ASTM D3212-20

(Specification)Standard Specification for Joints for Drain and Sewer Plastic Pipes Using Flexible Elastomeric Seals

Standard Specification for Joints for Drain and Sewer Plastic Pipes Using Flexible Elastomeric Seals

ABSTRACT

This specification covers joints for plastic pipe systems intended for drain, and gravity sewerage pipe at internal or external pressures less than a certain ft. head using flexible watertight elastomeric seals. The joints are classified into two types based on effecting watertightness through compression of an elastomeric seal or ring: push-on-joint is a joint in which an elastomeric ring gasket is compressed in the annular space between a bell end or socket and a spigot end of pipe and mechanical joint is a joint made using mechanical means or devices to develop a pressure seal. Joints shall not leak when subjected to the internal and external hydrostatic tests. All surfaces of the joint upon or against which the gasket bears shall be smooth and free of cracks, fractures, or imperfections. The gasket shall be the sole element depended upon to make the joint flexible and watertight. The gasket shall be a continuous elastomeric ring. In mechanical joints, the pipe spigot shall have a wall thickness sufficient to withstand, without deformation or collapse, the compressive force exerted when the fitting is tightened. Some joint designs provide for the angular deflection of a pipe joint, without reducing watertightness. Where greater deflections are required than permitted by the joint design, suitable fittings must be provided. The joint components shall be of such design that they will withstand the forces caused by the compression of the gasket when joined without cracking or fracturing when tested. Dimensions of joint components and gaskets shall meet the requirements specified. Test methods such as internal pressure test and vacuum test shall be performed.

SCOPE

1.1 This specification covers joints for plastic pipe systems intended for drain, and gravity sewerage pipe at internal or external pressures less than 25-ft head using flexible watertight elastomeric seals. This specification is intended to cover the test requirements, test methods, and acceptable materials. The test methods described for the joints are not intended to be routine quality control tests but to be reliability or performance requirements.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The following safety hazards caveat pertains only to the test method portion, paragraph 7.5, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3212 −20 An American National Standard

Standard Specification for

Joints for Drain and Sewer Plastic Pipes Using Flexible

1

Elastomeric Seals

This standard is issued under the fixed designation D3212; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

1.1 This specification covers joints for plastic pipe systems

F477 Specification for Elastomeric Seals (Gaskets) for Join-

intended for drain, and gravity sewerage pipe at internal or

ing Plastic Pipe

external pressures less than 25-ft head using flexible watertight

F913 Specification for Thermoplastic Elastomeric Seals

elastomeric seals. This specification is intended to cover the

(Gaskets) for Joining Plastic Pipe

test requirements, test methods, and acceptable materials. The

F1674 Test Method for Joint Restraint Products for Use with

test methods described for the joints are not intended to be

PVC Pipe

routine quality control tests but to be reliability or performance

requirements.

3. Types

1.2 The text of this specification references notes, footnotes,

3.1 This specification covers two types of joints based on

and appendixes which provide explanatory material. These

effectingwatertightnessthroughcompressionofanelastomeric

notesandfootnotes(excludingthoseintablesandfigures)shall

seal or ring:

not be considered as requirements of the specification.

3.1.1 Push-on Joint—A joint in which an elastomeric ring

1.3 The following safety hazards caveat pertains only to the

gasket is compressed in the annular space between a bell end

test method portion, paragraph 7.5, of this specification: This

or socket and a spigot end of pipe.

standarddoesnotpurporttoaddressallofthesafetyconcerns,

3.1.2 Mechanical Joint—A joint made using mechanical

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

means or devices to develop a pressure seal.

of this standard to establish appropriate safety, health, and

environmental practices and determine the applicability of

4. Materials

regulatory limitations prior to use.

1.4 This international standard was developed in accor-

4.1 Material used for elastomeric seal in push-on joints

dance with internationally recognized principles on standard-

shall meet the requirements of either Specification F477 or

ization established in the Decision on Principles for the

F913.

Development of International Standards, Guides and Recom-

4.2 Lubricant, if required, shall be suitable for lubricating

mendations issued by the World Trade Organization Technical

the parts of the joints in the assembly. The lubricant shall have

Barriers to Trade (TBT) Committee.

no deteriorating effects on the gasket and pipe materials.

2. Referenced Documents

5. General Requirements

2

2.1 ASTM Standards:

D1598 Test Method for Time-to-Failure of Plastic Pipe 5.1 Joints shall not leak when subjected to the internal and

Under Constant Internal Pressure external hydrostatic tests of Section 7 for a period of 10 min.

5.2 All surfaces of the joint upon or against which the

gasket bears shall be smooth and free of cracks, fractures, or

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

imperfections.

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

Current edition approved Nov. 15, 2020. Published December 2020. Originally

5.3 Drawings—The manufacturer shall furnish drawings of

approved in 1973. Last previous edition approved in 2020 as D3212 – 07(2020).

the joint and gasket if requested by the purchaser.

DOI: 10.1520/D3212-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.4 The gasket shall be the sole element depended upon to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

make the joint flexible and watertight. The gasket shall be a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. continuous elastomeric ring.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3212−20

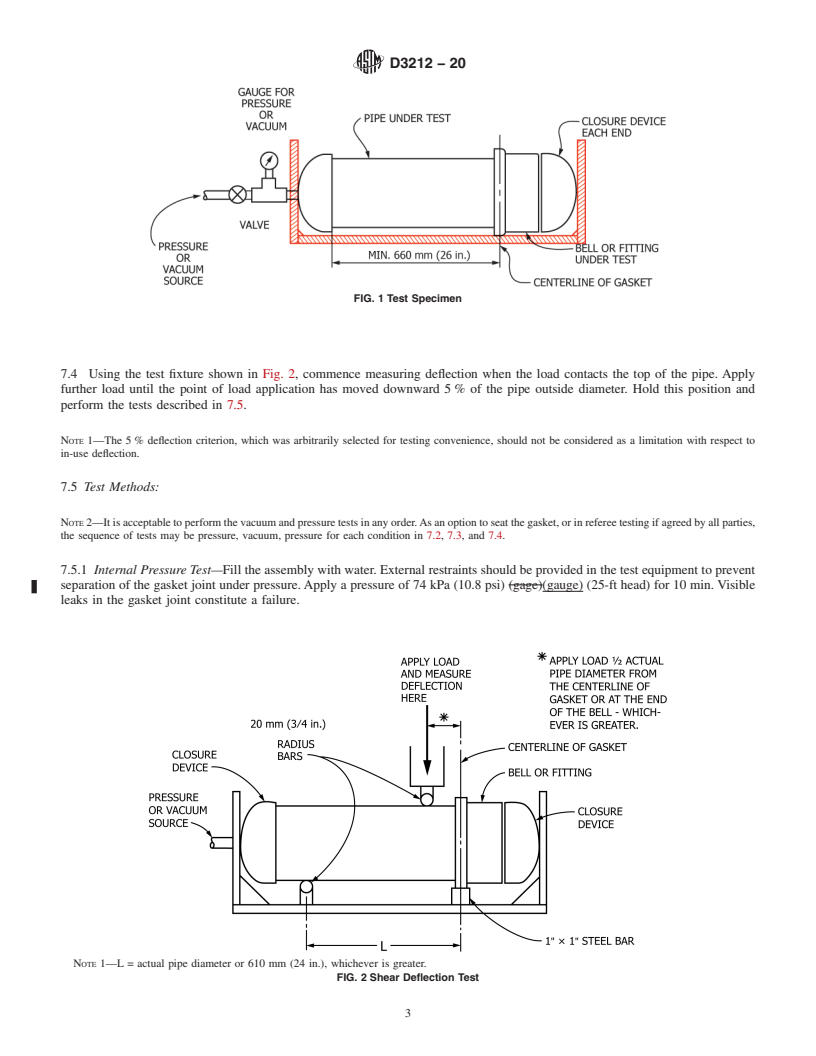

5.5 In mechanical joints, the pipe spigot shall have a wall 7.4 Using the test fixture shown in Fig. 2, commence

thickness sufficient to withstand, without deformation or measuring deflection when the load contacts the top of the

collapse, the compressive force exerted when the fitt

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3212 − 07 (Reapproved 2020) D3212 − 20 An American National Standard

Standard Specification for

Joints for Drain and Sewer Plastic Pipes Using Flexible

1

Elastomeric Seals

This standard is issued under the fixed designation D3212; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 This specification covers joints for plastic pipe systems intended for drain, and gravity sewerage pipe at internal or external

pressures less than 25-ft head using flexible watertight elastomeric seals. This specification is intended to cover the test

requirements, test methods, and acceptable materials. The test methods described for the joints are not intended to be routine

quality control tests but to be reliability or performance requirements.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The following safety hazards caveat pertains only to the test method portion, paragraph 7.5, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

F477 Specification for Elastomeric Seals (Gaskets) for Joining Plastic Pipe

F913 Specification for Thermoplastic Elastomeric Seals (Gaskets) for Joining Plastic Pipe

F1674 Test Method for Joint Restraint Products for Use with PVC Pipe

3. Types

3.1 This specification covers two types of joints based on effecting watertightness through compression of an elastomeric seal or

ring:

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

Current edition approved Feb. 1, 2020Nov. 15, 2020. Published March 2020December 2020. Originally approved in 1973. Last previous edition approved in 20132020

as D3212 – 07(2013).(2020). DOI: 10.1520/D3212-07R20.10.1520/D3212-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3212 − 20

3.1.1 Push-on Joint—A joint in which an elastomeric ring gasket is compressed in the annular space between a bell end or socket

and a spigot end of pipe.

3.1.2 Mechanical Joint—A joint made using mechanical means or devices to develop a pressure seal.

4. Materials

4.1 Material used for elastomeric seal in push-on joints shall meet the requirements of either Specification F477 or F913.

4.2 Lubricant, if required, shall be suitable for lubricating the parts of the joints in the assembly. The lubricant shall have no

deteriorating effects on the gasket and pipe materials.

5. General Requirements

5.1 Joints shall not leak when subjected to the internal and external hydrostatic tests of Section 7 for a period of 10 min.

5.2 All surfaces of the joint upon or against which the gasket bears shall be smooth and free of cracks, fractures, or imperfections.

5.3 Drawings—The manufacturer shall furnish drawings of the joint and gasket if requested by the purchaser.

5.4 The gasket shall be the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.