ASTM F3561-22

(Test Method)Standard Test Method for Forced-Entry-Resistance of Fenestration Systems After Simulated Active Shooter Attack

Standard Test Method for Forced-Entry-Resistance of Fenestration Systems After Simulated Active Shooter Attack

SIGNIFICANCE AND USE

5.1 The test requirements specified herein have been established for use in evaluating the forced-entry resistance characteristics of assemblies to be used in commercial, residential, schools, government, and other institutional installations where the risk of a single person active shooter attack is present.

5.2 The procedures of this test method are intended to evaluate the ability to create an opening of sufficient size to permit passage of a test shape through it.

5.3 The procedure presented herein is based on post-event examination and are not intended to be used to establish or confirm the absolute prevention of forced entries.

SCOPE

1.1 This test method sets forth the requirements and testing procedures to test forced-entry-resistant building components, construction components, and specialty security equipment. This test method is intended primarily for manufacturers to test and rate their windows, doors, modular panels, glazings, and similar products to ensure that all manufactured products meet the necessary requirements for forced-entry protection after sustaining an active shooter assault.

1.2 This test method is currently designed to simulate an active shooter weakening the system with repetitive shots followed by mechanically driven impact to simulate forced entry.

1.3 This test method is not to be used for ballistic resistant glazing rating. Test projectiles are permitted to perforate the entire specimen. The test projectile firings are intended to simulate actions taken by an assailant to aid in the ability to gain entry to a facility.

1.4 This is a laboratory test to be performed on full systems and therefore not applicable for field testing.

1.5 All tests are executed on the exterior surface of the fenestration.

1.6 Systems are required to be tested as complete units in a test frame or fielded conditions. Mulled systems must be tested in the mulled condition. Test results only apply to the component or system as tested. Once a system is tested and deemed to satisfy the requirements of this test method, no design change can be made without a retest except those that qualify under Annex A1 Substitution Criteria.

1.7 Components (such as glazing, door leaves, etc.) may be tested in accordance with Appendix X1, receiving a capability statement for the component, but not a system rating per this standard.

1.8 Window and door systems shall be rated to at least a minimum level of Test Methods F476, F588, or F842, or combinations thereof, as appropriate prior to commencing this test evaluation. This test does not dual certify to the above mentioned standards.

1.9 The values stated in this standard are SI units with the exception of the nominal descriptors for tools.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3561 − 22

Standard Test Method for

Forced-Entry-Resistance of Fenestration Systems After

1

Simulated Active Shooter Attack

This standard is issued under the fixed designation F3561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope combinations thereof, as appropriate prior to commencing this

test evaluation. This test does not dual certify to the above

1.1 This test method sets forth the requirements and testing

mentioned standards.

procedures to test forced-entry-resistant building components,

construction components, and specialty security equipment. 1.9 The values stated in this standard are SI units with the

This test method is intended primarily for manufacturers to test exception of the nominal descriptors for tools.

and rate their windows, doors, modular panels, glazings, and

1.10 This standard does not purport to address all of the

similar products to ensure that all manufactured products meet

safety concerns, if any, associated with its use. It is the

the necessary requirements for forced-entry protection after

responsibility of the user of this standard to establish appro-

sustaining an active shooter assault.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.2 This test method is currently designed to simulate an

1.11 This international standard was developed in accor-

active shooter weakening the system with repetitive shots

dance with internationally recognized principles on standard-

followed by mechanically driven impact to simulate forced

ization established in the Decision on Principles for the

entry.

Development of International Standards, Guides and Recom-

1.3 This test method is not to be used for ballistic resistant

mendations issued by the World Trade Organization Technical

glazing rating. Test projectiles are permitted to perforate the

Barriers to Trade (TBT) Committee.

entire specimen. The test projectile firings are intended to

simulate actions taken by an assailant to aid in the ability to

2. Referenced Documents

gain entry to a facility.

2

2.1 ASTM Standards:

1.4 This is a laboratory test to be performed on full systems

A36/A36M Specification for Carbon Structural Steel

and therefore not applicable for field testing.

A574 Specification for Alloy Steel Socket-Head Cap Screws

1.5 All tests are executed on the exterior surface of the

C719 Test Method for Adhesion and Cohesion of Elasto-

fenestration.

meric Joint Sealants Under Cyclic Movement (Hockman

Cycle)

1.6 Systems are required to be tested as complete units in a

C1036 Specification for Flat Glass

test frame or fielded conditions. Mulled systems must be tested

C1048 Specification for Heat-Strengthened and Fully Tem-

in the mulled condition. Test results only apply to the compo-

pered Flat Glass

nent or system as tested. Once a system is tested and deemed

C1135 Test Method for Determining Tensile Adhesion Prop-

to satisfy the requirements of this test method, no design

erties of Structural Sealants

change can be made without a retest except those that qualify

C1172 Specification for Laminated Architectural Flat Glass

under Annex A1 Substitution Criteria.

D1415 Test Method for Rubber Property—International

1.7 Components (such as glazing, door leaves, etc.) may be

Hardness

tested in accordance with Appendix X1, receiving a capability

D3575 Test Methods for Flexible Cellular Materials Made

statement for the component, but not a system rating per this

from Olefin Polymers

standard.

E631 Terminology of Building Constructions

1.8 Window and door systems shall be rated to at least a E3062/E3062M Specification for Indoor Ballistic Test

minimum level of Test Methods F476, F588, or F842, or Ranges for Small Arms and Fragmentation Testing of

1

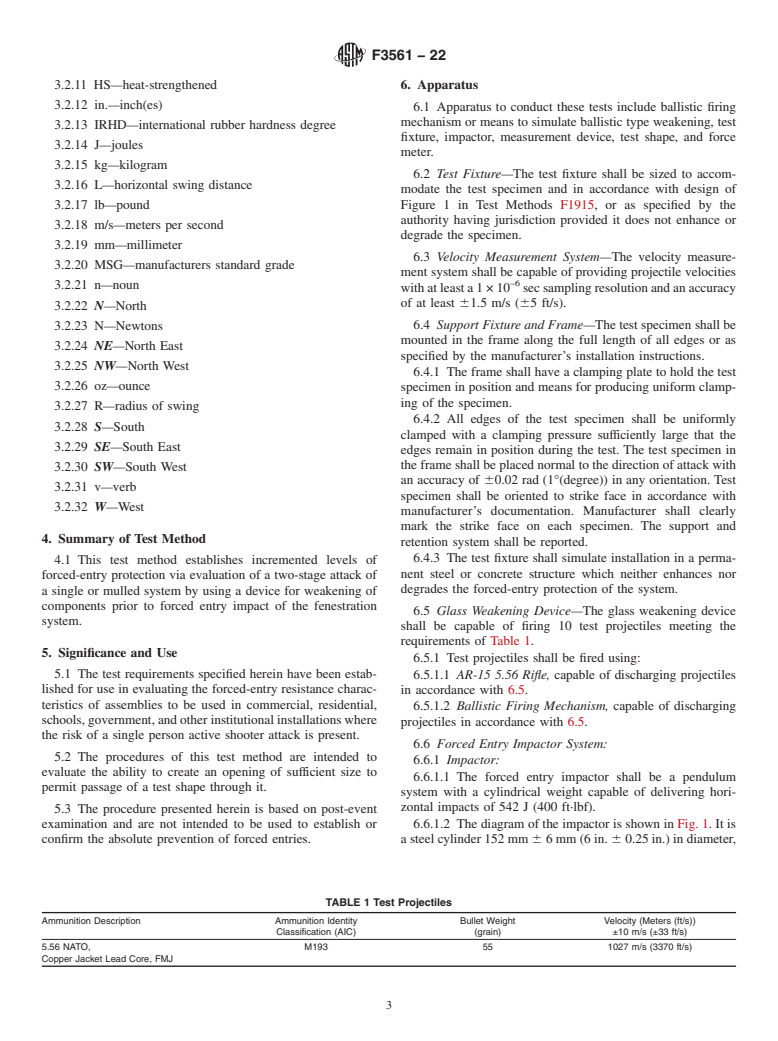

This test method is under the jurisdiction of ASTM Committee F12 on Security

2

Systems and Equipment and is the direct responsibility of Subcommittee F12.10 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Systems Products and Services. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Aug. 1, 2022. Published August 2022. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3561-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3561 − 22

Ballistic-resistant Items specimen shall consist of the entire fenestration assembly and

F476 Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.