ASTM D2538-18

(Practice)Standard Practice for Fusion of Poly(Vinyl Chloride) (PVC) Compounds Using a Torque Rheometer

Standard Practice for Fusion of Poly(Vinyl Chloride) (PVC) Compounds Using a Torque Rheometer

SIGNIFICANCE AND USE

5.1 When PVC compounds are mixed under appropriate conditions of heat and shear, a fused mass is produced. This mass has certain melt characteristics which can be defined with a torque rheometer operated under fixed conditions of shear and temperature. The fusion characteristics of a PVC compound are manifest as fusion time, fusion torque, melt torque, melt viscosity, and heat and color stability.

5.2 A control lot is to be used as a standard against which other test results are to be compared. Test data are to be evaluated relative to the control lot.

SCOPE

1.1 This practice covers the relative fusion characteristics of poly(vinyl chloride) compounds.

1.2 The test procedures appear in the following order:

Section

Fusion Test

9

Thermal Stability Test

10

Color-Hold Stability Test

11

Shear Stability Test

12

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

Note 1: There are no ISO standards covering the primary subject matter of this ASTM standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2538 − 18

Standard Practice for

Fusion of Poly(Vinyl Chloride) (PVC) Compounds Using a

1

Torque Rheometer

This standard is issued under the fixed designation D2538; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Determine the Precision of a Test Method

1.1 This practice covers the relative fusion characteristics of

3. Terminology

poly(vinyl chloride) compounds.

3.1 Definitions—Definitions are in accordance with Termi-

1.2 The test procedures appear in the following order:

nologies D883 and D1600 unless otherwise indicated.

Section

4. Summary of Practice

Fusion Test 9

Thermal Stability Test 10

4.1 A sample of powder-mix compound is added to the

Color-Hold Stability Test 11

heated roller mixer chamber and is transformed into a fused

Shear Stability Test 12

mass.

1.3 The values stated in SI units are to be regarded as the

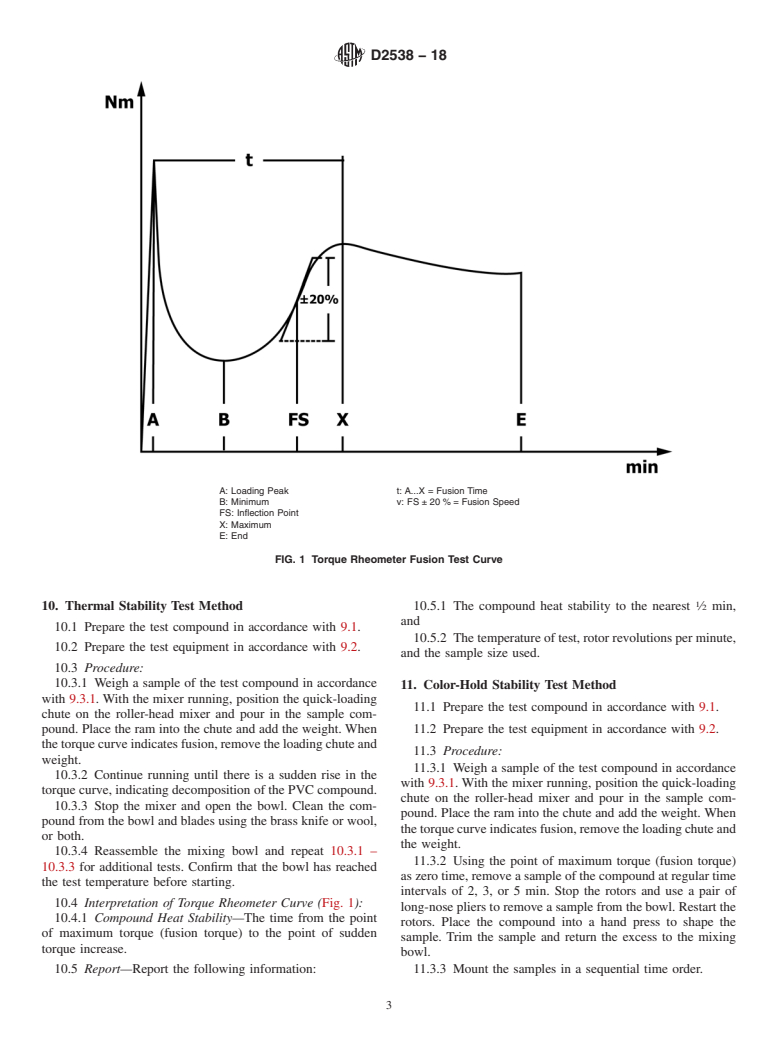

4.2 The resulting torque curve can be used to determine the

standard.

relative fusion time and fusion characteristics.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 When PVC compounds are mixed under appropriate

priate safety, health, and environmental practices and deter-

conditions of heat and shear, a fused mass is produced. This

mine the applicability of regulatory limitations prior to use.

mass has certain melt characteristics which can be defined with

Specific hazards statements are given in Section 8.

a torque rheometer operated under fixed conditions of shear

NOTE 1—There are no ISO standards covering the primary subject

and temperature. The fusion characteristics of a PVC com-

matter of this ASTM standard.

pound are manifest as fusion time, fusion torque, melt torque,

1.5 This international standard was developed in accor-

melt viscosity, and heat and color stability.

dance with internationally recognized principles on standard-

5.2 A control lot is to be used as a standard against which

ization established in the Decision on Principles for the

other test results are to be compared. Test data are to be

Development of International Standards, Guides and Recom-

evaluated relative to the control lot.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

6. Apparatus

3

2. Referenced Documents

6.1 Microprocessor Torque Rheometer, equipped with a

2

high-shear mixer with roller-style blades, bowl-jacket

2.1 ASTM Standards:

thermocouple, stock thermocouple, and temperature recorder.

D883 Terminology Relating to Plastics

D1600 Terminology forAbbreviatedTerms Relating to Plas-

NOTE 2—Atorque rheometer without microprocessor capability can be

tics used to perform the fusion, thermal stability, and color hold tests.

E691 Practice for Conducting an Interlaboratory Study to

6.1.1 For flexible and rigid compounds, use a Type 6 roller

head with a rotor ratio of 3 Drive: 2 Driven.

1 NOTE 3—AType 5 roller head can also be used, but the data generated

This practice is under the jurisdiction ofASTM Committee D20 on Plastics and

cannot be compared with the Type 6 data.

is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved Nov. 1, 2018. Published December 2018. Originally

6.2 Quick-Loading Powder Chute or equivalent.

approved in 1969. Last previous edition approved in 2010 as D2538 – 02(2010).

DOI:10.1520/D2538-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Suitable equipment may be obtained from C. W. Brabender, 50 E. Wesley St.,

Standards volume information, refer to the standard’s Document Summary page on South Hackensack, NJ 07606, and Haake Buchler Instruments, 244 Saddle River

the ASTM website. Rd., Saddle Brook, NJ 07662.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2538 − 18

6.3 Brass Knife. where:

V = volume of mixer bowl without rotors, and

6.4 Brass Wool or Brush.

D = volume displacement or rotors.

6.5 Insulated Gloves.

NOTE4—Thecorrectsamplesizeforthemixeriswhenthefusioncurve

will duplicate itself. As the mixer wears, it will be necessary to increase

6.6 Balance, 500-g minimum capacity, with a 0.1-g sensi-

the sample size to rep

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2538 − 02 (Reapproved 2010) D2538 − 18

Standard Practice for

Fusion of Poly(Vinyl Chloride) (PVC) Compounds Using a

1

Torque Rheometer

This standard is issued under the fixed designation D2538; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the relative fusion characteristics of poly(vinyl chloride) compounds.

1.2 The test procedures appear in the following order:

Section

Fusion Test 9

Thermal Stability Test 10

Color-Hold Stability Test 11

Shear Stability Test 12

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

NOTE 1—There are no ISO standards covering the primary subject matter of this ASTM standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminologies D883 and D1600 unless otherwise indicated.

4. Summary of Practice

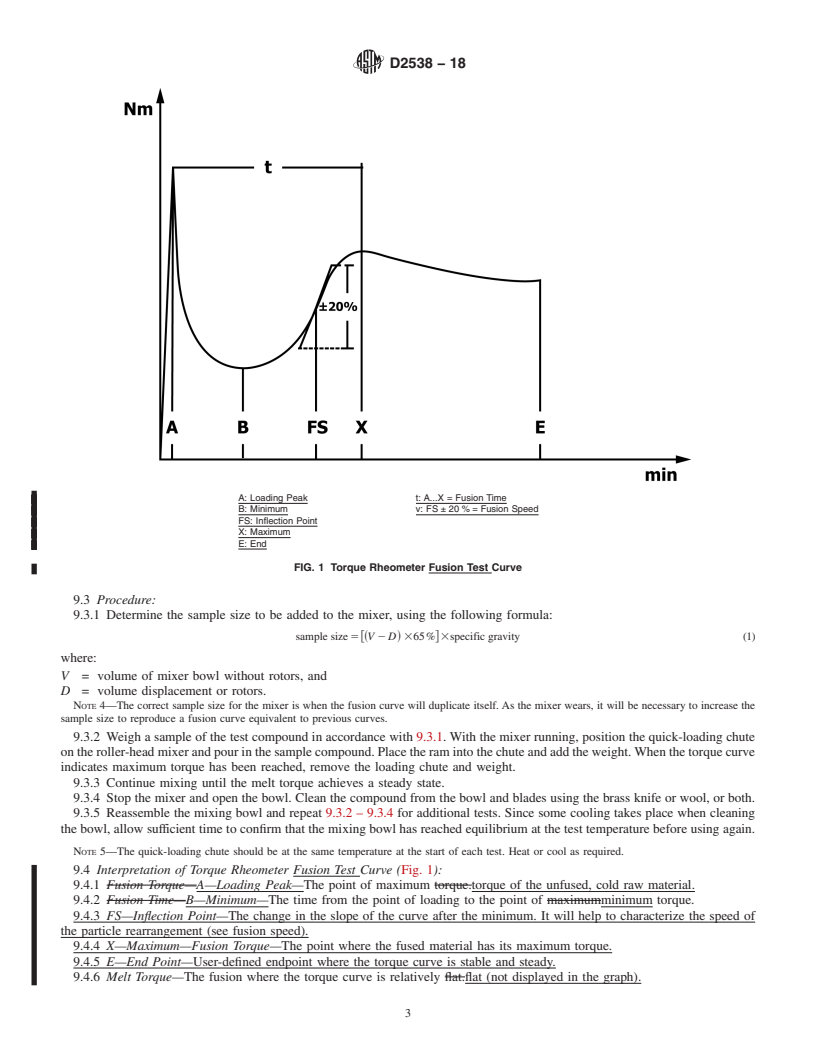

4.1 A sample of powder-mix compound is added to the heated roller mixer chamber and is transformed into a fused mass.

4.2 The resulting torque curve can be used to determine the relative fusion time and fusion characteristics.

5. Significance and Use

5.1 When PVC compounds are mixed under appropriate conditions of heat and shear, a fused mass is produced. This mass has

certain melt characteristics which can be defined with a torque rheometer operated under fixed conditions of shear and temperature.

The fusion characteristics of a PVC compound are manifest as fusion time, fusion torque, melt torque, melt viscosity, and heat and

color stability.

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved Nov. 1, 2010Nov. 1, 2018. Published March 2011December 2018. Originally approved in 1969. Last previous edition approved in 20022010 as

D2538 – 02.D2538 – 02 DOI:10.1520/D2538-02R10.(2010). DOI:10.1520/D2538-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2538 − 18

5.2 A control lot is to be used as a standard against which other test results are to be compared. Test data are to be evaluated

relative to the control lot.

6. Apparatus

3

6.1 Microprocessor Torque Rheometer, equipped with a high-shear mixer with roller-style blades, bowl-jacket thermocouple,

stock thermocouple, and temperature recorder.

NOTE 2—A torque rheometer without microprocessor capability can be used to perform the fusion, thermal stability, and color hold tests.

6.1.1 For flexible and rigid compounds, use a Type 6 roller head with a rotor ratio of 3 Drive: 2 Driven.

NOTE 3—A Type 5 roller head can also be used, but the data generated cannot be compared with the Type 6 data.

6.2 Quick-Loading Powder Chute or equivalent.

6.3 Brass Knife.

6.4 Brass Wool or Brush.

6.5 Insulated Gloves.

6.6 Balance, 500-g minimum capacity, with a 0.1-g sensitivity.

6.7 Beaker, stainless steel, 400 mL.

6.8 Oven.

6.9 Aluminum Foil.

6.10 Timer.

6.11 Long-Nose Pliers.

6.12 Hand-Press Mold.

7. Materials

7.1 Poly(Vinyl Chloride) Resin.

7.2 Filter.

7.3 Lubricants.

7.4 Plas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.