ASTM A414/A414M-09

(Specification)Standard Specification for Steel, Sheet, Carbon, for Pressure Vessels

Standard Specification for Steel, Sheet, Carbon, for Pressure Vessels

ABSTRACT

This specification covers hot-rolled carbon steel sheet for pressure vessels involving fusion welding or brazing. Tensile and yield strengths shall be determined after a tension test of the sheets. The material shall be furnished without removing the hot-rolled oxide or scale. When required, the material may be specified to be pickled or blast cleaned. When specified to be pickled or blast cleaned, the material shall be furnished oiled. When required, pickled or blast-cleaned material may be specified to be furnished dry.

SCOPE

1.1 This specification covers hot-rolled carbon steel sheet for pressure vessels involving fusion welding or brazing. Welding and brazing technique is of fundamental importance and shall be in accordance with commercial practices.

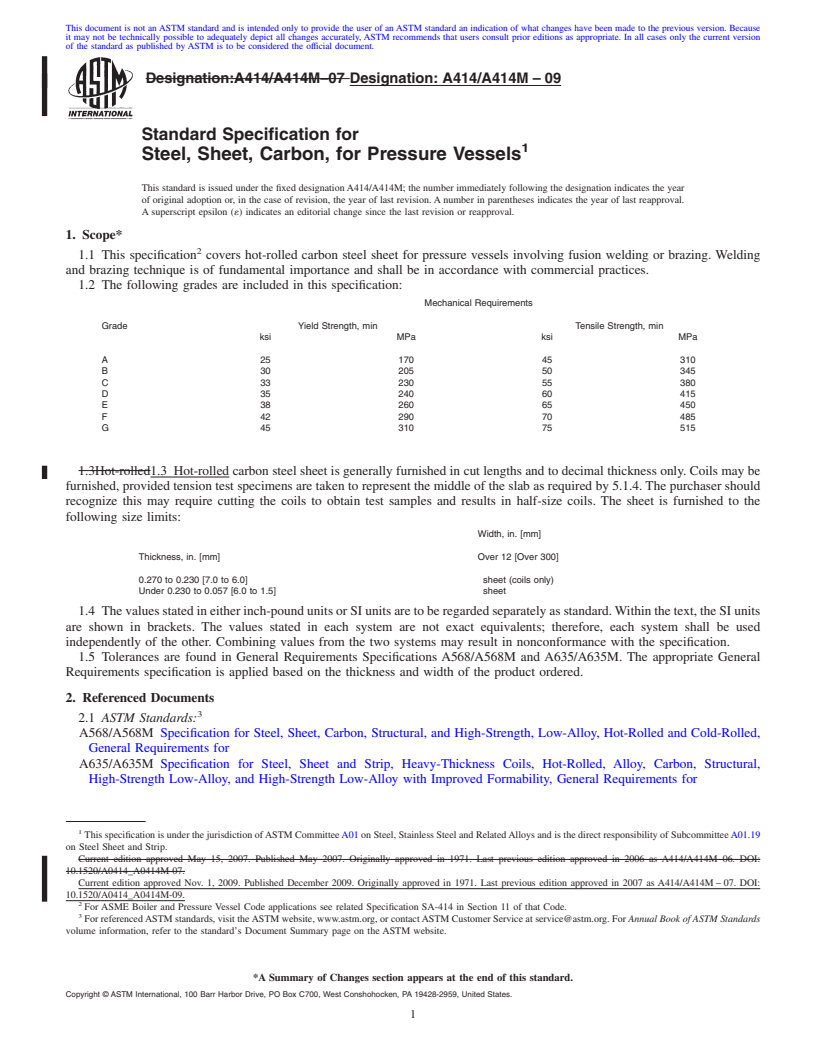

1.2 The following grades are included in this specification:

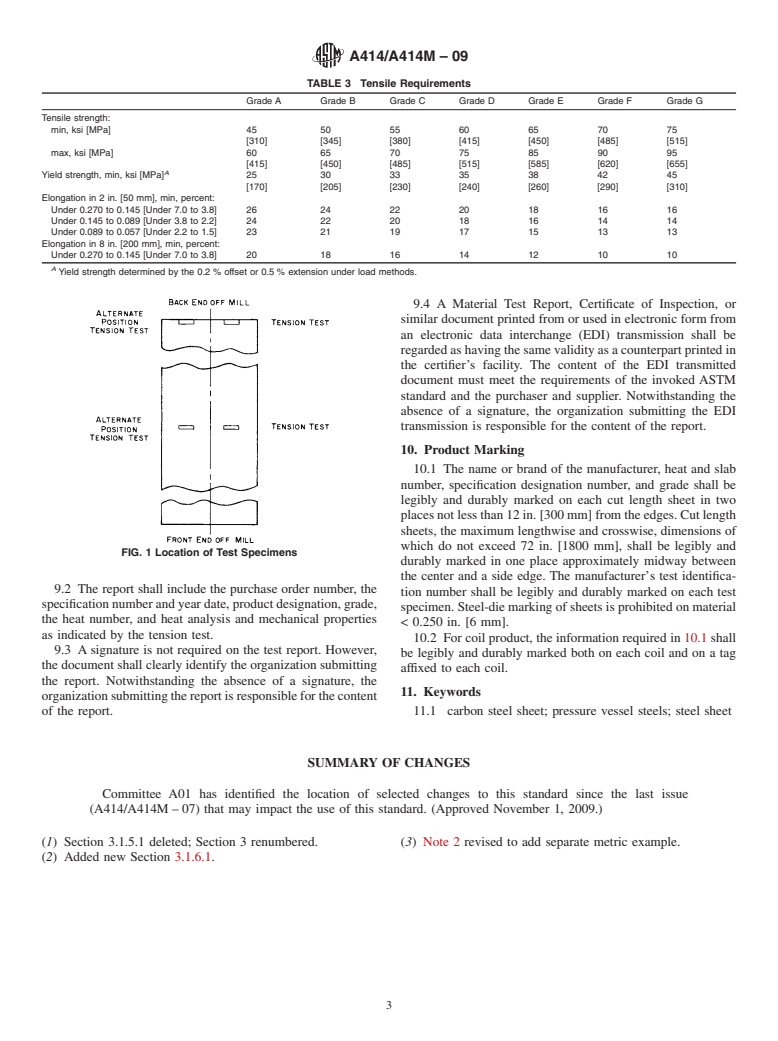

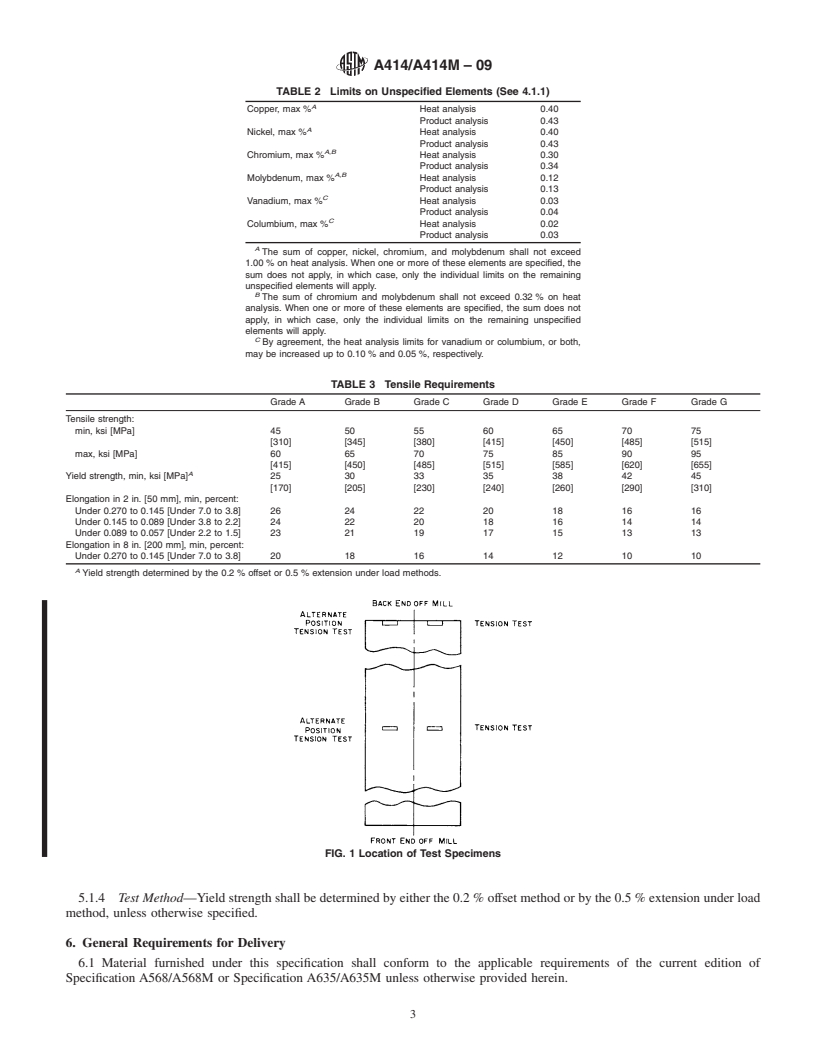

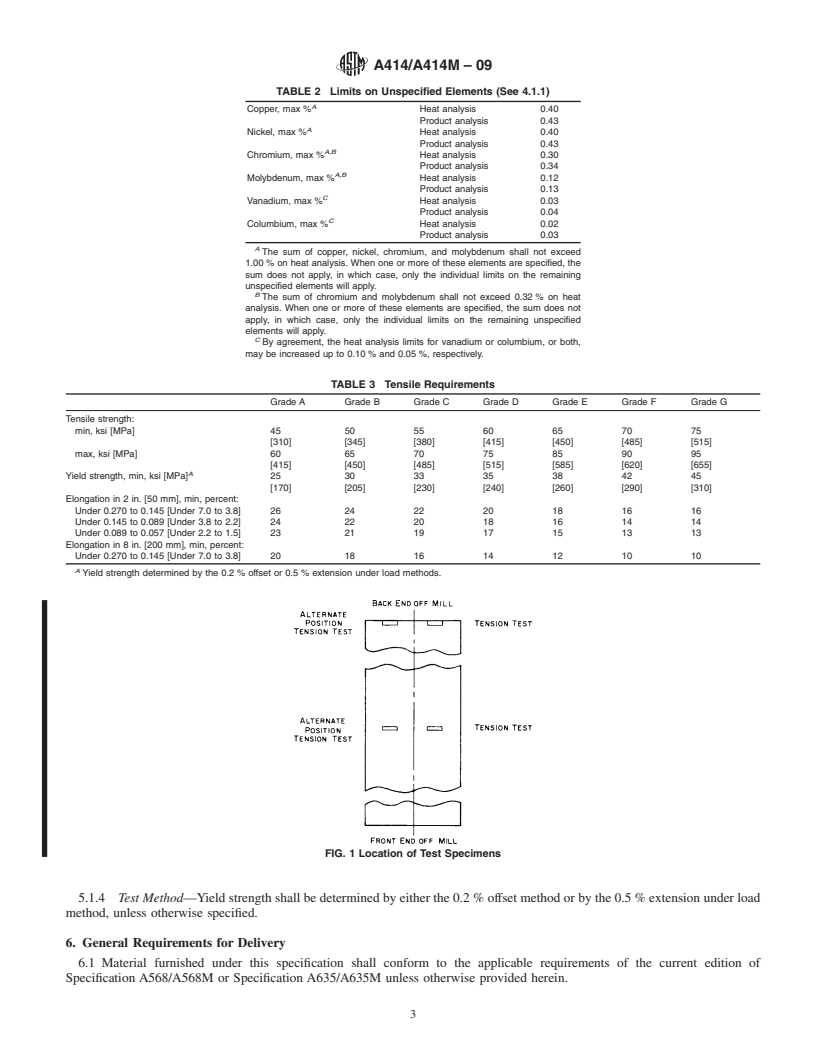

1.3 Hot-rolled carbon steel sheet is generally furnished in cut lengths and to decimal thickness only. Coils may be furnished, provided tension test specimens are taken to represent the middle of the slab as required by 5.1.4. The purchaser should recognize this may require cutting the coils to obtain test samples and results in half-size coils. The sheet is furnished to the following size limits:

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A414/A414M – 09

Standard Specification for

1

Steel, Sheet, Carbon, for Pressure Vessels

This standard is issued under the fixed designationA414/A414M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 Tolerances are found in General Requirements Specifi-

2

cationsA568/A568M andA635/A635M.The appropriate Gen-

1.1 This specification covers hot-rolled carbon steel sheet

eral Requirements specification is applied based on the thick-

for pressure vessels involving fusion welding or brazing.

ness and width of the product ordered.

Welding and brazing technique is of fundamental importance

and shall be in accordance with commercial practices.

2. Referenced Documents

1.2 The following grades are included in this specification:

3

2.1 ASTM Standards:

Mechanical Requirements

A568/A568M Specification for Steel, Sheet, Carbon, Struc-

Grade Yield Strength, min Tensile Strength, min

tural, and High-Strength, Low-Alloy, Hot-Rolled and

ksi MPa ksi MPa

Cold-Rolled, General Requirements for

A635/A635M Specification for Steel, Sheet and Strip,

A 25 170 45 310

B 30 205 50 345

Heavy-Thickness Coils, Hot-Rolled,Alloy, Carbon, Struc-

C 33 230 55 380

tural, High-Strength Low-Alloy, and High-Strength Low-

D 35 240 60 415

Alloy with Improved Formability, General Requirements

E 38 260 65 450

F 42 290 70 485

for

G 45 310 75 515

3. Ordering Information

3.1 Orders for material under this specification shall include

1.3 Hot-rolled carbon steel sheet is generally furnished in

the following information, as required, to describe the material

cut lengths and to decimal thickness only. Coils may be

adequately:

furnished, provided tension test specimens are taken to repre-

3.1.1 Designationorspecificationnumber,dateofissue,and

sent the middle of the slab as required by 5.1.4. The purchaser

grade,

should recognize this may require cutting the coils to obtain

3.1.2 Copper bearing steel, when required,

test samples and results in half-size coils. The sheet is

3.1.3 Condition—pickled (or blast cleaned), if required

furnished to the following size limits:

(material so ordered will be oiled unless ordered dry), and

Width, in. [mm]

3.1.4 Dimensions, including type of edges.

Thickness, in. [mm] Over 12 [Over 300]

NOTE 1—Not all producers are capable of meeting all of the limitations

of the thickness tolerance tables in Specification A568/A568M or Speci-

0.270 to 0.230 [7.0 to 6.0] sheet (coils only)

ficationA635/A635M. The purchaser should contact the producer regard-

Under 0.230 to 0.057 [6.0 to 1.5] sheet

ing possible limitations prior to placing an order.

1.4 The values stated in either inch-pound units or SI units

3.1.5 Cast or heat analysis, or test report request, or both, if

are to be regarded separately as standard. Within the text, the

required, and

SI units are shown in brackets. The values stated in each

3.1.6 Special Requirements (if any).

system are not exact equivalents; therefore, each system shall

3.1.6.1 Whenthepurchaserrequiresthicknesstolerancesfor

be used independently of the other. Combining values from the

3

⁄8 in. [10 mm] minimum edge distance (see Supplementary

two systems may result in nonconformance with the specifi-

Requirement in SpecificationsA568/A568M orA635/A635M,

cation.

as applicable), this requirement shall be specified in the

purchase order or contract.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

NOTE 2—Atypicalorderingdescriptionisasfollows:ASTMA414-XX,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip.

Current edition approved Nov. 1, 2009. Published December 2009. Originally

3

approved in 1971. Last previous edition approved in 2007 as A414/A414M – 07. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/A0414_A0414M-09. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SA-414 in Section 11 of that Code. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A414/A414M – 09

Grade A, Hot-Rolled Sheet, 0.100 in. by 36 in. by 96 in., cut edges, or TABLE 2 Limits on Unspecified Elements (See 4.1.1)

A414M-XX, GradeA, Hot-Rolled Sheet, 2.54 mm by 914.4 mm by 2438 A

Copper, max % Heat a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A414/A414M–07 Designation: A414/A414M – 09

Standard Specification for

1

Steel, Sheet, Carbon, for Pressure Vessels

This standard is issued under the fixed designationA414/A414M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers hot-rolled carbon steel sheet for pressure vessels involving fusion welding or brazing. Welding

and brazing technique is of fundamental importance and shall be in accordance with commercial practices.

1.2 The following grades are included in this specification:

Mechanical Requirements

Grade Yield Strength, min Tensile Strength, min

ksi MPa ksi MPa

A 25 170 45 310

B 30 205 50 345

C 33 230 55 380

D 35 240 60 415

E 38 260 65 450

F 42 290 70 485

G 45 310 75 515

1.3Hot-rolled1.3 Hot-rolled carbon steel sheet is generally furnished in cut lengths and to decimal thickness only. Coils may be

furnished, provided tension test specimens are taken to represent the middle of the slab as required by 5.1.4. The purchaser should

recognize this may require cutting the coils to obtain test samples and results in half-size coils. The sheet is furnished to the

following size limits:

Width, in. [mm]

Thickness, in. [mm] Over 12 [Over 300]

0.270 to 0.230 [7.0 to 6.0] sheet (coils only)

Under 0.230 to 0.057 [6.0 to 1.5] sheet

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Tolerances are found in General Requirements Specifications A568/A568M and A635/A635M. The appropriate General

Requirements specification is applied based on the thickness and width of the product ordered.

2. Referenced Documents

3

2.1 ASTM Standards:

A568/A568M Specification for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

General Requirements for

A635/A635M Specification for Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon, Structural,

High-Strength Low-Alloy, and High-Strength Low-Alloy with Improved Formability, General Requirements for

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.19

on Steel Sheet and Strip.

Current edition approved May 15, 2007. Published May 2007. Originally approved in 1971. Last previous edition approved in 2006 as A414/A414M–06. DOI:

10.1520/A0414_A0414M-07.

Current edition approved Nov. 1, 2009. Published December 2009. Originally approved in 1971. Last previous edition approved in 2007 as A414/A414M – 07. DOI:

10.1520/A0414_A0414M-09.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-414 in Section 11 of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A414/A414M – 09

3. Ordering Information

3.1 Orders for material under this specification shall include the following information, as required, to describe the material

adequately:

3.1.1 Designation or specification number, date of issue, and grade,

3.1.2 Copper bearing steel, when required,

3.1.3Special requirements, if required,

3.1.4Condition—pickled (or blast cleaned), if required (material so ordered will be oiled unless ordered dry), and

3.1.5Dimensions, including type of edges.

3.1.5.1As agreed upon between the purchaser and the producer, material ordered to this specification will be supplied to meet

the appropriate standard or restricted thickness tolerance table shown in Specification

3.1.3 Condition—pickled (or blast cleaned), if required (material so ordered will be oiled unless ordered dry), and

3.1.4 Dimensions, including type of edges.

NOTE 1—Not all producers are cap

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A414/A414M–07 Designation: A414/A414M – 09

Standard Specification for

1

Steel, Sheet, Carbon, for Pressure Vessels

This standard is issued under the fixed designationA414/A414M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers hot-rolled carbon steel sheet for pressure vessels involving fusion welding or brazing. Welding

and brazing technique is of fundamental importance and shall be in accordance with commercial practices.

1.2 The following grades are included in this specification:

Mechanical Requirements

Grade Yield Strength, min Tensile Strength, min

ksi MPa ksi MPa

A 25 170 45 310

B 30 205 50 345

C 33 230 55 380

D 35 240 60 415

E 38 260 65 450

F 42 290 70 485

G 45 310 75 515

1.3Hot-rolled1.3 Hot-rolled carbon steel sheet is generally furnished in cut lengths and to decimal thickness only. Coils may be

furnished, provided tension test specimens are taken to represent the middle of the slab as required by 5.1.4. The purchaser should

recognize this may require cutting the coils to obtain test samples and results in half-size coils. The sheet is furnished to the

following size limits:

Width, in. [mm]

Thickness, in. [mm] Over 12 [Over 300]

0.270 to 0.230 [7.0 to 6.0] sheet (coils only)

Under 0.230 to 0.057 [6.0 to 1.5] sheet

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Tolerances are found in General Requirements Specifications A568/A568M and A635/A635M. The appropriate General

Requirements specification is applied based on the thickness and width of the product ordered.

2. Referenced Documents

3

2.1 ASTM Standards:

A568/A568M Specification for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

General Requirements for

A635/A635M Specification for Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon, Structural,

High-Strength Low-Alloy, and High-Strength Low-Alloy with Improved Formability, General Requirements for

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.19

on Steel Sheet and Strip.

Current edition approved May 15, 2007. Published May 2007. Originally approved in 1971. Last previous edition approved in 2006 as A414/A414M–06. DOI:

10.1520/A0414_A0414M-07.

Current edition approved Nov. 1, 2009. Published December 2009. Originally approved in 1971. Last previous edition approved in 2007 as A414/A414M – 07. DOI:

10.1520/A0414_A0414M-09.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-414 in Section 11 of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A414/A414M – 09

3. Ordering Information

3.1 Orders for material under this specification shall include the following information, as required, to describe the material

adequately:

3.1.1 Designation or specification number, date of issue, and grade,

3.1.2 Copper bearing steel, when required,

3.1.3Special requirements, if required,

3.1.4Condition—pickled (or blast cleaned), if required (material so ordered will be oiled unless ordered dry), and

3.1.5Dimensions, including type of edges.

3.1.5.1As agreed upon between the purchaser and the producer, material ordered to this specification will be supplied to meet

the appropriate standard or restricted thickness tolerance table shown in Specification

3.1.3 Condition—pickled (or blast cleaned), if required (material so ordered will be oiled unless ordered dry), and

3.1.4 Dimensions, including type of edges.

NOTE 1—Not all producers are cap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.