ASTM A342/A342M-14

(Test Method)Standard Test Methods for Permeability of Weakly Magnetic Materials

Standard Test Methods for Permeability of Weakly Magnetic Materials

SIGNIFICANCE AND USE

3.1 This test method is suitable for specification acceptance, design purposes, service evaluation, regulatory statutes, manufacturing control, and research and development.

3.2 Because of the restrictions on the specimen shape and size, this test method is most often used to evaluate semifinished product before fabrication of parts.

SCOPE

1.1 These test methods cover four procedures for determination of the permeability [relative permeability]2 of materials having a permeability not exceeding 6.0.

1.2 The test methods covered are as follows:

1.2.1 Test Method 1—Fluxmetric Method is suitable for materials with permeabilities between 1.0 and 4.0. This method permits the user to select the magnetic field strength at which the permeability is to be measured.

1.2.2 Test Method 2—Permeability of Paramagnetic Materials has been eliminated as an acceptable method of test.

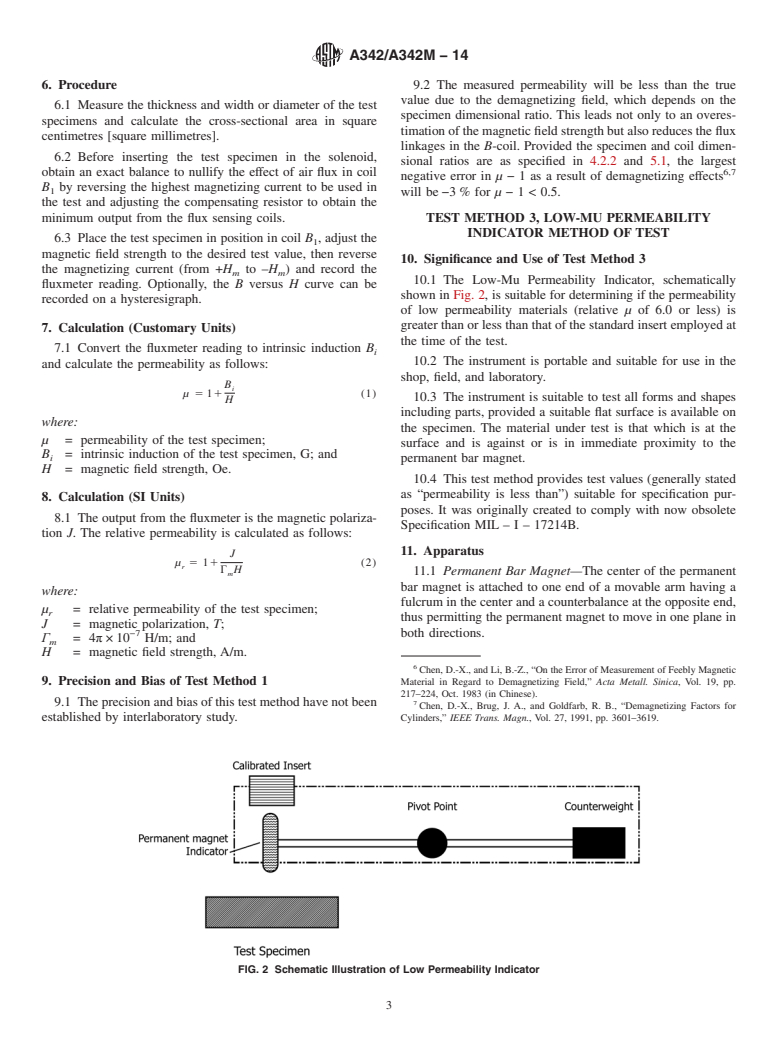

1.2.3 Test Method 3—Low Mu Permeability Indicator is suitable for measuring the permeability of a material as “less than” or “greater than” that of calibrated standard inserts with permeability between 1.01 and 6.0, as designated for use in a Low-Mu Permeability Indicator.3 In this method, a small volume of specimen is subjected to a local magnetic field that varies in magnitude and direction, so it is not possible to specify the magnetic field strength at which the measurement is made.

1.2.4 Test Method 4—Flux Distortion is suitable for materials with permeability between 1.0 and 2.0. In this method, a small volume of specimen is subjected to a local magnetic field that varies in magnitude and direction, so it is not possible to specify the magnetic field strength at which the measurement is made.4

1.2.5 Test Method 5—Vibrating Sample Magnetometry is suitable for materials with permeability between 1.0 and 4.0. This test method permits the user to select the magnetic field strength at which the permeability is to be measured.

1.3 Materials typically tested by these methods such as austenitic stainless steels may be weakly ferromagnetic. That is, the magnetic permeability is dependent on the magnetic field strength. As a consequence, the results obtained using the different methods may not closely agree with each other. When using Methods 1 and 5, it is imperative to specify the magnetic field strength or range of magnetic field strengths at which the permeabilities have been determined.

1.4 The values and equations stated in customary (cgs-emu and inch-pound) or SI units are to be regarded separately as standard. Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A342/A342M − 14

Standard Test Methods for

1

Permeability of Weakly Magnetic Materials

This standard is issued under the fixed designationA342/A342M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope that varies in magnitude and direction, so it is not possible to

specifythemagneticfieldstrengthatwhichthemeasurementis

1.1 These test methods cover four procedures for determi-

4

made.

2

nation of the permeability [relative permeability] of materials

1.2.5 Test Method 5—Vibrating Sample Magnetometry is

having a permeability not exceeding 6.0.

suitable for materials with permeability between 1.0 and 4.0.

This test method permits the user to select the magnetic field

1.2 The test methods covered are as follows:

strength at which the permeability is to be measured.

1.2.1 Test Method 1—Fluxmetric Method is suitable for

materialswithpermeabilitiesbetween1.0and4.0.Thismethod

1.3 Materials typically tested by these methods such as

permits the user to select the magnetic field strength at which

austenitic stainless steels may be weakly ferromagnetic. That

the permeability is to be measured.

is, the magnetic permeability is dependent on the magnetic

field strength.As a consequence, the results obtained using the

1.2.2 Test Method 2—Permeability of Paramagnetic Mate-

differentmethodsmaynotcloselyagreewitheachother.When

rials has been eliminated as an acceptable method of test.

usingMethods1and5,itisimperativetospecifythemagnetic

1.2.3 Test Method 3—Low Mu Permeability Indicator is

field strength or range of magnetic field strengths at which the

suitable for measuring the permeability of a material as “less

permeabilities have been determined.

than” or “greater than” that of calibrated standard inserts with

permeability between 1.01 and 6.0, as designated for use in a

1.4 The values and equations stated in customary (cgs-emu

3

Low-Mu Permeability Indicator. In this method, a small

and inch-pound) or SI units are to be regarded separately as

volume of specimen is subjected to a local magnetic field that

standard. Within this standard, SI units are shown in brackets

varies in magnitude and direction, so it is not possible to

exceptforthesectionsconcerningcalculationswherethereare

specifythemagneticfieldstrengthatwhichthemeasurementis

separate sections for the respective unit systems. The values

made.

stated in each system may not be exact equivalents; therefore,

each system shall be used independently of the other. Combin-

1.2.4 Test Method 4—Flux Distortion is suitable for mate-

ingvaluesfromthetwosystemsmayresultinnonconformance

rials with permeability between 1.0 and 2.0. In this method, a

with this standard.

smallvolumeofspecimenissubjectedtoalocalmagneticfield

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1 responsibility of the user of this standard to establish appro-

These test methods are under the jurisdiction of ASTM Committee A06 on

Magnetic Properties and are the direct responsibility of Subcommittee A06.01 on priate safety and health practices and determine the applica-

Test Methods.

bility of regulatory limitations prior to use.

Current edition approved May 1, 2014. Published May 2014. Originally

approved in 1949. Last previous edition approved in 2012 as A342/A342M–04

2. Referenced Documents

(2012). DOI: 10.1520/A0342_A0342M-14.

2

Test Methods 1 and 5 actually measure magnetic susceptibility. The perme- 5

2.1 ASTM Standards:

ability (µ) [relative permeability (µ )] is related to the susceptibility (κ)bythe

r

equations:

µ=1+4πκ (cgs-emu)

4

µ =1+κ (SI) ThesolesourceofsupplyoftheapparatusknowntotheCommitteeatthistime

r

The term permeability has been retained in these test methods because of its is the Magnetoscop manufactured by INSTITUT DR. POERSTER GmbH & Co.

widespread commercial and technological usage. KG. in Laisen 70, 72766, Reutlingen, Germany. (Probes can be returned for

3

Thesolesourceofsupplyoftheapparatusknowntothecommitteeatthistime calibration.) If you are aware of alternate suppliers, please provide this information

is Low-Mu Permeability Indicator, manufactured by Severn Engineering Co., Inc., to ASTM International Headquarters. Your comments will receive careful consid-

1

555 Stage Rd., Suite 1A, Auburn, AL 36830, http://www.severnengineering.com. erationatameetingoftheresponsibletechnicalcommittee, whichyoumayattend.

5

(Indicators can be returned for recalibration.) If you are aware of alternative For referenced ASTM sta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A342/A342M − 04 (Reapproved 2012) A342/A342M − 14

Standard Test Methods for

1

Permeability of FeeblyWeakly Magnetic Materials

This standard is issued under the fixed designation A342/A342M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

2

1.1 These test methods cover threefour procedures for determination of the permeability [relative permeability] of materials

having a permeability not exceeding 4.0.6.0.

1.2 The test methods covered are as follows:

1.2.1 Test Method 1 1—Fluxmetric Method is suitable for materials with permeabilities between 1.0 and 4.0. This method

permits the user to select the magnetic field strength at which the permeability is to be measured.

1.2.2 Test Method 2 2— is suitable for measuring the permeability of paramagnetic materialsPermeability of Paramagnetic

Materials having a permeability less than 1.05.has been eliminated as an acceptable method of test.

1.2.3 Test Method 3 3—Low Mu Permeability Indicator is a suitable means of for measuring the permeability of a material as

“less than” or “greater than” that of calibrated standard inserts with permeability between 1.01 and 6.0, as designated for use in

3

a Low-Mu Permeability Indicator. In this method, a small volume of specimen is subjected to a local magnetic field that varies

in magnitude and direction, so it is not possible to specify the magnetic field strength at which the measurement is made.

1.2.4 Test Method 4—Flux Distortion is suitable for materials with permeability between 1.0 and 2.0. In this method, a small

volume of specimen is subjected to a local magnetic field that varies in magnitude and direction, so it is not possible to specify

4

the magnetic field strength at which the measurement is made.

1.2.5 Test Method 5—Vibrating Sample Magnetometry is suitable for materials with permeability between 1.0 and 4.0. This test

method permits the user to select the magnetic field strength at which the permeability is to be measured.

1.3 Materials typically tested by these methods such as austenitic stainless steels may be weakly ferromagnetic. That is, the

magnetic permeability is dependent on the magnetic field strength. As a consequence, the results obtained using the different

methods may not closely agree with each other. When using Methods 1 and 5, it is imperative to specify the magnetic field strength

or range of magnetic field strengths at which the permeabilities have been determined.

1.4 The values and equations stated in customary (cgs-emu and inch-pound) or SI units are to be regarded separately as

standard. Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are

separate sections for the respective unit systems. The values stated in each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this

standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1

These test methods are under the jurisdiction of ASTM Committee A06 on Magnetic Properties and are the direct responsibility of Subcommittee A06.01 on Test

Methods.

Current edition approved May 1, 2012May 1, 2014. Published July 2012May 2014. Originally approved in 1949. Last previous edition approved in 20042012 as

A342/A342M–04. –04 (2012). DOI: 10.1520/A0342_A0342M-04R12.10.1520/A0342_A0342M-14.

2

Test Methods 1 and 25 actually measure magnetic susceptibility. The permeability (μ) [relative permeability (μ )] is related to the susceptibility (κ) by the equations:

r

μ = 1 + 4πκ (cgs-emu)

μ = 1 + κ (SI)

r

The term permeability has been retained in these test methods because of its widespread commercial and technological usage.

3

The sole source of supply of the apparatus known to the committee at this time is Low-Mu Permeability Indicator, manufactured by Severn Engineering Co., Inc., 555

Stage Rd., Suite 1A, Auburn, AL 36830, http://www.severnengineering.com. (Indic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.