ASTM D4403-84(2000)e1

(Practice)Standard Practice for Extensometers Used in Rock

Standard Practice for Extensometers Used in Rock

SCOPE

1.1 This practice covers the description, application, selection, installation, data collecting, and data reduction of the various types of extensometers used in the field of rock mechanics.

1.2 Limitations of each type of extensometer system are covered in Section 3.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are provided for information purposes only.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.5 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgement. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word "Standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: D 4403 – 84 (Reapproved 2000)

Standard Practice for

Extensometers Used in Rock

This standard is issued under the fixed designation D 4403; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout in December 2000.

1. Scope * tially unstable slopes, and in monitoring the performance of

rock support systems.

1.1 This practice covers the description, application, selec-

2.4 An extensometer should be selected on the basis of its

tion, installation, data collecting, and data reduction of the

intended use, the preciseness of the measurement required, the

various types of extensometers used in the field of rock

anticipated range of deformation, and the details accompany-

mechanics.

ing installation. No single instrument is suitable for all appli-

1.2 Limitations of each type of extensometer system are

cations.

covered in Section 3.

1.3 The values stated in inch-pound units are to be regarded

3. Apparatus

as the standard. The SI values given in parentheses are

3.1 General—Experience and engineering judgment are

provided for information purposes only.

required to match the proper type of extensometer systems to

1.4 The text of this standard references notes and footnotes

the nature of investigation for a given project.

which provide explanatory material. These notes and footnotes

3.1.1 In applications for construction in rock, precise mea-

(excluding those in tables and figures) shall not be considered

surements will usually allow the identification of significant,

as requirements of the standard.

possibly dangerous, trends in rock movement; however, pre-

1.5 This practice offers a set of instructions for performing

cise measurement is much less important than the overall

one or more specific operations. This document cannot replace

pattern of movement. Where measurements are used to deter-

education or experience and should be used in conjunction

mine rock properties (such as in plate-jack tests), accurate

with professional judgement. Not all aspects of this guide may

measurements involving a high degree of precision are re-

be applicable in all circumstances. This ASTM standard is not

quired. For in-situ rock testing, instrument sensitivity better

intended to represent or replace the standard of care by which

than 0.0012 in. (0.02 mm) is necessary for proper interpreta-

the adequacy of a given professional service must be judged,

tion.

nor should this document be applied without consideration of

3.1.2 Most field measurements related to construction in

a project’s many unique aspects. The word “Standard” in the

rock do not require the precision of in-situ testing. Precision in

title of this document means only that the document has been

the range of 0.001 to 0.01 in. (0.025 to 0.25 mm) is typically

approved through the ASTM consensus process.

required and is readily obtainable by several instruments.

1.6 This standard does not purport to address all of the

3.1.3 As the physical size of an underground structure or

safety concerns, if any, associated with its use. It is the

slope increases, the need for highly precise measurements

responsibility of the user of this standard to establish appro-

diminishes. A precision of 0.01 to 0.04 in. (0.25 to 1.0 mm) is

priate safety and health practices and determine the applica-

often sufficient. This range of precision is applicable to

bility of regulatory limitations prior to use.

underground construction in soil or weak rock. In most hard

2. Significance and Use rock applications, however, an instrument sensitivity on the

order of 0.001 in. (0.025 mm) is preferred.

2.1 Extensometers are widely used in the field of engineer-

3.1.4 The least precision is required for very large excava-

ing and include most devices used to measure displacements,

tions, such as open pit mines and large moving landslides. In

separation, settlements, convergence, and the like.

such cases, the deformations are large before failure and, thus,

2.2 For tunnel instrumentation, extensometers are generally

relatively coarse precision is required, on the order of 1 % of

used to measure roof and sidewall movements and to locate the

the range where the range may be 3 ft. (1 m) or more.

tension arch zone surrounding the tunnel opening.

3.1.5 For long-term monitoring, displacements are typically

2.3 Extensometers are also used extensively as safety moni-

smaller than those that occur during construction. Therefore,

toring devices in tunnels, in underground cavities, on poten-

greater precision may be required for the long-term measure-

ments.

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

3.2 Extensometers:

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

Current edition approved Aug. 31, 1984. Published November 1984.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4403

3.2.1 Rod Extensometers—A large variety of rod extensom-

eters are manufactured. They range from simple single-point

units to complicated multipoint systems with electrical readout.

The single-point extensometer is generally used to detect

support system failures. The rod can also serve as a safety

warning device in hazardous areas. Generally, the rod exten-

someter is read with a depth-measuring instrument such as a

dial gage or depth micrometer, however, various electrical

transducers such as LVDTs (linear variable differential trans-

formers), linear potentiometers, and microswitches have been

used where remote or continuous readings are required (as

shown in Fig. 1). Another type of readout recently developed is

a noncontact removable sonic probe digital readout system

which is interchangeable with the depth micrometer type.

Multipoint rod extensometers have up to eight measuring

points. Reduced rod diameters are required for multipoint

instruments and have been used effectively to depths of at least

150 ft (45 m). The rod acts as a rigid member and must react

in both tension and compression. When used in deep applica-

tions, friction caused by drill hole misalignment and rod

interference can cause erroneous readings.

3.2.2 Bar Extensometers—Bar extensometers are generally

used to measure diametric changes in tunnels. Most bar

extensometers consist of spring-loaded, telescopic tubes that

have fixed adjustment points to cover a range of several feet.

The fixed points are generally spaced at 1 to 4-in. (25 to

100-mm) increments. A dial gage is used to measure the FIG. 2 Bar Extensometer

displacements between the anchor points in the rock (as shown

distances, such as found in large tunnels or powerhouse

in Fig. 2). If the device is not constructed from invar steel,

openings. Tape extensometers consist of a steel tape (prefer-

ambient temperature should be recorded and the necessary

ably invar steel), a tensioning device to maintain constant

corrections applied to the results. Bar extensometers are

tension, and a readout head. Lengths of tape may be pulled out

primarily used for safety monitoring devices in mines and

from the tape spool according to the need. The readout may be

tunnels.

a dial gage or a vernier, and the tensioning mechanism may be

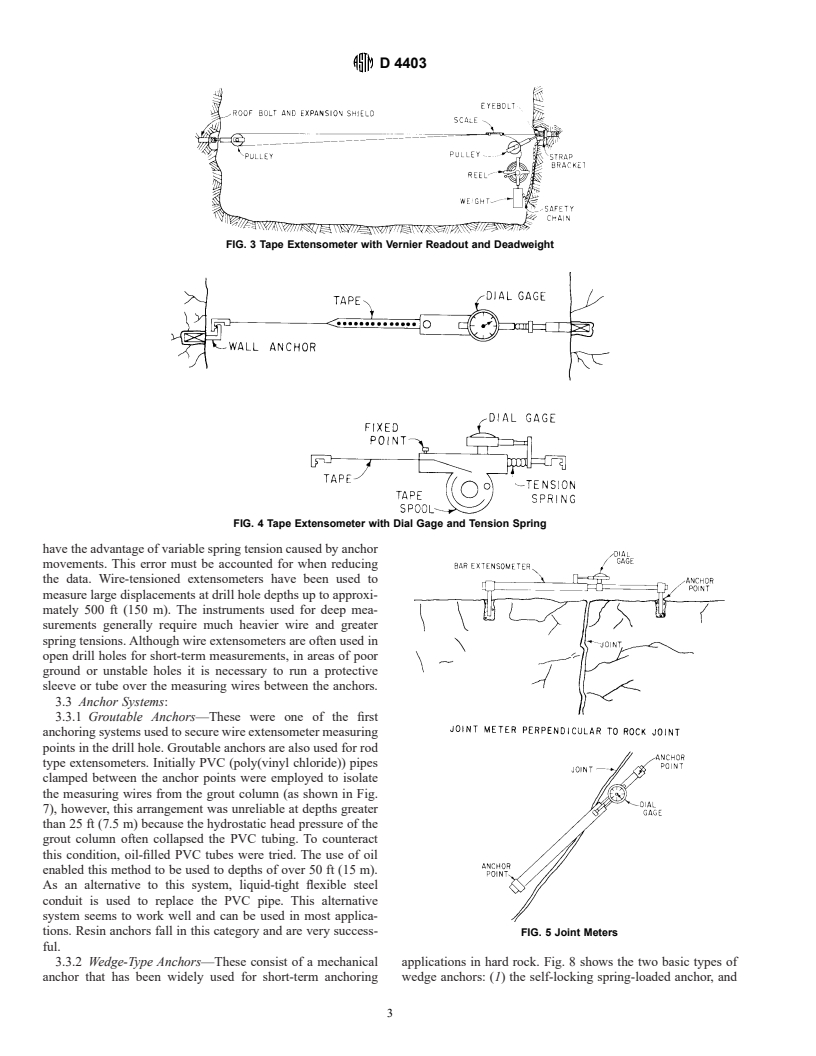

3.2.3 Tape Extensometers—Such devices are designed to be

a spring-loading device or a dead-weight (as shown in Fig. 3

used in much the same manner as bar extensometers, however,

and Fig. 4). The tape and readout head are fastened, or

tape extensometers allow the user to measure much greater

stretched in tension, between the points to be measured.

Accuracies of 0.010 to 0.002 in. (0.25 to 0.05 mm) can be

expected, depending on the length of the tape and the ability to

tension the tape to the same value on subsequent readings, and

provided that temperature corrections are made when neces-

sary.

3.2.4 Joint Meters—Normally, joint meters consist of an

extensometer fixed across the exposed surface of a joint (as

demonstrated in Fig. 5), and are used to measure displacements

along or across joints. The joint movements to be measured

may be the opening or closing of the joint or slippage along the

joint. Rod-type extensometers are generally used as joint

meters with both ends fixed across the joint. Preset limit

switches are often mounted on the joint meter to serve as a

warning device in problem areas such as slopes and founda-

tions.

3.2.5 Wire Extensometers—Such devices utilize a thin stain-

less steel wire to connect the reference point and the measuring

point of the instrument (as shown in Fig. 6). This allows a

greater number of measuring points to be placed in a single

drill hole. The wire or wires are tensioned by springs or

weights. The wire is extended over a roller shiv and connected

FIG. 1 Rod Extensometer to a hanging weight. Wire extensometers tensioned by springs

D 4403

FIG. 3 Tape Extensometer with Vernier Readout and Deadweight

FIG. 4 Tape Extensometer with Dial Gage and Tension Spring

have the advantage of variable spring tension caused by anchor

movements. This error must be accounted for when reducing

the data. Wire-tensioned extensometers have been used to

measure large displacements at drill hole depths up to approxi-

mately 500 ft (150 m). The instruments used for deep mea-

surements generally require much heavier wire and greater

spring tensions. Although wire extensometers are often used in

open drill holes for short-term measurements, in areas of poor

ground or unstable holes it is necessary to run a protective

sleeve or tube over the measuring wires between the anchors.

3.3 Anchor Systems:

3.3.1 Groutable Anchors—These were one of the first

anchoring systems used to secure wire extensometer measuring

points in the drill hole. Groutable anchors are also used for rod

type extensometers. Initially PVC (poly(vinyl chloride)) pipes

clamped between the anchor points were employed to isolate

the measuring wires from the grout column (as shown in Fig.

7), however, this arrangement was unreliable at depths greater

than 25 ft (7.5 m) because the hydrostatic head pressure of the

grout column often collapsed the PVC tubing. To counteract

this condition, oil-filled PVC tubes were tried. The use of oil

enabled this method to be used to depths of over 50 ft (15 m).

As an alternative to this system, liquid-tight flexible steel

conduit is used to replace the PVC pipe. This alternative

system seems to work well and can be used in most applica-

tions. Resin anchors fall in this category and are very success- FIG. 5 Joint Meters

ful.

3.3.2 Wedge-Type Anchors—These consist of a mechanical applications in hard rock. Fig. 8 shows the two basic types of

anchor that has been widely used for short-term anchoring wedge anchors: (1) the self-locking spring-loaded anchor, and

D 4403

practical or possible due to the instrument location or area

conditions.

3.4.2 Electrical Transducers—For remote or continuous

readings, electrical transducers are used rather than dial gages.

LVDTs are often used because of their accuracy, small size, and

availability. LVDTs require electrical readout equipment con-

sisting of an a-c regulated voltage source and an accurate

voltmeter, such as a digital voltmeter or bridge circuit. The use

of linear potentiometers or strain gages is often desirable

because of the simplicity of the circuitry involved. The

disadvantage of using linear potentiometers is their inherently

poor linearity and resolution.

3.4.3 When very accurate measurements are dictated by

certain excavations, for example, the determination of the

tension arch zone around a tunnel opening, extensometers

which can be calibrated in the field after installation shall be

used. In all cases, the accuracy of extensometers, either

determined through calibration or estimation, should be given

in addition to the sensitivity of the transducers. The strain-

gaged cantilever extensometer (shown in Fig. 10) has been

used successfully for many years. The strain-gaged cantilever

operates on the principles of the linear strain produced across

a given area of a spring material when flexed. This type of

extensometer readout is normally used when rock movements

FIG. 6 Wire Extensometers

of 0.5 in. (12.5 mm) or less are expected. Strain gages produce

a linear change in resistance of 1 to 3% of their initial

resistance, over their total measurement range. Because of this

(2) the mechanical-locking anchor. Self-locking anchors, when

small change in resistance, it is absolutely necessary to provide

used in areas subject to shock load vibrations caused by

extremely good electrical connections and cable insulation

blasting or other construction disturbances, may tend to slip in

when using this type of transducer. Standard strain-gage

the drill holes or become more deeply-seated, causing the

readout equipment can be used with this type of extensometer,

center wedge to move. Another disadvantage of the wedge

however, care must be taken to protect this equipment from the

anchor is that no protection is offered, if using wires, to the

hostile environments found in most field applications. Vibrat-

measuring wires in the drill hole against damage that might be

ing wire and sonic readouts are also reliable and are becoming

caused by water or loose rock.

more common than strain-gage readouts. Provision should

3.3.3 Hydraulic Anchors—These anchors have proven to be

always be made for mechanical readout capability.

successful in most types of rock and soil conditions. Fig. 9

4. Procedure

shows the two basic types of hydraulic anchors manufactured

for use with extensometer systems: (1) the uncoiling Bourdon

4.1 Preparatory Investigations:

tube anchor, and (2) the hydraulic piston of grappling hook

4.1.1 Select the location, orientation, length, and number of

anchor, which is limited to soft rock and soils. Both anchors

anchors for each extensometer on the basis of a thorough

have the disadvantage of being rather costly. The Bourdon tube

review of both the construction and geotechnical features of the

anchor works well in most rock and soil conditions and the

project. Among the items to be considered are: direction and

complete anchor system can be fabricated before installing it in

magnitude of anticipated rock movements, location and nature

the drill hole. There have been other specialized anchor

of other instruments to be installed, and the procedures and

systems developed, however, these systems have proven to be

timing of construction activities before, during, and after

too costly and unsuccesful for most applications.

in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.