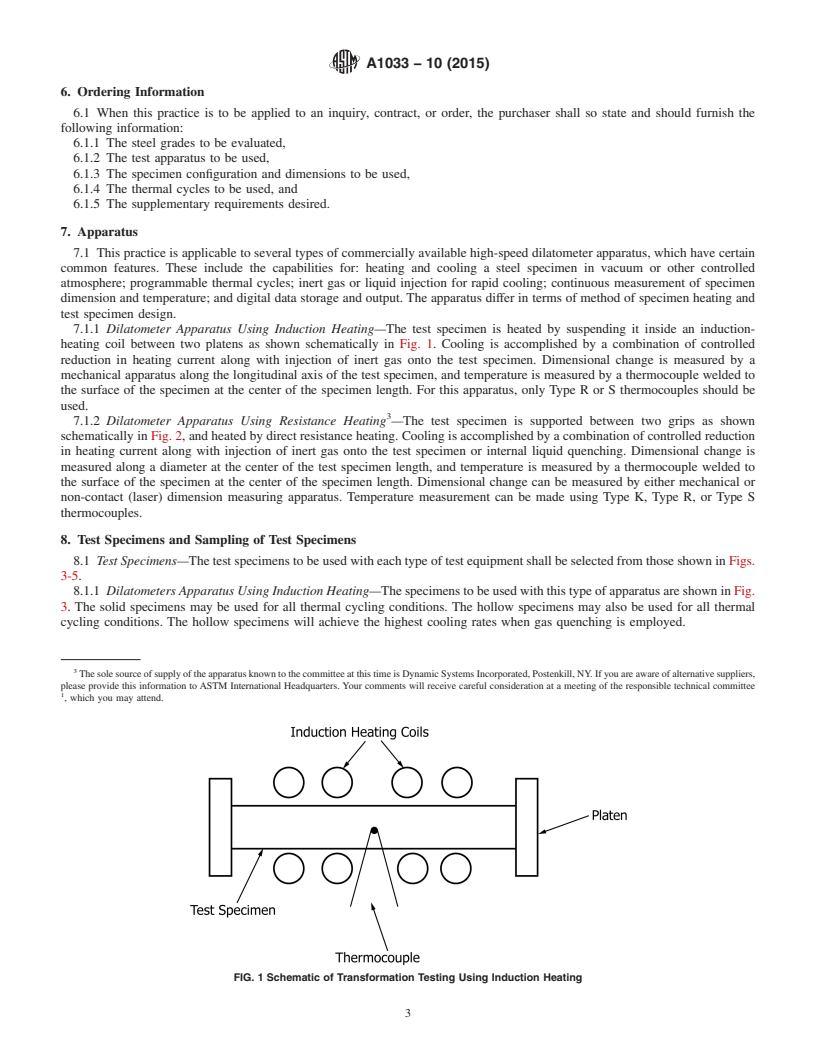

1. Scope* 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This practice covers the determination of hypoeutectoid

steel phase transformation behavior by using high-speed 3.1.1 diametrical linear engineering strain—the strain, ei-

dilatometry techniques for measuring linear dimensional ther thermal or resulting from phase transformation, that is

changeasafunctionoftimeandtemperature,andreportingthe determined from a change in diameter as a result of a change

resultsaslinearstrainineitheranumericalorgraphicalformat. intemperature,oroveraperiodoftime,andwhichisexpressed

as follows:

1.2 The practice is applicable to high-speed dilatometry

e 5∆d/d 5 d 2 d /d

equipment capable of programmable thermal profiles and with ~ !

D 0 1 0 0

digital data storage and output capability.

3.1.2 hypoeutectoid steel—a term used to describe a group

of carbon steels with a carbon content less than the eutectoid

1.3 This practice is applicable to the determination of steel

composition (0.8% by weight).

phase transformation behavior under both isothermal and

continuous cooling conditions. 3.1.3 longitudinal linear engineering strain—the strain, ei-

ther thermal or resulting from phase transformation, that is

1.4 This practice includes requirements for obtaining met-

determined from a change in length as a result of a change in

allographic information to be used as a supplement to the

temperature, or over a period of time, and which is expressed

dilatometry measurements.

as follows:

1.5 The values stated in SI units are to be regarded as

e 5∆l/L 5 l 2 l /l

~ !

L 0 1 0 0

standard. No other units of measurement are included in this

3.1.4 steel phase transformation—during heating, the crys-

standard.

tallographic transformation from ferrite, pearlite, bainite, mar-

1.6 This standard does not purport to address all of the

tensite or combinations of these constituents to austenite.

safety concerns, if any, associated with its use. It is the

During cooling, the crystallographic transformation from aus-

responsibility of the user of this standard to establish appro-

tenitetoferrite,pearlite,bainite,ormartensiteoracombination

priate safety and health practices and determine the applica-

thereof.

bility of regulatory limitations prior to use.

3.1.5 volumetric engineering strain—the strain, either ther-

mal or resulting from phase transformation, that is determined

2. Referenced Documents

fromachangeinvolumeasaresultofachangeintemperature,

2

2.1 ASTM Standards:

or over a period of time, and which is expressed as follows:

E3Guide for Preparation of Metallographic Specimens

e 5∆v/v 5 ~v 2 v !/v

V 0 1 0 0

E112Test Methods for Determining Average Grain Size

e '3e '3e

V L D

E407Practice for Microetching Metals and Alloys

3.2 Symbols:

e =longitudinal linear engineering strain

L

e =diametrical linear engineering strain

1 D

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

e =volumetric engineering strain

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

V

A01.13 on Mechanical and Chemical Testing and Processing Methods of Steel

∆l=change in test specimen length

Products and Processes.

l =test specimen length at specific temperature or time, or

1

Current edition approved March 1, 2015. Published March 2015. Originally

both

approved in 2004. Last previous edition approved in 2010 as A1033–10. DOI:

10.1520/A1033-10R15.

l =initial test specimen length

0

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

∆d=change in test specimen diameter

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

d =test specimen diameter at specific temperature or time,

Standards volume information, refer to the standard’s Document Summary page on 1

the ASTM website. or both

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1033 − 10 (2015)

d =initial test specimen diameter steels as functions of time and temperature. Such diagrams

0

∆v=change in test specimen volume provide a qualitative assessment of the effects of changes in

v =test specimen volume at a specific temperature or time, thermal

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A1033 − 10 A1033 − 10 (Reapproved 2015)

Standard Practice for

Quantitative Measurement and Reporting of Hypoeutectoid

1

Carbon and Low-Alloy Steel Phase Transformations

This standard is issued under the fixed designation A1033; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers the determination of hypoeutectoid steel phase transformation behavior by using high-speed

dilatometry techniques for measuring linear dimensional change as a function of time and temperature, and reporting the results

as linear strain in either a numerical or graphical format.

1.2 The practice is applicable to high-speed dilatometry equipment capable of programmable thermal profiles and with digital

data storage and output capability.

1.3 This practice is applicable to the determination of steel phase transformation behavior under both isothermal and continuous

cooling conditions.

1.4 This practice includes requirements for obtaining metallographic information to be used as a supplement to the dilatometry

measurements.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E112 Test Methods for Determining Average Grain Size

E407 Practice for Microetching Metals and Alloys

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 diametrical linear engineering strain—the strain, either thermal or resulting from phase transformation, that is determined

from a change in diameter as a result of a change in temperature, or over a period of time, and which is expressed as follows:

e 5 Δd/d 5 ~d 2 d !/d

D 0 1 0 0

3.1.2 hypoeutectoid steel—a term used to describe a group of carbon steels with a carbon content less than the eutectoid

composition (0.8 % by weight).

3.1.3 longitudinal linear engineering strain—the strain, either thermal or resulting from phase transformation, that is determined

from a change in length as a result of a change in temperature, or over a period of time, and which is expressed as follows:

e 5 Δl/L 5 l 2 l /l

~ !

L 0 1 0 0

3.1.4 steel phase transformation—during heating, the crystallographic transformation from ferrite, pearlite, bainite, martensite

or combinations of these constituents to austenite. During cooling, the crystallographic transformation from austenite to ferrite,

pearlite, bainite, or martensite or a combination thereof.

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.13

on Mechanical and Chemical Testing and Processing Methods of Steel Products and Processes.

Current edition approved April 1, 2010March 1, 2015. Published April 2010March 2015. Originally approved in 2004. Last previous edition approved in 20042010 as

A1033 – 04.A1033 – 10. DOI: 10.1520/A1033-10.10.1520/A1033-10R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1033 − 10 (2015)

3.1.5 volumetric engineering strain—the strain, either thermal or resulting from phase transformation, that is determined from

a change in volume as a result of a change in temperature, or over a period of time, and which is expressed as follows:

e 5 Δv/v 5 v 2 v /v

~ !

V 0 1 0 0

e '3e '3e

V L D

3.2 Symbols:

e = longitudinal linear engineering strain

L

e = diametrical linear engineering strain

D

e = volumetric engineering strain

V

Δl = change in test specimen length

l = test specimen length at specific temperature or time, or bot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.