ASTM E2109-01

(Test Method)Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings

Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings

SCOPE

1.1 These test methods cover procedures to perform porosity ratings on metallographic specimens of thermal sprayed coatings (TSCs) prepared in accordance with Guide E1920 by direct comparison to standard images and via the use of automatic image analysis equipment.

1.2 These test methods deal only with recommended measuring methods and nothing in them should be construed as defining or establishing limits of acceptability for any measured value of porosity.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2109 – 01

Test Methods for

Determining Area Percentage Porosity in Thermal Sprayed

1

Coatings

This standard is issued under the fixed designation E 2109; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 linear detachment, n—a region within aTSC in which

two successively deposited splats of coating material have not

1.1 These test methods cover procedures to perform poros-

metallurgically bonded.

ity ratings on metallographic specimens of thermal sprayed

3.2.3 porosity, n—cavity type discontinuities (voids) or

coatings (TSCs) prepared in accordance with Guide E 1920 by

linear detachments within a sprayed coating.

direct comparison to standard images and via the use of

3.2.4 splat, n—an individual globule of thermal sprayed

automatic image analysis equipment.

material that has been deposited on a substrate.

1.2 These test methods deal only with recommended mea-

suring methods and nothing in them should be construed as

4. Significance and Use

defining or establishing limits of acceptability for any mea-

4.1 TSCs are susceptible to the formation of porosity due to

sured value of porosity.

a lack of fusion between sprayed particles or the expansion of

1.3 This standard does not purport to address all of the

gases generated during the spraying process. The determina-

safety concerns, if any, associated with its use. It is the

tion of area percent porosity is important in order to monitor

responsibility of the user of this standard to establish appro-

the effect of variable spray parameters and the suitability of a

priate safety and health practices and determine the applica-

coating for its intended purpose. Depending on application,

bility of regulatory limitations prior to use.

some or none of this porosity may be tolerable.

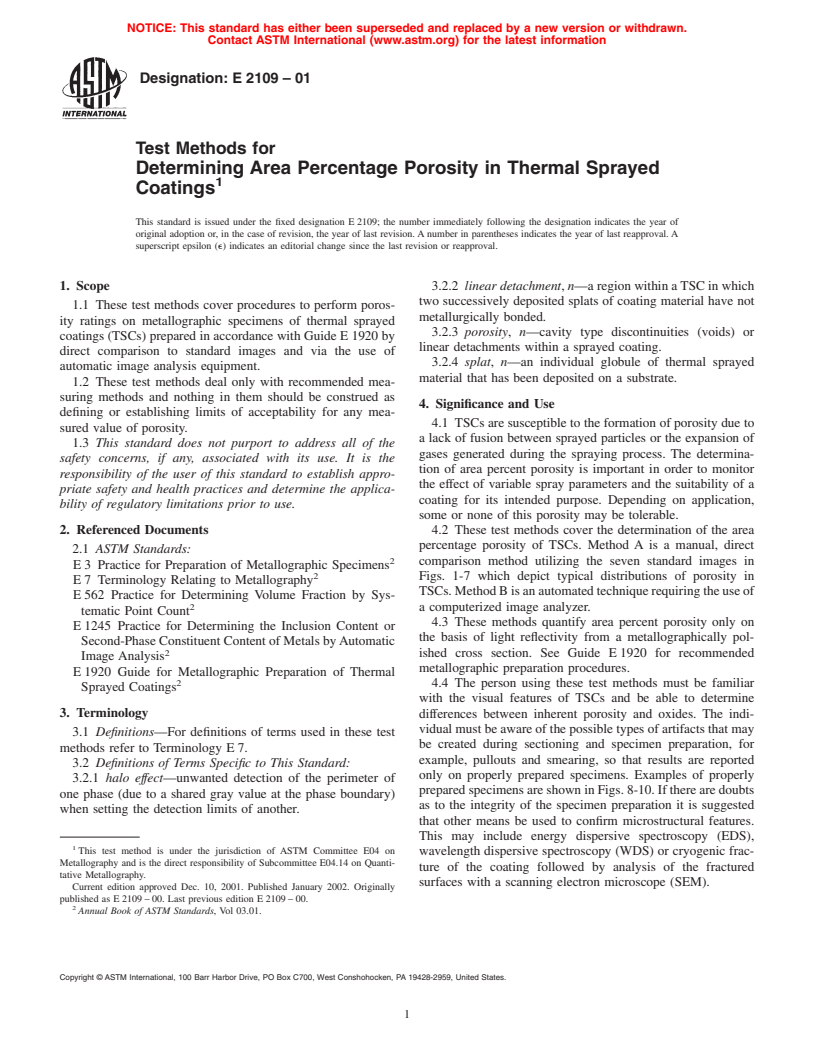

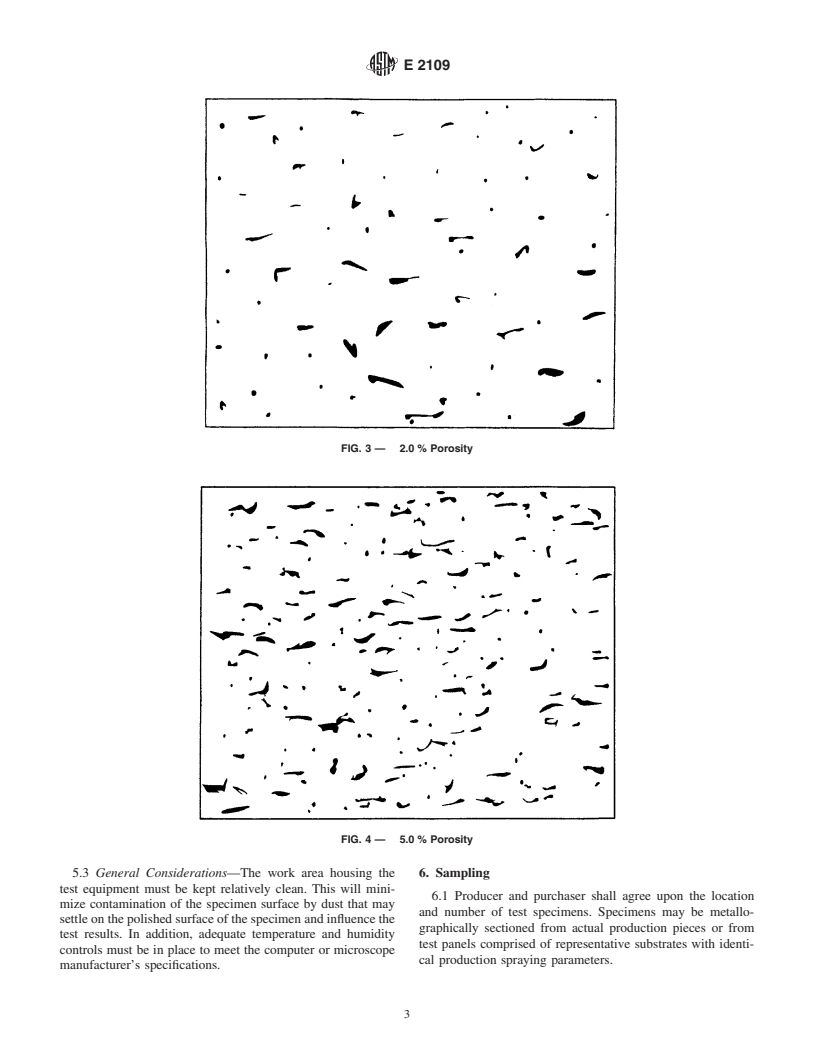

2. Referenced Documents 4.2 These test methods cover the determination of the area

percentage porosity of TSCs. Method A is a manual, direct

2.1 ASTM Standards:

2

comparison method utilizing the seven standard images in

E 3 Practice for Preparation of Metallographic Specimens

2

Figs. 1-7 which depict typical distributions of porosity in

E 7 Terminology Relating to Metallography

TSCs.MethodBisanautomatedtechniquerequiringtheuseof

E 562 Practice for Determining Volume Fraction by Sys-

2 a computerized image analyzer.

tematic Point Count

4.3 These methods quantify area percent porosity only on

E 1245 Practice for Determining the Inclusion Content or

the basis of light reflectivity from a metallographically pol-

Second-Phase Constituent Content of Metals byAutomatic

2

ished cross section. See Guide E 1920 for recommended

Image Analysis

metallographic preparation procedures.

E 1920 Guide for Metallographic Preparation of Thermal

2

4.4 The person using these test methods must be familiar

Sprayed Coatings

with the visual features of TSCs and be able to determine

3. Terminology

differences between inherent porosity and oxides. The indi-

vidual must be aware of the possible types of artifacts that may

3.1 Definitions—For definitions of terms used in these test

be created during sectioning and specimen preparation, for

methods refer to Terminology E 7.

example, pullouts and smearing, so that results are reported

3.2 Definitions of Terms Specific to This Standard:

only on properly prepared specimens. Examples of properly

3.2.1 halo effect—unwanted detection of the perimeter of

preparedspecimensareshowninFigs.8-10.Iftherearedoubts

one phase (due to a shared gray value at the phase boundary)

as to the integrity of the specimen preparation it is suggested

when setting the detection limits of another.

that other means be used to confirm microstructural features.

This may include energy dispersive spectroscopy (EDS),

1

This test method is under the jurisdiction of ASTM Committee E04 on

wavelength dispersive spectroscopy (WDS) or cryogenic frac-

Metallography and is the direct responsibility of Subcommittee E04.14 on Quanti-

ture of the coating followed by analysis of the fractured

tative Metallography.

surfaces with a scanning electron microscope (SEM).

Current edition approved Dec. 10, 2001. Published January 2002. Originally

published as E 2109 – 00. Last previous edition E 2109 – 00.

2

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 2109

FIG. 1 — 0.5 % Porosity

FIG. 2 — 1.0 % Porosity

5. Apparatus 5.2 Test Method B—TestMethodBrequiresareflectedlight

metallurgical microscope, upright or inverted, equipped

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.