ASTM D7065-06

(Test Method)Standard Test Method for Determination of Nonylphenol, Bisphenol A, p-tert-Octylphenol, Nonylphenol Monoethoxylate and Nonylphenol Diethoxylate in Environmental Waters by Gas Chromatography Mass Spectrometry

Standard Test Method for Determination of Nonylphenol, Bisphenol A, p-tert-Octylphenol, Nonylphenol Monoethoxylate and Nonylphenol Diethoxylate in Environmental Waters by Gas Chromatography Mass Spectrometry

SIGNIFICANCE AND USE

Nonylphenol, octylphenol, and bisphenol A have been shown to have toxic effects in aquatic organisms. The source of nonylphenol and octylphenol is prominently from the use of common commercial surfactants. The most widely used surfactant is NPEO which has an average ethoxylate chain of 9 mol of ethoxylate. The ethoxylate chain is readily biodegraded to form NP1EO and NP2EO, nonylphenol carboxylate (NPEC) and, under anaerobic conditions, nonylphenol. Nonylphenol will also biodegrade, but may be released into environmental waters directly at trace levels. This method has been investigated for use with surface water and waste treatment effluent samples and is applicable to these matrices. It has not been investigated for use with salt water or solid sample matrices.

SCOPE

1.1 This test method covers determination of nonylphenol (NP), nonylphenol ethoxylate (NP1EO), nonylphenol diethoxylate (NP2EO), octylphenol (OP), and bisphenol A (BPA) that are partitioned into organic solvent, separated using gas chromatography and detected with mass selective detection. These compounds or isomer mixtures are qualitatively and quantitatively determined by this method. This method adheres to selected ion monitoring mass spectrometry but full scan mass spectrometry has also been shown to work well under these conditions. Either analysis may be used.

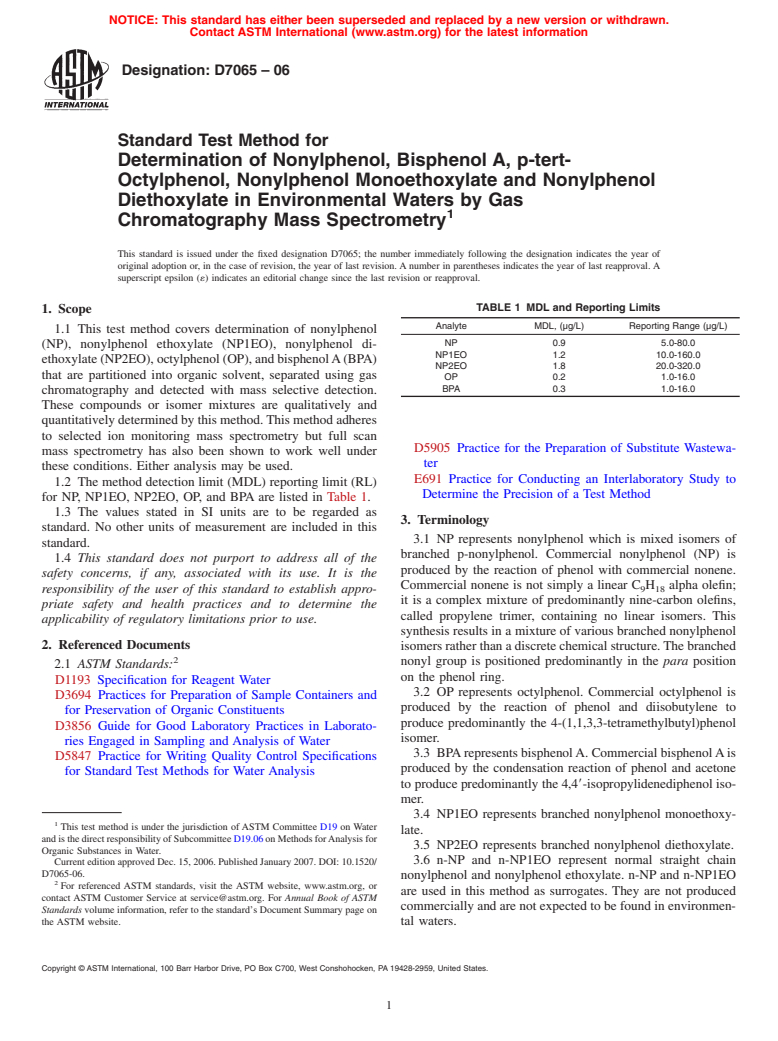

1.2 The method detection limit (MDL) reporting limit (RL) for NP, NP1EO, NP2EO, OP, and BPA are listed in Table 1.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7065 – 06

Standard Test Method for

Determination of Nonylphenol, Bisphenol A, p-tert-

Octylphenol, Nonylphenol Monoethoxylate and Nonylphenol

Diethoxylate in Environmental Waters by Gas

Chromatography Mass Spectrometry

This standard is issued under the fixed designation D7065; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

TABLE 1 MDL and Reporting Limits

1. Scope

Analyte MDL, (µg/L) Reporting Range (µg/L)

1.1 This test method covers determination of nonylphenol

NP 0.9 5.0-80.0

(NP), nonylphenol ethoxylate (NP1EO), nonylphenol di-

NP1EO 1.2 10.0-160.0

ethoxylate(NP2EO),octylphenol(OP),andbisphenolA(BPA)

NP2EO 1.8 20.0-320.0

that are partitioned into organic solvent, separated using gas

OP 0.2 1.0-16.0

BPA 0.3 1.0-16.0

chromatography and detected with mass selective detection.

These compounds or isomer mixtures are qualitatively and

quantitativelydeterminedbythismethod.Thismethodadheres

to selected ion monitoring mass spectrometry but full scan

D5905 Practice for the Preparation of Substitute Wastewa-

mass spectrometry has also been shown to work well under

ter

these conditions. Either analysis may be used.

E691 Practice for Conducting an Interlaboratory Study to

1.2 The method detection limit (MDL) reporting limit (RL)

Determine the Precision of a Test Method

for NP, NP1EO, NP2EO, OP, and BPA are listed in Table 1.

1.3 The values stated in SI units are to be regarded as

3. Terminology

standard. No other units of measurement are included in this

3.1 NP represents nonylphenol which is mixed isomers of

standard.

branched p-nonylphenol. Commercial nonylphenol (NP) is

1.4 This standard does not purport to address all of the

produced by the reaction of phenol with commercial nonene.

safety concerns, if any, associated with its use. It is the

Commercial nonene is not simply a linear C H alpha olefin;

9 18

responsibility of the user of this standard to establish appro-

it is a complex mixture of predominantly nine-carbon olefins,

priate safety and health practices and to determine the

called propylene trimer, containing no linear isomers. This

applicability of regulatory limitations prior to use.

synthesis results in a mixture of various branched nonylphenol

2. Referenced Documents

isomersratherthanadiscretechemicalstructure.Thebranched

nonyl group is positioned predominantly in the para position

2.1 ASTM Standards:

on the phenol ring.

D1193 Specification for Reagent Water

3.2 OP represents octylphenol. Commercial octylphenol is

D3694 Practices for Preparation of Sample Containers and

produced by the reaction of phenol and diisobutylene to

for Preservation of Organic Constituents

produce predominantly the 4-(1,1,3,3-tetramethylbutyl)phenol

D3856 Guide for Good Laboratory Practices in Laborato-

isomer.

ries Engaged in Sampling and Analysis of Water

3.3 BPArepresents bisphenolA. Commercial bisphenolAis

D5847 Practice for Writing Quality Control Specifications

produced by the condensation reaction of phenol and acetone

for Standard Test Methods for Water Analysis

to produce predominantly the 4,48-isopropylidenediphenol iso-

mer.

3.4 NP1EO represents branched nonylphenol monoethoxy-

This test method is under the jurisdiction of ASTM Committee D19 on Water

late.

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor

3.5 NP2EO represents branched nonylphenol diethoxylate.

Organic Substances in Water.

3.6 n-NP and n-NP1EO represent normal straight chain

Current edition approved Dec. 15, 2006. Published January 2007. DOI: 10.1520/

D7065-06.

nonylphenol and nonylphenol ethoxylate. n-NP and n-NP1EO

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

are used in this method as surrogates. They are not produced

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

commercially and are not expected to be found in environmen-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tal waters.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7065 – 06

3.7 Environmental water shall refer to water tested using interferences will vary considerably from sample source to

this method. See Section 5. sample source, depending on variations of the sample matrix.

4. Summary of Test Method

7. Apparatus

4.1 For NP, NP1EO, NP2EO, BPA, and OP analysis, con-

7.1 GC/MS System:

tinuous liquid-liquid extraction technique is used for water

7.1.1 Gas Chromatograph (GC) System—Ananalyticalsys-

samples.

tem complete with a temperature programmable gas chromato-

4.2 Continuous Liquid-Liquid Extraction Technique—A1-L

graph and all required accessories including syringes, analyti-

volumeofsampleadjustedtopH2isextractedwithmethylene

cal columns, autosamplers, and gases. The injection port must

chloride. The methylene chloride extract is dried using sodium

be designed for split/splitless when using the capillary col-

sulfateifneeded,concentratedtoavolumeof0.5 mL,andthen

umns.

analyzed by GC/MS operated in the selected ion monitoring

7.1.2 Analytical Column—An analytical column (DB-5MS

(SIM) or full scan mode.

30-m 3 0.25 mm i.d; film thickness—0.25 µm or equivalent;

4.3 The target compounds are identified by retention time

(5 %-phenyl)-methylpolysiloxane) suitable for the analysis of

and confirmed by comparing the sample mass spectrum to that 3

target alkylphenols.

of a known standard. The target compounds are quantitated

7.1.3 Mass Spectrometer (MS) System—An MS system

using the quantitation ions of the target compounds utilizing

capable of scanning 45 to 500 amu every2sor less, using

theinternalstandardsacenaphthene-d ,andphenanthrene-d .

10 10

70 eV in the electron impact mode, and producing a mass

The final report issued for each sample lists total concentration

spectrum which meets all the criteria when 50 ng of decafluo-

of NP, NP1EO, NP2EO, BPA, and OP, if detected, or MDLs, if

rotriphenylphosphine (DFTPP) is injected through the GC

not detected, in µg/L for water samples.

inlet.

7.2 CLLE Apparatus.

5. Significance and Use

7.3 Organic Solvent Evaporation Device.

5.1 Nonylphenol, octylphenol, and bisphenol A have been

showntohavetoxiceffectsinaquaticorganisms.Thesourceof

8. Reagents and Materials

nonylphenol and octylphenol is prominently from the use of

8.1 Purity of Reagents—Reagent grade chemicals shall be

common commercial surfactants. The most widely used sur-

used in all tests. Unless indicated otherwise, it is intended that

factant is NPEO which has an average ethoxylate chain of 9

all reagents shall conform to the specifications of the Commit-

mol of ethoxylate. The ethoxylate chain is readily biodegraded

teeonAnalyticalReagentsoftheAmericanChemicalSociety.

toformNP1EOandNP2EO,nonylphenolcarboxylate(NPEC)

Other reagent grades may be used provided it is first ascer-

and, under anaerobic conditions, nonylphenol. Nonylphenol

tained that they are of sufficiently high purity to permit their

will also biodegrade, but may be released into environmental

use without affecting the accuracy of the measurement.

waters directly at trace levels. This method has been investi-

8.2 Purity of Water—Unless otherwise indicated, references

gated for use with surface water and waste treatment effluent

towatershallbeunderstoodtomeanreagentwaterconforming

samples and is applicable to these matrices. It has not been

to Type I of specification D1193. It must be demonstrated that

investigated for use with salt water or solid sample matrices.

this water does not contain contaminants at concentrations

6. Interferences sufficient to interfere with the analysis.

8.3 Carrier Gases—Research grade nitrogen or helium of

6.1 Method interferences may be caused by contaminants in

highest purity are used as carrier gases.

solvents, reagents, glassware and other apparatus that lead to

8.4 Methylene Chloride, chromatography grade.

discreteartifactsorelevatedbaselineintheselectedioncurrent

8.5 Methanol, purge and trap grade.

profiles.All of these materials are routinely demonstrated to be

8.6 Branched Nonylphenol Monoethoxylate (NP1EO),

free from interferences by analyzing laboratory reagent blanks

available as a high purity custom standard.

under the same conditions as the samples.

6.2 All glassware is scrupulously cleaned. All glassware is

washed in hot water with detergent such as powderedAlconox,

Deto-Jet, Luminox, or Citrojet, rinsed in hot water and rinsed

The sole source of supply of the columns known to the committee at this time

with distilled water. The glassware is then dried and heated in isJ&WColumns,AgilentTechnologies,Inc.,2850CentervilleRd.,Wilmington,DE

19808. If you are aware of alternative suppliers, please provide this information to

an oven at 250°C for 15 to 30 min. All glassware is subse-

ASTM International Headquarters. Your comments will receive careful consider-

quently cleaned with acetone and methylene chloride. Deter-

ation at a meeting of the responsible technical committee, which you may attend.

gents containing alkylphenolic compounds must not be used.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

6.3 All reagents and solvents should be of pesticide residue

listed by the American Chemical Society, see Annual Standards for Laboratory

purity or higher to minimize interference problems.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

6.4 Matrix interferences may be caused by contaminants

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

that are co-extracted from the sample. The extent of matrix MD.

D7065 – 06

8.7 Branched Nonylphenol Diethoxylate (NP2EO), avail-

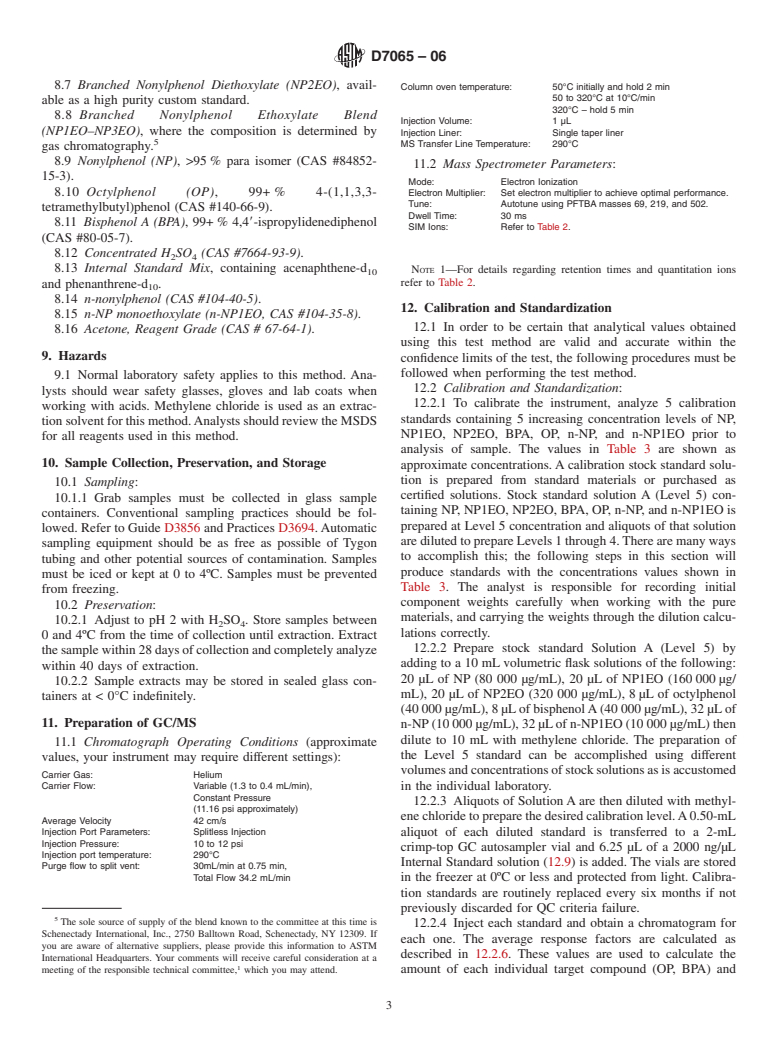

Column oven temperature: 50°C initially and hold 2 min

50 to 320°C at 10°C/min

able as a high purity custom standard.

320°C – hold 5 min

8.8 Branched Nonylphenol Ethoxylate Blend

Injection Volume: 1 µL

(NP1EO–NP3EO), where the composition is determined by

Injection Liner: Single taper liner

MS Transfer Line Temperature: 290°C

gas chromatography.

8.9 Nonylphenol (NP), >95 % para isomer (CAS #84852-

11.2 Mass Spectrometer Parameters:

15-3).

Mode: Electron Ionization

8.10 Octylphenol (OP), 99+ % 4-(1,1,3,3- Electron Multiplier: Set electron multiplier to achieve optimal performance.

Tune: Autotune using PFTBA masses 69, 219, and 502.

tetramethylbutyl)phenol (CAS #140-66-9).

Dwell Time: 30 ms

8.11 Bisphenol A (BPA), 99+ % 4,48-ispropylidenediphenol

SIM Ions: Refer to Table 2.

(CAS #80-05-7).

8.12 Concentrated H SO (CAS #7664-93-9).

2 4

8.13 Internal Standard Mix, containing acenaphthene-d

NOTE 1—For details regarding retention times and quantitation ions

refer to Table 2.

and phenanthrene-d .

8.14 n-nonylphenol (CAS #104-40-5).

12. Calibration and Standardization

8.15 n-NP monoethoxylate (n-NP1EO, CAS #104-35-8).

12.1 In order to be certain that analytical values obtained

8.16 Acetone, Reagent Grade (CAS # 67-64-1).

using this test method are valid and accurate within the

9. Hazards

confidence limits of the test, the following procedures must be

followed when performing the test method.

9.1 Normal laboratory safety applies to this method. Ana-

12.2 Calibration and Standardization:

lysts should wear safety glasses, gloves and lab coats when

12.2.1 To calibrate the instrument, analyze 5 calibration

working with acids. Methylene chloride is used as an extrac-

standards containing 5 increasing concentration levels of NP,

tionsolventforthismethod.AnalystsshouldreviewtheMSDS

NP1EO, NP2EO, BPA, OP, n-NP, and n-NP1EO prior to

for all reagents used in this method.

analysis of sample. The values in Table 3 are shown as

10. Sample Collection, Preservation, and Storage

approximate concentrations.Acalibration stock standard solu-

tion is prepared from standard materials or purchased as

10.1 Sampling:

certified solutions. Stock standard solution A (Level 5) con-

10.1.1 Grab samples must be collected in glass sample

taining NP, NP1EO, NP2EO, BPA, OP, n-NP, and n-NP1EO is

containers. Conventional sampling practices should be fol-

prepared at Level 5 concentration and aliquots of that solution

lowed. Refer to Guide D3856 and Practices D3694.Automatic

aredilutedtoprepareLevels1through4.Therearemanyways

sampling equipment should be as free as possible of Tygon

to accomplish this; the following steps in this section will

tubing and other potential sources of contamination. Samples

produce standards with the concentrations values shown in

must be iced or kept at 0 to 4ºC. Samples must be prevented

Table 3. The analyst is responsible for recording initial

from freezing.

component weights carefully when working with the pure

10.2 Preservation:

materials, and carrying the weights through the dilution calcu-

10.2.1 Adjust to pH 2 with H SO . Store samples between

2 4

lations correctly.

0 and 4ºC from the time of collection until extraction. Extract

12.2.2 Prepare stock standard Solution A (Level 5) by

thesamplewithin28daysofcollectionandcompletelyanalyze

adding to a 10 mL volumetric flask solutions of the following:

within 40 days of extraction.

20 µL of NP (80 000 µg/mL), 20 µL of NP1EO (160 000 µg/

10.2.2 Sample extracts may be stored in sealed glass con-

mL), 20 µL of NP2EO (320 000 µg/mL), 8 µL of octylphenol

tainers at < 0°C indefinitely.

(40 000 µg/mL), 8 µLof bisphenolA(40 000 µg/mL), 32 µLof

11. Preparation of GC/MS

n-NP(10000µg/mL),32µLofn-NP1EO(10 000 µg/mL)then

dilute to 10 mL with methylene chloride. The preparation of

11.1 Chromatograph Operating Conditions (approximate

the Level 5 standard can be accomplished using different

values, your instrument may require different settings):

volumesandconcentrationsofstocksolutionsasisaccustomed

Carrier Gas: Helium

Carrier Flow: Variable (1.3 to 0.4 mL/min), in the individual laboratory.

Constant Pressure

12.2.3 Aliquots of SolutionAare then diluted with methyl-

(11.16 psi approximately)

enechloridetopreparethedesiredcalibrationlevel.A0.50-mL

Average Velocity 42 cm/s

Injection Port Parameters: Splitless Injection

aliquot of each diluted standard is transferred to a 2-mL

Injection Pressure: 10 to 12 psi

crimp-top GC autosampler vial and 6.25 µL of a 2000 ng/µL

Injection port temperature: 290°C

Internal Standard solution (12.9) is added. The vials are stored

Purge flow to split vent: 30mL/min at 0.75 min,

Total Flow 34.2 mL/min in the freezer at 0ºC or less and protected from light. Calibra-

tion standards a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.