ASTM D3965-99

(Specification)Standard Specification for Rigid Acrylonitrile-Butadiene-Styrene (ABS) Materials for Pipe and Fittings

Standard Specification for Rigid Acrylonitrile-Butadiene-Styrene (ABS) Materials for Pipe and Fittings

SCOPE

1.1 This specification covers materials made from only virgin ABS polymers and blends of ABS polymers suitable for use in the extrusion of pipe and molding of fittings.

1.2 The requirements of this specification are applicable only to the ABS polymers and blends of ABS polymers as classified and do not address the requirements of the finished pipe or fittings. The applicable ASTM standard specification for pipe or fittings should be consulted for their requirements.

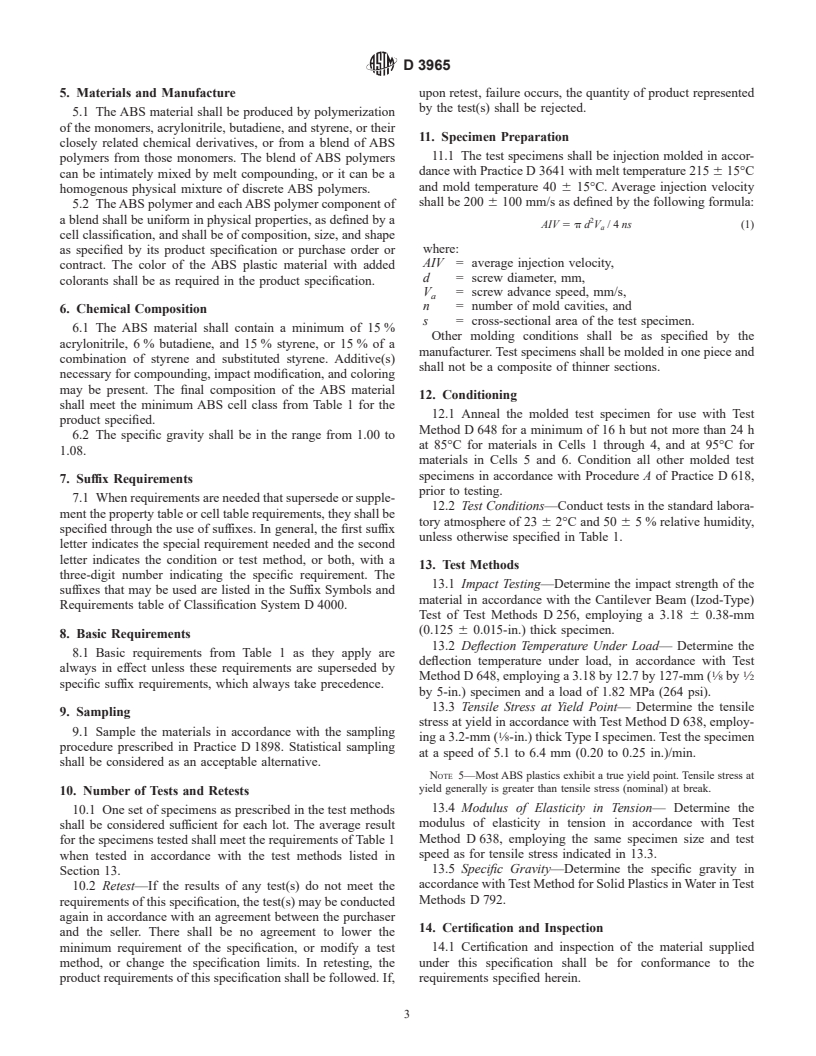

1.3 This specification excludes ABS polymers and blends of ABS polymers made from reprocessed, regrind, reclaimed, or recycled materials. ABS rework, generated in-house by the original plastic manufacturer, may be used by that original manufacturer, provided the ABS product shipped meets the physical and mechanical properties required by its callout in Table 1 of this document.

1.4 This specification provides a means for describing ABS materials used in the manufacture of pipe and fittings. It is not intended for the selection of materials. Material selection should be made by those having expertise in the plastics field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the inherent properties of the material other than those covered by this specification, and the economics.

1.5 This specification provides for the classification of ABS polymers and blends of ABS polymers into groups based on five properties: Izod impact strength at room temperature, Izod impact strength at low temperature, deflection temperature under load, tensile stress at yield point, and modulus of elasticity in tension. The properties included in this specification are those required to identify the ABS material by the cell classifications. Note 1-Other requirements necessary to identify particular characteristics of ABS polymers and blends of ABS polymers will be added as test methods become available or the need is identified. Note 2-Due to pipe and fitting standards requirements a separate standard is being developed for recycled materials. Note 3-This specification is similar to ISO 7245-1984, in title only. The technical content is significantly different.

1.6 The values stated in SI units, as detailed in Practice E380, are to be regarded as the standard. The practices of Practice E380 are incorporated herein. The values given in parentheses are for information only.

1.7 The following safety hazards caveat pertains only to the test methods portion, Section 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3965 – 99

Standard Specification for

Rigid Acrylonitrile-Butadiene-Styrene (ABS) Materials for

Pipe and Fittings

This standard is issued under the fixed designation D 3965; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 2—Due to pipe and fitting standards requirements a separate

1. Scope *

standard is planned for recycled materials.

1.1 This specification covers materials made from only

NOTE 3—This specification and ISO 7245-1984 are not equivalent.

virgin ABS polymers and blends of ABS polymers suitable for

1.6 The values stated in SI units, as detailed in Practice

use in the extrusion of pipe and molding of fittings.

E 380, are to be regarded as the standard. The practices of

1.2 The requirements of this specification are applicable

Practice E 380 are incorporated herein. The values given in

only to the ABS polymers and blends of ABS polymers as

parentheses are for information only.

classified and do not address the requirements of the finished

1.7 The following safety hazards caveat pertains only to the

pipe or fittings. The applicable ASTM standard specification

test methods portion, Section 13, of this specification: This

for pipe or fittings should be consulted for their requirements.

standard does not purport to address all of the safety concerns,

1.3 This specification excludes ABS polymers and blends of

if any, associated with its use. It is the responsibility of the user

ABS polymers made from reprocessed, regrind, reclaimed, or

of this standard to establish appropriate safety and health

recycled materials. ABS rework, generated in-house by the

practices and determine the applicability of regulatory limita-

original plastic manufacturer, may be used by that original

tions prior to use.

manufacturer, provided the ABS product shipped meets the

physical and mechanical properties required by its callout in

2. Referenced Documents

Table 1 of this specification.

2.1 ASTM Standards:

1.4 This specification provides a means for describing ABS

D 256 Test Methods for Impact Resistance of Plastics and

materials used in the manufacture of pipe and fittings. It is not

Electrical Insulating Materials

intended for the selection of materials. Material selection

D 618 Practice for Conditioning Plastics and Electrical

should be made by those having expertise in the plastics field

Insulating Materials for Testing

after careful consideration of the design and the performance

D 638 Test Method for Tensile Properties of Plastics

required of the part, the environment to which it will be

D 648 Test Method for Deflection Temperature of Plastics

exposed, the fabrication process to be employed, the inherent

Under Flexural Load

properties of the material other than those covered by this

D 792 Test Methods for Specific Gravity (Relative Density)

specification, and the economics.

and Density of Plastics by Displacement

1.5 This specification provides for the classification of ABS

D 883 Terminology Relating to Plastics

polymers and blends of ABS polymers into groups based on

D 1600 Terminology for Abbreviated Terms Relating to

five properties: Izod impact strength at room temperature, Izod

Plastics

impact strength at low temperature, deflection temperature

D 1898 Practice for Sampling of Plastics

under load, tensile stress at yield point, and modulus of

D 3641 Practice for Injection Molding Test Specimens of

elasticity in tension. The properties included in this specifica-

Thermoplastic Molding and Extrusion Materials

tion are those required to identify the ABS material by the cell

D 3892 Practice for Packaging/Packing of Plastics

classifications.

D 4000 Classification System for Specifying Plastic Mate-

NOTE 1—Other requirements necessary to identify particular character-

rials

istics of ABS polymers and blends of ABS polymers will be added as test

E 29 Practice for Using Significant Digits in Test Data to

methods become available or the need is identified.

Determine Conformance with Specifications

E 380 Practice for Use of the International Systems of Units

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved March 10, 1999. Published June 1999. Originally Annual Book of ASTM Standards, Vol 08.02.

published as D 3965 – 80. Last previous edition D 3965 – 94. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3965

TABLE 1 Physical Property Requirements for ABS Pipe and Fitting Materials

NOTE—The minimum property value for any material will determine the cell number although the maximum expected value may fall within the next

higher cell.

ASTM Cell Limits

Test Method

0 12345

Izod impact, min: D 256, Test Method A, Canti-

lever Beam (Izod-Type) Test

A

at 23°C (73°F), J/m 110 160 210 320 430

A

(ft-lbf/in. of notch) (2) (3) (4) (6) (8)

A

at − 30°C (−22°F), J/m 50 110 160 210 270

A

(ft-lbf/in. of notch) (1) (2) (3) (4) (5)

Deflection temperature under load, D 648

min, 1.82 MPa, (264 psi)

annealed, 3.18 mm (0.125 in.)

thickness:

A

°C 76 82 88 93 99

A

(°F) (170) (180) (190) (200) (210)

Tensile stress at yield point, min: D 638

A

MPa 24 31 38 45 52

A

(psi) (3500) (4500) (5500) (6500) (7500)

Modulus of elasticity in tension, D 638

min:

A

MPa 1380 1650 1930 2210 2480

A

(psi) (200 000) (240 000) (280 000) (320 000) (360 000)

A

Unspecified.

(SI) (the Modernized Metric System) pounding of virgin styrene-acrylonitrile plastic (SAN) and

F 412 Terminology Relating to Plastic Piping Systems

virgin polybutadiene rubber, which meets the requirements of

2.2 Military Standard:

this specification.

MIL-STD-105D Sampling Procedure and Tables for Inspec-

tion by Attributes

4. Classification

2.3 ISO Standard:

4.1 ABS polymers and blends of ABS polymers shall be

ISO 7245-1984 Pipes and Fittings of Acrylonitrile-

classified in accordance with Table 1. Each ABS polymer and

Butadiene-Styrene (ABS)—General Specification for

blend of ABS polymers is given a five-digit cell classification

Moulding and Extrusion Materials

representing the physical properties in the order in which they

are listed in Table 1.

3. Terminology

3.1 Definitions—Definitions are in accordance with Termi-

NOTE 4—The manner in which selected materials are identified by this

nologies D 883 and F 412 and abbreviations are in accordance

classification system is illustrated by an ABS Class 44222 material having

with Terminology D 1600, unless otherwise indicated. The the following requirements:

abbreviation for acrylonitrile-butadienestyrene plastic is ABS.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 blend—a homogenous mixture of polymers prepared

by melt compounding or physical combination.

3.2.2 lot—a unit of manufacture; may consist of a blend of

two or more production runs or batches of material.

3.2.3 natural material—a polymer as it exists when initially

made by the original producer without addition of colorants.

4.2 Although the values listed are necessary to include the

3.2.4 reprocessed plastic—a thermoplastic prepared from

range of properties available in existing materials, users should

usually melt-processed scrap or reject parts by a plastics

not infer that every possible combination of the properties

processor or from purchased nonstandard or nonuniform virgin

exists or can be obtained.

material.

4.3 Mechanical properties of pigmented or colored materi-

3.2.5 original plastic manufacturer—a company that pro-

als can differ from the mechanical properties of natural

duces ABS resin by polymerization of monomers or com-

material, depending on the choice of colorants and the concen-

tration. The main property affected is ductility, as illustrated by

a reduction in Izod impact strength and tensile elongation

Annual Book of ASTM Standards, Vol 08.04. values. ABS polymers and blends of ABS polymers containing

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

colorants or color concentrates, or both, shall meet the mini-

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

7 mum ABS material cell classification from Table 1 for the pipe

Available from American Natio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.