ASTM E2068-00(2022)

(Test Method)Standard Test Method for Determination of Operating Force of Sliding Windows and Doors

Standard Test Method for Determination of Operating Force of Sliding Windows and Doors

SIGNIFICANCE AND USE

5.1 This test method determines the operational forces of sliding windows and doors by simulating force applied by hand directly to movable sash or panels. Breakaway and in-motion operating forces are measures of the ease of operation of fenestration products. Product specifications, building codes, and building specifications establish operating force limits as measures of product performance or limits for handicapped accessibility, or both.

5.2 Window and door performance standards for air infiltration and water penetration in some cases require operating force measurements to be made and reported as an indication of the operability of the test specimen.

5.3 Operating forces can vary significantly from unit to unit due to factors such as installation parameters, wearing of sliding or rolling parts, lubrication, stiffening or softening of weather-strip, and environmental factors (for example, humidity, temperature, accumulation of dirt, and so forth). Therefore, when applied to new product designs, this test method requires that units be tested in a laboratory under controlled conditions including accurate mounting (plumb, square, and level) following the manufacturer's instructions. Use of this test method in the field does not necessarily indicate the operating forces that are inherent in the particular window design, but rather, provides a measurement of the forces required for operation of the particular unit at the particular time. The user is cautioned that installation defects such as bowed jambs, racked frames, or inadequate anchoring can result in binding or sticking of movable components and increased operating forces.

5.4 This test method requires measurement of both breakaway and in-motion operating forces. Generally, breakaway force is higher than in-motion operating force due to the difference between static and dynamic friction coefficients or the presence of weather-stripping and sash pockets, or both. Traditional fenestration product stand...

SCOPE

1.1 This test method determines the operating forces for opening and closing horizontal and vertical sliding windows and horizontal sliding door systems. It does not address the forces required for opening pivoting, projecting, or other fenestration systems. This test method does not address the use or performance of add-on devices or mechanical operators that might be installed to reduce operating forces of sliding windows or doors. It deals only with the forces necessary to open and close a sash or panel through the direct application of force to the operable sash or panel.

1.2 This test method is suitable for laboratory product comparisons or for qualifying products, or both, as meeting window or door operating force specifications. This test method is also suitable for use in the field to determine the operating forces required to open and close installed sliding windows and doors.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2068 − 00 (Reapproved 2022)

Standard Test Method for

Determination of Operating Force of Sliding Windows and

Doors

This standard is issued under the fixed designation E2068; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Document

2.1 ASTM Standard:

1.1 This test method determines the operating forces for

E631 Terminology of Building Constructions

opening and closing horizontal and vertical sliding windows

and horizontal sliding door systems. It does not address the

3. Terminology

forces required for opening pivoting, projecting, or other

3.1 Definitions are in accordance with Terminology E631

fenestration systems.This test method does not address the use

unless otherwise specified.

or performance of add-on devices or mechanical operators that

might be installed to reduce operating forces of sliding

3.2 Definitions of Terms Specific to This Standard:

windows or doors. It deals only with the forces necessary to

3.2.1 breakaway force—the force required to start a sash

open and close a sash or panel through the direct application of

(panel) in motion from a fully closed or fully open position.

force to the operable sash or panel.

3.2.2 fully closed position—the position of the sash or panel

after being closed, latched, and unlatched, or where the sash or

1.2 This test method is suitable for laboratory product

panel is closed to its maximum engagement within a frame or

comparisons or for qualifying products, or both, as meeting

pocket if no latching mechanism is provided.

window or door operating force specifications. This test

method is also suitable for use in the field to determine the

3.2.3 fully open position—the point at the limits of the

operating forces required to open and close installed sliding

operating hardware (if applicable) or the point at which the

windows and doors.

sash or panel contacts a limiting device.

3.2.4 in-motion operating force—theforcerequiredtomain-

1.3 The values stated in inch-pound units are to be regarded

tain a sash or panel in motion while moving the sash or panel

as standard. The values given in parentheses are mathematical

between 1 in. from fully open to 1 in. from fully closed

conversions to SI units that are provided for information only

positions, or 1 in. from fully closed to 1 in. from fully open

and are not considered standard.

position.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 Two equivalent test methods for determining operating

priate safety, health, and environmental practices and deter-

force are described. Test Method A uses dead weights and a

mine the applicability of regulatory limitations prior to use.

cable and pulley system to apply force to operate a sash or

For specific precautionary statements, see Section 7.

panel. Test Method B uses a force gage and hand-applied

1.5 This international standard was developed in accor-

pressure to operate a sash or panel. The test specimen is

dance with internationally recognized principles on standard-

mounted in a rigid support frame. After attaching the loading

ization established in the Decision on Principles for the

system to the operating sash or panel, the weight or force is

Development of International Standards, Guides and Recom-

applied and increased until the sash or panel is put into motion.

mendations issued by the World Trade Organization Technical

This determines breakaway force. Starting from 1 in. (25 mm)

Barriers to Trade (TBT) Committee.

from a closed or open position the minimum amount of weight

or force required to keep a sash in motion, once it is started

moving, is measured. This determines the in-motion operating

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.51

on Performance of Windows, Doors, Skylights and Curtain Walls. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2022. Published October 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2000. Last previous edition approved in 2016 as E2068 – 00(2016). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E2068-00R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2068 − 00 (2022)

force. Forces required to operate a sliding window or patio consideredtobelesslikelytobeaffectedbytheoperator’sskill

door in both opening and closing directions are determined by in applying loads in a steady and properly timed manner. The

this test method. force gage test method is considered simpler to apply and more

applicable to field testing where the installation of pulleys and

5. Significance and Use

cabling is often impractical. Both test methods are subject to a

similar uncertainty.

5.1 This test method determines the operational forces of

slidingwindowsanddoorsbysimulatingforceappliedbyhand

6. Apparatus

directly to movable sash or panels. Breakaway and in-motion

operating forces are measures of the ease of operation of 6.1 This description of apparatus is general in nature and

any arrangement of equipment capable of performing the test

fenestration products. Product specifications, building codes,

method, within allowable tolerances, is permitted.

and building specifications establish operating force limits as

measures of product performance or limits for handicapped

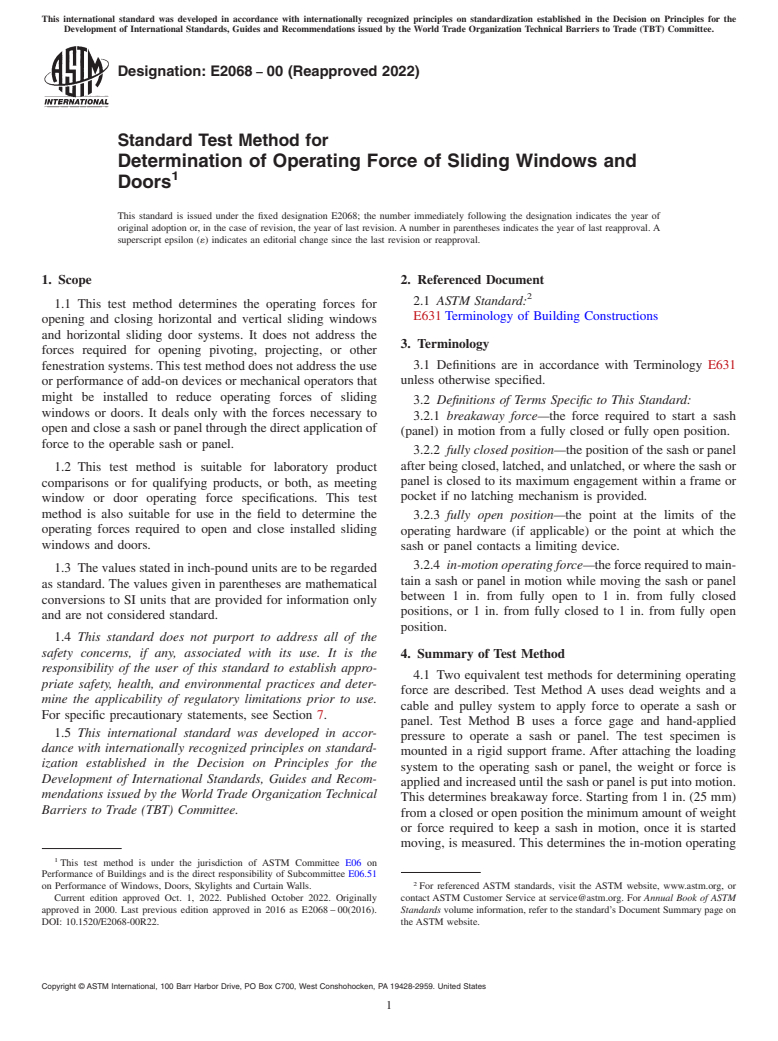

6.2 Test Method A—The primary equipment used in Test

accessibility, or both.

Method A consists of a set of weights capable of being

suspended and applied in 1 lb (0.5 kg) increments, a platen,

5.2 Window and door performance standards for air infil-

lightweight flexible cable or cord, ball-bearing sheave(s), and a

tration and water penetration in some cases require operating

framework capable of supporting the sheaves and cable system

force measurements to be made and reported as an indication

in the appropriate location. Sheaves used to transmit the

of the operability of the test specimen.

deadweightloadtothespecimenundertestshallbeaminimum

5.3 Operating forces can vary significantly from unit to unit

of 3 in. (75 mm) in diameter. Weights used are to be Class F or

due to factors such as installation parameters, wearing of

better. In addition, a force gage in accordance with 7.3.1 shall

sliding or rolling parts, lubrication, stiffening or softening of

be used to verify that the load applied is transmitted to the unit

weather-strip, and environmental factors (for example,

under test when two or more sheaves are used to direct the

humidity, temperature, accumulation of dirt, and so forth).

load. (See Fig. 1.)

Therefore, when applied to new product designs, this test

method requires that units be tested in a laboratory under 6.3 Test Method B—For Test Method B, a calibrated force

gagewithanaccuracyof 60.5lbf(2.0N)andwithapeakhold

controlled conditions including accurate mounting (plumb,

square, and level) following the manufacturer’s instructions. and continuous reading capability is required.

Useofthistestmethodinthefielddoesnotnecessarilyindicate

6.4 Hardware such as hooks, cable, cord, small pulleys, and

the operating forces that are inherent in the particular window

screw-eyes are to be used as necessary to provide for attach-

design, but rather, provides a measurement of the forces

ment of the loading system to the sash or panel.

required for operation of the particular unit at the particular

7. Safety Precautions

time. The user is cautioned that installation defects such as

bowed jambs, racked frames, or inadequate anchoring can

7.1 When using Test Method A, be prepared for sudden

result in binding or sticking of movable components and

movement of the sash or panel and potentially rapid dropping

increased operating forces.

of the weights. The weights are to be suspended in such a

manner that their fall will be stopped before the sash moves to

5.4 This test method requires measurement of both break-

away and in-motion operating forces. Generally, breakaway the full limit of its travel to reduce impact between compo-

nents. When using Test Method B, be prepared for sudden

force is higher than in-motion operating force due to the

difference between static and dynamic friction coefficients or movement of the sash or panel.

the presence of weather-stripping and sash pockets, or both.

7.2 There can be considerable energy and momentum in

Traditional fenestration product standards have required deter-

moving sash or panels that can cause a significant impact when

mination of in-motion operating force in the opening direction

the sash or panel hits the frame or limiting stops. Care must be

only and referred to this simply as operating force.

taken to avoid injury and potential breakage of the specimen.

5.5 This test method is intended to determine the forces

7.3 Glass breakage will not normally occur at the forces

required to operate a window or sliding door which is properly

applied in these test methods; however, sudden breakaway or

installed and which is operated by hand application of force to

motion can occur. Take precautions to prevent injury from the

a handle, pull bar, or sash member. Application of force

moving sash.

through jerking or impact motion is not measured or evaluated

by this test method. Operating forces can be significantly 8. Test Specimen

different between the opening and closing directions of move-

8.1 The test specimen shall consist of the entire unit as

ment; therefore, this test method involves measurements in

supplied by the manufacturer or as set forth in a referenced

both directions of movement.

specification if applicable. When testing a unit in the field, the

5.6 This test method provides for two procedures which unit’s location and description shall be detailed in the test

include a dead weight test method (Test MethodA) and a force report.

gage test method (Test Method B) of applying and measuring

9. Procedure

forces required to operate a sliding window or sliding door.

When properly applied, both test methods are deemed to 9.1 Mount the test specimen to the support framework in

produce equivalent results. The dead weight test method is accordance with the manufacturer’s installation instructions.

E2068 − 00 (2022)

FIG. 1 Vertically Sliding Window Typical Arrangements

The supporting structure shall have a strength and rigidity at with a cable or cord and apply force using a pulley strung on

least equivalent to a nominal 2 by 4 stud wall with studs 16 in. the cable or cord so that the force is evenly distributed between

(406 mm) on center and faced on one surface with nominal the two locations. All forces applied are to be in the direction

⁄2 in. (12 mm) plywood. parallel to the sash or panel surface that will cause the panel to

move in the desired direction. Force is to be applied as close to

9.2 Forlaboratorytests,allowsufficienttimeforthetestunit

the direction and plane of travel as possible.

to fully equilibrate to the laboratory conditions prior to testing.

Fully open and close the test specimen five times, fully

9.5 Number of Trials—For each test method conduct a

engaging the locks or latches on each closure.

minimum of three trials. If the results of three trials are all

within 10 % or 1 lb (0.5 kg), whichever is greater, of the

9.3 Identify the location of normal opening or closing force

average of the three trials, no additional trials are required. If

application. This will normally be one or two handles or finger

any of the results of the three trials deviates by more than 10 %

grip areas. For units with no clearly identified handle or grip

or 1 lb, whichever is greater, from the average, conduct seven

area use the following locations: (1) vertical sliding windows

additionaltrials(foratotaloften).Whententrialsarerequired,

(single or double-hung), two points spaced 18 in. (460 mm)

calculate the average value by eliminating the highest and

apart centered on either the sash top rail or bottom rail; or (2)

lowest values recorded and averaging the remaining eight

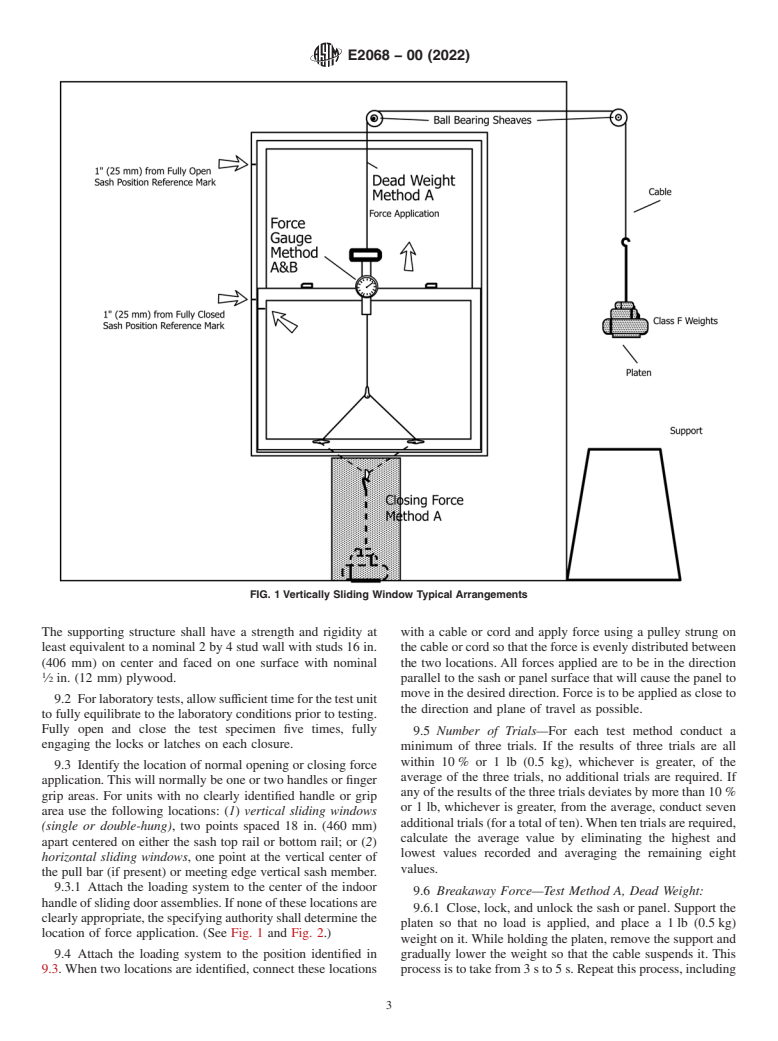

horizontal sliding windows, one point at the vertical center of

values.

the pull bar (if present) or meeting edge vertical sash member.

9.3.1 Attach the loading system to the center of the indoor

9.6 Breakaway Force—Test Method A, Dead Weight:

handleofslidingdoorassemblies.Ifnoneoftheselocationsare

9.6.1 Close, lock, and unlock the sash or panel. Support the

clearlyappropriate,thespecifyingauthorityshalldeterminethe

platen so that no load is applied, and place a 1 lb (0.5 kg)

location of force application. (See Fig. 1 and Fig. 2.)

weight on it. While holding the platen, remove the support and

9.4 Attach the loading system to the position identified in gradually lower the weight so that the cable suspends it. This

9.3. When two locations are identified, connect these locations process is to take from 3 s to 5 s. Repeat this process, including

E2068 − 00 (2022)

FIG. 2 Patio Door or Sliding Window Assembly

opening, closing, locking, and unlocking the latching open mark. If it does not open to the 1 in. from fully open mark

mechanism, increasing the weight on the platen by 1 lb for repeat the process adding 1 lb of weight to the platen. Continue

eachtrialuntiltheweightissufficienttocausethesashorpanel this process until the weight applied is sufficient to open the

to fully disengage from the frame and any weather-strip or sash or panel to or beyond the 1 in. from fully open mark.

framepocket.Recordthetotalweightappliedinthisprocessas Record the total applied weight including the weight of the

thebreakawayforce.Repeatthisentireprocesstwiceforatotal

platen. If two or more sheaves are included in the loading

of three trials. Determine if additional trials are required as system,verifythattheforcegagereadsthecorrectvalueforthe

specified in 9.5 and perform if necessary. If the sash movement

applied weight. Repeat this procedure at least two additional

required to disengage from weather strip or a frame pocket is times (minimum of three trials) in the ope

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.