ASTM C688-00

(Specification)Standard Specification for Functional Additions for Use in Hydraulic Cements

Standard Specification for Functional Additions for Use in Hydraulic Cements

SCOPE

1.1 This specification covers methods to investigate the effectiveness of a material to beneficially change the properties of hydraulic cements when the material is interground with the clinker during manufacture of the cement.

1.2 The values stated in SI units are to be regarded as the standard.

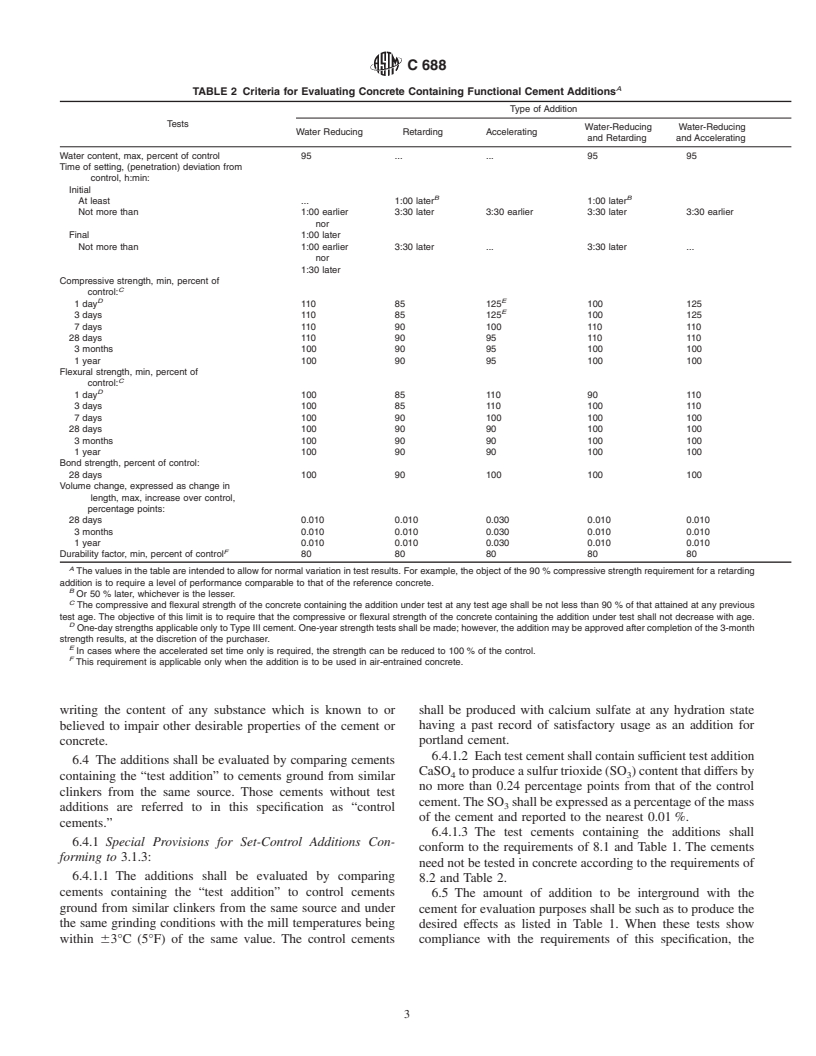

1.3 The effect of additions in cement may markedly change properties other than those they are intended to modify. This specification is designed to test for such changes. Table 1 sets forth values for those properties of cement pastes and mortars that would permit a judgment of the changes effected by an addition. Likewise, Table 2 sets forth similar criteria for concrete. Certain additions may be found effective for more than one purpose as indicated in 3.1.4 and 3.1.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 688 – 00

Standard Specification for

Functional Additions for Use in Hydraulic Cements

This standard is issued under the fixed designation C 688; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 219 Terminology Relating to Hydraulic Cement

C 226 Specification forAir-EntrainingAdditions for Use in

1.1 This specification covers methods to investigate the

the Manufacture of Air-Entraining Portland Cement

effectiveness of a material to beneficially change the properties

C 232 Test Method for Bleeding of Concrete

of hydraulic cements when the material is interground with the

C 234 Test Method for Comparing Concretes on the Basis

clinker during manufacture of the cement.

of the Bond Developed with Reinforcing Steel

1.2 The values stated in SI units are to be regarded as the

C 266 Test Method forTime of Setting of HydraulicCement

standard.

Paste by Gillmore Needles

1.3 The effect of additions in cement may markedly change

C 403 Test Method for Time of Setting of Concrete Mix-

properties other than those they are intended to modify. This

tures by Penetration Resistance

specification is designed to test for such changes. Table 1 sets

C 451 Test Method for Early Stiffening of Portland Cement

forth values for those properties of cement pastes and mortars

(Paste Method)

that would permit a judgment of the changes effected by an

C 465 Specification for ProcessingAdditions for Use in the

addition. Likewise, Table 2 sets forth similar criteria for

Manufacture of Hydraulic Cements

concrete. Certain additions may be found effective for more

C 595M Specification for Blended Hydraulic Cements

than one purpose as indicated in 3.1.4 and 3.1.5.

C 596 Test Method for Drying Shrinkage of Mortar Con-

2. Referenced Documents

taining Portland Cement

C 666 Test Method for Resistance of Concrete to Rapid

2.1 ASTM Standards:

Freezing and Thawing

C 39 Test Method for Compressive Strength of Cylindrical

C 845 Specification for Expansive Hydraulic Cement

Concrete Specimens

C 1157M Performance Specification for Blended Hydraulic

C 78 Test Method for Flexural Strength of Concrete (Using

Cement

Simple Beam with Third-Point Loading)

C 109/C 109M Test Method for Compressive Strength of

3. Terminology

Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube

3.1 Definitions:

Specimens)

3.1.1 accelerating addition—a functional addition that ac-

C 143 Test Method for Slump of Hydraulic Cement Con-

celerates the setting or early strength, or both, of concrete and

crete

3 mortar.

C 150 Specification for Portland Cement

3.1.2 retarding addition—a functional addition that retards

C 151 Test Method for Autoclave Expansion of Portland

3 the setting of concrete and mortar.

Cement

3.1.3 set-control addition—a functional addition composed

C 157 Test Method for Length Change of Hardened Hy-

2 essentially of calcium sulfate in any hydration state from

draulic Cement Mortar and Concrete

CaSO to CaSO ·2H O.

4 4 2

C 187 Test Method for Normal Consistency of Hydraulic

3.1.4 water-reducing addition—a functional addition used

Cement

to reduce the quantity of mixing water required to produce

C 191 Test Method for Time of Setting of Hydraulic Ce-

concrete and mortar of a given consistency.

ment by Vicat Needle

3.1.5 water-reducing and accelerating addition—a func-

tional addition that reduces the quantity of mixing water

This specification is under the jurisdiction of ASTM Committee C01 on

required to produce concrete of a given consistency and that

Cement and is the direct responsibility of Subcommittee C01.20 on Additions.

accelerates the setting or early strength development, or both,

Current edition approved June 10, 2000. Published September 2000. Originally

of concrete and mortar.

published as C 688 – 71 T. Last previous edition C 688 – 96.

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 04.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 688

TABLE 1 Criteria for Evaluating Neat Cement and Mortar Containing Functional Cement Additions

Type of Addition

Tests

Water-Reducing Water-Reducing and

Water Reducing Retarding Accelerating Set-Control

and Retarding Accelerating

Normal consistency, deviation from control, −1.0 min +1.0 max +1.0 max −1.0 min −1.0 mm 61.0 max

A

percentage points

Standard consistency (flow) deviation from −4.0 min +2.0 max +2.0 max −4.0 min −4.0 min 62.0 max

A

control, percentage points

Setting time, (Gillmore) deviation from control,

h:min

Initial

B B

At least . 1:00 later 1:00 later .

Not more than 1:00 earlier 3:30 later 1:30 earlier 3:30 later 1:30 earlier 1:00 earlier

nor nor nor nor

1:30 later 1:30 later 1:30 later 1:30 later

C

Setting time, Vicat Initial

B

At least . 0:50 later . . .

B

Not more than 0:50 earlier 2:50 later 1:15 earlier 0:50 later 1:15 earlier 0:50 earlier

nor nor nor nor

1:15 later 1:15 later 2:50 later 1:15 later 1:15 later

Final

Not more than 1:00 earlier 3:30 later 1:00 earlier 3:30 later 1:00 earlier 1:00 earlier

nor nor nor nor

1:30 later 1:30 later 1:30 later 1:30 later

D

Compressive strength, min, percent of control:

E F

1 day in moist air 110 90 125 90 125

E

1 day in moist air, 2 days in water 110 90 125 100 125

1 day in moist air, 6 days in water 110 90 100 110 110

1 day in moist air, 27 days in water 110 95 95 110 110

Autoclave Expansion

max increase in % change in length compared 0.10 0.10 0.10 0.10 0.10 0.10

to control

Drying Shrinkage of Mortar

max % change in length compared to control 0.020 0.020 0.030 0.020 0.020 0.020

A

The minus sign indicates that the percentage of water required shall be less than that of the control cement by at least the indicated percentage points.

B

Or 50 % later, whichever is the lesser.

C

Either Vicat or the Gilmore time of setting method shall be used at the choice of the manufacturer.

D

The compressive strength of mortar containing the test cement shall be not less than 95 % of that attained at any previous test age. The objective of this limit is to

require that the strength of mortar containing the addition under test shall not decrease with age.

E

In cases where the accelerated set time only is required, the strength can be reduced to 100 % of the control.

F

The grand average of the 1, 3, 7, and 28-day strengths shall be not less than 95 % of the grand average for the corresponding control cement.

3.1.6 water-reducing and retarding addition—a functional tive and quantitative determination of the addition in the

addition that reduces the quantity of mixing water required to finishedcement,andshallbefullydescribedinthereportofthe

produce concrete and mortar of a given consistency and tests on the addition.”

simultaneously retards the setting of concrete and mortar.

5.2 Aggregates—The aggregates used in the evaluation of

the addition shall be in accordance with theAggregates portion

NOTE 1—This section is intended to provide a specification that may be

of the Materials section of Specification C 465, using propor-

applied to calcium sulfates as defined in Terminology C 219.

NOTE 2—It should be realized that some calcium sulfates, particularly tions specified in Concrete Mixtures section of that specifica-

some byproduct calcium sulfates, have produced cements with undesired

tion.

set behavior after storage.

6. General Requirements

4. Ordering Information

6.1 The cement, mortar, and concrete in which each of the

4.1 The purchaser shall specify the type of functional

additions is used shall conform to the respective requirements

addition desired.

prescribed inTable 1 andTable 2, except that if the test cement

fails to meet the requirements of Table 1, but possesses all the

5. Materials

requirements listed in Table 2, then the requirements of Table

5.1 Cements—The cements used in the evaluation of the

2 shall govern approval of the addition.

addition shall be as described in Section 4.1 of Specification

6.2 The trade name, source, and character of the material

C 465 with the following exceptions:

shall be specified and the means for the quantitative determi-

5.1.1 At least one of the Type I cements shall contain not

nation of the proposed addition in the finished cement, shall be

less than 9 percent tricalcium aluminate (C A).

furnished by the manufacturer or seller of the addition, and the

5.1.2 Disregard the last sentence of Section 4.1.5 of Speci-

results of such pertinent quantitative analysis shall form a part

fication C 465 and substitute the following:“ Each control

of the record of tests of the addition.

cement shall comply with all the requirements in the specifi-

cation (C 150, C 595, C 845, and C 1157M) applicable to that 6.3 At the request of the purchaser of an addition for a

type of cement. The method shall be adequate for the qualita- specific functional purpose, the manufacturer shall state in

C 688

A

TABLE 2 Criteria for Evaluating Concrete Containing Functional Cement Additions

Type of Addition

Tests

Water-Reducing Water-Reducing

Water Reducing Retarding Accelerating

and Retarding and Accelerating

Water content, max, percent of control 95 . . 95 95

Time of setting, (penetration) deviation from

control, h:min:

Initial

B B

At least . 1:00 later 1:00 later

Not more than 1:00 earlier 3:30 later 3:30 earlier 3:30 later 3:30 earlier

nor

Final 1:00 later

Not more than 1:00 earlier 3:30 later . 3:30 later .

nor

1:30 later

Compressive strength, min, percent of

C

control:

D E

1 day 110 85 125 100 125

E

3 days 110 85 125 100 125

7 days 110 90 100 110 110

28 days 110 90 95 110 110

3 months 100 90 95 100 100

1 year 100 90 95 100 100

Flexural strength, min, percent of

C

control:

D

1 day 100 85 110 90 110

3 days 100 85 110 100 110

7 days 100 90 100 100 100

28 days 100 90 90 100 100

3 months 100 90 90 100 100

1 year 100 90 90 100 100

Bond strength, percent of control:

28 days 100 90 100 100 100

Volume change, exp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.