ASTM F2715-09(2015)

(Specification)Standard Specification for Temporary Protective Equipotential Bond Mat To Be Used on De-Energized Equipment

Standard Specification for Temporary Protective Equipotential Bond Mat To Be Used on De-Energized Equipment

SCOPE

1.1 This specification covers the manufacture and testing of the temporary protective equipotential bond mat used on or around de-energized electrical equipment.

1.2 It is common practice for users of protective equipment to prepare complete instructions and regulations to govern in detail the correct use and maintenance of such equipment.

1.3 The use and maintenance of this equipment is beyond the scope of this specification.

1.4 It is recognized that the use of temporary protective equipotential bond mats requires additional equipment for installation and use, typically temporary connecting jumper assemblies.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2715 −09 (Reapproved 2015)

Standard Specification for

Temporary Protective Equipotential Bond Mat To Be Used

on De-Energized Equipment

This standard is issued under the fixed designation F2715; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 Equipotential Grounding System, n— temporary

grounding system placed in such locations and arranged in

1.1 This specification covers the manufacture and testing of

such a manner as to minimize the likelihood of workers being

the temporary protective equipotential bond mat used on or

exposed to hazardous differences in electrical potential.

around de-energized electrical equipment.

3.1.3 carrier, n—the main body of the equipotential bond

1.2 It is common practice for users of protective equipment

mat on which the flat braid conductor is sewn.

to prepare complete instructions and regulations to govern in

detail the correct use and maintenance of such equipment.

4. Classification

1.3 The use and maintenance of this equipment is beyond

4.1 Equipotential bond mats covered under this specifica-

the scope of this specification.

tion shall be designated as Type I or Type II; Style 1 or Style

1.4 It is recognized that the use of temporary protective

2; Grid Conductor 1 to 24 and Carrier Material I or II.

equipotential bond mats requires additional equipment for

4.1.1 Type I, capable of being cascaded (joined together).

installation and use, typically temporary connecting jumper

4.1.2 Type II, without capability of being cascaded.

assemblies.

4.1.3 Style 1, exposed conductor termination.

2. Referenced Documents

4.1.4 Style 2, jacketed conductor termination.

2.1 ASTM Standards:

4.1.5 Grid Conductor, 1 to 6, in accordance with the normal

B33 Specification for Tin-Coated Soft or Annealed Copper

flat width, or equivalent, of the flat braid conductors combina-

Wire for Electrical Purposes

tion that makes up the grid conductor and perimeter conductor

D2261 Test Method for Tearing Strength of Fabrics by the

of the carrier, as shown in Table 1.

Tongue (Single Rip) Procedure (Constant-Rate-of-

4.1.6 Carrier material I, slip resistant.

Extension Tensile Testing Machine)

4.1.7 Carrier material II, without slip resistance.

2.2 Other Standards:

Fed Std 191/5100 Strength and Elongation, Breaking of

5. Ordering Information

Woven Cloth; Grab Method

FedStd191/5874 Temperature,Low;EffectonCoatedCloth

5.1 Orders for equipotential bond mats under this specifica-

Fed Std MVSS302 Flammability of Interior Materials tion shall include the ASTM designation and the following

A-A-59551 Wire, Electrical, Copper Un-insulated

information:

5.1.1 Quantity,

3. Terminology

5.1.2 Type,

3.1 Definitions:

5.1.3 Style,

3.1.1 bonding, n—the mechanical interconnection of con-

5.1.4 Grid Conductor,

ductive parts to maintain a common electrical potential.

5.1.5 Carrier Material,

5.1.6 Size, specified in length and width dimensions, noting

This specification is under the jurisdiction of ASTM Committee F18 on

any specific configuration requirements; rectangular, L shape,

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.45 on Mechanical Apparatus. rectangular shape with access hole in middle, etc.

Current edition approved April 1, 2015. Published May 2015. Originally

5.2 The listing of types, styles, grid conductors, carrier

appoved in 2008. Last previous edition approved in 2009 as F2715-09. DOI:

10.1520/F2715-09R15.

material and size is not intended to mean that all shall

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

necessarily be available from the manufacturers; it signifies

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

only that, if made they shall conform to the details of this

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specification.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2715−09 (2015)

TABLE 1 Bond Mat Conductor Size

9. Workmanship and Finish

Grid

Grid, in. Perimeter, in. 9.1 Components shall be free of structural defects that affect

Conductor

handling or performance, or both.

1 1

1 ⁄4 ⁄4

1 1

2 ⁄4 ⁄2

9.2 Cosmetic and other surface irregularities which do not

1 3

3 ⁄4 ⁄4

affect strength, performance, or handling, or combination

1 1

4 ⁄2 ⁄2

1 3

5 ⁄2 ⁄4 thereof, are not cause for rejection.

3 3

6 ⁄4 ⁄4

10. Sampling

10.1 A product model represents a manufacturer’s design

6. Manufacture and Marking specification standard according to which the production lot is

manufactured.

6.1 Eachequipotentialbondmatshallbemarkedclearlyand

permanently with the name of the manufacturer or supplier, 10.2 Aproduction lot shall consist of all equipotential bond

ASTM F2715, serial number, type, and style. mats of one product model produced at one time.

10.3 A test sample consists of two specimens, selected at

7. Chemical and Physical Requirements

random, for each different test specified. When a failure occurs

7.1 Equipotential bond mats samples selected in accordance

in one specimen from the first sample, a second sample from

with Section 10 shall conform to the physical and chemical

the same lot shall be selected and tested. If the second sample

requirements as specified in this section.

(two specimens) passes, the lot shall be accepted. If the one

specimen from the second sample fails, the lot shall be

7.2 Carrier Strength:

rejected.

7.2.1 Tensile (Grab)— Carrier material shall be capable of a

tensile (grab) of 1828 – 2037 N (411 – 458 lbf) in accordance

11. Electrical Test

with Fed Std 191/5100.

7.2.2 Tongue Tear— Carrier material shall be capable of

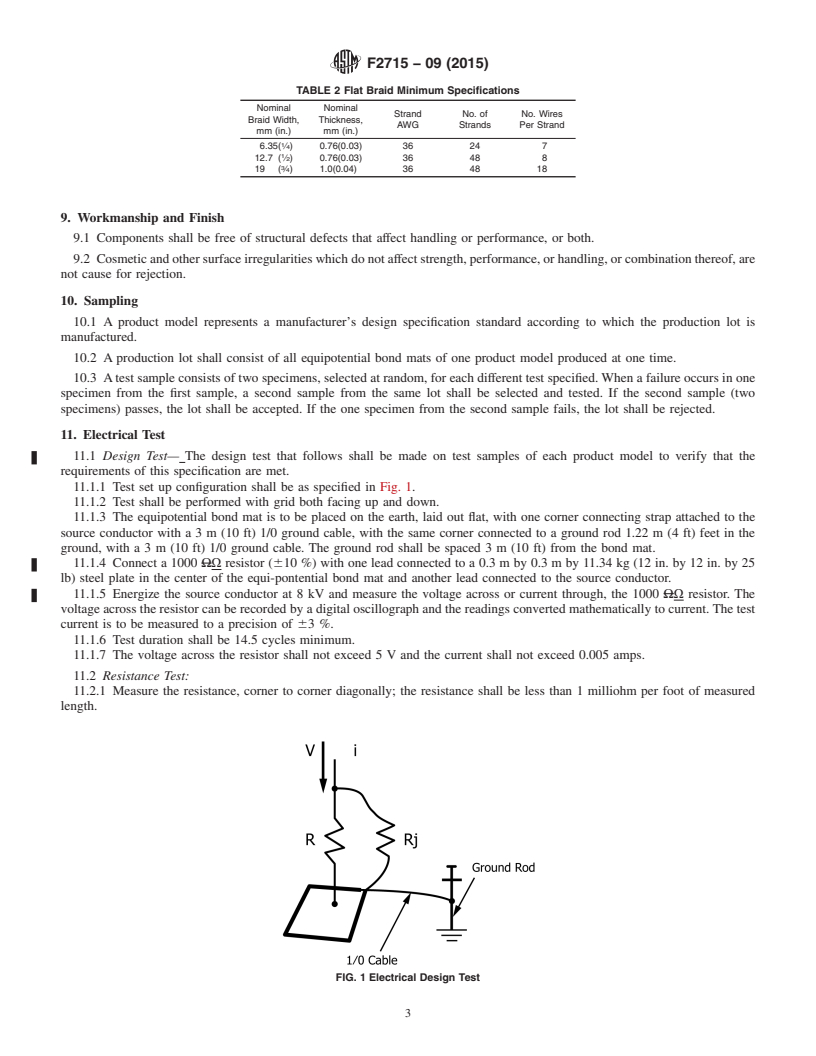

11.1 Design Test— The design test that follows shall be

tongue tear of 485 – 516 N (109 – 116 lbf) in accordance with

made on test samples of each product model to verify that the

Test Methods D2261. requirements of this specification are met.

7.2.3 Cold Flexure— Carrier material shall be capa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2715 − 09 F2715 − 09 (Reapproved 2015)

Standard Specification for

Temporary Protective Equipotential Bond Mat To Be Used

on De-Energized Equipment

This standard is issued under the fixed designation F2715; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the manufacture and testing of the temporary protective equipotential bond mat used on or around

de-energized electrical equipment.

1.2 It is common practice for users of protective equipment to prepare complete instructions and regulations to govern in detail

the correct use and maintenance of such equipment.

1.3 The use and maintenance of this equipment is beyond the scope of this specification.

1.4 It is recognized that the use of temporary protective equipotential bond mats requires additional equipment for installation

and use, typically temporary connecting jumper assemblies.

2. Referenced Documents

2.1 ASTM Standards:

B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

D2261 Test Method for Tearing Strength of Fabrics by the Tongue (Single Rip) Procedure (Constant-Rate-of-Extension Tensile

Testing Machine)

2.2 Other Standards:

Fed Std 191/5100 Strength and Elongation, Breaking of Woven Cloth; Grab Method

Fed Std 191/5874 Temperature, Low; Effect on Coated Cloth

Fed Std MVSS302 Flammability of Interior Materials

A-A-59551 Wire, Electrical, Copper Un-insulated

3. Terminology

3.1 Definitions:

3.1.1 bonding, n—the mechanical interconnection of conductive parts to maintain a common electrical potential.

3.1.2 Equipotential Grounding System, n— temporary grounding system placed in such locations and arranged in such a manner

as to minimize the likelihood of workers being exposed to hazardous differences in electrical potential.

3.1.3 carrier, n—the main body of the equipotential bond mat on which the flat braid conductor is sewn.

4. Classification

4.1 Equipotential bond mats covered under this specification shall be designated as Type I or Type II; Style 1 or Style 2; Grid

Conductor 1 to 24 and Carrier Material I or II.

4.1.1 Type I, capable of being cascaded (joined together).

4.1.2 Type II, without capability of being cascaded.

4.1.3 Style 1, exposed conductor termination.

4.1.4 Style 2, jacketed conductor termination.

This specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.45 on Mechanical Apparatus.

Current edition approved Jan. 1, 2009April 1, 2015. Published February 2009May 2015. Originally appoved in 2008. Last previous edition approved in 20082009 as

F2715-08.-09. DOI: 10.1520/F2715-09.10.1520/F2715-09R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2715 − 09 (2015)

4.1.5 Grid Conductor, 1 to 6, in accordance with the normal flat width, or equivalent, of the flat braid conductors combination

that makes up the grid conductor and perimeter conductor of the carrier, as shown in Table 1.

4.1.6 Carrier material I, slip resistant.

4.1.7 Carrier material II, without slip resistance.

5. Ordering Information

5.1 Orders for equipotential bond mats under this specification shall include the ASTM designation and the following

information:

5.1.1 Quantity,

5.1.2 Type,

5.1.3 Style,

5.1.4 Grid Conductor,

5.1.5 Carrier Material,

5.1.6 Size, specified in length and width dimensions, noting any specific configuration requirements; rectangular, L shape,

rectangular shape with access hole in middle, etc.

5.2 The listing of types, styles, grid conductors, carrier material and size is not intended to mean that all shall necessarily be

available from the manufacturers; it signifies only that, if made they shall conform to the details of this specification.

6. Manufacture and Marking

6.1 Each equipotential bond mat shall be marked clearly and permanently with the name of the manufacturer or supplier, ASTM

F2715, serial number, type, and style.

7. Chemical and Physical Requirements

7.1 Equipotential bond mats samples selected in accordance with Section 10 shall conform to the physical and chemical

requirements as specified in this section.

7.2 Carrier Strength:

7.2.1 Tensile (Grab)— Carrier material shall be capable of a tensile (grab) of 1828 – 2037 N (411 – 458 lbf) in accordance with

Fed Std 191/5100.

7.2.2 Tongue Tear— Carrier material shall be capable of tongue tear of 485 – 516 N (109 – 116 lbf) in accordance with Test

Methods D2261.

7.2.3 Cold Flexure— Carrier material shall be capable of a low cold crack of -40° C (-40° F) in accordance with Fed Std

191/5874-1978

7.3 Flat braid conductor shall comply with A-A-59551 and Specification B33 requirements and have the properties contained

in Table 2 or greater.

7.4 Carrier Fire Resistance—The flame resistance of the carrier shall be performed in accordance with Fed Std MVSS302 and

shall be self extinguishing.

8. Dimensions and Permissible Variations

8.1 Equipotential bond mat size is the combination of grid spacing and perimeter dimensional configurations.

8.2 The length and width of grid spacing shall be 200 by 200 mm (8 by 8 in.), with a permissible variation of 625 mm (61

in).

8.3 Thread stitch spacing shall be 6 stitches or more per 25.4 mm (6 stitches or more per 1 in).

2 2

8.4 A minimum adequate area must be provided for footing surface of 0.37 m (4 ft ) and a minimum of 0.6 m linear (2 ft) in

any direction, with a permissible variation of 625 mm ( 61 in).

TABLE 1 Bond Mat Conductor Size

Grid

Grid, in. Perimeter, in.

Conductor

1 1

1 ⁄4 ⁄4

1 1

2 ⁄4 ⁄2

1 3

3 ⁄4 ⁄4

1 1

4 ⁄2 ⁄2

1 3

5 ⁄2 ⁄4

3 3

6 ⁄4 ⁄4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.