ASTM A511/A511M-21

(Specification)Standard Specification for Seamless Stainless Steel Mechanical Tubing and Hollow Bar

Standard Specification for Seamless Stainless Steel Mechanical Tubing and Hollow Bar

ABSTRACT

This specification covers seamless stainless tubing for use in mechanical applications where corrosion-resistant or high-temperature strength is needed. The steel may be cast in ingots or may be strand cast. When steel of different grades is sequentially strand cast, identification of the resultant transition material is required. The tubes shall be made by a seamless process and by either cold working or hot working as specified. Seamless steel tubing is a tubular product made without a welded seam. It is usually manufactured by hot working steel and then cold finishing the hot-worked tubing to produce the desired shape, dimensions and properties All austenitic tubes shall be furnished in the annealed condition. An analysis of each heat of steel shall be made to determine the percentages of the elements specified. If secondary melting processes are employed, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt.

SCOPE

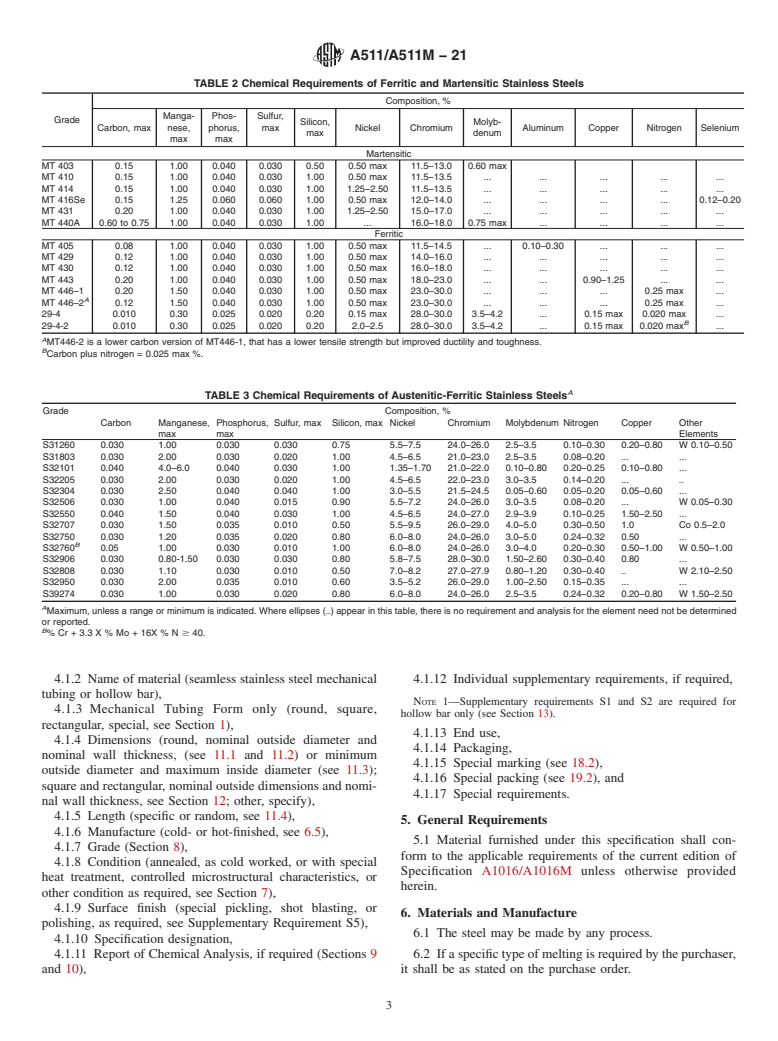

1.1 This specification covers seamless stainless tubing for use in mechanical applications or as hollow bar for use in the production of hollow components such as, but not limited to nozzles, reducers, and couplings by machining where corrosion-resistant or high-temperature strength is needed. The grades covered are listed in Table 1 , Table 2, and Table 3.

1.2 This specification covers seamless cold-finished mechanical tubing and hollow bar and seamless hot-finished mechanical tubing and hollow bar in sizes up to 123/4 in. [325 mm] in outside nominal diameter (for round tubing) with wall thicknesses or inside diameters as required.

1.3 Tubes for mechanical applications shall be furnished in one of the following shapes, as specified by the purchaser: round, square, rectangular, or special. Tubes to be used as hollow bar shall be furnished in round shape.

1.4 Optional supplementary requirements are provided and when desired, shall be stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard. Within the text, the SI units are shown in square brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A511/A511M −21

Standard Specification for

Seamless Stainless Steel Mechanical Tubing and Hollow

1

Bar

This standard is issued under the fixed designationA511/A511M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers seamless stainless tubing for 2.1 ASTM Standards:

use in mechanical applications or as hollow bar for use in the A262Practices for Detecting Susceptibility to Intergranular

production of hollow components such as, but not limited to Attack in Austenitic Stainless Steels

nozzles, reducers, and couplings by machining where A1016/A1016MSpecification for General Requirements for

corrosion-resistantorhigh-temperaturestrengthisneeded.The Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless

grades covered are listed in Table 1 , Table 2, and Table 3. Steel Tubes

A1058 Test Methods for Mechanical Testing of Steel

1.2 This specification covers seamless cold-finished me-

Products—Metric

chanical tubing and hollow bar and seamless hot-finished

E112Test Methods for Determining Average Grain Size

3

mechanical tubing and hollow bar in sizes up to 12 ⁄4 in. [325

2.2 Military Standards:

mm] in outside nominal diameter (for round tubing) with wall

3

MIL-STD-129 Marking for Shipment and Storage

thicknesses or inside diameters as required.

MIL-STD-163SteelMillProductsPreparationfor Shipment

3

1.3 Tubes for mechanical applications shall be furnished in

and Storage

one of the following shapes, as specified by the purchaser:

2.3 Federal Standard:

3

round, square, rectangular, or special. Tubes to be used as

Fed. Std. No. 123Marking for Shipments (CivilAgencies)

hollow bar shall be furnished in round shape.

3. Terminology

1.4 Optional supplementary requirements are provided and

3.1 Definitions:

when desired, shall be stated in the order.

3.1.1 hollow bar—round tubing that is intended to produce

1.5 The values stated in inch-pound units are to be regarded

engineering components by machining, generally specified by

as the standard. Within the text, the SI units are shown in

minimum outside diameter and maximum inside diameter.

square brackets.The values stated in each system are not exact

3.1.2 mechanical tubing—tubing of various shapes used for

equivalents;therefore,eachsystemshallbeusedindependently

mechanical and general engineering purposes, specified by

of the other.

nominal outside dimension and nominal wall.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Ordering Information

ization established in the Decision on Principles for the

4.1 Orders for material under this specification should

Development of International Standards, Guides and Recom-

include the following as required to describe the desired

mendations issued by the World Trade Organization Technical

material adequately:

Barriers to Trade (TBT) Committee.

4.1.1 Quantity (feet, mass, or number of pieces),

1 2

This specification is under the jurisdiction ofASTM Committee A01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.10 on Stainless and Alloy Steel Tubular Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2021. Published October 2021. Originally the ASTM website.

3

approved in 1964. Last previous edition approved in 2020 as A511/A511M–20. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

DOI: 10.1520/A0511_A0511M-21. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A511/A511M−21

2

TABLE 1 Chemical Requirements of Austenitic Stainless Steels

Composition, %

Phos- Sul-

Other

Grade

Manga- pho- fur, Silicon,

D

Carbon Nickel Chromium Molybdenum Titanium Niobium Selenium Iron Elements

nese rus, max max

max

MT 302 0.08 to 0.20 2.00 max 0.040 0.030 1.00 8.0–10.0 17.0–19.0 . . . . . .

MT 303 0.15 max 2.00 max 0.20 0.15 min 1.00 8.0–10.0 17.0–19.0 . . . . . .

MT 303Se 0.15 max 2.00 max 0.040 0.040 1.00 8.0–11.0 17.0–19.0 . . . 0.12–0.2 . .

MT 304 0.08 max 2.00 max 0.040 0

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A511/A511M − 20 A511/A511M − 21

Standard Specification for

Seamless Stainless Steel Mechanical Tubing and Hollow

1

Bar

This standard is issued under the fixed designation A511/A511M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers seamless stainless tubing for use in mechanical applications or as hollow bar for use in the production

of hollow components such as, but not limited to nozzles, reducers, and couplings by machining where corrosion-resistant or

high-temperature strength is needed. The grades covered are listed in Table 1 , Table 2, and Table 3.

1.2 This specification covers seamless cold-finished mechanical tubing and hollow bar and seamless hot-finished mechanical

3

tubing and hollow bar in sizes up to 12 ⁄4 in. [325 mm] in outside nominal diameter (for round tubing) with wall thicknesses or

inside diameters as required.

1.3 Tubes for mechanical applications shall be furnished in one of the following shapes, as specified by the purchaser: round,

square, rectangular, or special. Tubes to be used as hollow bar shall be furnished in round shape.

1.4 Optional supplementary requirements are provided and when desired, shall be stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard. Within the text, the SI units are shown in square

brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the

other.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

A1058 Test Methods for Mechanical Testing of Steel Products—Metric

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved Nov. 1, 2020Sept. 1, 2021. Published November 2020October 2021. Originally approved in 1964. Last previous edition approved in 20162020

as A511/A511M – 16.A511/A511M – 20. DOI: 10.1520/A0511_A0511M-20.10.1520/A0511_A0511M-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

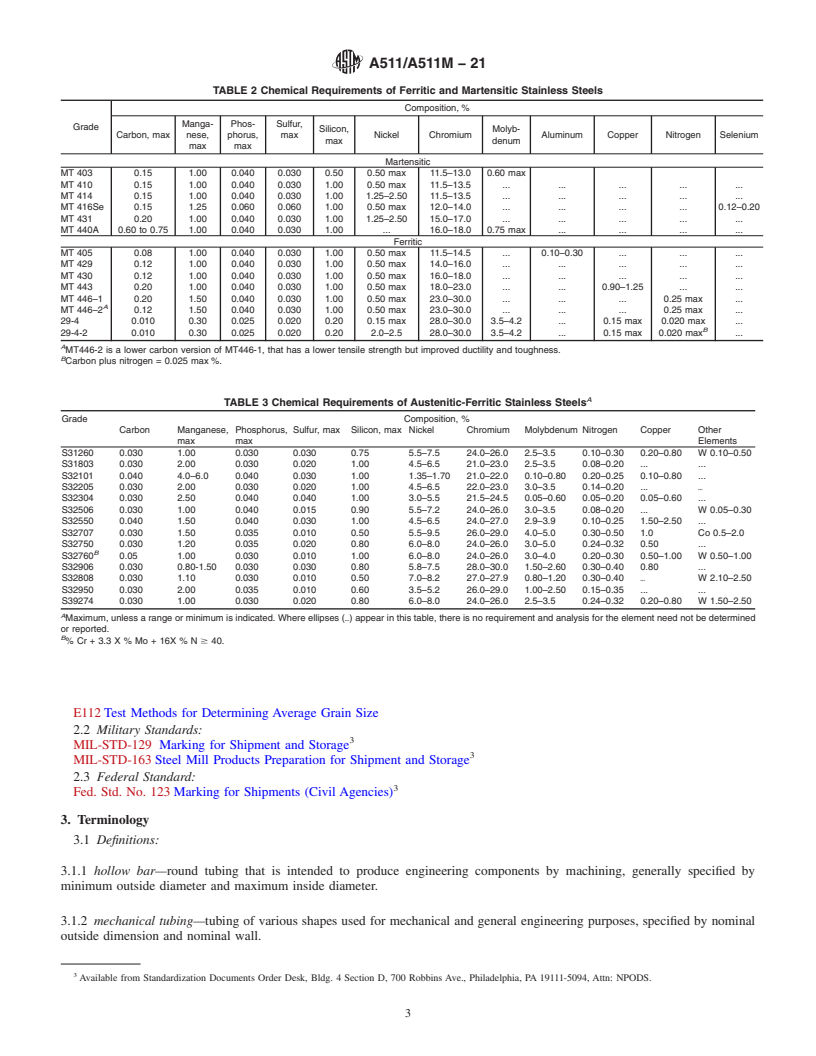

A511/A511M − 21

2

TABLE 1 Chemical Requirements of Austenitic Stainless Steels

Composition, %

Phos- Sul-

Other

Grade

Manga- pho- fur, Silicon,

D

Carbon Nickel Chromium Molybdenum Titanium Niobium Selenium Iron Elements

nese rus, max max

max

MT 302 0.08 to 0.20 2.00 max 0.040 0.030 1.00 8.0–10.0 17.0–19.0 . . . . . .

MT 303 0.15 max 2.00 max 0.20 0.15 min 1.00 8.0–10.0 17.0–19.0 . . . . . .

MT 303Se 0.15 max 2.00 max 0.040 0.040 1.00 8.0–11.0 17.0–19.0 . . . 0.12–0.2 . .

MT 304 0.08 max 2.00 max 0.040 0.030 1.00 8.0–11.0 18.0–20.0 . . . . . .

A

MT 304L 0.035 max 2.00 max 0.040 0.030 1.00 8.0–13.0 18.0–20.0 . . . . . .

MT 305 0.12 2.00 max 0.040 0.030 1.00 10.0–13.0 17.0–19.0 . . . . . .

MT 309S 0.08 max 2.00 max 0.040 0.030 1.00 12.0–15.0 22.0–24.0 . . . . . .

MT 310S 0.08 max 2.00 max 0.040 0.030 1.00 19.0–22.0 24.0–26.0 . . . . . .

MT 316 0.08 max 2.00 max 0.040 0.030 1.00 11.0–14.0 16.0–18.0 2.0–3.0 . . . . .

A

MT 316L 0.035 max 2.00 max 0.040 0.030 1.00 10.0–15.0 16.0–18.0 2.0–3.0 . . . .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.