ASTM C711-22

(Test Method)Standard Test Method for Low-Temperature Flexibility and Tenacity of One-Part, Elastomeric, Solvent-Release Type Sealants

Standard Test Method for Low-Temperature Flexibility and Tenacity of One-Part, Elastomeric, Solvent-Release Type Sealants

SIGNIFICANCE AND USE

4.1 This test method is not intended to simulate an actual use condition but it will give some indication of the elastomeric properties or flexibility of a building joint sealant at low temperature. It can serve to differentiate between elastomer-based sealants and sealants based on nonelastic binders that can harden or embrittle on aging and crack or lose adhesion when flexed at low temperature. In addition, it can aid in identifying sealants that have poor flexibility because they are overextended and contain a very low level of elastomeric binder as well as those sealants having binders that will embrittle at low temperature.

SCOPE

1.1 This test method covers determination of the low-temperature flexibility and tenacity of one-part, elastomeric, solvent-release type sealants after cyclic high- and low-temperature aging.

1.2 The subcommittee with jurisdiction is not aware of any similar ISO standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C711 − 22

Standard Test Method for

Low-Temperature Flexibility and Tenacity of One-Part,

1

Elastomeric, Solvent-Release Type Sealants

This standard is issued under the fixed designation C711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers determination of the low-

4.1 This test method is not intended to simulate an actual

temperature flexibility and tenacity of one-part, elastomeric, useconditionbutitwillgivesomeindicationoftheelastomeric

solvent-release type sealants after cyclic high- and low-

properties or flexibility of a building joint sealant at low

temperature aging. temperature. It can serve to differentiate between elastomer-

basedsealantsandsealantsbasedonnonelasticbindersthatcan

1.2 The subcommittee with jurisdiction is not aware of any

harden or embrittle on aging and crack or lose adhesion when

similar ISO standard.

flexed at low temperature. In addition, it can aid in identifying

1.3 The values stated in inch-pound units are to be regarded

sealants that have poor flexibility because they are overex-

as standard. The values given in parentheses are mathematical

tended and contain a very low level of elastomeric binder as

conversions to SI units that are provided for information only

well as those sealants having binders that will embrittle at low

and are not considered standard.

temperature.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

5.1 Aluminum Panels, three, thin, approximately 3 in. (76

priate safety, health, and environmental practices and deter-

mm) wide by 5 in. (127 mm) long by 0.012 in. (0.30 mm)

mine the applicability of regulatory limitations prior to use.

thick.

1.5 This international standard was developed in accor-

5.2 Spatula, steel, with thin knife edge.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 1

5.3 Template, rectangular, of steel or brass, ⁄8 in. (3.2 mm)

Development of International Standards, Guides and Recom- 3

high, 1 in. by 3 ⁄4 in. (25 mm by 95 mm) inside and

mendations issued by the World Trade Organization Technical 3

approximately 2 in. by 4 ⁄4 in. (51 mm by 121 mm) outside.

Barriers to Trade (TBT) Committee.

5.4 Oven,forced-drafttype,havingatemperaturecontrolled

at 158 °F 6 3.6 °F (70 °C 6 2 °C).

2. Referenced Documents

2

5.5 Freezer Chest or Cold Box, having a controlled tem-

2.1 ASTM Standards:

perature of −10 °F 6 5 °F (−23 °C 6 3 °C).

C717 Terminology of Building Seals and Sealants

1

5.6 Mandrel or Rod, with a diameter of ⁄4 in. (6.4 mm),

3. Terminology

with a suitable holder or rack to support it.

3.1 Definitions—Refer to Terminology C717 for definitions

5.7 Methyl Ethyl Ketone, or similar solvent.

of the following terms used in this Test Method: elastomer,

elastomeric, joint, sealant, solvent-release sealant, standard

6. Sampling

conditions.

6.1 Create the test specimen from a previously unopened

container of sealant as received from the sealant manufacturer.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

Seals and Sealantsand is the direct responsibility of Subcommittee C24.20 on

General Test Methods.

7. Test Specimens

CurrenteditionapprovedJune1,2022.PublishedJuly2022.Originallyapproved

7.1 Prepare three test specimens as follows:

in 1972. Last previous edition approved in 2014 as C711 – 14. DOI: 10.1520/

C0711-22.

7.1.1 Condition the sealant sample in the original closed

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

container for at least 24 h at standard conditions.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1.2 Thoroughly clean template and aluminum panels with

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. solvent.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C711 − 22

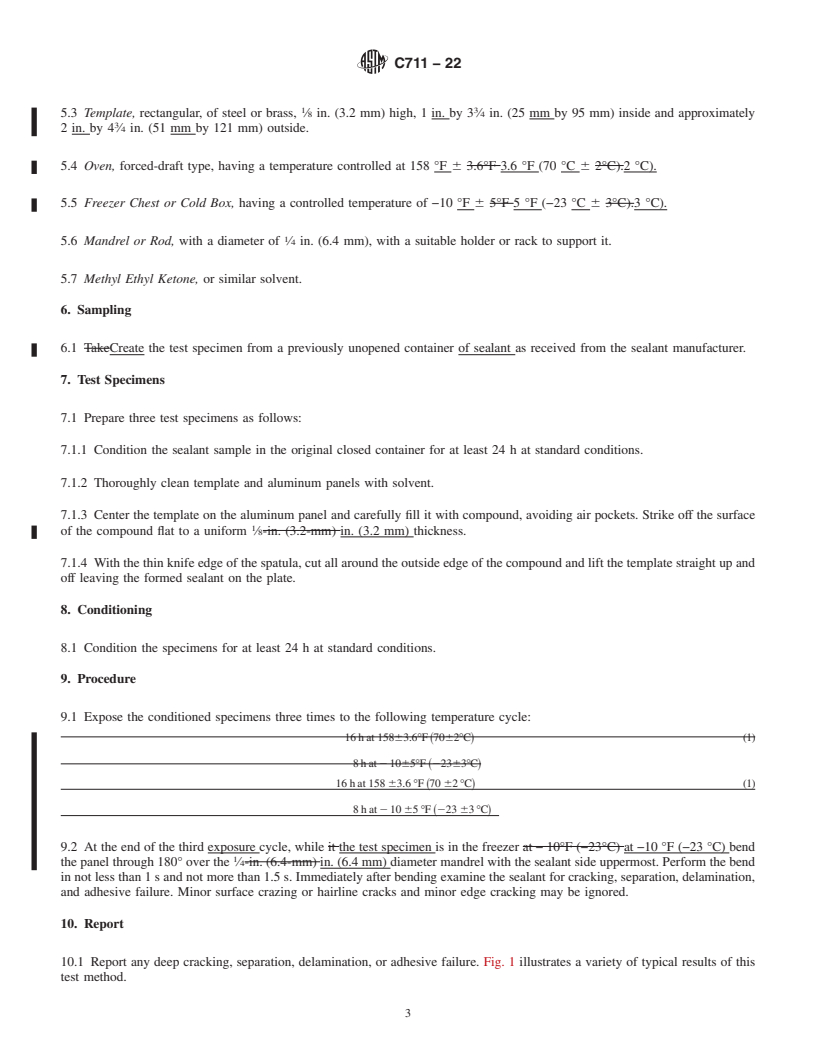

(a) Complete Cracking and Adhesive Failure (b) Severe Cracking

(c) No Cracking or Adhesive Failure

FIG. 1 Low-Temperature Flexibility (Tenacity)

7.1.3 Center the template on the aluminum panel and 7.1.4 With the thin knife edge of the spatula, cut all around

carefully fill it wi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C711 − 14 C711 − 22

Standard Test Method for

Low-Temperature Flexibility and Tenacity of One-Part,

1

Elastomeric, Solvent-Release Type Sealants

This standard is issued under the fixed designation C711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers determination of the low-temperature flexibility and tenacity of one-part, elastomeric, solvent-release

type sealants after cyclic high- and low-temperature aging.

1.2 The subcommittee with jurisdiction is not aware of any similar ISO standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

3. Terminology

3.1 Definitions—Refer to Terminology C717 for definitions of the following terms used in this Test Method: elastomer,

elastomeric, joint, sealant, solvent-release sealant, standard conditions.

4. Significance and Use

4.1 This test method is not intended to simulate an actual use condition but it will give some indication of the elastomeric

properties or flexibility of a building joint sealant at low temperature. It can serve to differentiate between elastomer-based sealants

and sealants based on nonelastic binders that can harden or embrittle on aging and crack or lose adhesion when flexed at low

1

This test method is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealantsand is the direct responsibility of Subcommittee C24.20 on General

Test Methods.

Current edition approved July 1, 2014June 1, 2022. Published August 2014July 2022. Originally approved in 1972. Last previous edition approved in 20092014 as

C711 – 03C711 – 14.(2009). DOI: 10.1520/C0711-14.10.1520/C0711-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C711 − 22

temperature. In addition, it can aid in identifying sealants that have poor flexibility because they are overextended and contain a

very low level of elastomeric binder as well as those sealants having binders that will embrittle at low temperature.

5. Apparatus

5.1 Aluminum Panels, 3, three, thin, approximately 3 in. (76 mm) wide by 5 in. (127 mm) long by 0.012 in. (0.30 mm) thick.

5.2 Spatula, steel, with thin knife edge.

(a) Complete Cracking and Adhesive Failure (b) Severe Cracking

(c) No Cracking or Adhesive Failure

FIG. 1 Low-Temperature Flexibility (Tenacity)

2

---------------------- Page: 2 ----------------------

C711 − 22

1 3

5.3 Template, rectangular, of steel or brass, ⁄8 in. (3.2 mm) high, 1 in. by 3 ⁄4 in. (25 mm by 95 mm) inside and approximately

3

2 in. by 4 ⁄4 in. (51 mm by 121 mm) outside.

5.4 Oven, forced-draft type, having a temperature controlled at 158 °F 6 3.6°F 3.6 °F (70 °C 6 2°C).2 °C).

5.5 Freezer Chest or Cold Box, having a controlled temperature of −10 °F 6 5°F 5 °F (−23 °C 6 3°C).3 °C).

1

5.6 Mandrel or Rod, with a diameter of ⁄4 in. (6.4 mm), with a suitable holder or rack to support it.

5.7 Methyl Ethyl Ketone, or similar solvent.

6. Sampling

6.1 TakeCreate the test specimen from a previously unopened container of sealant as received from the sealant manufacturer.

7. Test Specimens

7.1 Prepare three test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.