ASTM B755-00

(Specification)Standard Specification for Nickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Plate, Sheet, and Strip

Standard Specification for Nickel-Chromium-Molybdenum-Tungsten Alloys (UNS N06110) Plate, Sheet, and Strip

SCOPE

1.1 This specification covers rolled nickel-chromium-molybdenum-tungsten alloys (UNS N06110) plate, sheet, and strip.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 755 – 00

Standard Specification for

Nickel-Chromium-Molybdenum-Tungsten Alloys (UNS

N06110) Plate, Sheet, and Strip

This standard is issued under the fixed designation B 755; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 ASTM designation.

4.1.2 Alloy name or UNS number.

1.1 This specification covers rolled nickel-chromium-

4.1.3 Condition—Table 2 and Appendix X1.

molybdenum-tungsten alloys (UNS N06110) plate, sheet, and

4.1.4 Finish—Appendix X1.

strip.

4.1.5 Dimensions—Thickness, width, and length.

1.2 The values stated in inch-pound units are to be regarded

4.1.6 Quantity.

as the standard. The SI units in parentheses are provided for

4.1.7 Optional Requirements:

information only.

4.1.7.1 Sheet and Strip—Whether to be furnished in coil, in

2. Referenced Documents

cut straight lengths, or in random straight lengths, and

4.1.7.2 Plate—How plate is to be cut (Table 3 and Table 4).

2.1 ASTM Standards:

4.1.8 Certification—State if certification is required (see

B 756 Specification for Nickel-Chromium-Molybdenum-

Section 15).

Tungsten Alloy (UNS N06110) Rod and Bar

4.1.9 Samples for Product (Check) Analysis—Whether

B 880 Specification for General Requirements for Chemical

samples for product (check) analysis should be furnished (see

Check Analysis Limits for Nickel, Nickel Alloys and

5.2).

Cobalt Alloys

4.1.10 Purchaser Inspection—If the purchaser wishes to

E 8 Test Methods forTensionTesting of Metallic Materials

witness tests or inspection of material at place of manufacture,

E 29 Practice for Using Significant Digits in Test Data to

the purchase order must so state indicating which tests or

Determine Conformance with Specifications

inspections are to be witnessed (see Section 13).

E 1473 Test Methods for Chemical Analysis of Nickel,

Cobalt, and High-Temperature Alloys

5. Chemical Composition

3. Terminology 5.1 The material shall conform to the composition limits

specified in Table 5.

3.1 Definitions of Terms Specific to This Standard:

5.2 If a product (check) analysis is performed by the

3.1.1 The terms given in Table 1 shall apply.

purchaser, the material shall conform to the product (check)

4. Ordering Information

analysis variations per B 880.

4.1 It is the responsibility of the purchaser to specify all

6. Mechanical Properties

requirements that are necessary for the safe and satisfactory

6.1 The material shall conform to the mechanical properties

performance of material ordered under this specification.

specified in Table 2.

Examples of such requirements include, but are not limited to,

the following:

7. Dimensions and Permissible Variations

7.1 Thickness and Weight:

This specification is under the jurisdiction of ASTM Committee B02 on 7.1.1 Plate—For plate up to 2 in. (50.8 mm), inclusive, in

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

thickness, the permissible variation under the specified thick-

B02.07 on Refined Nickel and Cobalt and Their Alloys.

ness and permissible excess in overweight shall not exceed the

Current edition approved Oct. 10, 2000. Published November 2000. Originally

amounts prescribed in Table 6.

published as B 755 – 86. Last previous edition B 755 – 98a.

New designation established in accordance with ASTM E527 and SAE J1086,

7.1.1.1 For use with Table 6, plate shall be assumed to

3 3

Recommended Practice for Numbering Metals and Alloys (UNS).

weigh 0.303 lb/in. (8.386 g/cm ).

Annual Book of ASTM Standards, Vol 02.04.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 755

TABLE 1 Product Description

Product Thickness, in. (mm) Width, in. (mm)

A B

Hot-rolled plate ⁄16 (4.8) and over (Table 4 and Table 5) (Table 7)

A

Hot-rolled sheet 0.018 to 0.250 (0.46 to 6.4), incl (Table 6) (Table 9)

C

Cold-rolled sheet 0.018 to 0.250 (0.46 to 6.4), incl (Table 6) (Table 9)

C

Cold rolled strip 0.005 to 0.250 (0.13 to 6.4), incl (Table 6) (Table 9)

A 3 1

Material ⁄16 to ⁄4 in. (4.8 to 6.4 mm), incl, in thickness may be furnished as sheet or plate provided the material meets the specification requirements for the condition

ordered.

B

Hot-rolled plate, in widths 10 in. (254 mm) and under, may be furnished as hot-finished rectangles with shared or cut edges in accordance with Specification B 446

provided the mechanical property requirements of this specification are met.

C

Material under 48 in. (1219 mm) in width may be furnished as sheet or strip provided the material meets the specification requirements for the condition ordered.

TABLE 2 Mechanical Properties for Plate, Sheet, and Strip (All

7.6 Squareness (Sheet)—For sheets of all thicknesses, the

Thicknesses and Sizes Unless Otherwise Indicated)

angle between adjacent sides shall be 90 6 0.15° ( ⁄16 in. in 24

A

Yield strength Elongation in 2 in.

in.) 1.6 mm in 610 mm).

Condition Tensile strength,

(0.2% offset), min, or 50 mm (or 4D)

(Temper) min, ksi (MPa) 7.7 Flatness—Standard flatness tolerances for plate shall

B

ksi (MPa) min,%

conform to the requirements of Table 11.

C

Hot-Rolled Plate

Annealed 95 (655) 45 (310) 50

8. Workmanship, Finish, and Appearance

Hot-Rolled Sheet

Annealed 95 (655) 45 (310) 50

8.1 The material shall be uniform in quality and temper,

Cold-Rolled Sheet

smooth, commercially straight or flat, and free of injurious

Annealed 95 (655) 45 (310) 50

Cold-Rolled Strip

imperfections.

Annealed 95 (655) 45 (310) 50

A

Yield strength requirementc do not apply to material under 0.020 in. (0.51 mm) 9. Sampling

in thickness.

B

9.1 Lot Definition:

Not applicable for thicknesses under 0.010 in. (0.25 mm).

C

Applicable to 2.75 in. (70 mm) thickness and below.

9.1.1 A lot for chemical analysis shall consist of one heat.

9.1.2 A lot for mechanical testing shall consist of all

material from the same heat, nominal thickness, and condition.

9.1.2.1 Where material cannot be identified by heat, a lot

7.1.2 Plate—Forplateover2in.(50.8mm)inthickness,the

shall consist of not more than 500 lb (227 kg) of material in the

permissible variations over the specified thickness shall not

exceed the amounts prescribed in Table 7. same thickness and condition, except for plates weighing over

500 lb in which case only one specimen shall be taken.

7.1.3 Sheet and Strip—The permissible variations in thick-

ness of sheet and strip shall be as prescribed in Table 8. The 9.2 Test Material Selection:

9.2.1 Chemical Analysis—Representative samples from

thickness of strip and sheet shall be measured with the

micrometer spindle ⁄8 in. (9.5 mm) or more from either edge each lot shall be taken during pouring or subsequent process-

ing.

for material 1 in. (25.4 mm) or over in width and at any place

on the strip under 1 in. in width. 9.2.1.1 Product (check)Analysis—Product analysis shall be

wholly the responsibility of the purchaser.

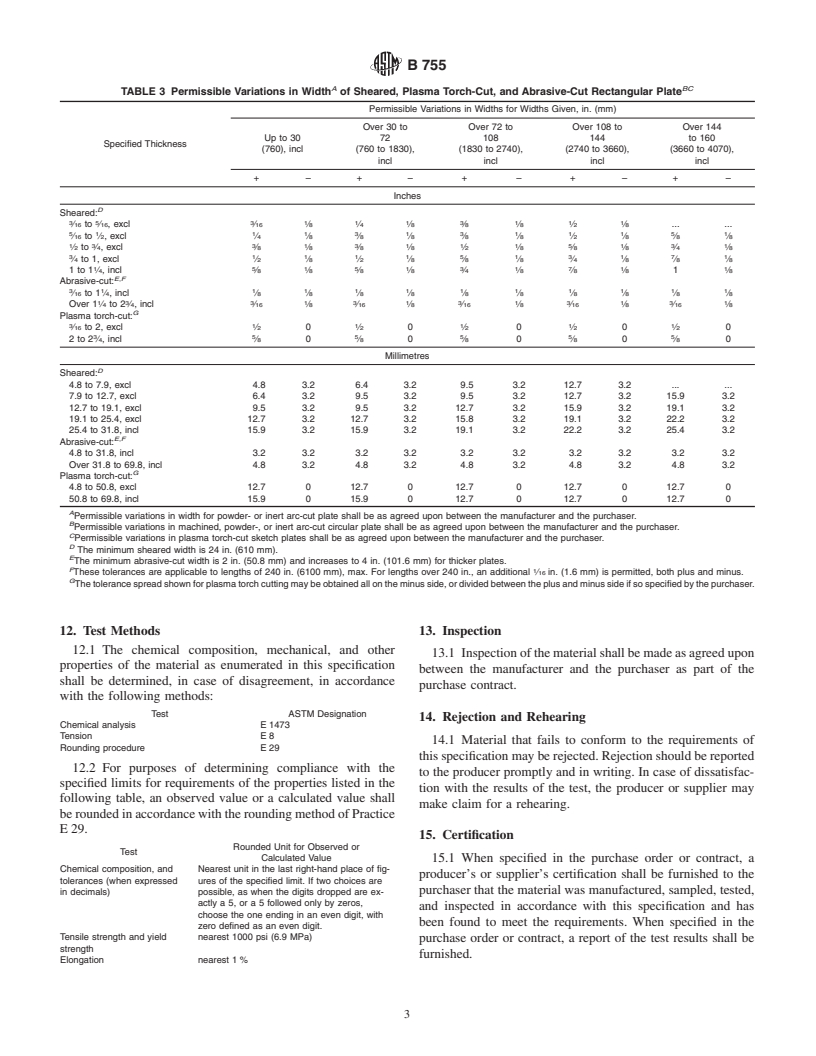

7.2 Width or Diameter:

7.2.1 Plate—The permissible variations in width or rectan- 9.2.2 Mechanical Properties—Samples of the material to

provide test specimens for mechanical properties shall be taken

gular plates and diameter of circular plates shall be as

prescribed in Table 3 and Table 9. from such locations in each lot as to be representative of that

lot.

7.2.2 Sheet and Strip—The permissible variations in width

for sheet and strip shall be as prescribed in Table 10.

10. Number of Tests

7.3 Length:

7.3.1 Sheet and strip of all sizes may be ordered to cut 10.1 Chemical Analysis—One test per lot.

lengths, in which case a variation of ⁄8 in. (3.2 mm) over the 10.2 Mechanical Properties—One test per lot.

specified length shall be permitted.

11. Specimen Preparation

7.3.2 Permissible variations in length of rectangular plate

shall be as prescribed in Table 4.

11.1 Tension test specimens shall be taken from material in

7.4 Straightness: the final condition (temper) and tested transverse to the

7.4.1 The edgewise curvature (depth of chord) of flat sheet,

direction of rolling when width will permit.

strip, and plate shall not exceed 0.05 in. multiplied by the 11.2 Tension test specimens shall be any of the standard or

length in feet (0.04 mm multiplied by the length in centime-

subsize specimens shown in Test Methods E 8.

ters). 11.3 In the event of disagreement, referee specimens shall

7.4.2 Straightness for coiled material is subject to agree-

be as follows:

ment between the manufacturer and the purchaser. 11.3.1 Full thickness of the material, machined to the form

7.5 Edges:

and dimensions shown for the sheet-type specimen in Test

7.5.1 Sheet and strip shall have sheared or slit edges. Methods E 8 for material under ⁄2 in. (12.7 mm) in thickness.

7.5.2 Plate shall have sheared or cut (machines, abrasive 11.3.2 The largest possible round specimen shown in Test

cut, powder cut, or inert arc cut) edges, as specified. Methods E 8 for material ⁄2 in. (12.7 mm) and over.

B 755

A BC

TABLE 3 Permissible Variations in Width of Sheared, Plasma Torch-Cut, and Abrasive-Cut Rectangular Plate

Permissible Variations in Widths for Widths Given, in. (mm)

Over 30 to Over 72 to Over 108 to Over 144

Up to 30 72 108 144 to 160

Specified Thickness

(760), incl (760 to 1830), (1830 to 2740), (2740 to 3660), (3660 to 4070),

incl incl incl incl

+– + – + – +– + –

Inches

D

Sheared:

3 5 3 1 1 1 3 1 1 1

⁄16 to ⁄16, excl ⁄16 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 ⁄2 ⁄8 . .

5 1 1 1 3 1 3 1 1 1 5 1

⁄16 to ⁄2, excl ⁄4 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄2 ⁄8 ⁄8 ⁄8

1 3 3 1 3 1 1 1 5 1 3 1

⁄2 to ⁄4, excl ⁄8 ⁄8 ⁄8 ⁄8 ⁄2 ⁄8 ⁄8 ⁄8 ⁄4 ⁄8

3 1 1 1 1 5 1 3 1 7 1

⁄4 to 1, excl ⁄2 ⁄8 ⁄2 ⁄8 ⁄8 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8

1 5 1 5 1 3 1 7 1 1

1to1 ⁄4, incl ⁄8 ⁄8 ⁄8 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 1 ⁄8

E,F

Abrasive-cut:

3 1 1 1 1 1 1 1 1 1 1 1

⁄16 to 1 ⁄4, incl ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8

1 3 3 1 3 1 3 1 3 1 3 1

Over 1 ⁄4 to 2 ⁄4, incl ⁄16 ⁄8 ⁄16 ⁄8 ⁄16 ⁄8 ⁄16 ⁄8 ⁄16 ⁄8

G

Plasma torch-cut:

3 1 1 1 1 1

⁄16 to 2, excl ⁄2 0 ⁄2 0 ⁄2 0 ⁄2 0 ⁄2 0

3 5 5 5 5 5

2to2 ⁄4, incl ⁄8 0 ⁄8 0 ⁄8 0 ⁄8 0 ⁄8 0

Millimetres

D

Sheared:

4.8 to 7.9, excl 4.8 3.2 6.4 3.2 9.5 3.2 12.7 3.2 . .

7.9 to 12.7, excl 6.4 3.2 9.5 3.2 9.5 3.2 12.7 3.2 15.9 3.2

12.7 to 19.1, excl 9.5 3.2 9.5 3.2 12.7 3.2 15.9 3.2 19.1 3.2

19.1 to 25.4, excl 12.7 3.2 12.7 3.2 15.8 3.2 19.1 3.2 22.2 3.2

25.4 to 31.8, incl 15.9 3.2 15.9 3.2 19.1 3.2 22.2 3.2 25.4 3.2

E,F

Abrasive-cut:

4.8 to 31.8, incl 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2

Over 31.8 to 69.8, incl 4.8 3.2 4.8 3.2 4.8 3.2 4.8 3.2 4.8 3.2

G

Plasma torch-cut:

4.8 to 50.8, excl 12.7 0 12.7 0 12.7 0 12.7 0 12.7 0

50.8 to 69.8, incl 15.9 0 15.9 0 12.7 0 12.7 0 12.7 0

A

Permissible variations in width for powder- or inert arc-cut plate shall be as agreed upon between the manufacturer and the purchaser.

B

Permissible variations in machined, powder-, or inert arc-cut circular plate shall be as agreed upon between the manufacturer and the purchaser.

C

Permissible variations in plasma torch-cut sketch plates shall be as agreed upon between the manufacturer and the purchaser.

D

The minimum sheared width is 24 in. (610 mm).

E

The minimum abrasive-cut width is 2 in. (50.8 mm) and increases to 4 in. (101.6 mm) for thicker plates.

F

These tolerances are applicable to lengths of 240 in. (6100 mm), max. For lengths over 240 in., an additional ⁄16 in. (1.6 mm) is permitted, both plus and minus.

G

Thetolerancespreadshownforplasmatorchcuttingmaybeobtainedallontheminusside,ordividedbetweentheplusandminussideifsospecifiedbythepurchaser.

12. Test Methods 13. Inspection

12.1 The chemical composition, mechanical, and other

13.1 Inspectionofthematerialshallbemadeasagreedupon

properties of the material as enumerated in this specification

between the manufacturer and the purchaser as part of the

shall be determined, in case of disagreement, in accordance

purchase contract.

with the following methods:

Test ASTM Designation

14. Rejection and Rehearing

Chemical analysis E 1473

Tension E 8

14.1 Material that fails to conform to the requirements of

Rounding procedure E 29

thisspecificationmayberejected.Rejectionshouldbereported

12.2 For purposes of determining compliance with the

to the producer promptly and in writing. In case of dissatisfac-

specified limits for requirements of the properties listed in the

tion with the results of the test, the producer or supplier may

following table, an observed value or a calculated value shall

make claim for a rehearing.

beroundedinaccordancewiththeroundingmethodofPractice

E 29.

15. Certification

Rounded Unit for Observed or

Test

Calculated Value

15.1 When specified in the purchase order or contract, a

Chemical composition, and Nearest unit in the last right-hand place of fig-

producer’s or supplier’s certification shall be furnished to the

tolerances (when expressed ures of the specified limit. If two choices are

purchaser that the material was manufactured, sampled, tested,

in decimals) possible, as when the digits dropped are ex-

actly a 5, or a 5 followed only by zeros,

and inspected in accordance with this specification and has

choose the one ending in an even digit, with

been found to meet the requirements. When specified in the

zero defined as an even digit.

Tensile strength and yield nearest 1000 psi (6.9 MPa)

purchase order or contract, a report of the test results shall be

strength

furnished.

Elongation nearest 1 %

B 755

A B C

TABLE 4 Permissible Variations in Length of Sheared, Plasma-Torch-Cut, and Abrasive-Cut Rectangular Plate

Permissible Variation in Length for Lengths Given, in. (mm)

Over 60 Over 96 Over 120 Over 240 Over 360 Over 450

Up to 60 to 96 to 120 to 240 to 360 to 450 to 540 Over 540

Specific Thickness

(1520), incl (1520 to 2440), (2440 to 3050), (3050 to 6096), (6096 to 9144), (9144 to (11 430 to (13 716)

incl incl incl incl 11 430), incl 13 716), incl

Plus Minus Plus Minus Plus Minus Plus Minus Plus Minus Plus Minus Plus Minus Plus Minus

Inches

D

Sheared:

3 5 3 1 1 1 3 1 1 1 5 1 3 1 7 1

⁄16 to ⁄16, excl ⁄16 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 ⁄2 ⁄8 ⁄8 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 . .

5 1 3 1 1 1 1 1 1 1 5 1 3 1 7 1 1

⁄16 to ⁄2, excl ⁄8 ⁄8 ⁄2 ⁄8 ⁄2 ⁄8 ⁄2 ⁄8 ⁄8 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 1 ⁄8

1 3 1 1 1 1 5 1 5 1 3 1 7 1 1 1 3 1

⁄2 to ⁄4, excl ⁄2 ⁄8 ⁄2 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 1 ⁄8 ⁄8 1 ⁄8 ⁄8

3 5 1 5 1 5 1 3 1 7 1 1 1 3 1 5 1

⁄4 to 1, excl ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 1 ⁄8 ⁄8 1 ⁄8 ⁄8 1 ⁄8 ⁄8

1 3 1 3 1 3 1 7 1 1 1 3 1 5 1

1to1 ⁄4, incl ⁄4 ⁄8 ⁄4 ⁄8 ⁄4 ⁄8 ⁄8 ⁄8 1 ⁄8 ⁄8 1 ⁄8 ⁄8 1 ⁄8 ⁄8 . .

E

Abrasive-cut:

3 1 1 1 1 1 1 1 1 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.