ASTM D1857-03

(Test Method)Standard Test Method for Fusibility of Coal and Coke Ash

Standard Test Method for Fusibility of Coal and Coke Ash

SCOPE

1.1 This test method covers the observation of the temperatures at which triangular pyramids (cones) prepared from coal and coke ash attain and pass through certain defined stages of fusing and flow when heated at a specified rate in controlled, mildly reducing, and where desired, oxidizing atmospheres.

1.2 The test method is empirical, and strict observance of the requirements and conditions is necessary to obtain reproducible temperatures and enable different laboratories to obtain concordant results.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1857 – 03

Standard Test Method for

1

Fusibility of Coal and Coke Ash

This standard is issued under the fixed designation D 1857; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the observation of the tempera-

tures at which triangular pyramids (cones) prepared from coal

and coke ash attain and pass through certain defined stages of

fusing and flow when heated at a specified rate in controlled,

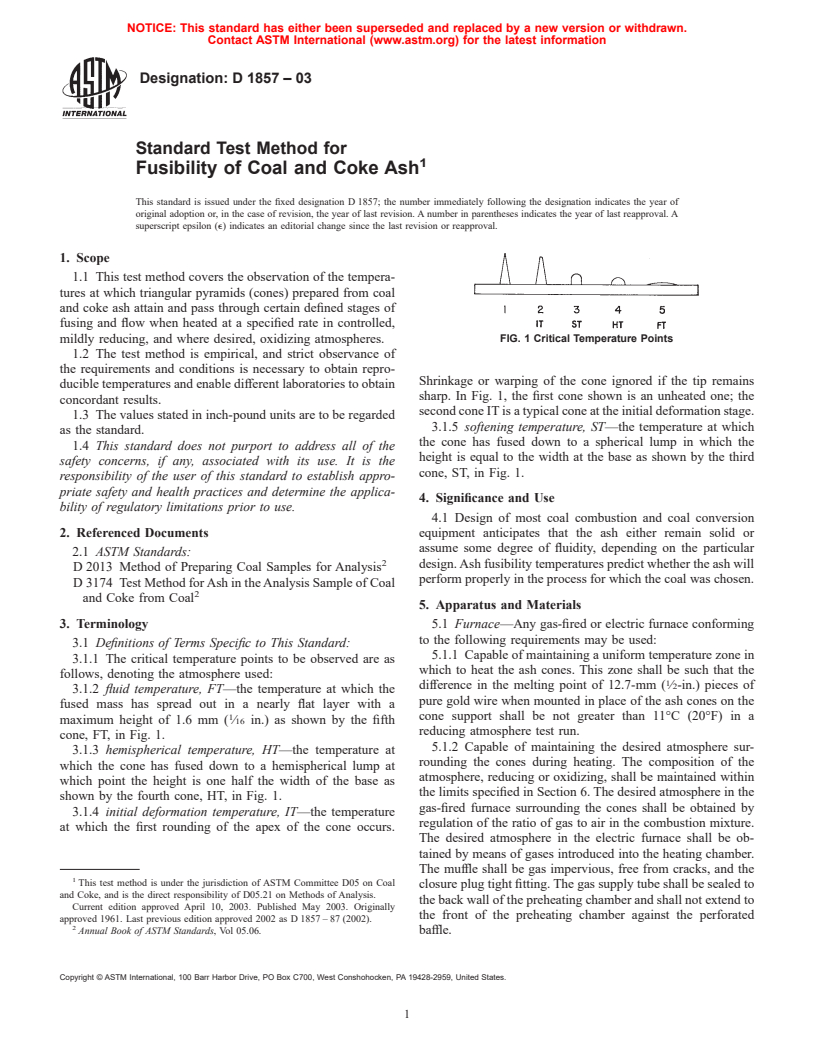

mildly reducing, and where desired, oxidizing atmospheres. FIG. 1 Critical Temperature Points

1.2 The test method is empirical, and strict observance of

the requirements and conditions is necessary to obtain repro-

Shrinkage or warping of the cone ignored if the tip remains

ducible temperatures and enable different laboratories to obtain

sharp. In Fig. 1, the first cone shown is an unheated one; the

concordant results.

second cone IT is a typical cone at the initial deformation stage.

1.3 The values stated in inch-pound units are to be regarded

3.1.5 softening temperature, ST—the temperature at which

as the standard.

the cone has fused down to a spherical lump in which the

1.4 This standard does not purport to address all of the

height is equal to the width at the base as shown by the third

safety concerns, if any, associated with its use. It is the

cone, ST, in Fig. 1.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

4.1 Design of most coal combustion and coal conversion

2. Referenced Documents equipment anticipates that the ash either remain solid or

assume some degree of fluidity, depending on the particular

2.1 ASTM Standards:

2

design. Ash fusibility temperatures predict whether the ash will

D 2013 Method of Preparing Coal Samples for Analysis

perform properly in the process for which the coal was chosen.

D 3174 Test Method for Ash in the Analysis Sample of Coal

2

and Coke from Coal

5. Apparatus and Materials

3. Terminology

5.1 Furnace—Any gas-fired or electric furnace conforming

to the following requirements may be used:

3.1 Definitions of Terms Specific to This Standard:

5.1.1 Capable of maintaining a uniform temperature zone in

3.1.1 The critical temperature points to be observed are as

which to heat the ash cones. This zone shall be such that the

follows, denoting the atmosphere used:

1

difference in the melting point of 12.7-mm ( ⁄2-in.) pieces of

3.1.2 fluid temperature, FT—the temperature at which the

pure gold wire when mounted in place of the ash cones on the

fused mass has spread out in a nearly flat layer with a

1 cone support shall be not greater than 11°C (20°F) in a

maximum height of 1.6 mm ( ⁄16 in.) as shown by the fifth

reducing atmosphere test run.

cone, FT, in Fig. 1.

5.1.2 Capable of maintaining the desired atmosphere sur-

3.1.3 hemispherical temperature, HT—the temperature at

rounding the cones during heating. The composition of the

which the cone has fused down to a hemispherical lump at

atmosphere, reducing or oxidizing, shall be maintained within

which point the height is one half the width of the base as

the limits specified in Section 6. The desired atmosphere in the

shown by the fourth cone, HT, in Fig. 1.

gas-fired furnace surrounding the cones shall be obtained by

3.1.4 initial deformation temperature, IT—the temperature

regulation of the ratio of gas to air in the combustion mixture.

at which the first rounding of the apex of the cone occurs.

The desired atmosphere in the electric furnace shall be ob-

tained by means of gases introduced into the heating chamber.

The muffle shall be gas impervious, free from cracks, and the

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal

closure plug tight fitting. The gas supply tube shall be sealed to

and Coke, and is the direct responsibility of D05.21 on Methods of Analysis.

the back wall of the preheating chamber and shall not extend to

Current edition approved April 10, 2003. Published May 2003. Originally

the front of the preheating chamber against the perforated

approved 1961. Last previous edition approved 2002 as D 1857 – 87 (2002).

2

Annual Book of ASTM Standards, Vol 05.06. baffle.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1857–03

5.1.3 Capable of regulation so that the rate of temperature thermocouple protective sheath shall be checked periodically

rise shall be 8 6 3°C (15 6 5°F)/min. for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.