ASTM D1394-76(2020)

(Test Method)Standard Test Methods for Chemical Analysis of White Titanium Pigments

Standard Test Methods for Chemical Analysis of White Titanium Pigments

ABSTRACT

These test methods cover procedures for the chemical analysis of white titanium dioxide pigments. The analytical procedures appear in the following order: sample preparation, qualitative analysis, moisture content determination, total titanium content determination by Jones Reductor and Aluminum Reduction methods, aluminum oxide content determination, and silica content determination. The reagents to be used shall include ammonium hydroxide, ammonium sulfate, hydrochloric acid, hydrogen peroxide, hydrogen sulfide, sulfuric acid, tartaric acid, tin, zinc, carbon steel, iron, ferric sulfate solution, nitric acid, sodium oxalate, potassium permanganate, aluminum metal foil, ammonium thiocyanate indicator solution, ferritic ammonium sulfate solution, sodium bicarbonate solution, sulfuric acid, titanium dioxide, acetic acid, ammonium phosphate, EDTA solution, methyl orange indicator solution, sodium bisulfate monohydrate, sodium fluoride, xylenol orange indicator solution, and zinc sulfate solution.

SCOPE

1.1 These test methods cover procedures for the chemical analysis of white titanium dioxide pigments.

1.2 The analytical procedures appear in the following order:

Sections

Preparation of Sample

4

Qualitative Analysis

5 and 6

Moisture

7

Total Titanium:

Jones Reductor Method

8 – 12

Aluminum Reduction Method

13 – 17

Aluminum Oxide

18 – 22

Silica

23 – 29

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. A specific hazard statement is given in Section 19.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1394 − 76 (Reapproved 2020)

Standard Test Methods for

Chemical Analysis of White Titanium Pigments

This standard is issued under the fixed designation D1394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E50Practices for Apparatus, Reagents, and Safety Consid-

erations for Chemical Analysis of Metals, Ores, and

1.1 These test methods cover procedures for the chemical

Related Materials

analysis of white titanium dioxide pigments.

1.2 Theanalyticalproceduresappearinthefollowingorder:

3. Reagents

Sections

3.1 Purity of Reagent—Reagent grade chemicals shall be

Preparation of Sample 4

used in all tests. Unless otherwise indicated, it is intended that

Qualitative Analysis 5 and 6

Moisture 7 all reagents shall conform to the specifications of the Commit-

Total Titanium:

tee onAnalytical Reagents of theAmerican Chemical Society,

Jones Reductor Method 8–12

where such specifications are available. Other grades may be

Aluminum Reduction Method 13–17

Aluminum Oxide 18–22

used, provided it is first ascertained that the reagent is of

Silica 23–29

sufficiently high purity to permit its use without lessening the

1.3 The values stated in SI units are to be regarded as

accuracy of the determination.

standard. No other units of measurement are included in this

3.2 Unless otherwise indicated, references to water shall be

standard.

understood to mean reagent water conforming to Type IV of

1.4 This standard does not purport to address all of the

Specification D1193.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Preparation of Sample

priate safety, health, and environmental practices and deter-

4.1 The sample shall, in all cases, be thoroughly mixed and

mine the applicability of regulatory limitations prior to use. A

comminuted before taking portions for analysis.

specific hazard statement is given in Section 19.

1.5 This international standard was developed in accor-

QUALITATIVE ANALYSIS

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5. Reagents

Development of International Standards, Guides and Recom-

5.1 Ammonium Hydroxide (sp gr 0.90)—Concentrated am-

mendations issued by the World Trade Organization Technical

monium hydroxide (NH OH).

Barriers to Trade (TBT) Committee.

5.2 Ammonium Sulfate—((NH ) SO ).

4 2 4

2. Referenced Documents

5.3 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

chloric acid (HCl).

2.1 ASTM Standards:

D280Test Methods for Hygroscopic Moisture (and Other

5.4 Hydrogen Peroxide (30 %)—Concentrated hydrogen

Matter Volatile Under the Test Conditions) in Pigments

peroxide (H O ).

2 2

D1193Specification for Reagent Water

5.5 Hydrogen Sulfide (H S).

5.6 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

These test methods are under the jurisdiction of ASTM Committee D01 on

(H SO ).

2 4

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.31 on Pigment Specifications.

Current edition approved June 1, 2020. Published June 2020. Originally

approved in 1956. Last previous edition approved in 2014 as D1394–76(2014). ACS Reagent Chemicals, Specifications and Procedures for Reagents and

DOI: 10.1520/D1394-76R20. Standard-Grade Reference Materials, American Chemical Society, Washington,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

Standards volume information, refer to the standard’s Document Summary page on U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

the ASTM website. copeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1394 − 76 (2020)

5.7 Sulfuric Acid (1+19)—Carefully mix 1 volume of

H SO (sp gr 1.84) with 19 volumes of water.

2 4

5.8 Tartaric Acid.

5.9 Tin or Zinc Metal.

6. Procedure

6.1 Place about 0.5 g of the sample in a 250-mL glass

beaker, and add 20 mLof H SO (sp gr 1.84) and 7 to8gof

2 4

(NH ) SO . Mix well and boil for a few minutes. The sample

4 2 4

should go completely into solution; a residue denotes the

presenceofsilicondioxide(SiO )orsiliceousmatter.Coolthe

solution,dilutewith100mLofwater,heattoboiling,letsettle,

filter, wash with hot H SO (1+19) until free of titanium, and

2 4

test the residue for lead, etc.

6.2 Test the filtrate for calcium, zinc, iron, chromium, etc.,

by the regular methods of qualitative analysis. For the iron

determinationaddtoaportionofthefiltrate5goftartaricacid,

render slightly ammoniacal, pass in H S in excess, and digest

on a steam bath. No precipitate after 30 min indicates the

absence of iron, nickel, cobalt, lead, copper, etc. A black

precipitate readily soluble in dilute HCl denotes iron. For

titanium, test a small portion of the original filtrate with H O

2 2

(aclearyellow-orangecolorshouldresult)andanotherportion

withmetallictinorzinc(apalebluetovioletcolorationshould

result). Negative results should be shown for sulfide,

carbonate, or appreciable water-soluble matter.

MOISTURE

FIG. 1 Jones Reduction

7. Procedure

7.1 Determine moisture and other volatile matter in accor-

dance with Test Method A of Test Methods D280.

of 0.25 M mercuric nitrate or chloride solution, and stirring

TOTAL TITANIUM BY THE JONES REDUCTOR rapidly for 3 min. Decant the solution and wash the amalgam

with water and store under water to which a few drops of HCl

METHOD

have been added. After using, keep the reductor filled with

8. Scope

water when not in use, in order that basic salts will not be

formed and clog it.

8.1 This method gives results similar to those obtained with

the Aluminum Reduction Method, Sections13–17.

10. Reagents

9. Apparatus

10.1 Ammonium Hydroxide (sp gr 0.90)—Concentratedam-

monium hydroxide (NH OH).

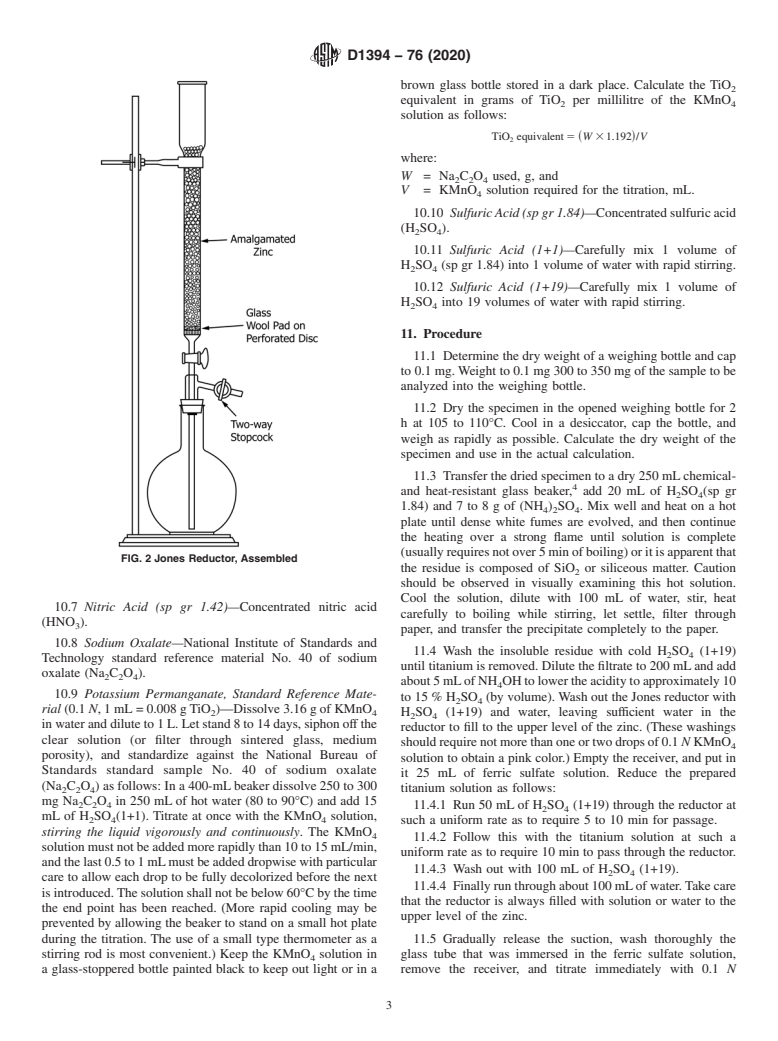

9.1 Jones Reductor having a zinc column at least 450 mm

in length, and 19 mm in diameter (Fig. 1 and Fig. 2). The

10.2 Ammonium Sulfate ((NH ) SO ).

4 2 4

filtering pad must be tight enough to hold all the particles of

10.3 Carbon Steel or Iron—Pure iron or plain carbon steel.

amalgamated zinc resting on it, and may be made of asbestos

or, preferably, glass-wool supported by platinum gauze or a 10.4 Ferric Sulfate Solution (1 mL = 0.02 g Fe)—Dissolve

20 g of iron or carbon steel in a slight excess of HCl, oxidize

perforated porcelain plate. Use the least amount (0.1 to 1.0%)

of mercury that will enable satisfactory control of hydrogen with approximately 12 mL of HNO , add about 80 mL of

evolution, since heavy amalgamation tends to reduce the rate H SO , and heat to dense white fumes. Cool, dilute with water

2 4

ofreaction.Preparetheamalgambywashing20-meshzincfor to 1 L, digest on a steam bath until sulfates are dissolved, and

1mininenough1 NHCltocoverit,addingtheproperamount filter if necessary. To oxidize any ferrous iron that may be

present, add 0.1 N KMnO solution until a faint pink color

persists for 5 min. Ferric ammonium sulfate (FeNH (SO ) ·

4 4 2

Borosilicate glass has been found satisfactory for this purpose.

12H O) may also be used to prepare this solution (See 15.4).

Treadwell,F.P.,andHall,WilliamT., Qualitative Analysis,JohnWiley&Sons,

Inc., New York, NY, Vol. 1, Ninth English Ed., 1937. 10.5 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

Directions for preparing a Jones Reductor may be found in Hillebrand, W. F.,

chloric acid (HCl).

et al., Applied Inorganic Analysis, JohnWiley & Sons, Inc., NewYork, NY, Second

Ed., 1953, p. 108. 10.6 Iron or Carbon Steel—Pure iron or plain carbon steel.

D1394 − 76 (2020)

brown glass bottle stored in a dark place. Calculate the TiO

equivalent in grams of TiO per millilitre of the KMnO

2 4

solution as follows:

TiO equivalent 5 W 31.192 /V

~ !

where:

W =Na C O used, g, and

2 2 4

V = KMnO solution required for the titration, mL.

10.10 Sulfuric Acid (sp gr 1.84)—Concentratedsulfuricacid

(H SO ).

2 4

10.11 Sulfuric Acid (1+1)—Carefully mix 1 volume of

H SO (sp gr 1.84) into 1 volume of water with rapid stirring.

2 4

10.12 Sulfuric Acid (1+19)—Carefully mix 1 volume of

H SO into 19 volumes of water with rapid stirring.

2 4

11. Procedure

11.1 Determine the dry weight of a weighing bottle and cap

to0.1mg.Weightto0.1mg300to350mgofthesampletobe

analyzed into the weighing bottle.

11.2 Dry the specimen in the opened weighing bottle for 2

h at 105 to 110°C. Cool in a desiccator, cap the bottle, and

weigh as rapidly as possible. Calculate the dry weight of the

specimen and use in the actual calculation.

11.3 Transferthedriedspecimentoadry250mLchemical-

and heat-resistant glass beaker, add 20 mL of H SO (sp gr

2 4

1.84) and 7 to8gof(NH ) SO . Mix well and heat on a hot

4 2 4

plate until dense white fumes are evolved, and then continue

the heating over a strong flame until solution is complete

(usuallyrequiresnotover5minofboiling)oritisapparentthat

FIG. 2 Jones Reductor, Assembled

the residue is composed of SiO or siliceous matter. Caution

should be observed in visually examining this hot solution.

Cool the solution, dilute with 100 mL of water, stir, heat

10.7 Nitric Acid (sp gr 1.42)—Concentrated nitric acid

carefully to boiling while stirring, let settle, filter through

(HNO ).

paper, and transfer the precipitate completely to the paper.

10.8 Sodium Oxalate—National Institute of Standards and

11.4 Wash the insoluble residue with cold H SO (1+19)

2 4

Technology standard reference material No. 40 of sodium

untiltitaniumisremoved.Dilutethefiltrateto200mLandadd

oxalate (Na C O ).

2 2 4

about5mLofNH OHtolowertheaciditytoapproximately10

10.9 Potassium Permanganate, Standard Reference Mate-

to 15% H SO (by volume).Wash out the Jones reductor with

2 4

rial(0.1 N,1mL=0.008gTiO )—Dissolve3.16gofKMnO

2 4 H SO (1+19) and water, leaving sufficient water in the

2 4

inwateranddiluteto1L.Letstand8to14days,siphonoffthe

reductor to fill to the upper level of the zinc. (These washings

clear solution (or filter through sintered glass, medium

shouldrequirenotmorethanoneortwodropsof0.1 NKMnO

porosity), and standardize against the National Bureau of

solution to obtain a pink color.) Empty the receiver, and put in

Standards standard sample No. 40 of sodium oxalate

it 25 mL of ferric sulfate solution. Reduce the prepared

(Na C O )asfollows:Ina400-mLbeakerdissolve250to300

titanium solution as follows:

2 2 4

mg Na C O in 250 mLof hot water (80 to 90°C) and add 15

2 2 4

11.4.1 Run 50 mLof H SO (1+19) through the reductor at

2 4

mL of H SO (1+1). Titrate at once with the KMnO solution,

2 4 4 such a uniform rate as to require 5 to 10 min for passage.

stirring the liquid vigorously and continuously. The KMnO

11.4.2 Follow this with the titanium solution at such a

solutionmustnotbeaddedmorerapidlythan10to15mL/min,

uniform rate as to require 10 min to pass through the reductor.

andthelast0.5to1mLmustbeaddeddropwisewithparticular

11.4.3 Wash out with 100 mL of H SO (1+19).

2 4

care to allow each drop to be fully decolorized before the next

11.4.4 Finallyrunthroughabout100mLofwater.Takecare

isintroduced.Thesolutionshallnotbebelow60°Cbythetime

that the reductor is always filled with solution or water to the

the end point has been reached. (More rapid cooling may be

upper level of the zinc.

prevented by allowing the beaker to stand on a small hot plate

during the titration. The use of a small type thermometer as a 11.5 Gradually release the suction, wash thoroughly the

stirring rod is most convenient.) Keep the KMnO solution in glass tube that was immersed in the ferric sulfate solution,

a glass-stoppered bottle painted black to keep out light or in a remove the receiver, and titrate immediately with 0.1 N

D1394 − 76 (2020)

KMnO solution. Run a blank determination, using the same where:

reagents and washing the reductor as in the above determina-

W = National Bureau of Standards standard sample ofTiO

1 2

tion.

used, g,

P = percentTiO inNationalBureauofStandardsstandard

12. Calculation sample, and

V = ferric ammonium sulfate solution required for the

12.1 Calculate the percent of TiO as follows:

titration, mL.

V 2 B 3 T

~ !

TiO,% 5 3100 15.5 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

S

chloric acid (HCl).

where:

15.6 Hydrogen Peroxide—3%.

V = KMnO solutionrequiredfortitrationofspecimen,mL

1 4

15.7 Sodium Bicarbonate Solution—Make up a saturated

B = KMnO solution required for titration of the blank, mL

solution at the time of analysis. About 10 g of sodium

T =TiO equivalent of the KMnO solution, g/mL, and

2 4

bicarbonate (NaHCO ) to 90 g of water is required.

S = dried specimen, g. 3

15.8 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

12.2 The results calculated in accordance with 12.1 will

(H SO ).

2 4

include iron, chromium, arsenic, and any other substance that

isreducedbyzincandacid.However,appreciablequantitiesof

15.9 Titanium Dioxide (TiO )—National Bureau of Stan-

interferingmaterialsarenotlikelytobeencounteredinnormal, dards standard sample No. 154 of titanium dioxide.

white titanium pigments.

16. Procedure

TOTAL TITANIUM BY THE ALUMINUM

16.1 Determine the dry weight of the weighing bottle and

REDUCTION METHOD

cap.Weigh to the nearest 0.1 mg, 190 to 210 mg of the sample

to be analyzed into the weighing bottle.

13. Scope

16.2 Drythespecimenintheopenweighingbottlefor2hat

13.1 This method gives results similar to those obtained

105to110°C.Coolinadesiccator,capthebottle,andweighas

with the Jones Reductor Method (Sections8–12).

rapidly as possible. Calculate the dry weight of the specimen

and use in the actual calculation.

14. Apparatus

16.3 Transfer the dry specimen to a 500-mL dry, wide-

14.1 Delivery Tube, made of about 4-mm inside diameter

mouthErlenmeyerflask.Add7to9gof(NH ) SO and20mL

4 2 4

glass tubing bent so that there is a horizontal run of about 6 in.

of H SO . Mix well, heat on a hot plate until dense white

2 4

(152mm)andaverticaldropofabout3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.