ASTM F2798-09

(Specification)Standard Specification for Sealless Lube Oil Pump with Oil Through Motor for Marine Applications

Standard Specification for Sealless Lube Oil Pump with Oil Through Motor for Marine Applications

SCOPE

1.1 This specification defines the requirements applicable to design, construction and testing of sealless, rotary positive displacement pumps with oil-through motors for ship lubricating oil service. The complete pump and motor assembly is referred to as canned lube oil pump (CLP). This specification applies to CLPs pumping oil with a SAE rating of 20-50.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2798 −09 AnAmerican National Standard

Standard Specification for

Sealless Lube Oil Pump with Oil Through Motor for Marine

Applications

This standard is issued under the fixed designation F2798; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A564/A564M Specification for Hot-Rolled and Cold-

Finished Age-Hardening Stainless Steel Bars and Shapes

1.1 This specification defines the requirements applicable to

A574 Specification forAlloy Steel Socket-Head Cap Screws

design, construction and testing of sealless, rotary positive

A582/A582M Specification for Free-Machining Stainless

displacement pumps with oil-through motors for ship lubricat-

Steel Bars

ing oil service. The complete pump and motor assembly is

B23 Specification for White Metal Bearing Alloys (Known

referred to as canned lube oil pump (CLP). This specification

Commercially as “Babbitt Metal”)

applies to CLPs pumping oil with a SAE rating of 20-50.

B148 Specification for Aluminum-Bronze Sand Castings

1.2 This standard does not purport to address all of the

B152/B152M Specification for Copper Sheet, Strip, Plate,

safety concerns, if any, associated with its use. It is the

and Rolled Bar

responsibility of the user of this standard to establish appro-

B187M Specification for Copper Bar, Bus Bar, Rod and

priate safety and health practices and determine the applica- 3

Shapes [Metric] (Withdrawn 2002)

bility of regulatory limitations prior to use.

B271 Specification for Copper-BaseAlloy Centrifugal Cast-

ings

2. Referenced Documents

B505/B505M Specification for Copper Alloy Continuous

2.1 ASTM Standards:

Castings

A27/A27M Specification for Steel Castings, Carbon, for

B584 Specification for Copper Alloy Sand Castings for

General Application

General Applications

A159 Specification for Automotive Gray Iron Castings

D2000 Classification System for Rubber Products in Auto-

A193/A193M Specification for Alloy-Steel and Stainless

motive Applications

Steel Bolting for High Temperature or High Pressure

D3951 Practice for Commercial Packaging

Service and Other Special Purpose Applications

F912 Specification for Alloy Steel Socket Set Screws

A194/A194M Specification for Carbon andAlloy Steel Nuts

F1510 Specification for Rotary Positive Displacement

for Bolts for High Pressure or High Temperature Service,

Pumps, Ships Use

or Both

2.2 ASME/ANSI Standard:

A216/A216M SpecificationforSteelCastings,Carbon,Suit-

ASME/ANSI B16.5 Pipe Flanges and Flanged Fittings

able for Fusion Welding, for High-Temperature Service 5

2.3 Hydraulic Institute Standard:

A395/A395M Specification for Ferritic Ductile Iron

ANSI/HI 3.6 Rotary Pump Tests

Pressure-Retaining Castings for Use at ElevatedTempera- 6

2.4 AISI Standards:

tures

1018 Carbon Steel

A449 Specification for Hex Cap Screws, Bolts and Studs,

1045 Carbon Steel

Steel, Heat Treated, 120/105/90 ksi Minimum Tensile

1141 Carbon Steel

Strength, General Use

1144 Carbon Steel

A536 Specification for Ductile Iron Castings

4140 Chromium-molybdenum steel

A563 Specification for Carbon and Alloy Steel Nuts

The last approved version of this historical standard is referenced on

This specification is under the jurisdiction of ASTM Committee F25 on Ships www.astm.org.

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Available from American Society of Mechanical Engineers (ASME), ASME

Machinery and Piping Systems. International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

Current edition approved Oct. 1, 2009. Published November 2009. www.asme.org.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Hydraulic Institute, 6 Campus Drive, First Floor North,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Parsippany NJ 07054-4406

Standards volume information, refer to the standard’s Document Summary page on Available from American Iron and Steel Institute (AISI), 1140 Connecticut

the ASTM website. Ave., NW, Suite 705, Washington, DC 20036, http://www.steel.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2798−09

4150 Chromium-molybdenum steel 5.1.8 OilViscosity and temperature for minimum and maxi-

4340 Nickel-chromium-molybdenum steel mum operating conditions.

5.1.9 External motor cooling oil supply, if required. (See

2.5 AIA Standard:

9.4.)

NASM 17829

5.1.10 Mounting configuration (vertical, horizontal).

2.6 API Standard:

5.1.11 Relief valve cracking pressure. (See 9.1.)

API Standard 676 Positive Displacement Pumps—Rotary

5.1.12 Airborne noise level (if different than 7.4).

3. Terminology

5.1.13 Packaging and boxing requirements (immediate use,

domestic; storage, domestic; or overseas)

3.1 Definitions of Terms Specific to This Standard:

5.1.14 Quantity of pumps.

3.2 canned lube oil pump unit—a unit, which when as-

5.1.15 Quantity of drawings.

sembled as a pump and motor, is completely sealed from

5.1.16 Quantity of technical manuals.

leakage to the environment. Lubrication and cooling of motor

5.1.17 Quantity of test reports, if required. (See Section 10.)

bearings and primary cooling of motor windings and insulation

5.1.18 Certified test data, if required. (See 10.3.)

are achieved by circulating a portion of the fluid being pumped

5.1.19 IACS (International Association of Classification

(oil) through the motor.

Societies) classification with applicable notions, if required.

3.3 capacity—the quantity of fluid actually delivered per

5.1.20 Motor Characteristics:

unit of time at the rated speed, including both the liquid and

5.1.20.1 Voltage/phase/frequency

dissolvedorentrainedgases,understatedoperatingconditions.

5.1.20.2 Duty—Continuous

In the absence of any gas or vapor entering or forming within

5.1.20.3 Ambient Temperature—50°C

thepump,thecapacityisequaltothevolumedisplacedperunit

5.1.20.4 Enclosure—Totally enclosed, oil through.

of time, less slip, motor bearing lubrication and motor cooling

5.1.20.5 Insulation—Class F, (vacuum pressure impregna-

flows.

tion (VPI))

3.4 displacement—the volume of fluid displaced per revo-

5.1.20.6 Conduit box orientation. (See 7.6.)

lution of the rotor(s).

6. Material

3.5 rated condition point—the required capacity at speed,

pressure, viscosity and power as specified by the purchaser.

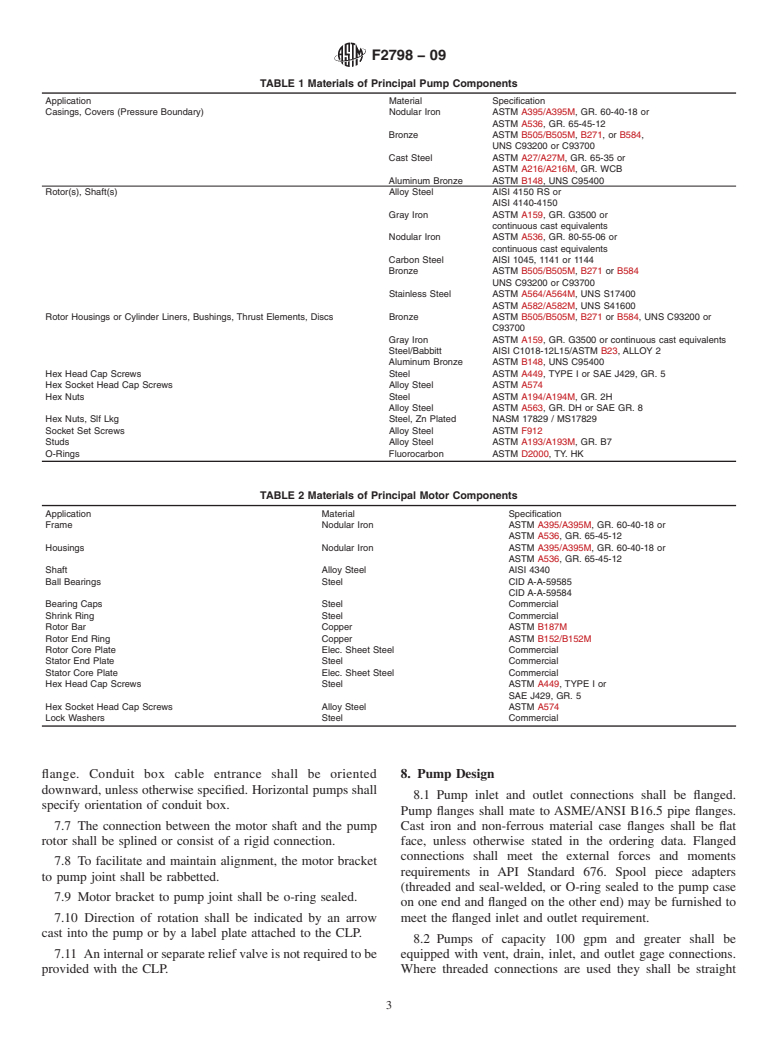

6.1 Materials of principal pump components shall be in

accordance with Table 1.

3.6 slip—the quantity of fluid that leaks through internal

6.1.1 Materials other than shown in Table 1 are considered

clearances of a pump per unit of time.

exceptions and are subject to approval by the purchaser before

4. Classification usage

4.1 Pumps will be classified as follows:

6.2 Materials of principal motor components shall be in

4.1.1 Type II—Screws with timing gears accordance with Table 2.

4.1.2 Type III—Screws without timing gears 6.2.1 Materials other than shown in Table 2 are considered

4.1.3 Type X—Vane (sliding) exceptions and are subject to approval by the purchaser before

4.1.4 Type XI—Sliding shoe usage.

4.2 Motor Types: Oil-through type that uses the oil to cool

7. General Requirements

the motor and lubricate the bearings.

7.1 CLPs shall be capable of sustained operation during

5. Ordering Information

inclinations up to 45º in any direction.

5.1 The ordering activity shall provide manufacturers with 7.2 CLPsshallbecapableofwithstandingexternalvibration

the following information:

in the frequency range of 4 to 25 Hz.

5.1.1 Title, name and date of specification

7.3 The internally excited vibration levels (displacement,

5.1.2 Type and size (see Section 4)

peak to peak) of the CLP shall not exceed the following:

5.1.3 Oil to be pumped (for example, 2190 TEP SAE 40)

RPM (SYN) Displacement, Peak to Peak,

5.1.4 Operating Conditions: Single speed, two-speed, or

Mils

variable speed. (See 9.1.) 3600 0.7

1800 1.4

5.1.5 Capacity in gallons per minute or litres per minute at

1200 1.8

rated discharge pressure at specified operating condition.

900 2.2

5.1.6 Discharge pressure in pound-force per square inch

600 2.6

gauge (psig) or kilopascal (kPa) gauge at specified operating

7.4 At normal operating conditions, the airborne noise level

condition.

of the pump shall not exceed 85 dBA.

5.1.7 Inlet pressure conditions (NPIPA)

7.5 CLPs shall be designed such that no damage will result

from reverse rotations of at least a one-minute duration with no

Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000 restriction in flow of oil to or from the CLP.

WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

7.6 Unless otherwise specified, vertical CLPs shall be as-

Available from American Petroleum Institute (API), 1220 L. St., NW,

Washington, DC 20005-4070, http://www.api.org. sembled with the conduit box mounted over the pump outlet

F2798−09

TABLE 1 Materials of Principal Pump Components

Application Material Specification

Casings, Covers (Pressure Boundary) Nodular Iron ASTM A395/A395M, GR. 60-40-18 or

ASTM A536, GR. 65-45-12

Bronze ASTM B505/B505M, B271,or B584,

UNS C93200 or C93700

Cast Steel ASTM A27/A27M, GR. 65-35 or

ASTM A216/A216M, GR. WCB

Aluminum Bronze ASTM B148, UNS C95400

Rotor(s), Shaft(s) Alloy Steel AISI 4150 RS or

AISI 4140-4150

Gray Iron ASTM A159, GR. G3500 or

continuous cast equivalents

Nodular Iron ASTM A536, GR. 80-55-06 or

continuous cast equivalents

Carbon Steel AISI 1045, 1141 or 1144

Bronze ASTM B505/B505M, B271 or B584

UNS C93200 or C93700

Stainless Steel ASTM A564/A564M, UNS S17400

ASTM A582/A582M, UNS S41600

Rotor Housings or Cylinder Liners, Bushings, Thrust Elements, Discs Bronze ASTM B505/B505M, B271 or B584, UNS C93200 or

C93700

Gray Iron ASTM A159, GR. G3500 or continuous cast equivalents

Steel/Babbitt AISI C1018-12L15/ASTM B23, ALLOY 2

Aluminum Bronze ASTM B148, UNS C95400

Hex Head Cap Screws Steel ASTM A449, TYPE I or SAE J429, GR. 5

Hex Socket Head Cap Screws Alloy Steel ASTM A574

Hex Nuts Steel ASTM A194/A194M, GR. 2H

Alloy Steel ASTM A563, GR. DH or SAE GR. 8

Hex Nuts, Slf Lkg Steel, Zn Plated NASM 17829 / MS17829

Socket Set Screws Alloy Steel ASTM F912

Studs Alloy Steel ASTM A193/A193M, GR. B7

O-Rings Fluorocarbon ASTM D2000,TY.HK

TABLE 2 Materials of Principal Motor Components

Application Material Specification

Frame Nodular Iron ASTM A395/A395M, GR. 60-40-18 or

ASTM A536, GR. 65-45-12

Housings Nodular Iron ASTM A395/A395M, GR. 60-40-18 or

ASTM A536, GR. 65-45-12

Shaft Alloy Steel AISI 4340

Ball Bearings Steel CID A-A-59585

CID A-A-59584

Bearing Caps Steel Commercial

Shrink Ring Steel Commercial

Rotor Bar Copper ASTM B187M

Rotor End Ring Copper ASTM B152/B152M

Rotor Core Plate Elec. Sheet Steel Commercial

Stator End Plate Steel Commercial

Stator Core Plate Elec. Sheet Steel Commercial

Hex Head Cap Screws Steel ASTM A449, TYPE I or

SAE J429, GR. 5

Hex Socket Head Cap Screws Alloy Steel ASTM A574

Lock Washers Steel Commercial

flange. Conduit box cable entrance shall be oriented 8. Pump Design

downward, unless otherwise specified. Horizontal pumps shall

8.1 Pump inlet and outlet connections shall be flanged.

specify orientation of conduit box.

Pump flanges shall mate to ASME/ANSI B16.5 pipe flanges.

7.7 The connection between the motor shaft and the pump

Cast iron and non-ferrous material case flanges shall be flat

rotor shall be splined or consist of a rigid connection. face, unless otherwise stated in the ordering data. Flanged

connections shall meet the external forces and moments

7.8 To facilitate and maintain alignment, the motor bracket

requirements in API Standard 676. Spool piece adapters

to pump joint shall be rabbetted.

(threaded and seal-welded, or O-ring sealed to the pump case

7.9 Motor bracket to pump joint shall be o-ring sealed.

on one end and flanged on the other end) may be furnished to

meet the flanged inlet and outlet requirement.

7.10 Direction of rotation shall be indicated by an arrow

cast into the pump or by a label plate attached to the CLP.

8.2 Pumps of capacity 100 gpm and greater shall be

7.11 An internal or separate relief valve is not required to be equipped with vent, drain, inlet, and outlet gage connections.

provided with the CLP. Where threaded connections are used they shall be straight

F2798−09

thread with O-ring seal. Tapered pipe thread connections are closuresrequiredforsegmentedcasingtestingandoperatingof

prohibited. Small capacity pumps (under 100 gpm) do not thehydrostatictestpumptomaintainpressurewillbeaccepted.

require vent, drain, and gage connections. 10.2.2 Each motor shall be tested hydrostatically at 50

PSIG. This test may be accomplished by testing the complete

8.3 Pumps shall be designed to counteract radial and axial

CLP.

thrust loads encountered during operation.

10.3 Certification Data and Testing—Certified performance

8.4 Pumpsshallbeself-primingandcapableofremovingair

test data shall be supplied when required. (See 5.1.18.)

from the suction lines.

10.3.1 Mechanical Running Test—The manufacturer shall

8.5 Pumps shall be designed to handle up to 8 % entrained

conduct a test on each CLP to ensure that rated capacity is

air.

achieved at the rated condition. Such tests may be performed

with other than the specified liquid and with viscosity up to 50

9. Motor Design

SSU greater than the minimum specified viscosity. Differential

9.1 Motors may be single speed, two-speed or single speed

pressure may be measured in place of specified inlet and

with a variable speed drive to support pump operation at

discharge pressures.

various temperatures and viscosities. Single speed motors shall

10.3.2 Performance Test—When required and as specified

be sized for the maximum flow at the system relief valve

by the ordering document, the manufacturer shall operate a

cracking pressure at maximum viscosity. If a two speed motor

CLP at the manufacturing facility or approved test facility to

is specified, rating of the low speed winding shall be based on

obtain complete mechanical, hydraulic and electrical test data.

power required at the low speed with maximum viscosity oil

The pump shall meet rated capacity at this condition and shall

during cold startup. The high speed winding rating shall be

meet the airborne noise levels in 7.4.

based on power required at pump rated conditions. Motors

driven by variable speed drive units should be sized so that the

11. Technical Documentation

motor can support pump cold start-up operation and normal

11.1 Unless otherwise specified, each pump shall include an

rated condition op

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.