ASTM A826/A826M-95(2001)

(Specification)Standard Specification for Seamless Austenitic and Martensitic Stainless Steel Duct Tubes for Liquid Metal-Cooled Reactor Core Components (Withdrawn 2004)

Standard Specification for Seamless Austenitic and Martensitic Stainless Steel Duct Tubes for Liquid Metal-Cooled Reactor Core Components (Withdrawn 2004)

SCOPE

1.1 This specification covers seamless, annealed or cold worked, austenitic or martensitic stainless steel duct tubes of 2 to 7-in. [51 to 178 mm] outside dimensions with wall thickness of 0.250 in. [6.35 mm] or less for use at high temperature in liquid metal-cooled reactor plants.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This specification and the applicable material specifications are expressed in both inch-pound and SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished in inch-pound units.

WITHDRAWN RATIONALE

This specification covers seamless, annealed or cold worked, austenitic or martensitic stainless steel duct tubes of 2 to 7-in. [51 to 178 mm] outside dimensions with wall thickness of 0.250 in. [6.35 mm] or less for use at high temperature in liquid metal-cooled reactor plants.

Formerly under the jurisdiction of Committee A01 on Steel, Stainless Stell, and Related Alloys, this specification was withdrawn in March 2004.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 826/A 826M – 95 (Reapproved 2001)

Standard Specification for

Seamless Austenitic and Martensitic Stainless Steel Duct

1

Tubes for Liquid Metal-Cooled Reactor Core Components

ThisstandardisissuedunderthefixeddesignationA826/A826M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

6

1. Scope leum Products (Bomb Method)

7

E3 Methods of Preparation of Metallographic Specimens

1.1 This specification covers seamless, annealed or cold

E29 Practice for Using Significant Digits in Test Data to

worked, austenitic or martensitic stainless steel duct tubes of 2

8

Determine Conformance with Specifications

to7-in.[51to178mm]outsidedimensionswithwallthickness

E45 Practice for Determining the Inclusion Content of

of 0.250 in. [6.35 mm] or less for use at high temperature in

7

Steel

liquid metal-cooled reactor plants.

E112 Test Methods for Determining the Average Grain

1.2 The values stated in either inch-pound units or SI units

7

Size

are to be regarded separately as standard. Within the text, the

9

E165 Test Method for Liquid Penetrant Examination

SI units are shown in brackets. The values stated in each

7

E384 Test Method for Microhardness of Materials

system are not exact equivalents; therefore, each system must

7

E407 Test Methods for Microetching Metals and Alloys

beusedindependentlyoftheother.Combiningvaluesfromthe

2.2 ANSI Standard:

two systems may result in nonconformance with the specifi-

10

B46.1 Surface Texture

cation.

2.3 ASME Standard:

1.3 This specification and the applicable material specifica-

NQA-1 Quality Assurance Program Requirements for

tions are expressed in both inch-pound and SI units. However,

10

Nuclear Facilities

unless the order specifies the applicable “M” specification

2.4 ASNT Standard:

designation (SI units), the material shall be furnished in

2

SNT-TC-1A Recommended Practice for Nondestructive

inch-pound units.

10

Testing Personnel Qualification and Certification

2. Referenced Documents

3. Ordering Information

2.1 ASTM Standards:

3.1 It is the responsibility of the purchaser to specify all

A370 TestMethodsandDefinitionsforMechanicalTesting

3

requirements that are necessary for the safe and satisfactory

of Steel Products

performance of material ordered under this specification.

A380 Practice for Cleaning and Descaling Stainless Steel

4

Examples of such requirements include but are not limited to

Parts, Equipment and Systems

the following:

A450/A450M Specification for General Requirements for

5

3.1.1 Quantity (feet, metres, or number of lengths),

Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes

3.1.2 Name of material (seamless duct tubes),

A 751 Test Methods, Practices, and Terminology for

3

3.1.3 Grade (Table 1),

Chemical Analysis of Steel Products

3.1.4 Melting process (5.1),

D129 Test Method for Sulfur in Petroleum Products (Gen-

6

3.1.5 Approval of procedures for conversion of ingot to bar

eral Bomb Method)

(5.2),

D808 Test Method for Chlorine in New and Used Petro-

3.1.6 Thermomechanical treatment requirements (5.4),

3.1.7 Annealingandtemperingrequirementsformartensitic

grades (5.4),

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

3.1.8 Condition(annealed,cold-worked,orthermomechani-

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products. cal treatment) (5.6),

Current edition approved Nov. 10, 1995. Published January 1996. Originally

published as A826–84. Last previous edition A826–88.

2

Available from the American Society for Nondestructive Testing, 3200 River-

7

side Drive, Columbus, OH 43221. Annual Book of ASTM Standards, Vol 03.01.

3 8

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 14.02.

4 9

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 03.03.

5 10

Annual Book of ASTM Standards, Vol 01.01. Available fromAmerican National Standards Institute, 11 West 42nd St., 13th

6

Annual Book of ASTM Standards, Vol 05.01. Floor, New York, NY 10036.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 826/A 826M – 95 (2001)

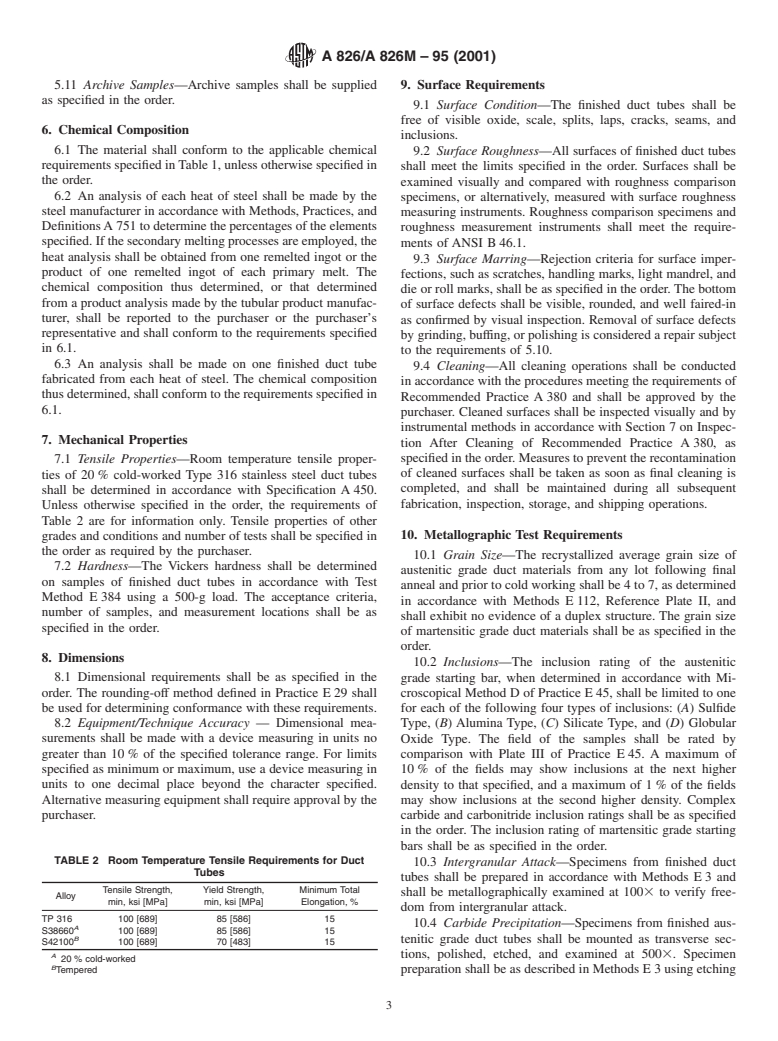

TABLE 1 Chemical Requirements of Duct Tubes

5.2 Ingot Processing—Procedures for converting ingots to

Grade TP 316 . . barsshallbeapprovedbythepurchaserpriortouseifspecified

UNS Designation S 31600 S38660 S42100

in the order. The parameters for the conversion of austenitic

Carbon 0.040–0.060 0.030–0.050 0.17–0.23

grades shall be selected to minimize the formation of complex

Mangane

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.