ASTM D1693-21

(Test Method)Standard Test Method for Environmental Stress-Cracking of Ethylene Plastics

Standard Test Method for Environmental Stress-Cracking of Ethylene Plastics

SIGNIFICANCE AND USE

5.1 This test method may be used for routine inspection purposes by subjecting a required number of specimens to the test conditions for a specified time and noting the number that fail. The cracking obtained with the test reagent is indicative of what may be expected from a wide variety of surface-active agents, soaps, and organic substances that are not absorbed appreciably by the polymer.

5.2 Environmental stress-cracking is a property that is highly dependent upon the nature and level of the stresses applied and on the thermal history of the specimen (1). Under the conditions of the test method, high local multiaxial stresses are developed through the introduction of a controlled imperfection (2, 3). Environmental stress-cracking has been found to occur most readily under such conditions.

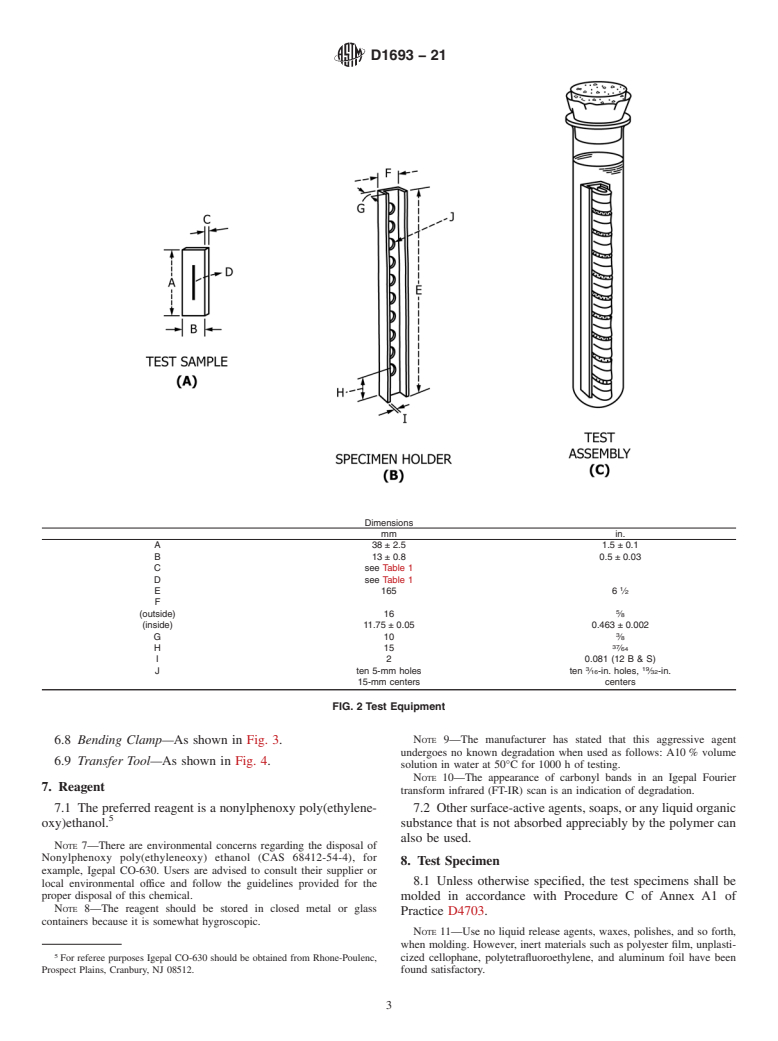

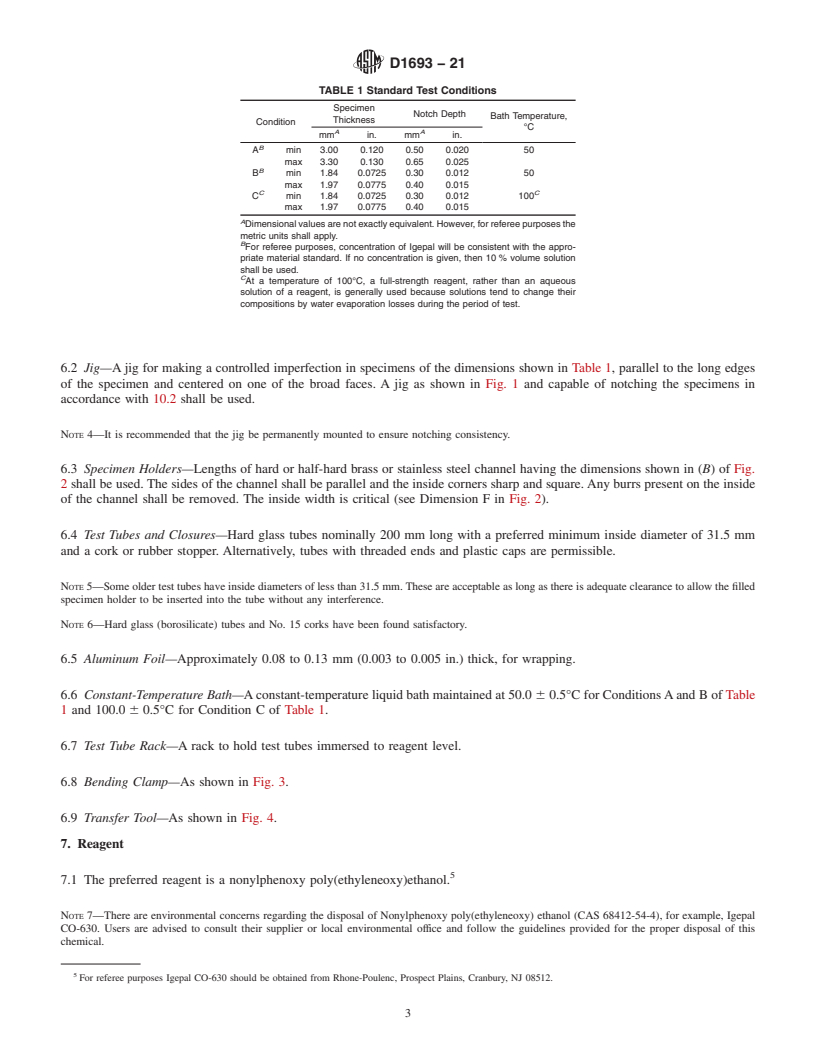

Note 2: Different types of polyethylene plastics as defined in Specification D1248 are generally tested under different levels of strain and stress. When it is expressly desired to compare the types at equal levels of strain, the specimens for all types should be tested under Condition B, Table 1 (4) . (A) Dimensional values are not exactly equivalent. However, for referee purposes the metric units shall apply.(B) For referee purposes, concentration of Igepal will be consistent with the appropriate material standard. If no concentration is given, then 10 % volume solution shall be used.(C) At a temperature of 100°C, a full-strength reagent, rather than an aqueous solution of a reagent, is generally used because solutions tend to change their compositions by water evaporation losses during the period of test.

5.3 Information from this test method is not intended to be used for direct application to engineering problems.

Note 3: Caution should be used in comparing and ranking various ethylene plastics into distinct and separate groups by this test method (see Section 13 and Note 12).

As thermal history is recognized as an important variable, test results by this...

SCOPE

1.1 This test method covers the determination of the susceptibility of ethylene plastics, as defined in Terminology D883, to environmental stress-cracking when subjected to the conditions herein specified. Under certain conditions of stress and in the presence of environments such as soaps, wetting agents, oils, or detergents, ethylene plastics may exhibit mechanical failure by cracking.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1693 − 21

Standard Test Method for

1

Environmental Stress-Cracking of Ethylene Plastics

This standard is issued under the fixed designation D1693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D3350 Specification for Polyethylene Plastics Pipe and Fit-

tings Materials

1.1 This test method covers the determination of the sus-

D4703 Practice for Compression Molding Thermoplastic

ceptibility of ethylene plastics, as defined in Terminology

Materials into Test Specimens, Plaques, or Sheets

D883, to environmental stress-cracking when subjected to the

D4976 Specification for Polyethylene Plastics Molding and

conditions herein specified. Under certain conditions of stress

Extrusion Materials

and in the presence of environments such as soaps, wetting

E691 Practice for Conducting an Interlaboratory Study to

agents, oils, or detergents, ethylene plastics may exhibit

Determine the Precision of a Test Method

mechanical failure by cracking.

2.2 ASTM Adjuncts:

1.2 The values stated in SI units are to be regarded as 3

Apparatus Drawings and Blueprints

standard.

3. Terminology

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1 Definitions:

responsibility of the user of this standard to establish appro-

3.1.1 stress-crack, n—an external or internal rupture in a

priate safety, health, and environmental practices and deter-

plastic caused by tensile stresses less than its short-time

mine the applicability of regulatory limitations prior to use.

mechanical strength.

3.1.1.1 Discussion—The development of such cracks is

NOTE 1—There is no known ISO equivalent to this standard.

frequently accelerated by the environment to which the plastic

1.4 This international standard was developed in accor-

is exposed. The stresses which cause cracking may be present

dance with internationally recognized principles on standard-

internally or externally, or may be a combination of these

ization established in the Decision on Principles for the

stresses. The appearance of a network of fine cracks is called

Development of International Standards, Guides and Recom-

crazing.

mendations issued by the World Trade Organization Technical

3.1.2 stress-crack failure, n—for purposes of this test

Barriers to Trade (TBT) Committee.

method, any crack visible to an observer with normal eyesight

4

2. Referenced Documents

shall be interpreted as a failure of the entire specimen (1).

2

Extension of the controlled imperfection shall not be construed

2.1 ASTM Standards:

as a failure. The appearance of more than one crack in a single

D618 Practice for Conditioning Plastics for Testing

specimen shall be construed as a single failure.

D883 Terminology Relating to Plastics

3.1.2.1 Discussion—Cracks generally develop at the con-

D1204 Test Method for Linear Dimensional Changes of

trolled imperfection and run to the outer edge of the specimen

Nonrigid Thermoplastic Sheeting or Film at Elevated

approximately at right angles to it (2). The cracks need not

Temperature

extend completely through the specimen to constitute failure.

D1248 Specification for Polyethylene Plastics Extrusion

Cracks sometimes develop under the polymer surface, mani-

Materials for Wire and Cable

festing themselves as depressions on the surface. The time

when this occurs should be noted, and if the depression later

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

develops into a crack, the time of dimpling should be consid-

and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materi-

ered as the failure time.

als.

Current edition approved Oct. 1, 2021. Published October 2021. Originally

ɛ1

approved in 1959. Last previous edition approved in 2015 as D1693 - 15 . DOI:

3

10.1520/D1693-21. Detailed drawings of the apparatus are available from ASTM Headquarters.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Request ADJD169302, ADJD169303,or ADJD169304. For a complete set of all

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM drawings, request ADJD1693CS.

4

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this test method.

*A Summary of Chan

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1693 − 15 D1693 − 21

Standard Test Method for

1

Environmental Stress-Cracking of Ethylene Plastics

This standard is issued under the fixed designation D1693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Adjunct footnote was editorially corrected in August 2020.

1. Scope*

1.1 This test method covers the determination of the susceptibility of ethylene plastics, as defined in Terminology D883, to

environmental stress-cracking when subjected to the conditions herein specified. Under certain conditions of stress and in the

presence of environments such as soaps, wetting agents, oils, or detergents, ethylene plastics may exhibit mechanical failure by

cracking.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1204 Test Method for Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated Temperature

D1248 Specification for Polyethylene Plastics Extrusion Materials for Wire and Cable

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

D4703 Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets

D4976 Specification for Polyethylene Plastics Molding and Extrusion Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved May 1, 2015Oct. 1, 2021. Published June 2015October 2021. Originally approved in 1959. Last previous edition approved in 20132015 as

ɛ1

D1693 - 13.D1693 - 15 . DOI: 10.1520/D1693-15E01.10.1520/D1693-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1693 − 21

2.2 ASTM Adjuncts:

3

Apparatus Drawings and Blueprints

3. Terminology

3.1 Definitions:

3.1.1 stress-crack, n—an external or internal rupture in a plastic caused by tensile stresses less than its short-time mechanical

strength.

3.1.1.1 Discussion—

The development of such cracks is frequently accelerated by the environment to which the plastic is exposed. The stresses which

cause cracking may be present internally or externally, or may be a combination of these stresses. The appearance of a network

of fine cracks is called crazing.

3.1.2 stress-crack failure, n—for purposes of this test method, any crack visible to an observer with normal eyesight shall be

4

interpreted as a failure of the entire specimen (1). Extension of the controlled imperfection shall not be construed as a failure. The

appearance of more than one crack in a single specimen shall be construed as a single failure.

3.1.2.1 Discussion—

Cracks generally develop at the controlled imperfection and run to the outer edge of the specimen approximately at right angles

to it (2). The cracks need not extend completely through the specimen to constitute failure. Cracks sometimes develop under the

polymer surface, manifesting the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.