ASTM F1483-98

(Specification)Standard Specification for Oriented Poly(Vinyl Chloride), PVCO, Pressure Pipe

Standard Specification for Oriented Poly(Vinyl Chloride), PVCO, Pressure Pipe

SCOPE

1.1 This specification covers requirements for materials, dimensions, sustained pressure, accelerated regression testing, burst pressure, flattening, impact resistance, workmanship, and methods of marking for oriented poly(vinyl chloride) (PVCO) pipe for pressure applications.

1.2 The PVCO pipe shall be joined using elastomeric seals (gaskets). The joint shall meet the requirements of Specification D3139 and the elastomeric seal shall meet the requirements of Specification F477. The PVCO shall not be joined by solvent cementing.

1.3 The values stated in inch-pound units are to be regarded as standard. The values in parentheses are given for information only.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 8 of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1483 – 98

Standard Specification for

Oriented Poly(Vinyl Chloride), PVCO, Pressure Pipe

This standard is issued under the fixed designation F 1483; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope moplastic Pipe and Fittings

D 2152 Test Method for Degree of Fusion of Extruded

1.1 This specification covers requirements for materials,

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

dimensions, sustained pressure, accelerated regression testing,

Acetone Immersion

burst pressure, flattening, impact resistance, workmanship, and

D 2444 Test Method for Impact Resistance of Thermoplas-

methods of marking for oriented poly(vinyl chloride) (PVCO)

tic Pipe and Fittings by Means of a Tup (Falling Weight)

pipe for pressure applications.

D 2837 Test Method for Obtaining Hydrostatic Design

1.2 The PVCO pipe shall be joined using elastomeric seals

Basis for Thermoplastic Pipe Materials

(gaskets). The joint shall meet the requirements of Specifica-

D 3139 Specification for Joints for Plastic Pressure Pipe

tion D 3139 and the elastomeric seal shall meet the require-

Using Flexible Elastomeric Seals

ments of Specification F 477.The PVCO shall not be joined by

F 412 Terminology Relating to Plastic Piping Systems

solvent cementing.

F 477 Specification for Elastomeric Seals (Gaskets) for

1.3 The values stated in inch-pound units are to be regarded

Joining Plastic Pipe

as standard. The values in parentheses are given for informa-

2.2 Other Standards:

tion only.

NSF Standard No. 14 for Plastic Piping Components and

1.4 The following safety hazards caveat pertains only to the

Related Materials

test method portion, Section 8 of this specification: This

ANSI/NSF Standard No. 61 for Drinking Water System

standard does not purport to address all of the safety concerns,

Components—Health Effects

if any, associated with its use. It is the responsibility of the user

PPI-TR 3 Policies and Procedures for Developing Recom-

of this standard to establish appropriate safety and health

mended Hydrostatic Design Stresses for Thermoplastic

practices and determine the applicability of regulatory limita-

Pipe

tions prior to use.

3. Terminology

2. Referenced Documents

3.1 Definitions:

2.1 ASTM Standards:

3.1.1 General—Definitions are in accordance with Termi-

D 618 Methods of Conditioning Plastics & Electrical Insu-

2 nologies D 883 and F 412 and abbreviations are in accordance

lating Materials for Testing

with Terminology D 1600, unless otherwise indicated. The

D 883 Terminology Relating to Plastics

abbreviation for poly(vinyl chloride) plastics is PVC.

D 1598 Test Methods for Time-to-Failure of Plastic Pipe

3.1.2 PVCO pipe—abbreviation for oriented poly(vinyl

Under Constant Internal Pressure

chloride) plastics. PVCO pipe is PVC pressure pipe which

D 1599 Test Method for Short-Time Hydraulic Pressure of

attains a relatively high strength by reorienting the molecules.

Plastic Pipe, Tubing, and Fittings

Conventionally extruded PVC pipe is expanded circumferen-

D 1600 Terminology of Abbreviated Terms Relating to

tially (for example, 2-in. diameter is expanded to 4-in. diam-

Plastics

eter) through the application of pressure and temperature. The

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

expansion reorients the PVC molecular structure in the hoop

Compounds and Chlorinated Poly(Vinyl Chloride)

direction, thereby increasing the material strength.

(CPVC) Compounds

3.2 Definitions of Terms Specific to This Standard: D

D 2122 Test Method for Determining Dimensions of Ther-

3.2.1 expansion ratio (ER)—theratiooftheoriginalstarting

stock outside diameter to the outside diameter of the finished

1 PVCO pipe.

This specification is under the jurisdiction ofASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

Based Pipe.

Current edition approved Dec. 10, 1998. Published March 1999. Originally Available from the National Sanitation Foundation, P.O. Box 1468,AnnArbor,

published as F 1483 – 93. Last previous edition F 1483 – 95. MI 48106.

2 5

Annual Book of ASTM Standards, Vol 08.01. Available from Plastics Pipe Institute, 1275 K St. N.W., Suite 400,Washington,

Annual Book of ASTM Standards, Vol 08.04. DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1483 – 98

3.2.2 standard thermoplastic pipe material designation 6. Requirements

code—the molecularly oriented poly(vinyl chloride) materials

6.1 General—These requirements are for finished PVCO

designation code shall consist of the abbreviation PVCO for

pipe, unless otherwise noted.

the type of plastics, followed by the ASTM type and grade in

6.2 Dimensions and Tolerances:

arabic numerals and the hydrostatic design stress in units of

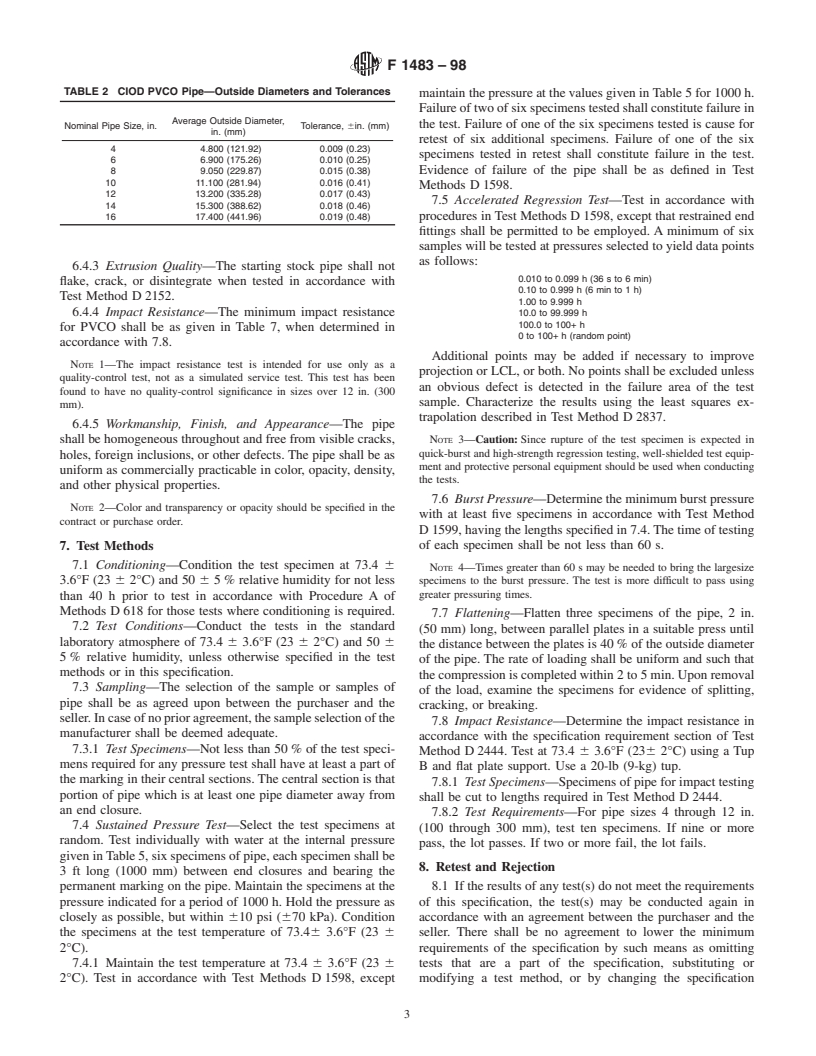

6.2.1 Outside Diameters—The outside diameters and toler-

100 psi (0.69 MPa) with any decimal figures dropped. The

ances shall be shown in Table 1 and Table 2 when measured in

ASTM type and grade shall be that of the starting stock

accordance with Test Method D 2122. The tolerances for

material. The hydrostatic design stress shall be that of the

out-of-roundness shall apply only on pipe prior to shipment.

finished PVCO pipe.

6.2.2 Wall Thicknesses—The wall thicknesses and toler-

3.2.3 DISCUSSION—A complete material designation

ances shall be as shown in Table 3 and Table 4 when measured

code shall consist of four letters and four figures (for example;

in accordance with Test Method D 2122.

a PVCO pipe manufactured from 12454B (Type 1, Grade 1)

6.3 Qualification Tests—These tests are for qualification of

material starting stock and having an HDB of 7100 psi (48.92

the compound and extrusion process, not for quality control.

MPa) [HDS of 3550 psi) (24.46 MPa)] will have a material

6.3.1 Sustained Pressure—The sustained pressure test shall

designation code of PVCO 1135).

be completed for each diameter at initial start-up. Thereafter, it

shall be completed whenever there is a change in the ER

3.2.4 starting stock—the conventionally extruded PVC pipe

of uniform wall thickness which will be expanded to a larger (3.2.1), or the WTR (3.2.5), or whenever a change is made to

diameter, molecular oriented pipe. the compound which is outside the allowable limits of the

Plastics Pipe Institute PVC compound range formula (see PPI

3.2.5 wall-thickness-ratio (WTR)—the ratio of the starting

TR-3). The pipe shall not fail, balloon, burst, or weep as

stockwallthicknesstothewallthicknessofthefinishedPVCO

defined in Test Method D 1598 at the test pressures given in

pipe.

Table 5 when tested in accordance with 7.4.

6.3.2 Accelerated Regression Test—This test shall be com-

4. Classification

pleted on a representative diameter at initial start-up. A

4.1 General—This specification covers PVCO made from

representative diameter is one which has an ER, a WTR, and a

PVC plastic pipe, starting stock, having a hydrostatic design

compound which is the same as the other diameters manufac-

stress of 2000 psi (13.78 MPa) determined in accordance with

tured. Thereafter, it shall be completed on a representative

Test Method D 2837. Finished PVCO pipe shall have a

diameter whenever there is a change in the ER or the WTR, or

hydrostatic design stress of 3550 psi (24.46 MPa) or 3150 psi

whenever a change is made to the compound which is outside

(21.70 MPa) determined by testing in accordance with Test

the allowable limits of the Plastics Pipe Institute PVC com-

Methods D 1598, with data evaluated in accordance with Test

pound range formula (see PPI Tr-3). The test shall be con-

Methods D 2837, as in 6.3.2.

ducted in accordance with 7.5.

6.3.2.1 The pipe shall demonstrate a minimum hydrostatic

5. Materials

design basis projection, at the 100 000-h intercept, of 6810 psi

(46.92 MPa) or 6040 psi (41.62 MPa) (see Table 1 for

5.1 General—Poly(vinyl chloride) plastics used to make

PVCO pipe meeting the requirements of this specification are Hydrostatic Design Basis Categories of Test Method D 2837).

At the option of the manufacturer, the accelerated regression

categorized by means of two criteria, namely (1) short-term

strength tests; and (2) long-term strength tests. test may be used as a substitute for both pressure tests,

sustained and burst (6.4.1).

5.1.1 Supplementary Requirement—This applies whenever

6.4 Quality Control Tests—These tests are intended to

a regulatory authority or user calls for the product to be used to

ensure the quality of the finished pipe product.

convey or to be in contact with potable water. Potable water

6.4.1 Burst Pressure—The minimum burst pressure for

applications products intended for contact with potable water

PVCO pipe shall be as given in Table 6, when determined in

shall be evaluated, tested, and certified for conformance with

accordance with 7.6.

ANSI/NSF Standard 61 or the health effects portion of NSF

6.4.2 Flattening—There shall be no evidence of splitting,

Standard No. 14 by an acceptable certifying organization when

cracking, or breaking when the pipe is tested in accordance

required by the regulatory authority having jurisdiction.

with 7.7.

5.2 Basic Materials—This specification covers PVCO pipe

made from PVC compounds having certain physical and

chemical properties as described in Specification D 1784.

TABLE 1 IPS PVCO Pipe—Outside Diameters and Tolerances

5.3 The PVC compound used for the starting stock of this

pipe shall equal or exceed one of the following cell classifica-

Average Outside Diameter,

Nominal Pipe Size, in. Tolerance, 6in. (mm)

in. (mm)

tions described in Specification D 1784: PVC 12454-B (Type

4 4.500 (114.30) 0.009 (0.23)

1, Grade 1), 12454-C (Type 1, Grade 2). Recycled materials

6 6.625 (168.28) 0.011 (0.28)

shall not be used in the compound.

8 8.625 (219.08) 0.015 (0.38)

5.4 Rework Materials—Clean, rework material, generated 10 10.750 (273.05) 0.016 (0.41)

12 12.750 (323.85) 0.017 (0.43)

from the manufacturer’s own pipe production, shall be permit-

14 14.000 (355.60) 0.018 (0.46)

ted to be used by the same manufacturer, as long as the pipe

16 16.000 (406.40) 0.019 (0.48)

produced meets all the requirements of this specification.

F 1483 – 98

TABLE 2 CIOD PVCO Pipe—Outside Diameters and Tolerances

maintain the pressure at the values given in Table 5 for 1000 h.

Failure of two of six specimens tested shall constitute failure in

Average Outside Diameter,

the test. Failure of one of the six specimens tested is cause for

Nominal Pipe Size, in. Tolerance, 6in. (mm)

in. (mm)

retest of six additional specimens. Failure of one of the six

4 4.800 (121.92) 0.009 (0.23)

specimens tested in retest shall constitute failure in the test.

6 6.900 (175.26) 0.010 (0.25)

8 9.050 (229.87) 0.015 (0.38) Evidence of failure of the pipe shall be as defined in Test

10 11.100 (281.94) 0.016 (0.41)

Methods D 1598.

12 13.200 (335.28) 0.017 (0.43)

7.5 Accelerated Regression Test—Test in accordance with

14 15.300 (388.62) 0.018 (0.46)

procedures in Test Methods D 1598, except that restrained end

16 17.400 (441.96) 0.019 (0.48)

fittings shall be permitted to be employed. A minimum of six

samples will be tested at pressures selected to yield data points

as follows:

6.4.3 Extrusion Quality—The starting stock pipe shall not

0.010 to 0.099 h (36 s to 6 min)

flake, crack, or disintegrate when tested in accordance with

0.10 to 0.999 h (6 min to 1 h)

Test Method D 2152.

1.00 to 9.999 h

6.4.4 Impact Resistance—The minimum impact resistance

10.0 to 99.999 h

100.0 to 100+ h

for PVCO shall be as given in Table 7, when determined in

0 to 100+ h (random point)

accordance with 7.8.

Additional points may be added if necessary to improve

NOTE 1—The impact resistance test is intended for use only as a

projection or LCL, or both. No points shall be excluded unless

quality-control test, not as a simulated service test. This test has been

an obvious defect is detected in the failure area of the test

found to have no quality-control significance in sizes over 12 in. (300

sample. Characterize the results using the least squares ex-

mm).

trapolation described in Test Method D 2837.

6.4.5 Workmanship, Finish, and Appearance—The pipe

shall be homogeneous throughout and free from visible cracks, NOTE 3—Caution: Since rupture of the test specimen is expected in

quick-burst and high-strength regression testing, well-shielded test equip-

holes, foreign inclusions, or other defects. The pipe shall be as

ment and protective personal equipment should be used when conducting

uniform as commercially practicable in color, opacity, density,

the tests.

and other physical properties.

7.6 Burst Pressure—Determine the minimum burst pressure

NOTE 2—Color and transparency or opacity should be specified in the

with at least five specimens in accordance with Test Method

contract or purchase order.

D 1599, having the lengths specified in 7.4.The time of testing

of each specimen shall be not less than 60 s.

7. Test Methods

7.1 Conditioning—Condition the test specimen at 73.4 6

NOTE 4—Times greater than 60 s may be needed to bring the largesize

3.6°F (23 6 2°C) and 50 6 5 % relative humidity for not less specimens to the burst pressure. The test is more difficult to pass using

greater pressuring times.

than 40 h prior to test in accordance with Procedure A of

Methods D 618 for those tests where conditioning is required.

7.7 Flattening—Flatten three specimens of the pipe, 2 in.

7.2 Test Conditions—Conduct the tests in the standard

(50 mm) long, between parallel plates in a suitable press until

laboratory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 6

the distance between the plates is 40 % of the outside diameter

5 % relative humidity, unless otherwise specified in the test

of the pipe. The rate of loading shall be uniform and such that

methods or in this specification.

the compression is completed within 2 to 5 min. Upon removal

7.3 Sampling—The selection of the sample or samples of

of the load, examine the specimens for evidence of splitting,

pipe shall be as agreed upon between the purchaser and the

cracking, or breaking.

seller.Incaseofnoprioragreement,thesampleselectionofthe

7.8 Impact Resistance—Determine the impact resistance in

manufacturer shall be deemed adequate.

accordance with the specification requirement section of Test

7.3.1 Test Specimens—Not less than 50 % of the test speci-

Method D 2444. Test at 73.4 6 3.6°F (236 2°C) using a Tup

mens required for any pressure test shall have at least a part of

B and flat plat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.