ASTM D1394-76(2014)

(Test Method)Standard Test Methods for Chemical Analysis of White Titanium Pigments

Standard Test Methods for Chemical Analysis of White Titanium Pigments

ABSTRACT

These test methods cover procedures for the chemical analysis of white titanium dioxide pigments. The analytical procedures appear in the following order: sample preparation, qualitative analysis, moisture content determination, total titanium content determination by Jones Reductor and Aluminum Reduction methods, aluminum oxide content determination, and silica content determination. The reagents to be used shall include ammonium hydroxide, ammonium sulfate, hydrochloric acid, hydrogen peroxide, hydrogen sulfide, sulfuric acid, tartaric acid, tin, zinc, carbon steel, iron, ferric sulfate solution, nitric acid, sodium oxalate, potassium permanganate, aluminum metal foil, ammonium thiocyanate indicator solution, ferritic ammonium sulfate solution, sodium bicarbonate solution, sulfuric acid, titanium dioxide, acetic acid, ammonium phosphate, EDTA solution, methyl orange indicator solution, sodium bisulfate monohydrate, sodium fluoride, xylenol orange indicator solution, and zinc sulfate solution.

SCOPE

1.1 These test methods cover procedures for the chemical analysis of white titanium dioxide pigments.

1.2 The analytical procedures appear in the following order:

Sections

Preparation of Sample

4

Qualitative Analysis

5 and 6

Moisture

7

Total Titanium:

Jones Reductor Method

8 – 12

Aluminum Reduction Method

13 – 17

Aluminum Oxide

18 – 22

Silica

23 – 29

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific hazard statement is given in Section 19.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1394 − 76 (Reapproved 2014)

Standard Test Methods for

1

Chemical Analysis of White Titanium Pigments

This standard is issued under the fixed designation D1394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

1.1 These test methods cover procedures for the chemical

3

where such specifications are available. Other grades may be

analysis of white titanium dioxide pigments.

used, provided it is first ascertained that the reagent is of

1.2 Theanalyticalproceduresappearinthefollowingorder:

sufficiently high purity to permit its use without lessening the

Sections

accuracy of the determination.

Preparation of Sample 4

Qualitative Analysis 5 and 6

3.2 Unless otherwise indicated, references to water shall be

Moisture 7

understood to mean reagent water conforming to Type IV of

Total Titanium:

Specification D1193.

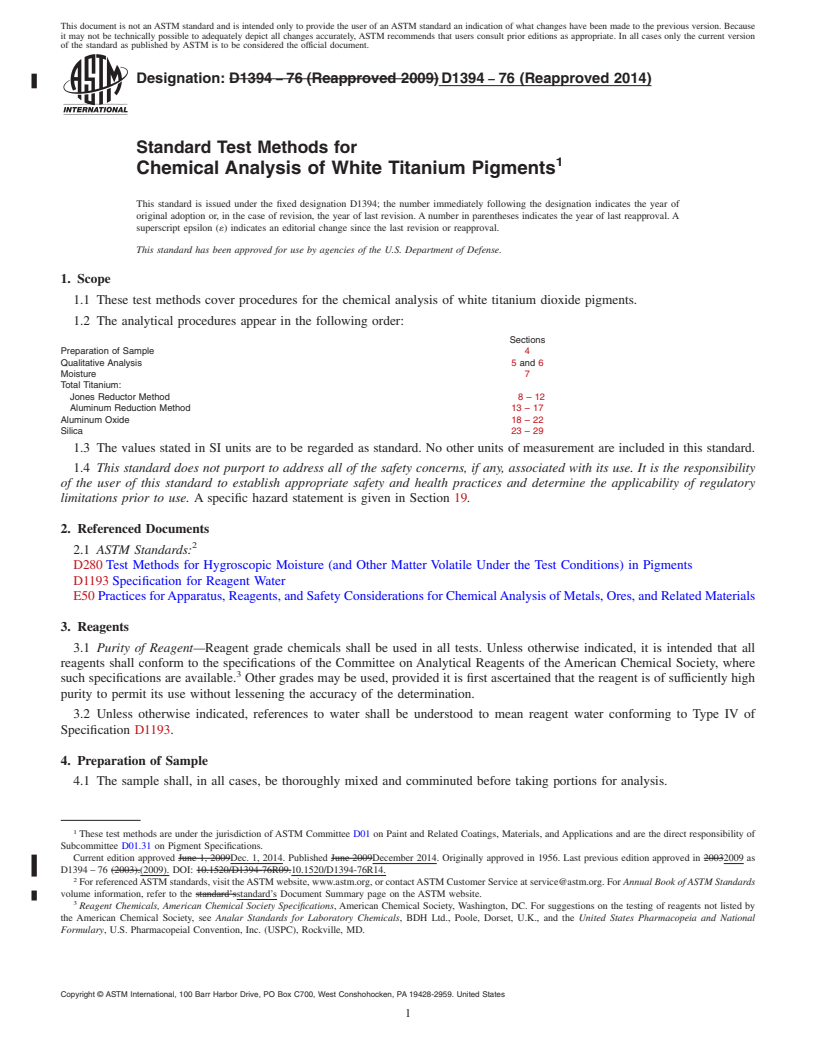

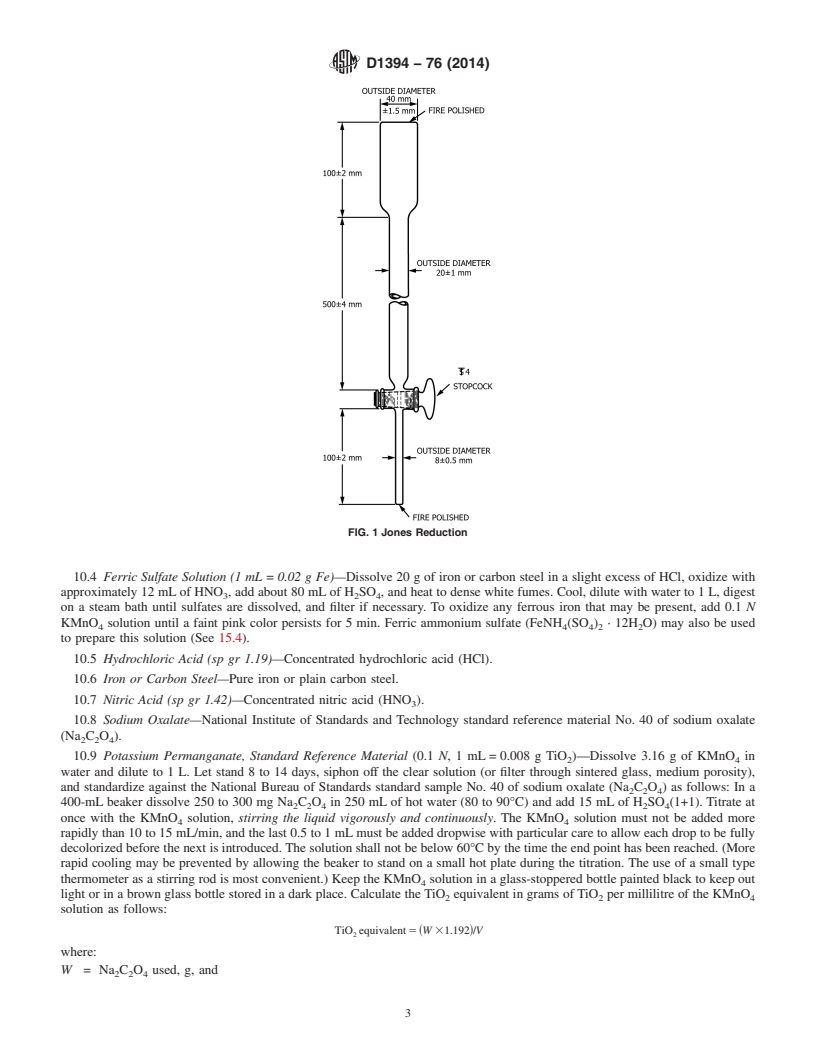

Jones Reductor Method 8–12

Aluminum Reduction Method 13–17

Aluminum Oxide 18–22

4. Preparation of Sample

Silica 23–29

4.1 The sample shall, in all cases, be thoroughly mixed and

1.3 The values stated in SI units are to be regarded as

comminuted before taking portions for analysis.

standard. No other units of measurement are included in this

standard.

QUALITATIVE ANALYSIS

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Reagents

responsibility of the user of this standard to establish appro-

5.1 Ammonium Hydroxide (sp gr 0.90)—Concentrated am-

priate safety and health practices and determine the applica-

monium hydroxide (NH OH).

bility of regulatory limitations prior to use. A specific hazard

4

statement is given in Section 19.

5.2 Ammonium Sulfate—((NH ) SO ).

4 2 4

2. Referenced Documents

5.3 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

2

chloric acid (HCl).

2.1 ASTM Standards:

D280Test Methods for Hygroscopic Moisture (and Other

5.4 Hydrogen Peroxide (30 %)—Concentrated hydrogen

Matter Volatile Under the Test Conditions) in Pigments

peroxide (H O ).

2 2

D1193Specification for Reagent Water

5.5 Hydrogen Sulfide (H S).

E50Practices for Apparatus, Reagents, and Safety Consid- 2

erations for Chemical Analysis of Metals, Ores, and

5.6 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

Related Materials

(H SO ).

2 4

3. Reagents

5.7 Sulfuric Acid (1+19)—Carefully mix 1 volume of

H SO (sp gr 1.84) with 19 volumes of water.

3.1 Purity of Reagent—Reagent grade chemicals shall be 2 4

used in all tests. Unless otherwise indicated, it is intended that

5.8 Tartaric Acid.

5.9 Tin or Zinc Metal.

1

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.31 on Pigment Specifications.

Current edition approved Dec. 1, 2014. Published December 2014. Originally

3

approved in 1956. Last previous edition approved in 2009 as D1394–76(2009). Reagent Chemicals, American Chemical Society Specifications, American

DOI: 10.1520/D1394-76R14. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1394 − 76 (2014)

6. Procedure

6.1 Place about 0.5 g of the sample in a 250-mL glass

4

beaker, and add 20 mLof H SO (sp gr 1.84) and 7 to8gof

2 4

(NH ) SO . Mix well and boil for a few minutes. The sample

4 2 4

should go completely into solution; a residue denotes the

presenceofsilicondioxide(SiO )orsiliceousmatter.Coolthe

2

solution,dilutewith100mLofwater,heattoboiling,letsettle,

filter, wash with hot H SO (1+19) until free of titanium, and

2 4

test the residue for lead, etc.

6.2 Test the filtrate for calcium, zinc, iron, chromium, etc.,

5

by the regular methods of qualitative analysis. For the iron

determinationaddtoaportionofthefiltrate5goftartaric

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1394 − 76 (Reapproved 2009) D1394 − 76 (Reapproved 2014)

Standard Test Methods for

1

Chemical Analysis of White Titanium Pigments

This standard is issued under the fixed designation D1394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover procedures for the chemical analysis of white titanium dioxide pigments.

1.2 The analytical procedures appear in the following order:

Sections

Preparation of Sample 4

Qualitative Analysis 5 and 6

Moisture 7

Total Titanium:

Jones Reductor Method 8 – 12

Aluminum Reduction Method 13 – 17

Aluminum Oxide 18 – 22

Silica 23 – 29

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. A specific hazard statement is given in Section 19.

2. Referenced Documents

2

2.1 ASTM Standards:

D280 Test Methods for Hygroscopic Moisture (and Other Matter Volatile Under the Test Conditions) in Pigments

D1193 Specification for Reagent Water

E50 Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

3. Reagents

3.1 Purity of Reagent—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

3

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

3.2 Unless otherwise indicated, references to water shall be understood to mean reagent water conforming to Type IV of

Specification D1193.

4. Preparation of Sample

4.1 The sample shall, in all cases, be thoroughly mixed and comminuted before taking portions for analysis.

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.31 on Pigment Specifications.

Current edition approved June 1, 2009Dec. 1, 2014. Published June 2009December 2014. Originally approved in 1956. Last previous edition approved in 20032009 as

D1394 – 76 (2003).(2009). DOI: 10.1520/D1394-76R09.10.1520/D1394-76R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1394 − 76 (2014)

QUALITATIVE ANALYSIS

5. Reagents

5.1 Ammonium Hydroxide (sp gr 0.90)—Concentrated ammonium hydroxide (NH OH).

4

5.2 Ammonium Sulfate—((NH ) SO ).

4 2 4

5.3 Hydrochloric Acid (sp gr 1.19)—Concentrated hydrochloric acid (HCl).

5.4 Hydrogen Peroxide (30 %)—Concentrated hydrogen peroxide (H O ).

2 2

5.5 Hydrogen Sulfide (H S).

2

5.6 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid (H SO ).

2 4

5.7 Sulfuric Acid (1+19)—Carefully mix 1 volume of H SO (sp gr 1.84) with 19 volumes of water.

2 4

5.8 Tartaric Acid.

5.9 Tin or Zinc Metal.

6. Procedure

4

6.1 Place about 0.5 g of the sample in a 250-mL glass beaker, and add 20 mL of H SO (sp gr 1.84) and 7 to 8 g of (NH ) SO .

2 4 4 2 4

Mix well and boil for a few minutes. The sample should go completely into solution; a residue denotes the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.