ASTM F1718-01(2013)

(Specification)Standard Specification for Rotary Positive Displacement Distillate Fuel Pumps

Standard Specification for Rotary Positive Displacement Distillate Fuel Pumps

ABSTRACT

This specification covers the design and construction requirements of rotary positive displacement distillate fuel pumps intended for use in shipboard. Pumps covered by this specification are of Types II, III, IV, V, VIII, X, and XI and of sizes A-H. The pump shall be manufactured capable of sustaining operation in any direction up to a certain inclination, shall withstand environmental vibration induced by shipboard machinery and equipment, shall be driven by an electric motor, and besides distillate fuel, the pump shall also be used to pump aviation turbine fuel. Performance acceptance tests shall be performed, including mechanical running test, noise test, and hydrostatic test, and shall conform to the requirements specified.

SCOPE

1.1 This specification covers the requirements applicable to the design and construction of rotary positive displacement distillate fuel pumps for shipboard use.

1.2 Lineal dimensions and units of force in this specification are expressed as inches and pounds respectively. A companion metric standard is in the process of preparation.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1718 −01 (Reapproved 2013) An American National Standard

Standard Specification for

Rotary Positive Displacement Distillate Fuel Pumps

This standard is issued under the fixed designation F1718; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A312/A312M Specification for Seamless, Welded, and

Heavily Cold Worked Austenitic Stainless Steel Pipes

1.1 This specification covers the requirements applicable to

A354Specification for Quenched and TemperedAlloy Steel

the design and construction of rotary positive displacement

Bolts, Studs, and Other Externally Threaded Fasteners

distillate fuel pumps for shipboard use.

A434Specification for Steel Bars, Alloy, Hot-Wrought or

1.2 Linealdimensionsandunitsofforceinthisspecification

Cold-Finished, Quenched and Tempered

are expressed as inches and pounds respectively.Acompanion

A449Specification for Hex Cap Screws, Bolts and Studs,

metric standard is in the process of preparation.

Steel, Heat Treated, 120/105/90 ksi Minimum Tensile

1.3 This international standard was developed in accor-

Strength, General Use

dance with internationally recognized principles on standard-

A563Specification for Carbon and Alloy Steel Nuts

ization established in the Decision on Principles for the

A564/A564M Specification for Hot-Rolled and Cold-

Development of International Standards, Guides and Recom-

Finished Age-Hardening Stainless Steel Bars and Shapes

mendations issued by the World Trade Organization Technical

A574SpecificationforAlloySteelSocket-HeadCapScrews

Barriers to Trade (TBT) Committee.

A582/A582MSpecification for Free-Machining Stainless

Steel Bars

2. Referenced Documents

A743/A743MSpecification for Castings, Iron-Chromium,

2.1 ASTM Standards:

Iron-Chromium-Nickel, Corrosion Resistant, for General

A36/A36MSpecification for Carbon Structural Steel

Application

A53/A53MSpecification for Pipe, Steel, Black and Hot-

A747/A747MSpecification for Steel Castings, Stainless,

Dipped, Zinc-Coated, Welded and Seamless

Precipitation Hardening

A106/A106MSpecification for Seamless Carbon Steel Pipe

B148Specification for Aluminum-Bronze Sand Castings

for High-Temperature Service

B150/B150MSpecification forAluminum Bronze Rod, Bar,

A193/A193MSpecification for Alloy-Steel and Stainless

and Shapes

Steel Bolting for High Temperature or High Pressure

B209Specification for Aluminum and Aluminum-Alloy

Service and Other Special Purpose Applications

Sheet and Plate

A194/A194MSpecification for Carbon Steel, Alloy Steel,

B221Specification forAluminum andAluminum-Alloy Ex-

and Stainless Steel Nuts for Bolts for High Pressure or

truded Bars, Rods, Wire, Profiles, and Tubes

High Temperature Service, or Both

B271Specification for Copper-BaseAlloy Centrifugal Cast-

A240/A240MSpecification for Chromium and Chromium-

ings

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

B505/B505MSpecification for Copper Alloy Continuous

Vessels and for General Applications

Castings

A269Specification for Seamless and Welded Austenitic

B584Specification for Copper Alloy Sand Castings for

Stainless Steel Tubing for General Service

General Applications

A276Specification for Stainless Steel Bars and Shapes

D1418 Practice for Rubber and Rubber Latices—

Nomenclature

D2000Classification System for Rubber Products in Auto-

This specification is under the jurisdiction ofASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

motive Applications

Machinery and Piping Systems.

D3951Practice for Commercial Packaging

Current edition approved May 1, 2013. Published May 2013. Originally

F104Classification System for Nonmetallic Gasket Materi-

approved in 1997. Last previous edition approved in 2006 as F1718–01 (2006).

DOI: 10.1520/F1718-01R13.

als

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F467Specification for Nonferrous Nuts for General Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F468Specification for Nonferrous Bolts, Hex Cap Screws,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Socket Head Cap Screws, and Studs for General Use

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1718−01 (2013)

F593Specification for Stainless Steel Bolts, Hex Cap ISO 9066 Information Processing Systems—Text

Screws, and Studs Communication—Reliable Transfer—Part 2: Protocol

F594Specification for Stainless Steel Nuts Specification

F837Specification for Stainless Steel Socket Head Cap

3. Terminology

Screws

F880Specification for Stainless Steel Socket, Square Head,

3.1 Definitions:

and Slotted Headless-Set Screws

3.1.1 capacity, n—the quantity of fluid actually delivered

F912Specification for Alloy Steel Socket Set Screws

perunitoftimeattheratedspeed,includingboththeliquidand

F1511Specification for Mechanical Seals for Shipboard

dissolvedorentrainedgases,understatedoperatingconditions.

Pump Applications

3.1.1.1 Discussion—In the absence of any gas or vapor

2.2 ANSI Standard:

entering or forming within the pump, the capacity is equal to

B16.24Pipe Flanges and Flanged Fittings

the volume displaced per unit of time, less slip.

2.3 ANSI/HI Standard:

3.1.2 capacity, maximum, n—thequantityoffluiddelivered

3.6Rotary Pump Tests

that does not exceed the limit determined by the formula in

2.4 AMS Standards:

4.1.2.1.

3215Acrylonitrile Butadiene (NBR) Rubber Aromatic Fuel

3.1.3 capacity, rated, n—the minimum quantity of fluid

Resistant 65-75

deliveredatthespecifiedconditionsofdischargepressure,inlet

4676Bars and Forgings, Corrosion Resistant, Hot Finished,

pressure and viscosity as shown in Table 1.

Precipitation Hardenable 66.5 Ni, 3.0AL, 0.62 Ti, 28 Cu

3.1.4 displacement, n—the volume displaced per revolution

4677BarsandForgings,CorrosionResistant,Annealed66.5

of the rotor(s).

Ni, 2.9 AL, 30 Cu

3.1.4.1 Discussion—In pumps incorporating two or more

5894Bars,Sheet,andPlate,Alloy60Co,28Cr,4.5W,1.15

rotors operating at different speeds, the displacement is the

C, Solution Heat Treated

volume displaced per revolution of the driving rotor. Displace-

2.5 ABMA Standards:

ment depends only on the physical dimensions of the pumping

9Load Ratings and Fatigue Life for Ball Bearings

elements.

11 Load Ratings and Fatigue Life for Roller Bearings

2.6 AGMA Standard: 3.1.5 dry operation, n—a brief run during priming or

390.03Gear Classification, Materials and Measuring Meth- stripping with suction and discharge lines unrestricted and

ods for Unassembled Gears pump chamber wet with liquid but pumping only air or vapor

available from the suction.

2.7 Military Standards:

MIL-STD-167-1(Ships) Mechanical Vibrations of Ship-

3.1.6 effıciency, mechanical, n—the ratio of the pump

board Equipment (Type 1—Environmental and Type

power output (hydraulic horsepower) to the pump power input

2—Internally Excited)

(brake horsepower) expressed in percent.

MIL-STD-740-1(Ships)AirborneSoundMeasurementsand

3.1.7 effıciency, volumetric, n—the ratio of the pump’s

Acceptance Criteria of Shipboard Equipment

capacity to the product of the displacement and the speed

MIL-STD-740-2(Ships) StructureborneVibratoryAccelera-

expressed in percent.

tion Measurements andAcceptance Criteria of Shipboard

3.1.8 fuel, clean, n—fuel purified for direct use.

Equipment

3.1.9 fuel, dirty, n—fuelbeforepurificationthatmaycontain

2.8 Military Specifications:

MIL-N-25027Nut, Self-Locking, 250°F, 450°F and 800°F, water and some solids.

125 KSI FTU, 60 KSI FTU and 30 KSI FTU

3.1.10 net positive inlet pressure available (NPIPA), n—the

MIL-S-901 Shock Tests, HI (High Impact) Shipboard

total inlet pressure available from the system at the pump inlet

Machinery, Equipment and Systems, Requirements for

connection at the rated flow, minus the vapor pressure of the

Navy

liquid at the pumping temperature.

MIL-R-83248 Rubber Fluorocarbon Elastomer, High Per-

3.1.11 net positive inlet pressure required (NPIPR), n—the

formance Fluid, and Compression Set Resistant

net pressure above the liquid vapor pressure at rated flow and

2.9 International Standards Organization Standards:

pumping temperature and at the pump inlet connection re-

ISO9001Quality Systems and QualityAssurance—Design/

quired to avoid performance impairment due to cavitation.

Development, Production, Installation, and Service

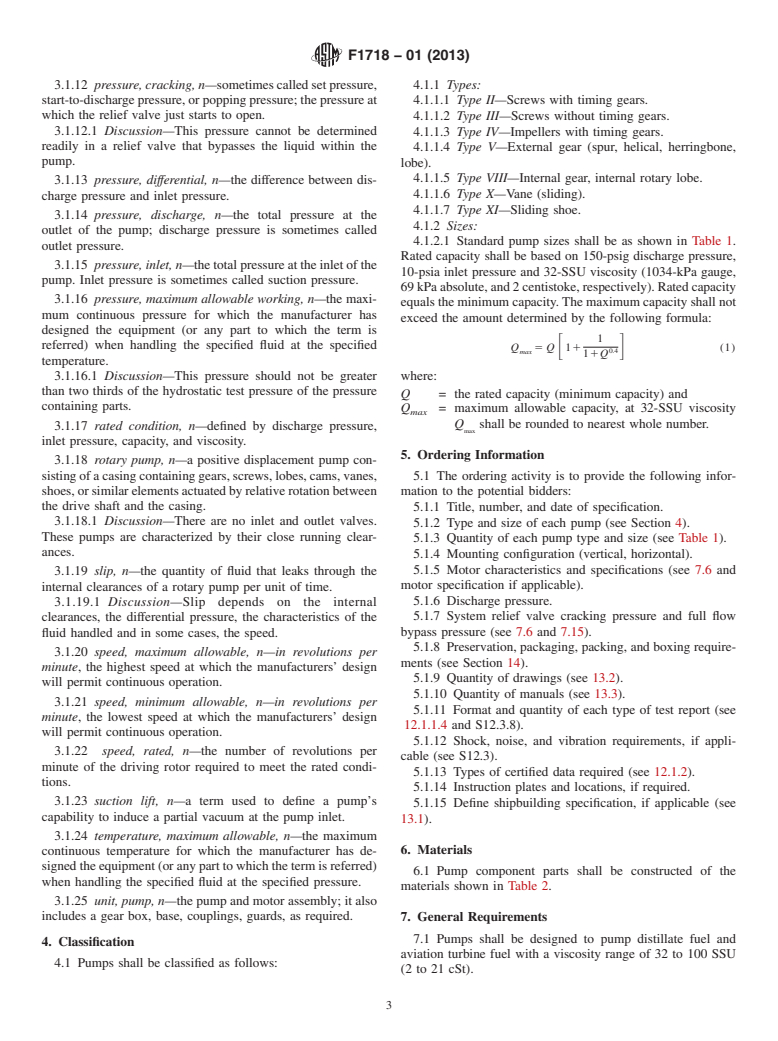

TABLE 1 Pump Sizes

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

Size A B C D E F G H

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Rated capacity (gpm) 10 25 50 75 100 200 300 400

Available from American Bearing Manufacturers Association (ABMA), 2025

M Street, NW Suite 800, Washington, DC 20036, http://www.abma-dc.org/.

Maximum capacity (gpm) 13 30 59 86 114 221 328 433

Available from American Gear Manufacturer’s Association (AGMA), 500

Montgomery St., Suite 350,Alexandria, VA22314-1581, http://www.agma.org.

Flange rating (lb) 150 150 150 150 150 150 150 150

Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

F1718−01 (2013)

3.1.12 pressure, cracking, n—sometimescalledsetpressure, 4.1.1 Types:

start-to-dischargepressure,orpoppingpressure;thepressureat 4.1.1.1 Type II—Screws with timing gears.

which the relief valve just starts to open.

4.1.1.2 Type III—Screws without timing gears.

3.1.12.1 Discussion—This pressure cannot be determined

4.1.1.3 Type IV—Impellers with timing gears.

readily in a relief valve that bypasses the liquid within the

4.1.1.4 Type V—External gear (spur, helical, herringbone,

pump.

lobe).

4.1.1.5 Type VIII—Internal gear, internal rotary lobe.

3.1.13 pressure, differential, n—the difference between dis-

4.1.1.6 Type X—Vane (sliding).

charge pressure and inlet pressure.

4.1.1.7 Type XI—Sliding shoe.

3.1.14 pressure, discharge, n—the total pressure at the

4.1.2 Sizes:

outlet of the pump; discharge pressure is sometimes called

4.1.2.1 Standard pump sizes shall be as shown in Table 1.

outlet pressure.

Rated capacity shall be based on 150-psig discharge pressure,

3.1.15 pressure, inlet, n—thetotalpressureattheinletofthe

10-psia inlet pressure and 32-SSU viscosity (1034-kPa gauge,

pump. Inlet pressure is sometimes called suction pressure.

69kPaabsolute,and2centistoke,respectively).Ratedcapacity

3.1.16 pressure, maximum allowable working, n—the maxi-

equalstheminimumcapacity.Themaximumcapacityshallnot

mum continuous pressure for which the manufacturer has

exceed the amount determined by the following formula:

designed the equipment (or any part to which the term is

referred) when handling the specified fluid at the specified

Q 5 Q 11 (1)

F G

max 0.4

11Q

temperature.

3.1.16.1 Discussion—This pressure should not be greater where:

than two thirds of the hydrostatic test pressure of the pressure

Q = the rated capacity (minimum capacity) and

containing parts.

Q = maximum allowable capacity, at 32-SSU viscosity

max

Q shall be rounded to nearest whole number.

3.1.17 rated condition, n—defined by discharge pressure,

max

inlet pressure, capacity, and viscosity.

5. Ordering Information

3.1.18 rotary pump, n—a positive displacement pump con-

sistingofacasingcontaininggears,screws,lobes,cams,vanes, 5.1 The ordering activity is to provide the following infor-

shoes,orsimilarelementsactuatedbyrelativerotationbetween

mation to the potential bidders:

the drive shaft and the casing. 5.1.1 Title, number, and date of specification.

3.1.18.1 Discussion—There are no inlet and outlet valves.

5.1.2 Type and size of each pump (see Section 4).

These pumps are characterized by their close running clear-

5.1.3 Quantity of each pump type and size (see Table 1).

ances.

5.1.4 Mounting configuration (vertical, horizontal).

5.1.5 Motor characteristics and specifications (see 7.6 and

3.1.19 slip, n—the quantity of fluid that leaks through the

motor specification if applicable).

internal clearances of a rotary pump per unit of time.

3.1.19.1 Discussion—Slip depends on the internal 5.1.6 Discharge pressure.

5.1.7 System relief valve cracking pressure and full flow

clearances, the differential pressure, the characteristics of the

fluid handled and in some cases, the speed. bypass pressure (see 7.6 and 7.15).

5.1.8 Preservation, packaging, packing, and boxing require-

3.1.20 speed, maximum allowable, n—in revolutions per

ments (see Section 14).

minute, the highest speed at which the manufacturers’ design

5.1.9 Quantity of drawings (see 13.2).

will permit continuous operation.

5.1.10 Quantity of manuals (see 13.3).

3.1.21 speed, minimum allowable, n—in revolutions per

5.1.11 Format and quantity of each type of test report (see

minute, the lowest speed at which the manufacturers’ design

12.1.1.4 and S12.3.8).

will permit continuous operation.

5.1.12 Shock, noise, and vibration requirements, if appli-

3.1.22 speed, rated, n—the number of revolutions per

cable (see S12.3).

minute of the driving rotor required to meet the rated condi-

5.1.13 Types of certified data required (see 12.1.2).

tions.

5.1.14 Instruction plates and locations, if required.

3.1.23 suction lift, n—a term used to define a pump’s

5.1.15 Define shipbuilding specification, if applicable (see

capability to induce a partial vacuum at the pump inlet.

13.1).

3.1.24 temperature, maximum allowable, n—the maximum

6. Materials

continuous temperature for which the manufacturer has de-

signedtheequipment(oranyparttowhichthetermisreferred)

6.1 Pump component parts shall be constructed of the

when handling the specified fluid at the specified pressure.

materials shown in Table 2.

3.1.25 unit, pump, n—thepumpandmotorassembly;italso

includes a gear box, base, couplings, guards, as required.

7. General Requirements

7.1 Pumps shall be designed to pump distillate fuel and

4. Classification

aviation turbine fuel with a viscosity range of 32 to 100 SSU

4.1 Pumps shall be classified as follows:

(2 to 21 cSt).

F1718−01 (2013)

TABLE 2 Materials

Component Materials Specification (UNS)

Casings, heads and covers Aluminum bronze B148 (C95800)

Leaded tin bronze B584 (C93700)

Stainless steel, precipitation hardening A747/A747M

Shafts Ni-Cu-Al alloy (Monel K-500) AMS 4676, AMS 4677 (N05500)

Stainless steel A564/A564M (S17400)

Rotors Aluminum bronze B150/B150M (C63000)

Leaded tin bronze B584 (C93700)

Ni-Cu-Al alloy (Monel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.