ASTM D5632-95

(Specification)Standard Specification for Halon 1301, Bromotrifluoromethane (CF3Br)

Standard Specification for Halon 1301, Bromotrifluoromethane (CF<sub>3</sub>Br)

SCOPE

1.1 This specification covers the requirements for Halon 1301 as a fire-fighting medium.

1.2 This specification does not address the fire-fighting equipment or hardware that employs Halon 1301 or the conditions of employing such equipment (for example, handhelds, fixed installations, etc.).

1.3 This specification does not address the storage or transportation of Halon 1301. Storage, handling, and transportation issues are addressed in Practice D 5631.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in 4.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5632 – 95 An American National Standard

Standard Specification for

Halon 1301, Bromotrifluoromethane (CF Br)

This standard is issued under the fixed designation D 5632; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers requirements for Halon 1301 3.1 Definitions of Terms Specific to This Standard:

as a fire-fighting medium. 3.1.1 halon—a halogenated hydrocarbon used as a fireex-

1.2 This specification does not address the fire-fighting tinguishing medium.

equipment or hardware that employs Halon 1301 or the 3.1.1.1 Discussion—The halon terminology system pro-

conditions of employing such equipment (for example, hand- vides a convenient means to reference halogenated hydrocar-

helds, fixed installations, etc.). bon fire extinguishants. Halogenated hydrocarbons are acyclic

1.3 This specification does not address the storage or saturated hydrocarbons in which one or more of the hydrogen

transportation of Halon 1301. Storage, handling, and transpor- atoms have been replaced by atoms from the halogen series

tation issues may be addressed in future ASTM specifications. (that is, fluorine, chlorine, bromine, and iodine). By definition,

1.4 The following safety hazards caveat pertains only to the the first digit of the halon numbering system represents the

test methods portion, Section 6, of this specification: This number of carbon atoms in the compound molecule; the second

standard does not purport to address all of the safety concerns, digit, the number of fluorine atoms; the third digit, the number

if any, associated with its use. It is the responsibility of the user of chlorine atoms; the fourth digit, the number of bromine

of this standard to establish appropriate safety and health atoms; and the fifth digit, the number of iodine atoms. Trailing

practices and determine the applicability of regulatory limita- zeros are not expressed. Unaccounted for valence requirements

tions prior to use. Specific hazards statements are given in are assumed to be hydrogen atoms.

Note 1.

number of hydrogen atoms 5

@~~number of carbon atoms 3 2!1 2!2~sum of halogen atoms!#

2. Referenced Documents

(1)

2.1 ASTM Standards:

For example,

D 4081 Specification for Drycleaning Grade Perchloroeth-

2 bromotrifluoromethane 2 CF Br 2 Halon 1301 (2)

ylene

2.2 ISO Standards:

4. Material Requirements

ISO 3363 Fluorochlorinated Hydrocarbons for Industrial

3 4.1 Type I:

Use—Determination of Acidity—Titrimetric Method

4.1.1 The nitrogen (N ) partial pressure shall be such that

ISO 3427 Gaseous Halogenated Hydrocarbons (Liquified

3 the safe working pressure of the receiving vessel is not

Gases)—Taking of a Sample

exceeded. To prevent excessive pressure, the fill density of the

ISO 5789 Fluorinated Hydrocarbons for Industrial Use—

3 halon within a container should not exceed that needed to

Determination of Nonvolatile Residue

achieve complete filling of the container at the maximum

2.3 U.S. Military Standards:

envisaged storage temperature. For example, the U.S. DOT

MIL-STD-105 Sampling Procedures and Tables for Inspec-

4BA500 cylinder partial pressure shall not exceed 12.1 bar at

tion by Attributes

3 3

4 21°C (161 psig at 70°F) for a 1121-kg/m (70-lb/ft ) fill density

MIL-STD-129 Marking for Shipment and Storage

(yielding a total pressure of 25.8 bar at 21°C (360 psig at

MIL-STD-1188 Commercial Packaging of Supplies and

4 70°F)). For this example, the safe working pressure of the

Equipment

4BA500 cylinder is not exceeded for temperatures below 54°C

(130°F).

This specification is under the jurisdiction of ASTM Committee D-26 on 4.1.2 Halon 1301 shall conform to the requirements pre-

Halogenated Organic Solvents and Fire Extinguishing Agents and is the direct

scribed in Table 1 when tested by the appropriate test meth-

responsibility of Subcommittee D26.09 on Recycled Halon 1301.

od(s) listed in Section 6.

Current edition approved April 15, 1995. Published June 1995. Originally

4.1.3 When a material analysis is required, by agreement

published as D 5632 – 94a. Last previous edition D 5632 – 94a.

Annual Book of ASTM Standards, Vol 15.05.

between the purchaser and the supplier, the total pressure in the

Available from American National Standards Institute, 11 W. 42nd St., 13th

Halon 1301 container, partial pressure of the N , the fill density

Floor, New York, NY 10036.

4 of the halon within the container, and the maximum safe

Available from Standardization Documents Order Desk, Bld. 4 Section D, 700

Robbins Av., Philadelphia, PA 19111-5904, Attn: NPODS. storage temperature shall be part of the material analysis

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

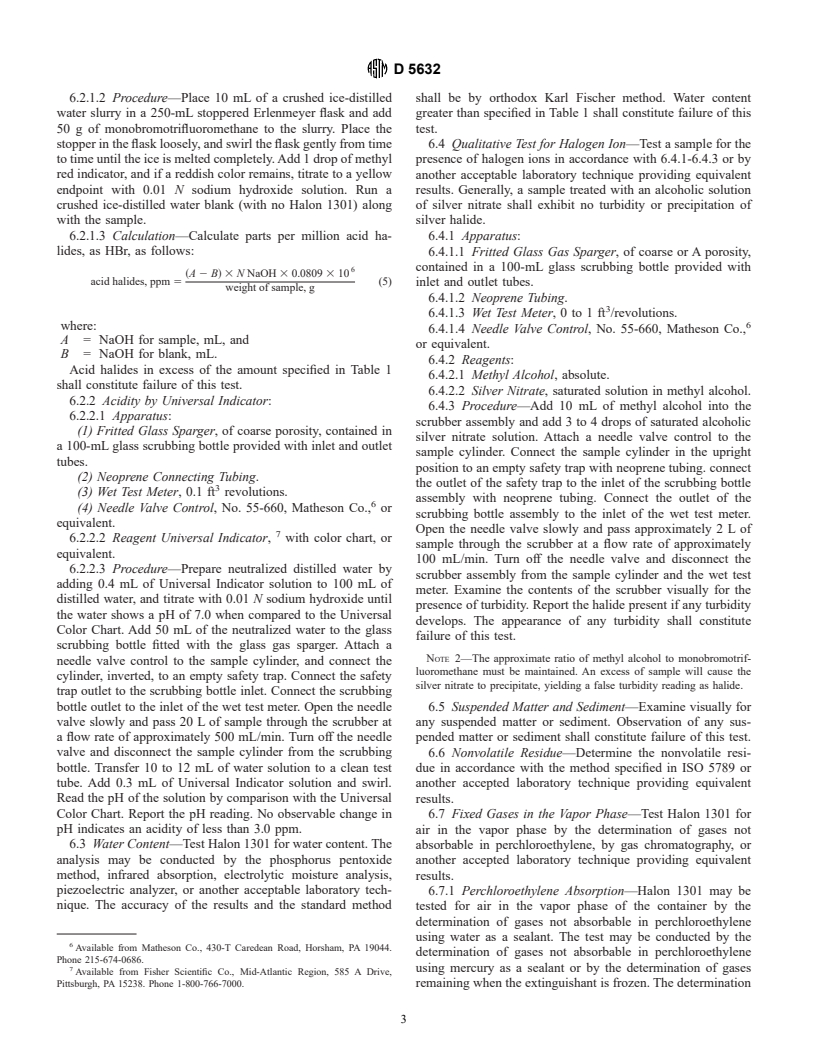

D 5632

TABLE 1 Requirements

6.1.2.3 Gas Sampling Valve, 5-mL volume or a volume

Property Requirement sufficient to achieve proper separation in the specified column.

6.1.3 Reagents—The carrier gas shall be a commercial

Halon 1301 purity, %, mol/mol, min 99.6 (exclusive of any N present)

Acidity, ppm by mass, max 3.0

grade of helium. The column packing shall consist of a

Water content, ppm by mass, max 10

standard solution, for example, 20 % (weight/weight) practical

Nonvolatile residue, % by weight, max 0.01

hexadecane, on 80 to 100-mesh Porapak Q or equivalent.

Halogen ion passes test

suspended matter or sediment none visible

6.1.4 Procedure:

6.1.4.1 Install the column and adjust the temperature of the

column oven to 80°C, injection port to 160°C, and detector

block to 100 to 110°C. The temperature should be programmed

(certification). The pressure shall be reported in bar (preferred)

to rise 10 to 15°C/min, to a maximum of 180°C.

or pound-force per square inch gage. The fill density shall be

6.1.4.2 Adjust the helium flow to 20 mL/min.

reported in kilograms per cubic metre at 21°C (preferred) or

pounds per cubic foot at 70°F. The maximum safe storage 6.1.4.3 Adjust the detector voltage to 8 V or to the mid-

range of the thermal conductivity detector (TCD) instrument

temperature of the Halon 1301 container shall be reported in

degrees Celsius (preferred) or in degrees Fahrenheit and shall being used and allow the instrument to stabilize.

6.1.4.4 Take the sample from the liquid phase (inverted

conform to applicable regulations for the Halon 1301 container

design and use. cylinder). Flush the sample loop and sample valve for approxi-

mately 30 s before sampling.

4.2 Type II—Halon 1301 shall conform to the requirements

of Type I, as listed in 4.1, and shall contain no more than 1.5 % 6.1.4.5 Rotate the gas sampling valve to transfer the sample

by volume fixed gases in vapor phase, expressed as air when into the chromatographic system and note the time.

tested by the appropriate test method(s) listed in Section 6.

6.1.4.6 Close the sample cylinder valve.

4.3 By agreement between the purchaser and the supplier,

6.1.4.7 Allow the sample to elute, for approximately 18

analysis may be required and limits established for elements or

min, attenuating as necessary to make the peak heights a

compounds not specified in Table 1. convenient size. Under proper instrument settings, the Halon

1301 should elute after approximately 5 min.

NOTE 1—Warning: Exposure to concentrations of Halon 1301 in

6.1.5 Calculation:

excess of 10 % (halon volume/air volume) during periods of elevated

adrenaline could produce cardiac arrhythmia in some personnel. 6.1.5.1 Calculate percent Halon 1301 as follows:

A~CF Br!

4.4 Unless otherwise specified, Type I is assumed.

%CF Br 5 3 100

A

s

(3)

5. Sampling

5.1 Samples of halons, taken from the liquid phase, shall be

where:

taken from filled containers in accordance with the method

A(CF Br) = area of monobromotrifluoromethane peak

specified in ISO 3427 or MIL-STD-105, Inspection Level S-4.

multiplied by recorder range setting, and

The sampling bottle shall be capable of safely resisting the

A = sum of the relative peak heights excluding

s

vapor pressure of the sample at the highest temperature that

the nitrogen (air) peak height.

could be encountered.

6.1.5.2 Percent nitrogen may be calculated as follows:

5.2 The Halon 1301 selected in accordance with 5.1 shall be

A

n

tested for quality conformance in accordance with Section 6. %N 5 3 100 (4)

A 1 A

s n

The presence of one or more defects shall be cause for

rejection.

where:

6. Test Methods A = area of nitrogen peak multiplied by the recorder

n

range setting, and

6.1 Purity:

A +A = sum of the relative peak heights including the

s n

6.1.1 Determine the purity by gas-liquid chromatography in

nitrogen peak.

accordance with the technique described in 6.1.2-6.1.5 or

It is useful to calculate percent nitrogen in order to judge a

another acceptable laboratory technique providing equivalent

safe fill density. Percent Halon 1301 below that specified in

results.

Table 1 shall constitute failure of this test method.

6.1.2 Apparatus—The following special apparatus is re-

6.2 Acidity—Vaporize a large sample in the presence of

quired to determine the percent of Halon 1301:

distilled water. Determine the acidity of the solution by the

6.1.2.1 Gas Chromatograph, equipped with a 1-mV re-

appropriate method specified in ISO 3363, titration in accor-

corder and thermal conductance detector.

1 dance with 6.2.1.2-6.2.2.3, a pH indicator, or another accept-

6.1.2.2 Column,3mby ⁄8-in. (3.175-mm) outside diameter

able laboratory technique providing equivalent results.

thin-wall stainless steel tubing, packed with 80 to 100 mesh

6.2.1 Sodium Hydroxide Titration:

Porapak Q or equivalent.

6.2.1.1 Reagents:

(1) Sodium Hydroxide, 0.01 N solution, standardized

5 against reagent grade potassium acid phthalate.

Available from Alltech, 2051 Waukegan Road, Deerfield, IL 60015. Phone

1-800-255-8325. (2) Methyl Red Indicator, 0.1 % solution.

-------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.