ASTM F948-94(2006)

(Test Method)Standard Test Method for Time-to-Failure of Plastic Piping Systems and Components Under Constant Internal Pressure With Flow

Standard Test Method for Time-to-Failure of Plastic Piping Systems and Components Under Constant Internal Pressure With Flow

SIGNIFICANCE AND USE

The data obtained by this test method are useful for establishing pressure, or hoop stress where applicable, versus failure-time relationships, under independently controlled internal and external environments that simulate actual anticipated product end-use conditions, from which the design basis (DB) for piping products or materials, or both, can be determined. (Refer to Test Method D 2837 and Practice D 2992, and Appendix X1 of this test method.)

Note 3—Reference to design basis (DB) in this test method refers to the hydrostatic design basis (HDB) for material in straight hollow cylindrical shapes where hoop stress can be easily calculated, or is based on applied pressure design basis (PDB) for complex-shaped products or systems where complex stress fields seriously prohibit the use of hoop stress.

In order to characterize plastics as piping products, it is necessary to establish the stress-to-rupture-time, or pressure-to-rupture-time relationships over two or more logarithmic decades of time (hours) within controlled environmental parameters. Because of the nature of the test and specimens employed, no single line can adequately represent the data. Therefore, the confidence limits should be established.

Results obtained at one set of environmental conditions should not be used for other conditions, except that higher temperature data can be used for a design basis assignment for lower application temperatures, provided that it can be demonstrated that the application conditions present a less stringent environment. The design basis should be determined for each specific plastic material and each different set of environmental constraints. Design and processing can significantly affect the long-term performance of piping products, and therefore should be taken into consideration during any evaluation (see Appendix X2).

Specimens used must be representative of the piping product or material under evaluation (see Appendix X2).

SCOPE

1.1 This test method covers the determination of the time-to-failure of plastic piping products under constant internal pressure and flow.

1.2 This test method provides a method of characterizing plastics in the form of pipe, components, and systems under any reasonable combination of internal and external temperatures and environments, under the procedures described.

1.3 This test method can be used to characterize the tested plastic materials or products, or both, on the basis of pressure-, or stress-rupture data developed under the conditions prescribed.

1.4 The values stated in inch-pound units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F948– 94 (Reapproved 2006)

Standard Test Method for

Time-to-Failure of Plastic Piping Systems and Components

Under Constant Internal Pressure With Flow

ThisstandardisissuedunderthefixeddesignationF948;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers the determination of the time-

2.2 PPI Documents:

to-failure of plastic piping products under constant internal

TR-2 Policies and Procedures for the Listing of Thermo-

pressure and flow.

plastic Pipe, Fittings, and Fixture Materials When Evalu-

1.2 This test method provides a method of characterizing

ated Under Constant Internal Pressure With Flow

plastics in the form of pipe, components, and systems under

TR-3 Policies and Procedures for Developing Recom-

any reasonable combination of internal and external tempera-

mended Hydrostatic Design Stresses for Thermoplastic

tures and environments, under the procedures described.

Pipe Materials

1.3 This test method can be used to characterize the tested

plastic materials or products, or both, on the basis of pressure-,

3. Terminology

or stress-rupture data developed under the conditions pre-

3.1 Definitions:

scribed.

3.1.1 failure—bursting, cracking, splitting, or weeping

1.4 The values stated in inch-pound units are to be regarded

(seepage of test fluid through the wall of the product) during

as the standard.

the test, which results in the inability of the specimen to

1.5 This standard does not purport to address all of the

maintain pressure or contain the internal test fluid, shall

safety concerns, if any, associated with its use. It is the

constitute failure of the test specimen. Failure may sometimes

responsibility of the user of this standard to establish appro-

occur by ballooning, an excessive extension leading to struc-

priate safety and health practices and determine the applica-

tural failure. When failure occurs by ballooning the degree of

bility of regulatory limitations prior to use.

distension should be recorded. Assemblies may also fail to

2. Referenced Documents joint leakage or separation.

2.1 ASTM Standards:

NOTE 1—Overall distension, which results from creep caused by

D543 Practices for Evaluating the Resistance of Plastics to long-term stress, is not considered to be a ballooning failure.

Chemical Reagents

3.1.2 hoop stress—thetensilestressinthewallofthepiping

D2122 Test Method for Determining Dimensions of Ther-

product in the circumferential direction due to internal pres-

moplastic Pipe and Fittings

sure. Units will be reported as pounds per square inch (psi) or

D2837 TestMethodforObtainingHydrostaticDesignBasis

mega pascals (MPa). Hoop stress will be calculated by the

forThermoplastic Pipe Materials or Pressure Design Basis

following ISO equation:

for Thermoplastic Pipe Products

S 5 P ~D 2 t!/2t

D2992 Practice for Obtaining Hydrostatic or Pressure De-

sign Basis for “Fiberglass” (Glass-Fiber-Reinforced

where:

Thermosetting-Resin) Pipe and Fittings

S = hoop stress, psi (MPa),

D3567 Practice for Determining Dimensions of “Fiber-

D = average outside diameter, in. (mm),

glass” (Glass-Fiber-Reinforced Thermosetting Resin) Pipe

P = internal pressure, psig (MPag), and

and Fittings t = mimimum wall thickness in. (mm).

NOTE 2—Hoop stress should only be determined on straight hollow

cylindrical specimens. Products of more complex shape may be evaluated

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

by Option 2 of Appendix X1 based on pressure.

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

Methods.

Current edition approved Aug. 1, 2006. Published August 2006. Originally

´1 2

approved in 1985. Last previous edition approved in 2001 as F948 – 94(2001) . Available from Plastics Pipe Institute, Division of The Society of the Plastics

DOI: 10.1520/F0948-94R06. Industry, 250 Park Avenue, New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F948– 94 (2006)

3.1.3 make-up fluid—an exchange of internal fluid with 5.4 Specimens used must be representative of the piping

fresh fluid at a minimum rate of 10 % of the total system product or material under evaluation (see Appendix X2).

volume per week.

3.1.4 maximum internal surface temperature—that tem- 6. Apparatus

perature attained when increased fluid velocity results in no

6.1 Constant-Temperature System:

further increase in the outside surface temperature of the

6.1.1 Controlling the Internal Environment of Test

specimen (see X2.7).

Specimens—Any system that will ensure that the test fluid

3.1.5 pressure—the force per unit area exerted by the test

entering and exiting the test specimen is maintained at a

fluidinthepipingproduct.Unitswillbereportedaspoundsper

constant temperature within6 3.6°F (62°C) throughout the

square inch gage (psig) or mega pascals gage (MPag).

duration of the test.

3.1.6 test assembly—components (such as, pipe, fittings,

6.1.2 Controlling the External Environment of Test

valves, etc.) tested separately or together in an array that may

Specimens—Any system that will ensure constant external

simulate an actual field system that might include joints,

environment temperature within 63.6°F (62°C) throughout

fusions, plastic-to-metal transitions, etc.

the duration of the test.

6.2 Dynamic Flowing Pressure System—Any device that is

4. Summary of Test Method

capable of continuously applying a constant internal pressure

4.1 This test method consists of exposing specimens of

within the tolerance limits defined in Table 1, while allowing a

extruded, molded, or otherwise manufactured pipe or compo-

continuous flow through the test specimens. The flow rate

nents (such as fittings, valves, assemblies, etc.) to a constant

should be substantial enough to control the internal tempera-

internal pressure by a flowing test fluid of controlled tempera-

ture of each test specimen. The device shall be capable of

ture and composition, while in a controlled external environ-

reaching the test pressures without exceeding it, and holding

ment. Time-to-failure and specimen surface temperature

the pressures within the tolerances listed in Table 1 for the

should be measured during exposure under the test conditions.

duration of the test.

Unless otherwise specified the internal fluid shall be water and

the external environment will be air.

NOTE 4—Pressure variations from pumps may exceed the tolerance

limits. (See X2.6.)

5. Significance and Use

6.3 Pressure Gage—A pressure measuring instrument ca-

5.1 The data obtained by this test method are useful for

pable of determining the internal pressure of the test speci-

establishing pressure, or hoop stress where applicable, versus

men(s) within the limits as required in Table 1.

failure-time relationships, under independently controlled in-

6.4 Timing Device—Any timing device or system capable

ternal and external environments that simulate actual antici-

of determining the time-to-failure for each test specimen,

pated product end-use conditions, from which the design basis

within the tolerances listed in Table 1.

(DB) for piping products or materials, or both, can be deter-

6.5 Specimen Holder—Any device that will support the

mined. (Refer to Test Method D2837 and Practice D2992, and

specimens, but will minimize externally induced stresses.

Appendix X1 of this test method.)

Provisions shall be made to allow for normal bidirectional

NOTE 3—Reference to design basis (DB) in this test method refers to

thermal expansion of the test specimen.

the hydrostatic design basis (HDB) for material in straight hollow

6.6 Feed-and-Bleed System—Provisions shall be made to

cylindrical shapes where hoop stress can be easily calculated, or is based

introduce fresh make-up fluid to the system while bleeding off

on applied pressure design basis (PDB) for complex-shaped products or

an equivalent amount necessary to maintain a constant volume

systems where complex stress fields seriously prohibit the use of hoop

stress.

and ensure constant composition of the test fluid. This system

should be designed to maintain composition of the internal

5.2 In order to characterize plastics as piping products, it is

fluid within prescribed limits.

necessary to establish the stress-to-rupture-time, or pressure-

6.7 Other Provisions—Additional provisions may be neces-

to-rupture-time relationships over two or more logarithmic

sary to maintain constant composition.

decades of time (hours) within controlled environmental pa-

6.8 Flow Control—Provisions shall be made to ensure that

rameters. Because of the nature of the test and specimens

the internal fluid velocity shall be adequate to ensure constant

employed, no single line can adequately represent the data.

internaltemperatureinthespecimenwithin 63.6°F(62°C).In

Therefore, the confidence limits should be established.

the special case of hot water inside/ambient air outside,

5.3 Results obtained at one set of environmental conditions

provision shall be made to ensure maximum internal surface

should not be used for other conditions, except that higher

temperature of the specimen within 63.6°F (62°C).

temperature data can be used for a design basis assignment for

lower application temperatures, provided that it can be dem-

onstratedthattheapplicationconditionspresentalessstringent

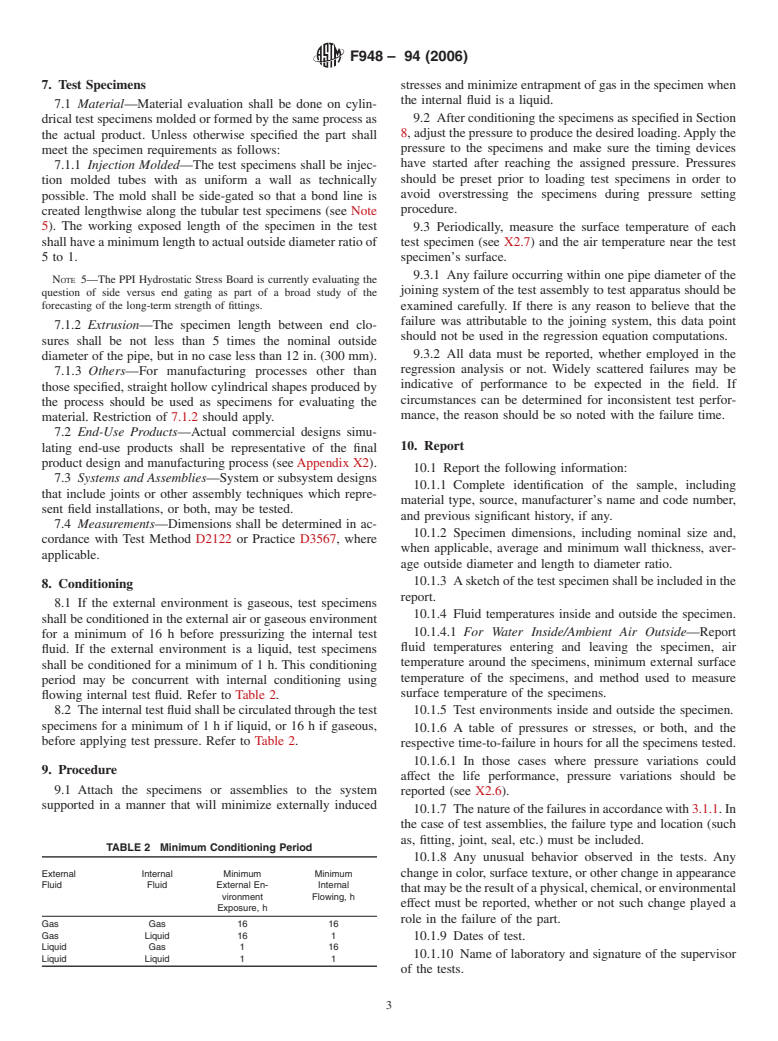

TABLE 1 Tolerances for Testing Thermoplastic Piping Products

environment. The design basis should be determined for each

specificplasticmaterialandeachdifferentsetofenvironmental

Test Periods, h Pressure, % Time, %

constraints. Design and processing can significantly affect the

0to10 60.5 60.5

long-term performance of piping products, and therefore

10 to 100 60.5 61.0

should be taken into consideration during any evaluation (see

100+ 61.0 62.0

Appendix X2).

F948– 94 (2006)

7. Test Specimens stresses and minimize entrapment of gas in the specimen when

the internal fluid is a liquid.

7.1 Material—Material evaluation shall be done on cylin-

9.2 After conditioning the specimens as specified in Section

drical test specimens molded or formed by the same process as

8, adjust the pressure to produce the desired loading.Apply the

the actual product. Unless otherwise specified the part shall

pressure to the specimens and make sure the timing devices

meet the specimen requirements as follows:

have started after reaching the assigned pressure. Pressures

7.1.1 Injection Molded—The test specimens shall be injec-

should be preset prior to loading test specimens in order to

tion molded tubes with as uniform a wall as technically

avoid overstressing the specimens during pressure setting

possible. The mold shall be side-gated so that a bond line is

procedure.

created lengthwise along the tubular test specimens (see Note

5). The working exposed length of the specimen in the test 9.3 Periodically, measure the surface temperature of each

shallhaveaminimumlengthtoactualoutsidediameterratioof test specimen (see X2.7) and the air temperature near the test

5to1. specimen’s surface.

9.3.1 Any failure occurring within one pipe diameter of the

NOTE 5—The PPI Hydrostatic Stress Board is currently evaluating the

joining system of the test assembly to test apparatus should be

question of side versus end gating as part of a broad study of the

forecasting of the long-term strength of fittings. examined carefully. If there is any reason to believe that the

failure was attributable to the joining system, this data point

7.1.2 Extrusion—The specimen length between end clo-

should not be used in the regression equation computations.

sures shall be not less than 5 times the nominal outside

9.3.2 All data must be reported, whether employed in the

diameter of the pipe, but in no case less than 12 in. (300 mm).

regression analysis or not. Widely scattered failures may be

7.1.3 Others—For manufacturing processes other than

indicative of performance to be expected in the field. If

those specified, straight hollow cylindrical shapes produced by

circumstances can be determined for inconsistent test perfor-

the process should be used as specimens for evaluating the

mance, the reason should be so noted with the failure time.

material. Restriction of 7.1.2 should apply.

7.2 End-Use Products—Actual commercial designs simu-

10. Report

lating end-use products shall be representative of the final

product design and manufacturing process (seeAppendix X2).

10.1 Report the following information:

7.3 Systems and Assemblies—System or subsystem designs

10.1.1 Complete identification of the sample, including

that include joints or other assembly techniques which repre-

material type, source, manufacturer’s name and code number,

sent field installations, or both, may be tested.

and previous significant history, if any.

7.4 Measurements—Dimensions shall be determined in ac-

10.1.2 Specimen dimensions, including nominal size and,

cordance with Test Method D2122 or Practice D3567, where

when applicable, average and minimum wall thickness, aver-

applicable.

age outside diameter and length to diameter ratio.

10.1.3 Asketch of the test specimen shall be included in the

8. Conditioning

report.

8.1 If the external environment is gaseous, test specimens

10.1.4 Fluid temperatures inside and outside the specimen.

shall be conditioned in the external air or gaseous environment

10.1.4.1 For Water Inside/Ambient Air Outside—Report

for a minimum of 16 h before pressurizing the internal test

fluid temperatures entering and leaving the specimen, air

fluid. If the external environment is a liquid, test specimens

temperature around the specimens, minimum external surface

shall be conditioned for a minimum of 1 h. This conditioning

temperature of the specimens, and method used to measure

period may be concurrent with internal conditioning using

surface temperature of the specimens.

flowing internal test fluid. Refer to Table 2.

8.2 The internal test fluid shall be circulated through the test 10.1.5 Test environments inside and outside the specimen.

specimens for a minimum of1hif liquid, or 16 h if gaseous,

10.1.6 A table of pressures or stresses, or both, and the

before applying test pressure. Refer to Table 2.

respective time-to-failure in hours for all the specimens tested.

10.1.6.1 In those cases where pressure variations could

9. Procedure

affect the life performance, pressure variations should be

9.1 Attach the specimens or assemblies to the system

r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.