ASTM E1399/E1399M-97(2013)e1

(Test Method)Standard Test Method for Cyclic Movement and Measuring the Minimum and Maximum Joint Widths of Architectural Joint Systems

Standard Test Method for Cyclic Movement and Measuring the Minimum and Maximum Joint Widths of Architectural Joint Systems

SIGNIFICANCE AND USE

4.1 Types of architectural joint systems included in this test method are the following:

4.1.1 Metallic systems;

4.1.2 Compression seals:

4.1.2.1 With frames, and

4.1.2.2 Without frames,

4.1.3 Strip seals;

4.1.4 Preformed sealant systems (see Appendix X1):

4.1.4.1 With frames, and

4.1.4.2 Without frames,

4.1.5 Preformed foams and sponges:

4.1.5.1 Self-Expanding, and

4.1.5.2 Nonexpanding,

4.1.6 Fire barriers:

4.1.6.1 Used as joint systems, and

4.1.6.2 Used as a part of the joint system, and

4.1.7 Elastomeric membrane systems:

4.1.7.1 With nosing material(s), and

4.1.7.2 Without nosing material(s).

4.2 This test method will assist users, producers, building officials, code authorities, and others in verifying some performance characteristics of representative specimens of architectural joint systems under common test conditions. The following performance characteristics are verifiable:

4.2.1 The maximum joint width,

4.2.2 The minimum joint width, and

4.2.3 The movement capability.

4.3 This test compares similar architectural joint systems by cycling but does not accurately reflect the system's application. Similar refers to the same type of architectural system within the same subsection under 4.1.

4.4 This test method does not provide information on:

4.4.1 Durability of the architectural joint system under actual service conditions, including the effects of cycled temperature on the joint system,

4.4.2 Loading capability of the system and the effects of a load on the functional parameters established by this test method,

4.4.3 Rotational, vertical, and horizontal shear capabilities of the specimen,

4.4.4 Any other attributes of the specimen, such as fire resistance, wear resistance, chemical resistance, air infiltration, watertightness, and so forth, and

4.4.5 Testing or compatibility of substrates.

4.5 This test method is only to be used as one element in the selection of an architectural j...

SCOPE

1.1 This test method covers testing procedures for architectural joint systems. This test method is intended for the following uses for architectural joint systems:

1.1.1 To verify movement capability information supplied to the user by the producer,

1.1.2 To standardize comparison of movement capability by relating it to specified nominal joint widths,

1.1.3 To determine the cyclic movement capability between specified minimum and maximum joint widths without visual deleterious effects, and

1.1.4 To provide the user with graphic information, drawings or pictures in the test report, depicting them at minimum, maximum, and nominal joint widths during cycling.

1.2 This test method is intended to be used only as part of a specification or acceptance criterion due to the limited movements tested.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1399/E1399M − 97 (Reapproved 2013)

Standard Test Method for

Cyclic Movement and Measuring the Minimum and

Maximum Joint Widths of Architectural Joint Systems

ThisstandardisissuedunderthefixeddesignationE1399/E1399M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units information was editorially corrected and keywords were added in September 2013.

1. Scope 2. Referenced Documents

1.1 This test method covers testing procedures for architec- 2.1 ASTM Standards:

tural joint systems. This test method is intended for the C719 Test Method for Adhesion and Cohesion of Elasto-

following uses for architectural joint systems: meric Joint Sealants Under Cyclic Movement (Hockman

1.1.1 To verify movement capability information supplied Cycle)

to the user by the producer, C794 TestMethodforAdhesion-in-PeelofElastomericJoint

1.1.2 To standardize comparison of movement capability by Sealants

relating it to specified nominal joint widths, C962 Standards Guide for Use of Elastomeric Joint Sealants

1.1.3 To determine the cyclic movement capability between (Withdrawn 1992)

specified minimum and maximum joint widths without visual D1079 Terminology Relating to Roofing and Waterproofing

deleterious effects, and E577 Guide for Dimensional Coordination of Rectilinear

1.1.4 To provide the user with graphic information, draw- Building Parts and Systems (Withdrawn 2011)

ings or pictures in the test report, depicting them at minimum, E631 Terminology of Building Constructions

maximum, and nominal joint widths during cycling. IEEE/ASTM SI 10 Standard for Use of the International

System of Units (SI): The Modern Metric System

1.2 This test method is intended to be used only as part of a

specification or acceptance criterion due to the limited move-

3. Terminology

ments tested.

3.1 Defintions—Terms defined in Terminology E631 will

1.3 The values stated in either SI units or inch-pound units

prevail for terms not defined in this test method.

are to be regarded separately as standard. The values stated in

3.2 Definitions of Terms Specific to This Standard:

each system may not be exact equivalents; therefore, each

3.2.1 architectural joint system—any filler or cover, except

system shall be used independently of the other. Combining

poured or formed in place sealants, used to span, cover, fill, or

values from the two systems may result in non-conformance

seal a joint.

with the standard.

3.2.1.1 Discussion—Joint is defined in Guide E577.

1.4 This standard does not purport to address all of the

3.2.2 compression seal—an elastomeric extrusion, having

safety concerns, if any, associated with its use. It is the

an internal baffle system produced continuously and longitu-

responsibility of the user of this standard to establish appro-

dinally throughout the material having side walls without

priate safety and health practices and determine the applica-

horizontal edge flaps.

bility of regulatory limitations prior to use.

1 2

This test method is under the jurisdiction of ASTM Committee E06 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Performance of Buildings and is the direct responsibility of Subcommittee E06.21 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

on Serviceability. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2013. Published September 2013. Originally the ASTM website.

approved in 1991. Last previous edition approved in 2009 as E1399 – 97 (2009). The last approved version of this historical standard is referenced on

DOI: 10.1520/E1399_E1399M-97R13E01. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1399/E1399M − 97 (2013)

3.2.3 cyclic movement—the periodic change between the 4.1.6.2 Used as a part of the joint system, and

widestandnarrowestjointwidthsinanautomaticallymechani-

4.1.7 Elastomeric membrane systems:

cally controlled system.

4.1.7.1 With nosing material(s), and

4.1.7.2 Without nosing material(s).

3.2.4 elastomeric membrane systems—an elastomeric extru-

sion being either a baffled, single, or multi-layered system

4.2 This test method will assist users, producers, building

incorporating horizontal edge flaps normally used with a

officials, code authorities, and others in verifying some perfor-

nosing material.

mance characteristics of representative specimens of architec-

3.2.5 fire barriers—any material or material combination,

tural joint systems under common test conditions. The follow-

when fire tested after cycling, designated to resist the passage

ing performance characteristics are verifiable:

of flame and hot gases through a movement joint.

4.2.1 The maximum joint width,

3.2.6 maximum joint width—the widest linear gap an archi- 4.2.2 The minimum joint width, and

tectural joint system tolerates and performs its designed

4.2.3 The movement capability.

function without damaging its functional capabilities.

4.3 This test compares similar architectural joint systems by

3.2.7 metallic systems—one or more metal components

cyclingbutdoesnotaccuratelyreflectthesystem’sapplication.

integrated to perform the specific function of sealing or

Similar refers to the same type of architectural system within

bridging a joint, or both.

the same subsection under 4.1.

3.2.8 minimum joint width—the narrowest linear gap an

4.4 This test method does not provide information on:

architectural joint system tolerates and performs its designed

4.4.1 Durability of the architectural joint system under

function without damaging its functional capabilities.

actual service conditions, including the effects of cycled

3.2.9 movement capability—the value obtained from the

temperature on the joint system,

difference between the widest and narrowest widths of a joint

4.4.2 Loading capability of the system and the effects of a

opening typically expressed in numerical values (mm or in.) or

load on the functional parameters established by this test

a percentage of the nominal value of the joint width.

method,

3.2.9.1 Discussion—Nominal value is defined in IEEE/

4.4.3 Rotational, vertical, and horizontal shear capabilities

ASTM SI 10.

of the specimen,

3.2.10 preformed foam and sponges—a porous elastomeric

4.4.4 Any other attributes of the specimen, such as fire

open or closed cell material capable of being compressed and

resistance, wear resistance, chemical resistance, air infiltration,

recovering once the compressive force is removed.

watertightness, and so forth, and

3.2.11 preformed sealant system—a device composed of a 4.4.5 Testing or compatibility of substrates.

previously shaped or molded mixture of polymers, fillers, and

4.5 This test method is only to be used as one element in the

pigments used to fill and seal joints where moderate movement

selection of an architectural joint system for a particular

is expected; unlike caulking, it cures to a resilient solid (see

application. It is not intended as an independent pass/fail

Appendix X1).

acceptance procedure. In conjunction with this test method,

3.2.11.1 Discussion—Sealant is defined in Terminology

other test methods are to be used to evaluate the importance of

D1079.

other service conditions such as durability, structural loading,

3.2.12 strip seal—a single or multi-layered elastomeric

and compatibility.

extrusion, not having an internal baffle system produced

continuously and longitudinally throughout the material, used

5. Apparatus

in conjunction with a compatible frame(s).

5.1 Testing Machine, capable of attaining specified maxi-

mum and minimum joint widths.

4. Significance and Use

5.2 Measuring Device, capable of an accuracy of 0.25 6

4.1 Types of architectural joint systems included in this test

0.013 mm [0.010 6 0.005 in.].

method are the following:

4.1.1 Metallic systems;

5.3 Cyclic Device, capable of continual repetitious move-

4.1.2 Compression seals:

ment between two specified dimensions, equipped with an

4.1.2.1 With frames, and

automatic counter which records movement of the joint during

4.1.2.2 Without frames,

the test.

4.1.3 Strip seals;

5.4 Mounting Plates, or other apparatus suitable to install

4.1.4 Preformed sealant systems (see Appendix X1):

the specimen and undergo the test procedures.

4.1.4.1 With frames, and

4.1.4.2 Without frames,

6. Safety Hazards

4.1.5 Preformed foams and sponges:

4.1.5.1 Self-Expanding, and

6.1 Warning—Take proper precautions to protect the ob-

4.1.5.2 Nonexpanding, serversintheeventofanyfailure.Ifextremepressuresdevelop

4.1.6 Fire barriers:

during this test, considerable energy and hazard are involved.

4.1.6.1 Used as joint systems, and Incasesoffailure,thehazardtopersonnelislessifaprotective

´1

E1399/E1399M − 97 (2013)

shield is used and protective eye wear worn. Do not permit 9.1.5 Specimen failure is indicated by the inability to meet

personnel between the shield and equipment during the test the minimum or maximum joint width criteria that is specified

procedure. in 7.4 or the appearance of a condition that in the judgement of

the laboratory will affect the performance of the test specimen

(see Appendix X2.2).

7. Sampling

9.1.6 Record the specified dimension in 9.1 being verified

7.1 A lot of material consists of the quantity for each cross

and all data to the nearest 0.10 mm [0.004 in.] at which the test

section agreed upon by the user and the producer. Sample each

was terminated.

lot.

9.1.7 Describefailedspecimensindetailusingphotographs,

7.2 Obtain samples by one of the following methods:

if necessary, to clarify the descriptions.

7.2.1 Samples provided by the producer, or

9.1.8 Note failed specimen measurements with an asterisk.

7.2.2 Samples taken at random from each shipment.

9.2 Verifying Cyclic Movement:

7.3 A sample constitutes a minimum length as required to

9.2.1 Standard machine speeds are 1 r/m, 10 r/m, and 30

perform the tests, but not less than 914.4 mm [36.00 in.].

r/min.

9.2.2 The maximum time duration of the specimen at rest

7.4 Producer specifies the following in mm [in.]:

during cyclic movement is 4 s.

7.4.1 Nominal joint width,

9.2.3 Follow procedures in 9.1.1 and 9.1.2.

7.4.2 Minimum joint width,

9.2.4 According to the producer’s instructions, while main-

7.4.3 Maximum joint width, and

taining parallelism and the nominal joint width, secure the

7.4.4 Movement capability.

specimen in the cyclic device.

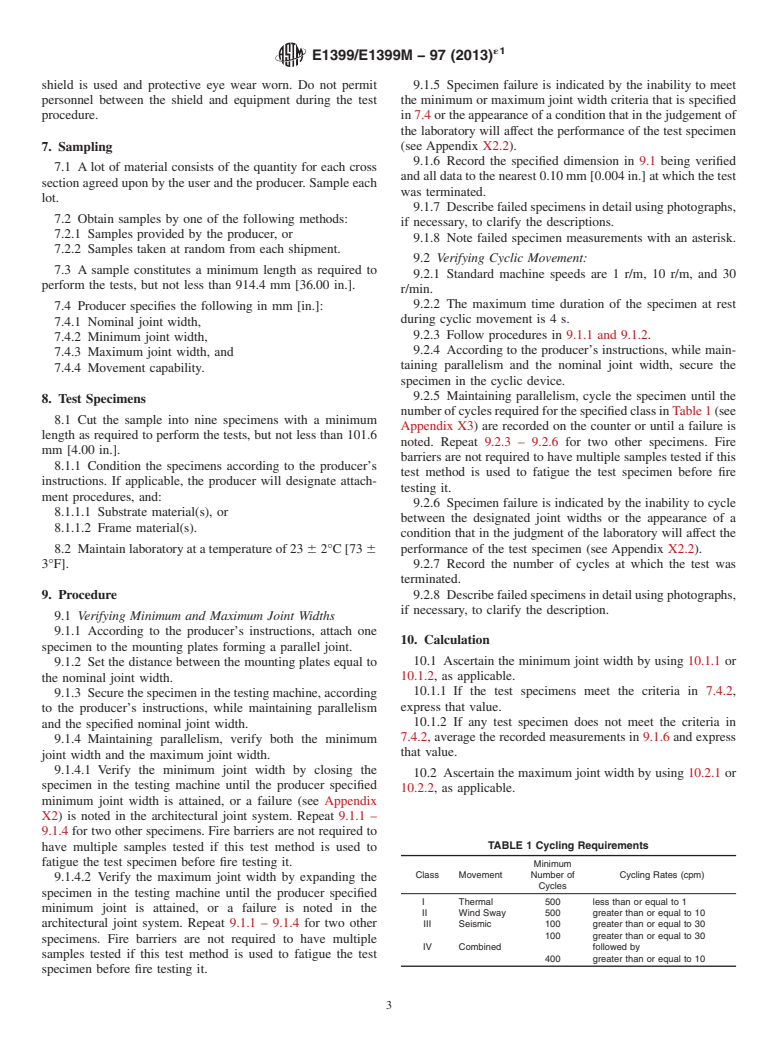

9.2.5 Maintaining parallelism, cycle the specimen until the

8. Test Specimens

numberofcyclesrequiredforthespecifiedclassinTable1(see

8.1 Cut the sample into nine specimens with a minimum

Appendix X3) are recorded on the counter or until a failure is

length as required to perform the tests, but not less than 101.6

noted. Repeat 9.2.3 – 9.2.6 for two other specimens. Fire

mm [4.00 in.].

barriers are not required to have multiple samples tested if this

8.1.1 Condition the specimens according to the producer’s

test method is used to fatigue the test specimen before fire

instructions. If applicable, the producer will designate attach-

testing it.

ment procedures, and:

9.2.6 Specimen failure is indicated by the inability to cycle

8.1.1.1 Substrate material(s), or

between the designated joint widths or the appearance of a

8.1.1.2 Frame material(s).

condition that in the judgment of the laboratory will affect the

8.2 Maintain laboratory at a temperature of 23 6 2°C [73 6

performance of the test specimen (see Appendix X2.2).

3°F]. 9.2.7 Record the number of cycles at which the test was

terminated.

9. Procedure 9.2.8 Describefailedspecimensindetailusingphotographs,

if necessary, to clarify the description.

9.1 Verifying Minimum and Maximum Joint Widths

9.1.1 According to the producer’s instructions, attach one

10. Calculation

specimen to the mounting plates forming a parallel joint.

10.1 Ascertain the minimum joint width by using 10.1.1 or

9.1.2 Set the distance between the mounting plates equal to

10.1.2, as applicable.

the nominal joint width.

10.1.1 If the test specimens meet the criteria in 7.4.2,

9.1.3 Secure the specimen in the testing machine, according

express that value.

to the producer’s instructions, while maintaining parallelism

10.1.2 If any test specimen does not meet the criteria in

and the specified nominal joint width.

7.4.2, average the recorded measurements in 9.1.6 and express

9.1.4 Maintaining parallelism, verify both the minimum

that value.

joint width and the maximum joint width.

9.1.4.1 Verify the minimum joint width by closing the

10.2 Ascertain the maximum joint width by using 10.2.1 or

specimen in the testing machine until the producer specified

10.2.2, as applicable.

minimum joint width is attained, or a failure (see Appendix

X2) is noted in the architectural joint system. Repeat 9.1.1 –

9.1.4 for two other specimens. Fire barriers are not required to

TABLE 1 Cycling Requirements

have multiple samples tested if this test method is used to

fatigue the test specimen before fire testing it. Minimum

Class Movement Number of Cycling Rates (cpm)

9.1.4.2 Verify the maximum joint width by expanding the

Cycles

specimen in the testing machine until the producer specified

I Thermal 500 less than or equal to 1

minimum joint is attained, or a failure is noted in the

II Wind Sway 500 greater than or equal to 10

architectural joint system. Repeat 9.1.1 – 9.1.4 for two other III Seismic 100 greater than or equal to 30

100 greater than or equal to 30

specimens. Fire barriers are not required to have multiple

IV Combined followed by

samples tested if this test method is used to fatigue the test

400 greater than or equal to 10

specimen before fire testing it.

´1

E1399/E1399M − 97 (2013)

10.2.1 If the test specimens meet the criteria in 7.4.3, 50.8 mm,212.7 mm, 38.1 mm

@2.00 in.,20.50 in., 1.50 in.#

express that value.

10.2.2 If any test specimen does not meet the criteria in

10.7 Calculate the contraction and expansion percentages.

7.4.3, average the recorded measurements in 9.2.6 and express

10.7.1 The contraction percentage formula is as follows:

that value.

C/W 3100% 5 C

~ !

nom p

10.3 Ascertain the movement capability by using 10.3.1 or

where C = contraction percentage related to nominal joint

p

10.3.2, as applicable.

width.

10.3.1 If the test specimens meet the criteria in 7.4.4,

10.7.2 The expansion percentage formula is as follows:

express that value.

E/W 3100% 5 E

10.3.2 If any test specimen does not meet the criteria in ~ !

nom p

7.4.4, calculate th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.