ASTM F667/F667M-16(2021)

(Specification)Standard Specification for 3 through 24 in. Corrugated Polyethylene Pipe and Fittings

Standard Specification for 3 through 24 in. Corrugated Polyethylene Pipe and Fittings

ABSTRACT

This specification covers requirements and test methods for materials, workmanship, dimensions, perforations, pipe stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, bond, and marking of corrugated polyethylene (PE) pipe and fittings. This specification covers tubularly extruded, spirally laminated, and rotationally molded corrugated polyethylene pipe. Corrugated PE pipe and fittings are intended for underground applications where soil provides support to their flexible walls. Their major use is to collect or convey drainage water, or both. The following tests shall be performed: dimensions and tolerances; pipe stiffness; elongation; pipe stiffness while elongated; joint-separation test; and brittleness.

SCOPE

1.1 This specification covers requirements and test methods for materials, workmanship, dimensions, perforations, pipe stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, bond, and marking of corrugated polyethylene (PE) pipe and fittings. It covers nominal sizes 3 in. [76 mm], 4 in. [102 mm], 5 in. [127 mm] 6 in. [152 mm], 8 in. [203 mm], 10 in. [254 mm], 12 in. [305 mm], 15 in. [381 mm], 18 in. [457 mm], and 24 in. [610 mm].

1.2 This specification covers tubularly extruded, spirally laminated, and rotationally molded corrugated polyethylene pipe.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F667/F667M −16 (Reapproved 2021)

Standard Specification for

3 through 24 in. Corrugated Polyethylene Pipe and Fittings

This standard is issued under the fixed designation F667/F667M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D2412Test Method for Determination of External Loading

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.1 This specification covers requirements and test methods

D2444Practice for Determination of the Impact Resistance

for materials, workmanship, dimensions, perforations, pipe

of Thermoplastic Pipe and Fittings by Means of a Tup

stiffness, elongation, joint separation resistance, quality of

(Falling Weight)

extruded polyethylene, brittleness, bond, and marking of cor-

D3350Specification for Polyethylene Plastics Pipe and Fit-

rugated polyethylene (PE) pipe and fittings. It covers nominal

tings Materials

sizes 3 in. [76 mm], 4 in. [102 mm], 5 in. [127 mm] 6 in. [152

F412Terminology Relating to Plastic Piping Systems

mm],8in.[203mm],10in.[254mm],12in.[305mm],15in.

F449Practice for Subsurface Installation of Corrugated

[381 mm], 18 in. [457 mm], and 24 in. [610 mm].

Polyethylene Pipe for Agricultural Drainage or Water

1.2 This specification covers tubularly extruded, spirally

Table Control

laminated, and rotationally molded corrugated polyethylene

2.2 Federal Standard:

pipe.

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

1.3 The values stated in inch-pound units are to be regarded

2.3 Military Standard:

as standard. The values given in parentheses are mathematical

MIL-STD-129Marking for Shipment and Storage

conversions to SI units that are provided for information only

and are not considered standard.

3. Terminology

1.4 The following precautionary caveat pertains only to the

3.1 Definitions—Definitions used in this specification are in

test method portion, Section 9, of this specification: This

accordance with Terminology F412, unless otherwise noted.

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

3.2 Definitions:

of this standard to establish appropriate safety, health, and

3.2.1 split—any break or crack that extends through the

environmental practices and determine the applicability of

wall.

regulatory limitations prior to use.

3.2.2 crease—a deformation that cannot be removed like a

1.5 This international standard was developed in accor-

dent: generally associated with wall buckling.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.1 Corrugated PE pipe and fittings are intended for under-

Barriers to Trade (TBT) Committee.

ground applications where soil provides support to their

flexible walls.Their major use is to collect or convey drainage

2. Referenced Documents

water, or both.

2.1 ASTM Standards:

4.2 Exclusions from Recommended Use:

D618Practice for Conditioning Plastics for Testing

4.2.1 Exposure to flame at any time,

4.2.2 Permanent exposure to sunlight or weathering, or

1 both, and

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land

4.2.3 Exposure to chemicals, other than those normally

Drainage.

found in ground water, whose compatibility with the tubing

Current edition approved April 1, 2021. Published April 2021. Originally

and fittings is not known.

approved in 1980. Last previous edition approved in 2016 as F667/F667M–16.

DOI: 10.1520/F0667_F0667M-16R21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA

the ASTM website. 19111-5094 http://quicksearch.dla.mil/

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F667/F667M − 16 (2021)

5. Materials and circumference of the pipe in a size, shape, and pattern

suited to the needs of the user.

5.1 Basic Materials—Compounds used in the manufacture

7.3.2 The inlet area of the perforations shall be a minimum

of corrugated PE drainage pipe and fittings shall have a

2 2

of 1 in. /ft [21 cm /m] of pipe, unless otherwise specified by

minimumcellclassificationof323410Cor333410Casdefined

the user.

and described in Specification D3350. Compounds that have a

higher cell classification in one or more properties are 7.4 Pipe Stiffness—The pipe shall have a minimum pipe

acceptable, provided the product requirements are met.

stiffnessof30psi[0.21MPa]at5%deflectionand25psi[0.18

MPa] at 10% deflection, when tested in accordance with 9.5.

NOTE1—ClassBpigmentsmaybesubstitutedforClassCprovidedthat

ultraviolet protection is acceptable to the publisher as satisfactory for the

7.5 Elongation—Continuously extruded pipe that elongates

intended use.

more than 5%, but less than 10%, when tested in accordance

5.2 Rework Material—Clean rework material, generated

with 9.6, shall meet the requirements of 7.4 when tested in

from the manufacturer’s own production of the product, may accordance with 9.7. Pipe that elongates more than 10% shall

be used by the manufacturer provided that the tubing and

be rejected.

fittings produced meet all requirements of this specification.

7.6 Brittleness—Pipeandfittingspecimensshallbetestedin

accordance with 9.9.

6. General Requirements

7.7 Bond—The bond between layers of spirally laminated

6.1 Workmanship—The pipe and fittings shall be homog-

pipe shall be strong and uniform. There shall be no separation

enous throughout and essentially uniform in color, opacity,

of layers when the pipe is deflected 20%, in accordance with

density, and other properties. The inside and outside surfaces

Test Method D2412, nor shall it be possible to separate the

shall be semimatte or glossy in appearance (depending on the

layerswiththepointofaknifewhenthepipeisinthedeflected

type of plastic) and free of chalking, sticky, or tacky material.

condition.

Thepipeandfittingwallsshallbefreeofcracks,holes,blisters,

voids,foreigninclusions,orotherdefectsthatarevisibletothe

NOTE 3—This test may be conducted as a continuation of pipe stiffness

naked eye and that may affect the wall integrity. Holes testing as specified in 9.5.

NOTE 4—Until an ASTM specification for an acceptable stress-crack

deliberately placed in perforated pipe are acceptable. The

testispublished,environmentalstresscrackingshouldbeevaluatedbythe

surface shall be free of excessive bloom. Bloom or chalking

user on the basis of data furnished by the manufacturer.

may develop in pipe exposed to the direct rays of the sun

7.8 Fitting Requirements:

(ultravioletradiantenergy)forextendedperiods;consequently,

7.8.1 The fittings shall not reduce or impair the overall

these requirements do not apply to pipe and fittings after

integrity or function of the pipe line.

extended exposure to direct rays of the sun.

NOTE5—Commoncorrugatedfittingsincludein-linejointfittings,such

NOTE 2—Wall thickness may vary within each corrugation.Variation is

as tees, Y’s, reducers, couplers, elbows, and end caps. These fittings are

acceptable provided the tubing meets all physical requirements.

installed internally or externally by various methods, such as snap-on,

V-insertion, screw-on, or wrap around.

7. Detail Requirements

NOTE 6—Some corrugated fittings will not fit all pipe. Only fittings

7.1 General:

supplied or recommended by the pipe manufacturer should be used.

7.1.1 Thefollowingrequirementsshallbemetbyperforated

7.8.2 Joints made with couplers, installed in accordance

or nonperforated pipe, as applicable.

with the manufacturer’s instructions, shall not separate when

7.1.2 Individual results shall be used to determine compli-

tested in accordance with 9.8.

ance with the requirements, unless otherwise stated.

7.8.3 Fitting specimens shall not crack or split when tested

7.2 Dimensions and Tolerances:

in accordance with 9.9.

7.2.1 Pipe:

7.2.1.1 Nominal Diameter—The nominal diameter of the

8. Sampling and Retest

pipeshallbetheaverageinsidediameterroundedtothenearest

8.1 Sampling—Samples of pipe and fittings sufficient to

whole number.

determineconformancewiththisspecificationshallbetakenat

7.2.1.2 Inside Diameter—The tolerance on the nominal

random from stock by the testing agency. Samples shall be

inside diameter shall be +3%; −1.5%, when measured in

representative of the product type under consideration.

accordance with 9.3.

8.2 Retest and Rejection—Ifanytestfailureoccurs,thepipe

7.2.1.3 Length—The pipe may be sold in any length agree-

orfittingmayberetestedtoestablishconformity.Thetestshall

able to the user. Length shall not be less than 99% of stated

be repeated on two additional samples from the same lot or

quantity, when measured in accordance with 9.4.

shipment.Ifeitherofthesetwoadditionalsamplesfail,thepipe

7.2.2 Fittings:

or fitting does not comply with this specification.

7.2.2.1 The maximum allowable gap between pipe and

fitting shall not exceed ⁄8 in. [3 mm] unless otherwise

9. Test Methods

specified.

7.3 Perforations: 9.1 Conditioning Test Specimens—Condition the specimen

7.3.1 Drainage Pipe—When perforations are necessary, prior to test at 73.4°F 6 3.6°F [23°C 6 2°C] and 50% 6

theyshallbecleanlycutanduniformlyspacedalongthelength 5% relative humidity for not less than 40 h prior to the test, in

F667/F667M − 16 (2021)

accordance with Procedure A in Practice D618 for those tests elongation 3100

E,% 5

where conditioning is required, unless otherwise specified. gaugelength

9.2 Test Conditions—Conduct tests in laboratory atmo- Calculate the average of the three values.

sphere of 73.4°F 6 3.6°F [23°C 6 2°C] and 50% 65%

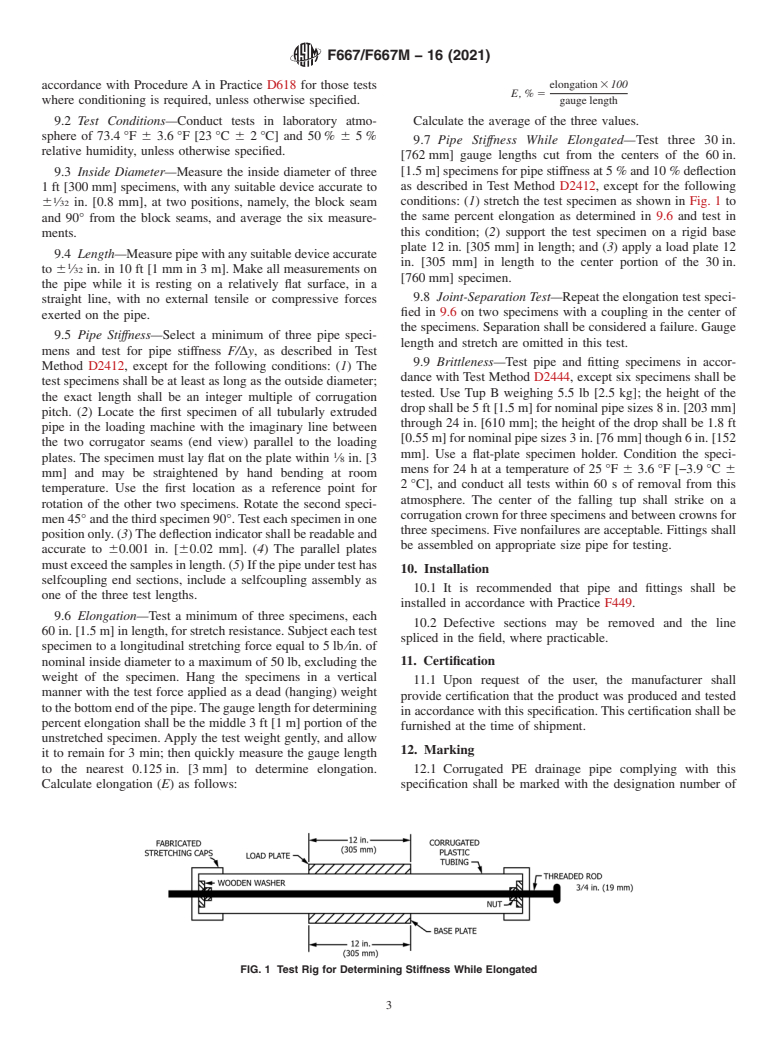

9.7 Pipe Stiffness While Elongated—Test three 30 in.

relative humidity, unless otherwise specified.

[762mm] gauge lengths cut from the centers of the 60in.

[1.5m]specimensforpipestiffnessat5%and10%deflection

9.3 Inside

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.