ASTM D6986-03

(Test Method)Standard Test Method for Free Water, Particulate and Other Contamination in Aviation Fuels (Visual Inspection Procedures)

Standard Test Method for Free Water, Particulate and Other Contamination in Aviation Fuels (Visual Inspection Procedures)

SIGNIFICANCE AND USE

The two procedures in the test method provide rapid methods for field detection of free water and solid contaminants, or any other visually apparent contamination. Uncertain or marginal results by either of these methods would normally result in the performance of methods such as D 2276, D 5452, or D 3240 for quantitative determination of contaminants.

5.1.1 Particulate determination in appearance tests is sensitive to sampling procedures. The presence of a small number of particles may indicate, for example, that the sample line was not flushed to provide a representative sample. The persistent presence of even a small number of particles, however, may be cause for further investigation depending on the situation.

Experience has shown that an experienced tester using a clear bottle can detect as little as 40 ppm of free, suspended water in the fuel. Thus, a fuel rated as clear and bright can still fail lower limits set by quantitative methods. A rater will also have difficulty resolving particles smaller than 40 μm. Smaller particles must be determined by other than visual methods such as D 2276, D 5452 or chemical field tests listed in Manual 5.5

Experience has shown the visual appearance of fuel in a white porcelain bucket to be the most suitable method for the detection of dye contamination or other unusual discoloration. In the U. S., the white porcelain bucket is used to detect the dye.

SCOPE

1.1 This test method covers two procedures for establishing the presence of suspended free water, solid particulate, and other contaminants in aviation gasoline and aviation turbine fuels.

1.1.1 Both procedures are intended primarily for use as field tests with the fuel at handling temperature.

1.1.2 Procedure A uses transparent sample containers; Procedure B uses opaque containers.

1.2 Both procedures are rapid methods for contamination detection and include ratings of haze appearance and particulate presence.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D6986–03

Standard Test Method for

Free Water, Particulate and Other Contamination in Aviation

Fuels (Visual Inspection Procedures)

This standard is issued under the fixed designation D6986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Fuel quality is paramount in aviation fuels because of their critical application. Many successive

types of inspections are conducted to ensure quality protection. Rapid, visual inspections carried out

at various locations in the fuel supply system are a critical part of the inspection program. Experience

hasshownthatsubjectiveevaluationssuchasdescribedbythistestmethodformaneffectivefieldalert

system that is backed by other, more quantitative tests.

The present test method duplicates much of Test Method D4176, a test method applicable to all

distillate fuels. However, the present test method also includes field methods applicable especially to

aviation fuels, and is therefore published as a separate test method.

1. Scope D4176 Test Method for Free Water and Particulate Con-

tamination in Distillate Fuels (Visual Inspection Proce-

1.1 This test method covers two procedures for establishing

dures)

the presence of suspended free water, solid particulate, and

2.2 ASTM Adjuncts:

other contaminants in aviation gasoline and aviation turbine

ADJD417601 Distillate Fuel Bar Chart

fuels.

ADJD417602 Distillate Fuel Haze Rating Standard

1.1.1 Both procedures are intended primarily for use as field

tests with the fuel at handling temperature.

3. Terminology

1.1.2 Procedure A uses transparent sample containers; Pro-

3.1 Definitions of Terms Specific to This Standard:

cedure B uses opaque containers.

3.1.1 aviation fuels—as used in this standard, the term

1.2 Both procedures are rapid methods for contamination

includes both aviation gasoline and aviation turbine fuels.

detection and include ratings of haze appearance and particu-

3.1.2 clear and bright—a condition in which the fuel

late presence.

contains no visible water drops or particulates and is free of

1.3 The values stated in SI units are to be regarded as the

haze or cloudiness.

standard. The values given in parentheses are for information

3.1.3 free water—water in excess to that soluble in the fuel

only.

at the temperature of the test and may appear in the fuel as a

2. Referenced Documents haze, cloudiness, droplets, or water layer.

3.1.4 solid particulates—small solid or semi-solid particles,

2.1 ASTM Standards:

sometimes referred to as silt or sediment, present in a fuel as

D2276 Test Method for Particulate Contaminant inAviation

the result of contamination by airborne dusts, corrosion by-

Fuel by Line Sampling

products, or wear products.

D3240 Test Method for Undissolved Water In Aviation

Turbine Fuels

4. Summary of Test Method

D4057 Practice for Manual Sampling of Petroleum and

4.1 The test method describes two types of sampling con-

Petroleum Products

tainers for evaluating the appearance of aviation fuel samples.

Procedure A covers transparent sample containers, including

This test method is under the jurisdiction of ASTM Committee D02 on

the open jar and the closed circuit sampler, while Procedure B

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

uses opaque containers such as the white bucket.

D02.J0 on Aviation Fuels.

Current edition approved Dec. 1, 2003. Published January 2004. DOI: 10.1520/

D6986-03.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from ASTM International Headquarters. Order Adjunct No.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM ADJD417601.

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD417602.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6986–03

4.2 Intheopenjarprocedure,aminimumof750mL(24oz) 6. Apparatus

of fuel is placed into a clear one litre (1 qt) container and

6.1 Cylindrical Clear Container, such as:

examined visually. The jar is then closed and the sample is

6.1.1 Clear Container, with lid, capable of holding 750 mL

swirled and examined for visual sediment and water at the

(nominal 1 U.S. qt) of fuel and having a diameter of 100 6 10

bottom of the vortex.Additionally, fuel clarity may be rated by

mm (4 6 0.4 in.). There should be no gasket in the lid.

placing a standard bar chart behind the sample and comparing

6.1.2 Closed Circuit Sampler,holdingabout4L(1galU.S.)

its visual appearance with the standard haze rating photo-

of fuel and being permanently mounted to receive fuel from a

graphs. The presence or absence of free water and of particu-

fuel line or a storage tank and having inlet and outlet valves to

lates is reported.

control filling and emptying of the container. The sampler base

4.3 In the closed circuit sampler procedure, approximately

is normally conical and incorporates the fuel inlet and outlet.

3500 mL (0.9 U.S. gal) of fuel is placed into the sampler and

The fill port is designed to cause the fuel to swirl around the

is examined for clarity and for visual sediment or water

sides of the clear glass tube. The circuit sampler may also

droplets on the bottom of the sampler.Additionally, fuel clarity

contain hydrometer and chemical water detection ports.

may be rated by placing a standard bar chart behind the sample

6.2 Appearance Card and Photographs:

and comparing its visual appearance with the standard haze

6.2.1 Paper Card (Bar Chart), laminated in clear plastic

rating photographs. The presence or absence of free water and

having five parallel lines of different widths (see ASTM

of particulates is reported.

adjunct ADJD417601).

4.4 In the white bucket procedure fuel to a depth of

6.2.2 Appearance Photographs, a series of standard photo-

approximately 15 cm (6 in.) is collected in a white porcelain

graphs of the bar chart through a series of samples of different

coated or stainless steel bucket. The sample is examined for

haze levels, numbered from one through six. Photograph No. 1

solids or sediment, or both, on the bottom of the bucket.

is the clearest, while No. 6 represents the densest haze (see

Sample clarity can be checked by the appearance of a small,

ASTM adjunct ADJD417602). A fuel sample rated clear and

shiny coin on the bucket’s bottom. If the fuel is dry, the raised

bright will have a rating of “one.”

letters on the coin should be easily readable. The amount of

6.2.2.1 The differences between these haze levels are arbi-

sediment can be described by a letter category using a rating

trary and are not intended to represent equivalent increases in

guide.

suspended water content or particulates. It is essential, there-

4.5 In both procedures, the sample is inspected for color or

fore, that only the proper approved bar charts and photographs

other unusual appearance.

be used.

4.6 Field inspection procedures are performed immediately

6.3 Opaque Sample Containers:

after sampling at fuel handling temperature conditions.

6.3.1 White Bucket, a circular bucket with straight but

non-parallel sides and a flat bottom and a minimum capacity of

5. Significance and Use

7.5 L (2.0 U.S. gal) and approximately 20 cm (8 in.) high,

5.1 The two procedures in the test method provide rapid

either coated with white porcelain enamel or made of stainless

methods for field detection of free water and solid contami-

steel. Porcelain coatings must be free of dark spots, chips, or

nants, or any other visually apparent contamination. Uncertain

other surface damage, most particularly on the bottom of the

or marginal results by either of these methods would normally

bucket. Stainless steel buckets shall be made of a rust-resistant

resultintheperformanceofmethodssuchasD2276,D5452,or

steel and have a polished internal surface. The white porcelain

D3240 for quantitative determination of contaminants.

bucket should be used for the optimum detection of unusual

5.1.1 Particulate determination in appearance tests is sensi-

coloration.

tivetosamplingprocedures.Thepresenceofasmallnumberof

NOTE 1—A quantitative description of acceptable white color is in

particles may indicate, for example, that the sample line was

preparation.

not flushed to provide a representative sample. The persistent

NOTE 2—Buckets made of white, hard plastic have been found to stain

presence of even a small number of particles, however, may be

a yellow color over time, which can make it difficult to observe a haze or

cause for further investigation depending on the situation.

color changes. The use of plastic containers is also discouraged unless

5.2 Experience has shown that an experienced tester using a

provision is made for bonding such containers to the filling line.

clear bottle can detect as little as 40 ppm of free, suspended

6.4 Color and Particle Assessment Rating Guide:

water in the fuel.Thus, a fuel rated as clear and bright can still

6.4.1 This guide contains both a series of photographs of

fail lower limits set by quantitative methods. A rater will also

particulates of differing concentrations, each having a different

have difficulty resolving particles smaller than 40 µm. Smaller

letter rating, and a series of color photographs for rating filter

particlesmustbedeterminedbyotherthanvisualmethodssuch

5 membranes obtained by Test Methods D2276. For this test

as D2276, D5452 or chemical field tests listed in Manual 5.

method, only the particle rating scale is used. The particle

5.3 Experience has shown the visual appearance of fuel in a

rating scale does not bear a direct relationship to the mass of

white porcelain bucket to be the most suitable method for the

particulates but is simply a way of communicating the amount

detection of dye contamination or other unusual discoloration.

of visible particulates in the sample.

In the U. S., the white porcelain bucket is used to detect the

dye.

5 6

Manual 5, Aviation Fuel Quality Control Procedures, 2nd Ed.,ASTM Interna- The “Color and Particle Assessment Rating Guide,” SGTP-3940, is available

tional, W. Conshohocken, PA, 1995. from Gammon Technical Products, Manasquan, NJ.

D6986–03

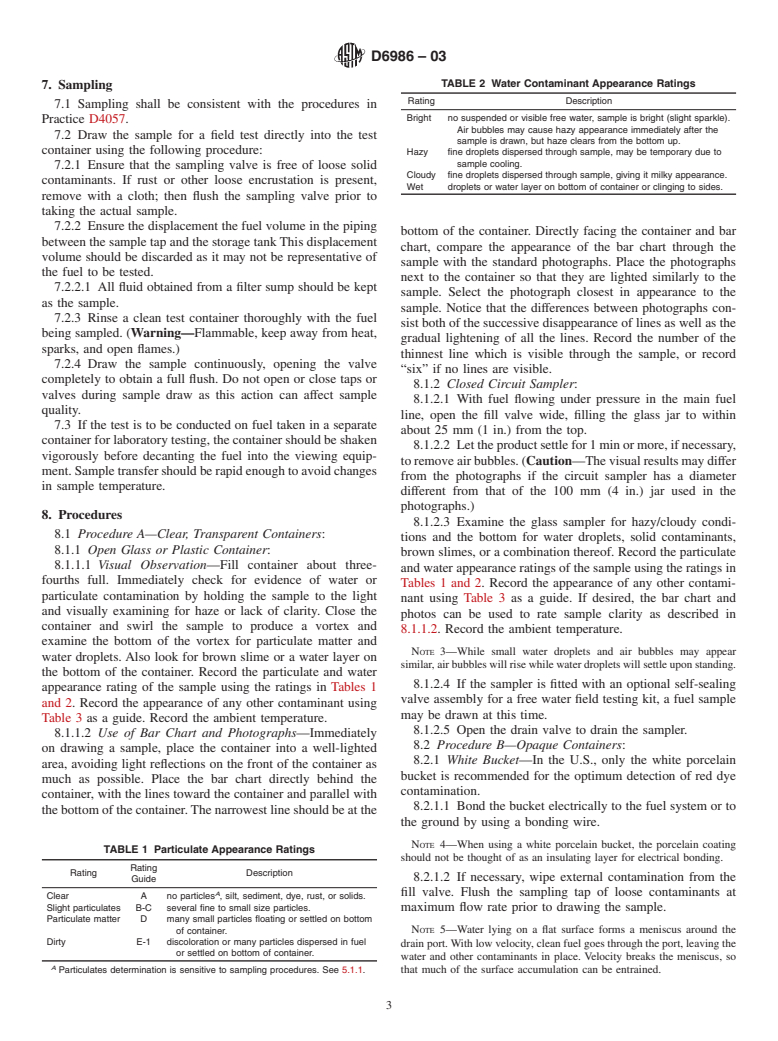

TABLE 2 Water Contaminant Appearance Ratings

7. Sampling

Rating Description

7.1 Sampling shall be consistent with the procedures in

Bright no suspended or visible free water, sample is bright (slight sparkle).

Practice D4057.

Air bubbles may cause hazy appearance immediately after the

7.2 Draw the sample for a field test directly into the test

sample is drawn, but haze clears from the bottom up.

container using the following procedure:

Hazy fine droplets dispersed through sample, may be temporary due to

sample cooling.

7.2.1 Ensure that the sampling valve is free of loose solid

Cloudy fine droplets dispersed through sample, giving it milky appearance.

contaminants. If rust or other loose encrustation is present,

Wet droplets or water layer on bottom of container or clinging to sides.

remove with a cloth; then flush the sampling valve prior to

taking the actual sample.

7.2.2 Ensure the displacement the fuel volume in the piping

bottom of the container. Directly facing the container and bar

between the sample tap and the storage tank This displacement

chart, compare the appearance of the bar chart through the

volume should be discarded as it may not be representative of

sample with the standard photographs. Place the photographs

the fuel to be tested.

next to the container so that they are lighted similarly to the

7.2.2.1 All fluid obtained from a filter sump should be kept

sample. Select the photograph closest in appearance to the

as the sample.

sample. Notice that the differences between photographs con-

7.2.3 Rinse a clean test container thoroughly with the fuel

sist both of the successive disappearance of lines as well as the

being sampled. (Warning—Flammable, keep away from heat,

gradual lightening of all the lines. Record the number of the

sparks, and open flames.)

thinnest line which is visible through the sample, or record

7.2.4 Draw the sample continuously, opening the valve

“six” if no lines are visible.

completely to obtain a full flush. Do not open or close taps or

8.1.2 Closed Circuit Sampler:

valves during sample draw as this action can affect sample

8.1.2.1 With fuel flowing under pressure in the main fuel

quality.

line, open the fill valve wide, filling the glass jar to within

7.3 If the test is to be conducted on fuel taken in a separate

about 25 mm (1 in.) from the top.

container for laboratory testing, the container should be shaken

8.1.2.2 Lettheproductsettlefor1minormore,ifnecessary,

vigorously before decanting the fuel into the viewing equip-

toremoveairbubbles.(Caution—Thevisualresultsmaydiffer

ment.Sampletransfershouldberapidenoughtoavoidchanges

from the photographs if the circuit sampler has a diameter

in sample temperature.

different from that of the 100 mm (4 in.) jar used in the

photographs.)

8. Procedures

8.1.2.3 Examine the glass sampler for hazy/cloudy condi-

8.1 Procedure A—Clear, Transparent Containers:

tions and the bottom for water droplets, solid contaminants,

8.1.1 Open Glass or Plastic Container:

brown slimes, or a combination thereof. Record the particulate

8.1.1.1 Visual Observation—Fill container about three-

and water appearance ratings of the sample using the ratings in

fourths full. Immediately check for evidence of water or

Tables 1 and 2. Record the appearance of any other contami-

particulate contamination by holding the sample to the light

nant using Table 3 as a guide. If desired, the bar chart and

and visually examining for haze or lack of clarity. Close the

photos can be used to rate sample clarity as described in

container and swirl the sample to produce a vortex and

8.1.1.2. Record the ambient temperature.

examine the bottom of the vortex for particulate matter and

NOTE 3—While small water droplets and air bubbles may appear

water droplets. Also look for brown slime or a water layer on

similar,airbubbleswillrisewhilewaterdropletswillsettleuponstanding.

the bottom of the container. Record the particulate and water

8.1.2.4 If the sampler is fitted with an optional self-sealing

appearance rating of the sample using the ratings in Tables 1

valve assembly for a free water field testing kit, a fuel sample

and 2. Record the appearance of any other contaminant using

may be drawn at this time.

Table 3 as a guide.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.