ASTM F2080-04

(Specification)Standard Specification for Cold-Expansion Fittings With Metal Compression-Sleeves for Cross-Linked Polyethylene (PEX) Pipe

Standard Specification for Cold-Expansion Fittings With Metal Compression-Sleeves for Cross-Linked Polyethylene (PEX) Pipe

SCOPE

1.1 This specification covers cold-expansion fittings using metal compression-sleeves for use with cross-linked polyethylene (PEX) plastic pipe in 3/8-in., 1/2-in., 5/8-in., 3/4-in., 1-in., 11/4-in., 11/2-in., and 2 in. nominal diameters, whereby the PEX pipe is cold-expanded before fitting assembly. These cold-expansion fittings and metal compression-sleeves are intended for use in residential and commercial, hot and cold, potable water distribution systems, as well as sealed central heating, including under-floor heating systems, with continuous operation at pressures up to and including 100 psi (690 kPa), and at temperatures up to and including 180°F (82°C).

1.2 Included in this specification are the requirements for materials, workmanship, dimensions, and markings to be used on the fittings and compression-sleeves. Performance requirements are as referenced in Specification F 877.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI values stated in parentheses are provided for information purposes only.

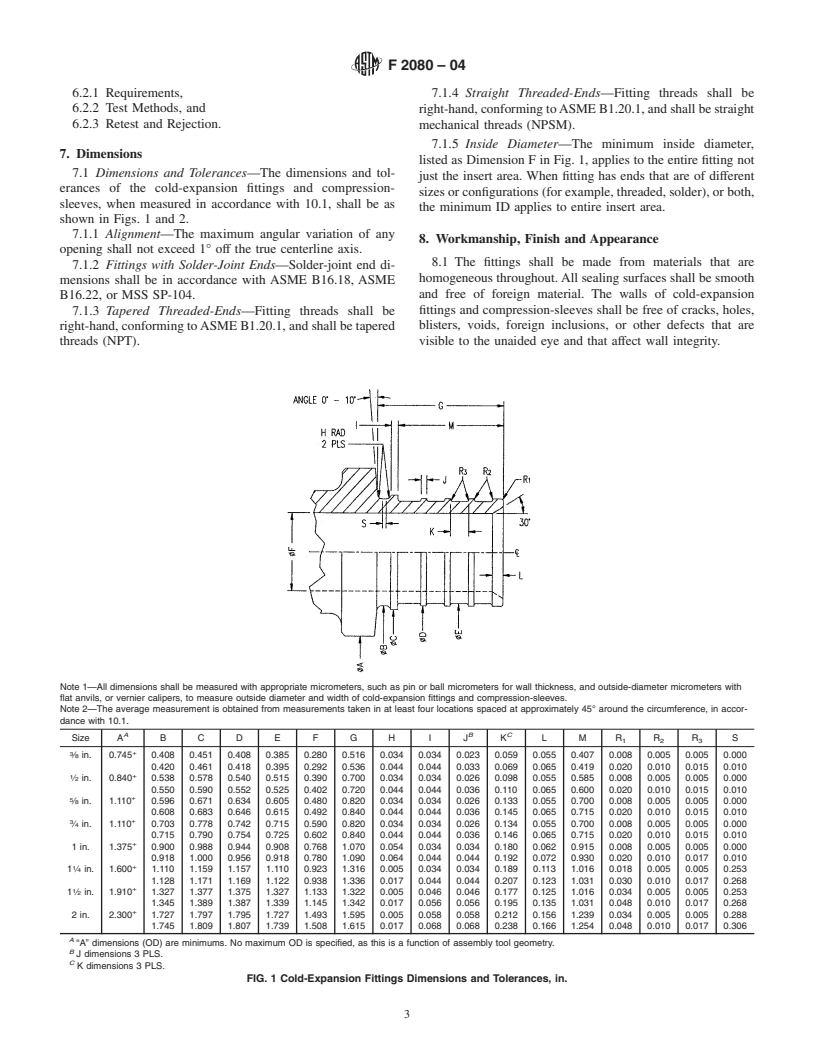

1.4 The following precautionary caveat pertains only to the test method portion, Section 10, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2080 – 04

Standard Specification for

Cold-Expansion Fittings With Metal Compression-Sleeves

1

for Cross-Linked Polyethylene (PEX) Pipe

This standard is issued under the fixed designation F 2080; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope tenitic Stainless Steel Pipes

A 519 Specification for Seamless Carbon and Alloy Steel

1.1 This specification covers cold-expansion fittings using

Mechanical Tubing

metal compression-sleeves for use with cross-linked polyeth-

A 584 Specification for Copper Alloy Sand Castings for

3 1 5 3

ylene (PEX) plastic pipe in ⁄8-in., ⁄2-in., ⁄8-in., ⁄4-in., 1-in.,

1 1 General Applications

1 ⁄4-in., 1 ⁄2-in., and 2 in. nominal diameters, whereby the PEX

B 16/B 16M Specification for Free-Cutting Brass Rod, Bar,

pipe is cold-expanded before fitting assembly. These cold-

and Shapes for Use in Screw Machines

expansion fittings and metal compression-sleeves are intended

B 62 Specification for Composition Bronze or Ounce Metal

for use in residential and commercial, hot and cold, potable

Castings

water distribution systems, as well as sealed central heating,

B 140/B 140M Specification for Copper-Zinc-Lead

including under-floor heating systems, with continuous opera-

(Leaded Red Brass or Hardware Bronze) Rod, Bar and

tion at pressures up to and including 100 psi (690 kPa), and at

Shapes

temperatures up to and including 180°F (82°C).

B 283 SpecificationforCopperandCopper-AlloyDieForg-

1.2 Included in this specification are the requirements for

ings (Hot-Pressed)

materials, workmanship, dimensions, and markings to be used

B 689 Specification for Electroplated Engineering Nickel

on the fittings and compression-sleeves. Performance require-

Coatings

ments are as referenced in Specification F 877.

B 851 SpecificationforAutomatedControlledShotPeening

1.3 The values stated in inch-pound units are to be regarded

of Metallic Articles Prior to Nickel, Autocatalytic Nickel,

as the standard. The SI values stated in parentheses are

or Chromium Plating, or As a Final Finish

provided for information purposes only.

D 1600 Terminology for Abbreviated Terms Relating to

1.4 The following precautionary caveat pertains only to the

Plastics

test method portion, Section 10, of this specification. This

D 2122 Test Method for Determining Dimensions of Ther-

standard does not purport to address all of the safety concerns,

moplastic Pipe and Fittings

if any, associated with its use. It is the responsibility of the user

D 6394 Specification for Sulfone Plastics (SP)

of this standard to establish appropriate safety and health

F 412 Terminology Relating to Plastic Piping Systems

practices and determine the applicability of regulatory limita-

F 876 Specification for Crosslinked Polyethylene (PEX)

tions prior to use.

Tubing

2. Referenced Documents

F 877 Specification for Crosslinked Polyethylene (PEX)

2

Plastic Hot- and Cold-Water Distribution Systems

2.1 ASTM Standards:

2.2 ASME Standards:

A 108 Specification for Steel Bars, Carbon, Cold Finished,

3

B1.20.1 Pipe Threads General Purpose (Inch)

Standard Quality

B16.18 Cast Copper Alloy Solder Joint Pressure Fittings

A 269 Specification for Seamless and Welded Austenitic

3

(Inch)

Stainless Steel Tubing for General Service

B16.22 Wrought Copper Alloy Solder Joint Pressure Fit-

A 276 Specification for Stainless Steel Bars and Shapes

3

tings (Inch)

A 312/A 312M SpecificationforSeamlessandWeldedAus-

2.3 NSF Standards:

Standard No. 14 for Plastic Piping Components and Related

4

1

Materials

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved April 1, 2004. Published April 2004. Originally

approved in 2001. Last previous edition approved in 2002 as F 2080 – 02.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society of Mechanical Engineers (ASME), ASME

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM International Headquarters, Three Park Ave., New York, NY 10016-5990.

4

Standards volume information, refer to the standard’s Document Summary page on Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

the ASTM website. Arbor, MI 48113-0140.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2080–04

Standard No. 61 for Drinking Water System Components— 5.1.5 Cast Copper Alloys—Cast copper alloy cold-

4

Health Effects expa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.