ASTM C993-97(2003)

(Guide)Standard Guide for In-Plant Performance Evaluation of Automatic Pedestrian SNM Monitors

Standard Guide for In-Plant Performance Evaluation of Automatic Pedestrian SNM Monitors

SIGNIFICANCE AND USE

SNM monitors are an effective and unobtrusive means to search pedestrians for concealed SNM. Facility security plans use SNM monitors as one means to prevent theft or unauthorized removal of designated quantities of SNM from access areas. Daily testing of the monitors with radioactive sources guarantees only the continuity of alarm circuits. The in-plant evaluation is a way to estimate whether an acceptable level of performance for detecting chosen quantities of SNM is obtained from a monitor in routine service or after repair or calibration.

The evaluation verifies acceptable performance or discloses faults in hardware or calibration.

The evaluation uses test sources shielded only by normal source filters and encapsulation and, perhaps, by intervening portions of the transporting individual’body. The transporting individual also provides another form of shielding when the body intercepts environmental radiation that would otherwise reach the monitor’detectors. Hence, transporting individuals play an important role in the evaluation by reproducing an important condition of routine operation.

The evaluation, when applied as a routine-operational evaluation, provides evidence for continued compliance with the performance goals of security plans or regulatory guidance. It is the responsibility of the users of this evaluation to coordinate its application with the appropriate regulatory authority so that mutually agreeable evaluation frequency, test sources, way of transporting the test source, number of test-source passages, and nuisance-alarm-rate goals are used. Agreed written procedures should be used to document the coordination.

SCOPE

1.1 This guide is affiliated with Guide C1112 on special nuclear material (SNM) monitors, Guide C1169 on laboratory performance evaluation, and Guide C1189 on calibrating pedestrian SNM monitors. This guide to in-plant performance evaluation is a comparatively rapid way to verify whether a pedestrian SNM monitor performs as expected for detecting SNM or SNM-like test sources.

1.1.1 In-plant performance evaluation should not be confused with the simple daily functional test recommended in Guide C1112. In-plant performance evaluation takes place less often than daily tests, usually at intervals ranging from weekly to once every three months. In-plant evaluations are also more extensive than daily tests and may examine both a monitor's nuisance alarm record and its detection sensitivity for a particular SNM or alternative test source.

1.1.2 In-plant performance evaluation also should not be confused with laboratory performance evaluation. In-plant evaluation is comparatively rapid, takes place in the monitor's routine operating environment, and its results are limited to verifying that a monitor is operating as expected, or to disclosing that it is not and needs repair or recalibration.

1.2 In-plant evaluation is one part of a program to keep SNM monitors in proper operating condition. Every monitor in a facility is evaluated. There are two applications of the in-plant evaluation: one used during routine operation and another used after calibration.

1.2.1 Routine Operational Evaluation -In this form of the evaluation, nuisance alarm records for each monitor are examined, and each monitor's detection sensitivity is estimated during routine operation. The routine operational evaluation is intended to reassure the plant operator, and his regulatory agency, that the monitor is performing as expected during routine operation. This evaluation takes place without pretesting, recalibration, or other activity that might change the monitor's operation, and the evaluation simulates the normal use of the monitor.

1.2.2 Post-Calibration Evaluation -This form of the evaluation is part of a maintenance procedure; it should always follow scheduled monitor recalibration, or recalibration connected with repair or relocation of the monitor, to verify that an e...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C993–97(Reapproved2003)

Standard Guide for

In-Plant Performance Evaluation of Automatic Pedestrian

SNM Monitors

This standard is issued under the fixed designation C993; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope testing, recalibration, or other activity that might change the

monitor’s operation, and the evaluation simulates the normal

1.1 This guide is affiliated with Guide C1112 on applying

use of the monitor.

special nuclear material (SNM) monitors, Guide C1169 on

1.2.2 Post-Calibration Evaluation—This form of the evalu-

laboratory performance evaluation, Guide C1189 on calibrat-

ation is part of a maintenance procedure; it should always

ing pedestrian SNM monitors, and Guides C1236 and C1237

follow scheduled monitor recalibration, or recalibration con-

on in-plant evaluation. This guide to in-plant performance

nectedwithrepairorrelocationofthemonitor,toverifythatan

evaluation is a comparatively rapid way to verify whether a

expected detection sensitivity is achieved. Nuisance alarm data

pedestrian SNM monitor performs as expected for detecting

do not apply in this case because the monitor has just been

SNM or SNM-like test sources.

recalibrated. Also, having just been calibrated, the monitor is

1.1.1 In-plant performance evaluation should not be con-

likelytobeoperatingatitsbest,whichmaybesomewhatbetter

fused with the simple daily functional test recommended in

than its routine operation.

Guide C1112. In-plant performance evaluation takes place less

1.3 The values stated in SI units are to be regarded as

often than daily tests, usually at intervals ranging from weekly

standard.

to once every three months. In-plant evaluations are also more

1.4 This standard does not purport to address the safety

extensive than daily tests and may examine both a monitor’s

problems, if any, associated with its use. It is the responsibility

nuisance alarm record and its detection sensitivity for a

of the user of this standard to establish appropriate safety and

particular SNM or alternative test source.

health practices and determine the applicability of regulatory

1.1.2 In-plant performance evaluation also should not be

limitations prior to use.

confused with laboratory performance evaluation. In-plant

evaluation is comparatively rapid, takes place in the monitor’s

2. Referenced Documents

routine operating environment, and its results are limited to

2.1 The guide is based on ASTM standards that describe

verifying that a monitor is operating as expected, or to

application and evaluation of SNM monitors, as well as

disclosing that it is not and needs repair or recalibration.

technical publications that describe aspects of SNM monitor

1.2 In-plant evaluation is one part of a program to keep

design and use.

SNM monitors in proper operating condition. Every monitor in

2.2 ASTM Standards:

a facility is evaluated. There are two applications of the

C859 Terminology Relating to Nuclear Materials

in-plant evaluation: one used during routine operation and

C1112 Guide for Application of Radiation Monitors to the

another used after calibration.

Control and Physical Security of Special Nuclear Material

1.2.1 Routine Operational Evaluation—In this form of the

C1169 Guide for Laboratory Evaluation of Automatic Pe-

evaluation, nuisance alarm records for each monitor are exam-

destrian SNM Monitor Performance

ined, and each monitor’s detection sensitivity is estimated

C1189 Guide to Procedures for Calibrating Automatic Pe-

during routine operation. The routine operational evaluation is

destrian SNM Monitors

intended to reassure the plant operator, and his regulatory

C1236 Guide for In-Plant Performance Evaluation ofAuto-

agency, that the monitor is performing as expected during

matic Vehicle SNM Monitors

routine operation. This evaluation takes place without pre-

C1237 Guide to In-Plant Performance Evaluation of Hand-

Held SNM Monitors

This guide is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel

Cycle and is the direct responsibility of Subcommittee C26.12 on Safeguard

Applications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 10, 2003. Published February 2003. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 1997 as C993 – 97. DOI:

Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0993-97R03.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C993–97 (2003)

3. Terminology pressed in percentage. In that case, the detection probability as

a proportion can be obtained by dividing the percentage by

3.1 Definitions:

100.

3.1.1 alternative test source—although no other radioactive

3.1.7 nuisance alarm—a monitoring alarm not caused by

materials individually or collectively duplicate the radioactive

SNM but by other causes, such as statistical variation in the

emissions of uranium or plutonium, some materials have

measurement process, a background intensity variation, or an

somewhat similar attributes and are sometimes used as alter-

equipment malfunction.

native test sources.

3.1.8 process-SNM test source—an SNM test source fabri-

3.1.2 alternative gamma-ray test sources—examples of al-

cated by a facility from process material that differs in physical

ternativegamma-raysourcesareHEUor Bausedinplaceof

or isotopic form from the material recommended in 3.1.11 for

plutonium when a plutonium source is not readily available or

standard test sources.

is prohibited.

3.1.8.1 Discussion—This type of source is used when it

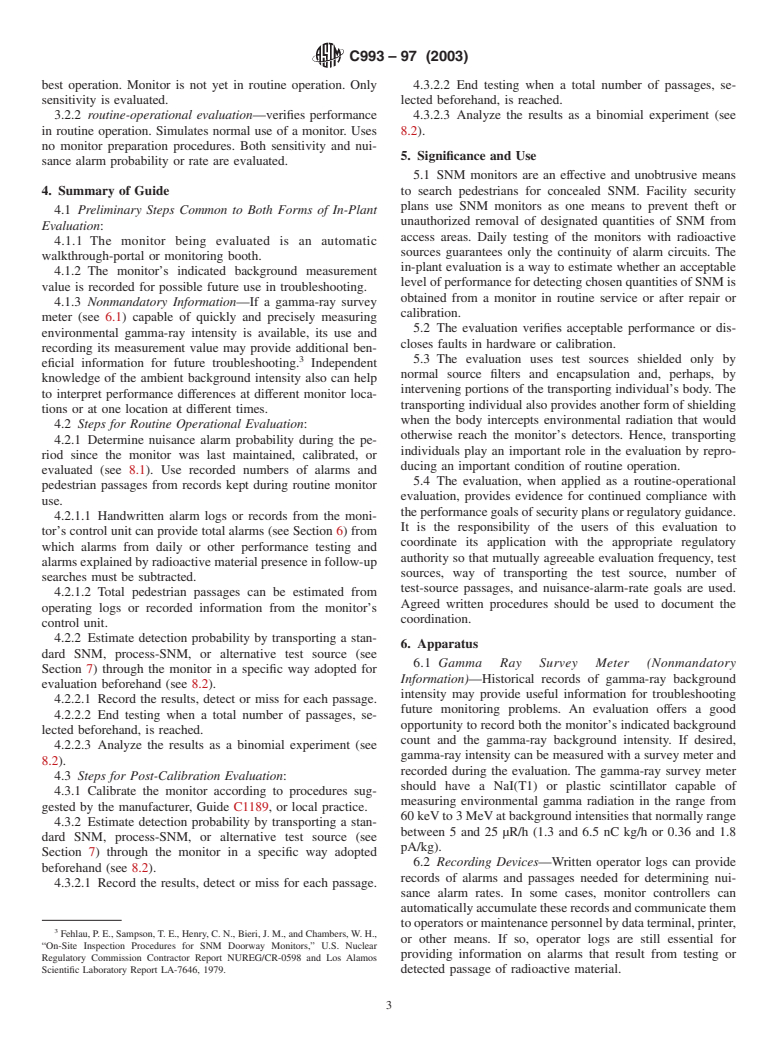

3.1.2.1 Discussion—Table 1 tabulates amounts of HEU

meetsplantoperatororregulatoryagencyperformancerequire-

mass, plutonium mass, and Ba source activity that produce

ments and a suitable standard source is not readily available.

equal response in two different types of monitor.

Encapsulation and filtering should follow that recommended in

3.1.3 alternative neutron test source—acommonalternative

3.1.11.

neutron source used in place of plutonium is Cf that emits

3.1.9 SNM—special nuclear material: plutonium of any

neutrons from spontaneous fission as does plutonium.

isotopic composition, U, or enriched uranium as defined in

3.1.3.1 Discussion—Alternativetestsourcesmayhaveshort

Terminology C859.

decay half-lives in comparison to SNM isotopes; for example,

133 252

3.1.9.1 Discussion—This term is used here to describe both

the half-life of Ba is 10.7 years and Cf 2.64 years. Larger

SNM and strategic SNM, which includes plutonium, U, and

source activities than initially needed are often purchased to

uranium enriched to 20 % or more in the U isotope.

obtain a longer working lifetime for the source.

3.1.10 SNM monitor—radiation detection system that mea-

3.1.4 confidence coeffıcient—the theoretical proportion of

sures ambient radiation intensity, determines an alarm thresh-

confidence intervals from an infinite number of repetitions of

old from the result, and then, when it monitors, sounds an

an evaluation that would contain the true result.

alarm if its measured radiation intensity exceeds the threshold.

3.1.4.1 Discussion—In a demonstration, if the true result

3.1.11 standard SNM test source—a metallic sphere or cube

were known the theoretical confidence coefficient would be the

of SNM having maximum self attenuation of its emitted

approximate proportion of confidence intervals, from a large

radiation and an isotopic composition listed below that mini-

number of repetitions of an evaluation, that contain the true

mizes the intensity of its radiation emission. Encapsulation and

result. Typical confidence coefficients are 0.90, 0.95 and 0.99.

filteringalsoaffectradiationintensity,andparticulardetailsare

3.1.5 Confidence Interval for a Detection Probability—An

listed for each source. This type of test source is used in

interval, based on an actual evaluation situation, so constructed

laboratoryevaluationbut,ifsuitableandreadilyavailable,may

that it contains the (true) detection probability with a stated

be used for in-plant evaluation.

confidence.

3.1.12 standard plutonium test source—a metallic sphere or

3.1.5.1 Discussion—Confidence is often expressed as 100*

cube of low-burnup plutonium containing at least 93 % Pu,

the confidence coefficient. Thus, typical confidence levels are

less than 6.5 % Pu, and less than 0.5 % impurities.

90, 95 and 99 %.

3.1.12.1 Discussion—A cadmium filter can reduce the im-

3.1.6 detection probability—the proportion of passages for

pact of Am, a plutonium decay product that will slowly

which the monitor is expected to alarm during passages of a

build up in time and emit increasing amounts of 60-keV

particular test source.

radiation. Begin use of a 0.04-cm thick cadmium filter when

3.1.6.1 Discussion—Althoughprobabilitiesareproperlyex-

three or more years have elapsed since separation of plutonium

pressedasproportions,performancerequirementsfordetection

decay products. If ten or more years have elapsed since

probability in regulatory guidance have sometimes been ex-

separation, use a cadmium filter 0.08 cm thick. The protective

encapsulation should be in as many layers as local rules

A require. A nonradioactive encapsulation material, such as,

TABLE 1 Alternative Test Source Equivalent Amounts

aluminum (#0.32 cm-thick) or thin (#0.16 cm-thick) stainless

Ba (µCi)

steel or nickel, should be used to reduce unnecessary radiation

Required in

Monitor Monitor Plutonium, Uranium,

absorption.

NaI(T1) Plastic

Category Description g g

Scintillator Scintillator

3.1.13 standard uranium test source—a metallic sphere or

Monitors Monitors

cube of highly enriched uranium (HEU) containing at least

I Standard plutonium 1 64 2.5 3.2

93 % U and less than 0.25 % impurities. Protective encap-

II Standard uranium 0.29 10 0.9 1.4

sulation should be thin plastic or thin aluminum (#0.32 cm

III Improved sensitivity 0.08 3 0.4 0.6

thick) to reduce unnecessary radiation absorption in the encap-

IV High sensitivity 0.03 1 0.2 0.3

A

sulation. No additional filter is needed.

This table combines information from Tables II and V of the report referenced

inFootnote8.Notethattheterm“category”referstoanSNMmonitorperformance

3.2 Definitions of Terms Specific to This Standard:

category used in that report and not to an SNM accountability category.Also note

133 3.2.1 post-calibration evaluation—verifies performance af-

that the Ba source strengths depend on individual differences in how the

scintillators respond to radiation from the barium isotope and plutonium. ter repair, relocation, or recalibration. Monitor is prepared for

C993–97 (2003)

best operation. Monitor is not yet in routine operation. Only 4.3.2.2 End testing when a total number of passages, se-

sensitivity is evaluated. lected beforehand, is reached.

3.2.2 routine-operational evaluation—verifies performance 4.3.2.3 Analyze the results as a binomial experiment (see

in routine operation. Simulates normal use of a monitor. Uses 8.2).

no monitor preparation procedures. Both sensitivity and nui-

5. Significance and Use

sance alarm probability or rate are evaluated.

5.1 SNM monitors are an effective and unobtrusive means

4. Summary of Guide to search pedestrians for concealed SNM. Facility security

plans use SNM monitors as one means to prevent theft or

4.1 Preliminary Steps Common to Both Forms of In-Plant

unauthorized removal of designated quantities of SNM from

Evaluation:

access areas. Daily testing of the monitors with radioactive

4.1.1 The monitor being evaluated is an automatic

sources guarantees only the continuity of alarm circuits. The

walkthrough-portal or monitoring booth.

in-plant evaluation is a way to estimate whether an acceptable

4.1.2 The monitor’s indicated background measurement

level of performance for detecting chosen quantities of SNM is

value is recorded for possible future use in troubleshooting.

obtained from a monitor in routine service or after repair or

4.1.3 Nonmandatory Information—If a gamma-ray survey

calibration.

meter (see 6.1) capable of quickly and precisely measuring

5.2 The evaluation verifies acceptable performance or dis-

environmental gamma-ray intensity is available, its use and

closes faults in hardware or calibration.

recording its measurement value may provide additional ben-

3 5.3 The evaluation uses test sources shielded only by

eficial information for future troubleshooting. Independent

normal source filters and encapsulation and, perhaps, by

knowledge of the ambient background intensity also can help

intervening portions of the transporting individual’s body. The

to interpret performance differences at different monitor loca-

transporting individual also provides another form of shielding

tions or at one location at different times.

when the body intercepts environmental radiation that would

4.2 Steps for Routine Operational Evaluation:

otherwise reach the monitor’s detectors. Hence, transporting

4.2.1 Determine nuisance alarm probability during the pe-

individuals play an important role in the evaluation by repro-

riod since the monitor was last maintained, calibrated, or

ducing an important condition of routine operation.

evaluated (see 8.1). Use recorded numbers of alarms and

5.4 The evaluation, when applied as a routine-operational

pedestrian passages from records kept during routine monitor

evaluation, provides evidence for continued compliance with

use.

theperformancegoalsofsecurityplansorregulatoryguidance.

4.2.1.1 Handwritten alarm logs or records from the moni-

It is the responsibility of the users of this evaluation to

tor’s control unit can provide total alarms (see Section 6) from

coordinate its application with the appropriate regulatory

which alarms from daily or other performance testing and

authority so that mutually agreeable evaluation frequency, test

alarms explained by radioactive material presence in follow-up

sources, way of transporting the test source, number of

searches must be subtracted.

test-source passages, and nuisance-alarm-rate goals are used.

4.2.1.2 Total pedestrian passages can be estimated from

Agreed written procedures should be used to document the

operating logs or recorded information from the monitor’s

coordination.

control unit.

4.2.2 Estimate detection probability by transporting a stan-

6. Apparatus

dard SNM, process-SNM, or alternative test source (see

6.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.