ASTM D4729-04

(Test Method)Standard Test Method for In Situ Stress and Modulus of Deformation Using the Flatjack Method

Standard Test Method for In Situ Stress and Modulus of Deformation Using the Flatjack Method

SIGNIFICANCE AND USE

Tests in Orthogonal Directions—The flatjack most accurately determines the stress parallel to the long axis of the adit, because this stress is the least affected by the presence of the opening. (The other tangential stress is highly concentrated.) In addition, if the adit is in a stress field where one of the stresses is significantly larger than the others (3 or 4 times), certain locations in the adit may be in very low compressive or even tensile stress. Flatjack tests in these locations can give anomalous and misleading results. Because of these factors, the test adit should have at least two, and preferably three, long (at least 4 to 5 times the diameter), straight sections at about 90° to each other. Testing should be distributed evenly in all three sections to provide redundant data and, if results in one section are anomalous, to allow the program to produce sufficient usable data.

Note 1—Not withstanding the statements on precision and bias contained in this test method; the precision of this test method is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing. Users of this test method are cautioned that compliance with Practice D 3740 does not in itself assure reliable testing. Reliable testing depends on many factors; Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 The flatjack test measures stress at a rock surface. The modulus of deformation and the long-term deformational properties (creep) may also be evaluated.

1.2 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D 6026.

1.2.1 The method used to specifiy how data are collected, calculated, or recorded in this standard is not directly related to the accuracy to which the data can be applied in design or other uses, or both. How one applies the results obtained using this standard is beyond its scope.

1.3 LimitationThe flatjack test measures the average stress normal to the surface of the test chamber. Undisturbed stress levels must be determined by theoretical interpretations of these data.

1.4 Assumptions and Factors Influencing the Data

1.4.1 The stress relief is assumed to be an elastic, reversible process. In nonhomogeneous or highly fractured materials, this may not be completely true.

1.4.2 The equations assume that the rock mass is isotropic and homogeneous. Anisotropic effects may be estimated by testing in different orientations.

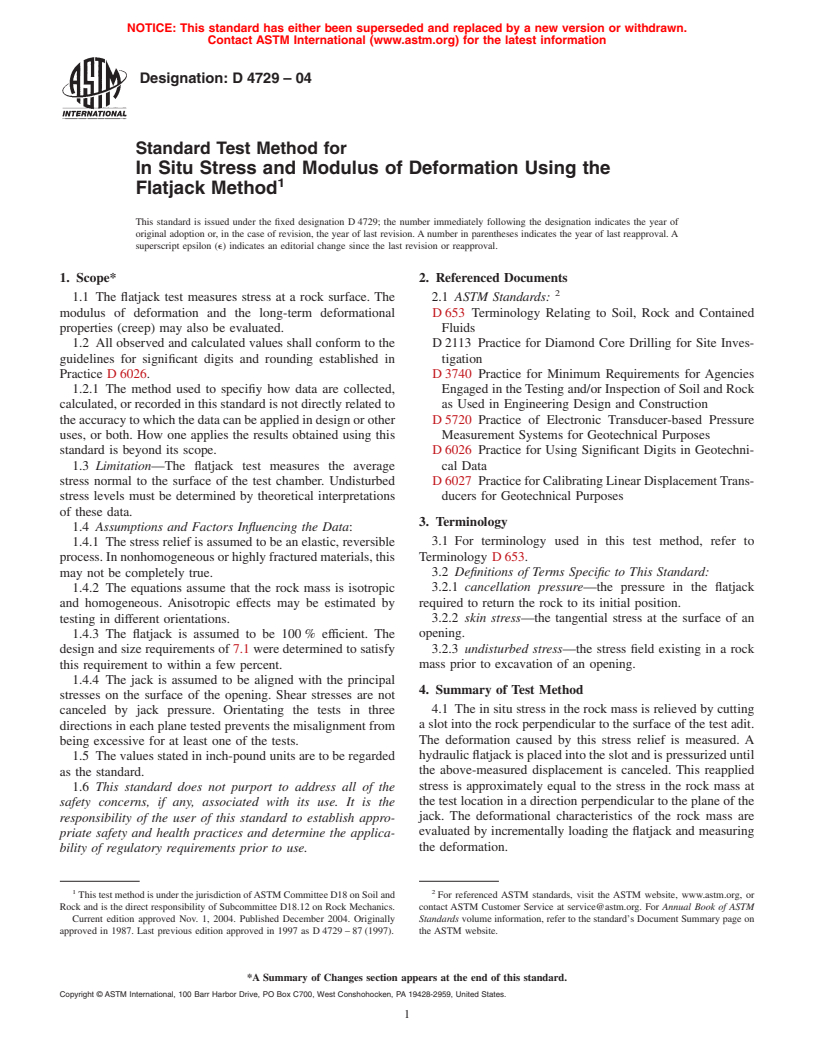

1.4.3 The flatjack is assumed to be 100 % efficient. The design and size requirements of were determined to satisfy this requirement to within a few percent.

1.4.4 The jack is assumed to be aligned with the principal stresses on the surface of the opening. Shear stresses are not canceled by jack pressure. Orientating the tests in three directions in each plane tested prevents the misalignment from being excessive for at least one of the tests.

1.5 The values stated in inch-pound units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4729 – 04

Standard Test Method for

In Situ Stress and Modulus of Deformation Using the

1

Flatjack Method

This standard is issued under the fixed designation D 4729; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 The flatjack test measures stress at a rock surface. The

modulus of deformation and the long-term deformational D 653 Terminology Relating to Soil, Rock and Contained

properties (creep) may also be evaluated. Fluids

1.2 All observed and calculated values shall conform to the D 2113 Practice for Diamond Core Drilling for Site Inves-

guidelines for significant digits and rounding established in tigation

Practice D 6026. D 3740 Practice for Minimum Requirements for Agencies

1.2.1 The method used to specifiy how data are collected, Engaged in the Testing and/or Inspection of Soil and Rock

calculated, or recorded in this standard is not directly related to as Used in Engineering Design and Construction

theaccuracytowhichthedatacanbeappliedindesignorother D 5720 Practice of Electronic Transducer-based Pressure

uses, or both. How one applies the results obtained using this Measurement Systems for Geotechnical Purposes

standard is beyond its scope. D 6026 Practice for Using Significant Digits in Geotechni-

1.3 Limitation—The flatjack test measures the average cal Data

stress normal to the surface of the test chamber. Undisturbed D 6027 PracticeforCalibratingLinearDisplacementTrans-

stress levels must be determined by theoretical interpretations ducers for Geotechnical Purposes

of these data.

3. Terminology

1.4 Assumptions and Factors Influencing the Data:

1.4.1 The stress relief is assumed to be an elastic, reversible 3.1 For terminology used in this test method, refer to

Terminology D 653.

process. In nonhomogeneous or highly fractured materials, this

may not be completely true. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 cancellation pressure—the pressure in the flatjack

1.4.2 The equations assume that the rock mass is isotropic

required to return the rock to its initial position.

and homogeneous. Anisotropic effects may be estimated by

testing in different orientations. 3.2.2 skin stress—the tangential stress at the surface of an

opening.

1.4.3 The flatjack is assumed to be 100 % efficient. The

design and size requirements of 7.1 were determined to satisfy 3.2.3 undisturbed stress—the stress field existing in a rock

mass prior to excavation of an opening.

this requirement to within a few percent.

1.4.4 The jack is assumed to be aligned with the principal

4. Summary of Test Method

stresses on the surface of the opening. Shear stresses are not

4.1 The in situ stress in the rock mass is relieved by cutting

canceled by jack pressure. Orientating the tests in three

a slot into the rock perpendicular to the surface of the test adit.

directions in each plane tested prevents the misalignment from

The deformation caused by this stress relief is measured. A

being excessive for at least one of the tests.

hydraulic flatjack is placed into the slot and is pressurized until

1.5 The values stated in inch-pound units are to be regarded

the above-measured displacement is canceled. This reapplied

as the standard.

stress is approximately equal to the stress in the rock mass at

1.6 This standard does not purport to address all of the

the test location in a direction perpendicular to the plane of the

safety concerns, if any, associated with its use. It is the

jack. The deformational characteristics of the rock mass are

responsibility of the user of this standard to establish appro-

evaluated by incrementally loading the flatjack and measuring

priate safety and health practices and determine the applica-

the deformation.

bility of regulatory requirements prior to use.

1 2

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2004. Published December 2004. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1987. Last previous edition approved in 1997 as D 4729 – 87 (1997). the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ---------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.