ASTM C829-81(2022)

(Practice)Standard Practices for Measurement of Liquidus Temperature of Glass by the Gradient Furnace Method

Standard Practices for Measurement of Liquidus Temperature of Glass by the Gradient Furnace Method

SIGNIFICANCE AND USE

3.1 These practices are useful for determining the maximum temperature at which crystallization will form in a glass, and a minimum temperature at which a glass can be held, for extended periods of time, without crystal formation and growth.

SCOPE

1.1 These practices cover procedures for determining the liquidus temperature (Note 1) of a glass (Note 1) by establishing the boundary temperature for the first crystalline compound, when the glass specimen is held at a specified temperature gradient over its entire length for a period of time necessary to obtain thermal equilibrium between the crystalline and glassy phases.

Note 1: These terms are defined in Terminology C162.

1.2 Two methods are included, differing in the type of sample, apparatus, procedure for positioning the sample, and measurement of temperature gradient in the furnace. Both methods have comparable precision. Method B is preferred for very fluid glasses because it minimizes thermal and mechanical mixing effects.

1.2.1 Method A employs a trough-type platinum container (tray) in which finely screened glass particles are fused into a thin lath configuration defined by the trough.

1.2.2 Method B employs a perforated platinum tray on which larger screened particles are positioned one per hole on the plate and are therefore melted separately from each other.2

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C829 − 81 (Reapproved 2022)

Standard Practices for

Measurement of Liquidus Temperature of Glass by the

1

Gradient Furnace Method

This standard is issued under the fixed designation C829; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 These practices cover procedures for determining the 2.1 ASTM Standards:

liquidus temperature (Note 1) of a glass (Note 1) by establish- C162Terminology of Glass and Glass Products

ing the boundary temperature for the first crystalline

2.2 Other Document:

4

compound, when the glass specimen is held at a specified NIST Certificate for Liquidus Temperature, SRM 773

temperature gradient over its entire length for a period of time

3. Significance and Use

necessarytoobtainthermalequilibriumbetweenthecrystalline

and glassy phases.

3.1 Thesepracticesareusefulfordeterminingthemaximum

temperature at which crystallization will form in a glass, and a

NOTE 1—These terms are defined in Terminology C162.

minimum temperature at which a glass can be held, for

1.2 Two methods are included, differing in the type of

extended periods of time, without crystal formation and

sample, apparatus, procedure for positioning the sample, and

growth.

measurement of temperature gradient in the furnace. Both

methodshavecomparableprecision.MethodBispreferredfor

4. Apparatus

veryfluidglassesbecauseitminimizesthermalandmechanical

4.1 The apparatus for determining the liquidus temperature

mixing effects.

shall consist essentially of an electrically heated gradient

1.2.1 Method A employs a trough-type platinum container

furnace, a device for controlling the furnace temperature,

(tray) in which finely screened glass particles are fused into a

temperature measuring equipment, and other items listed.

thin lath configuration defined by the trough.

4.1.1 Furnace:

1.2.2 Method B employs a perforated platinum tray on

4.1.1.1 Method A—Horizontal temperature gradient, electri-

which larger screened particles are positioned one per hole on

cally heated furnace, tube type, as illustrated in Figs. 1-3 and

2

the plate and are therefore melted separately from each other.

described in A1.1.

1.3 This standard does not purport to address all of the

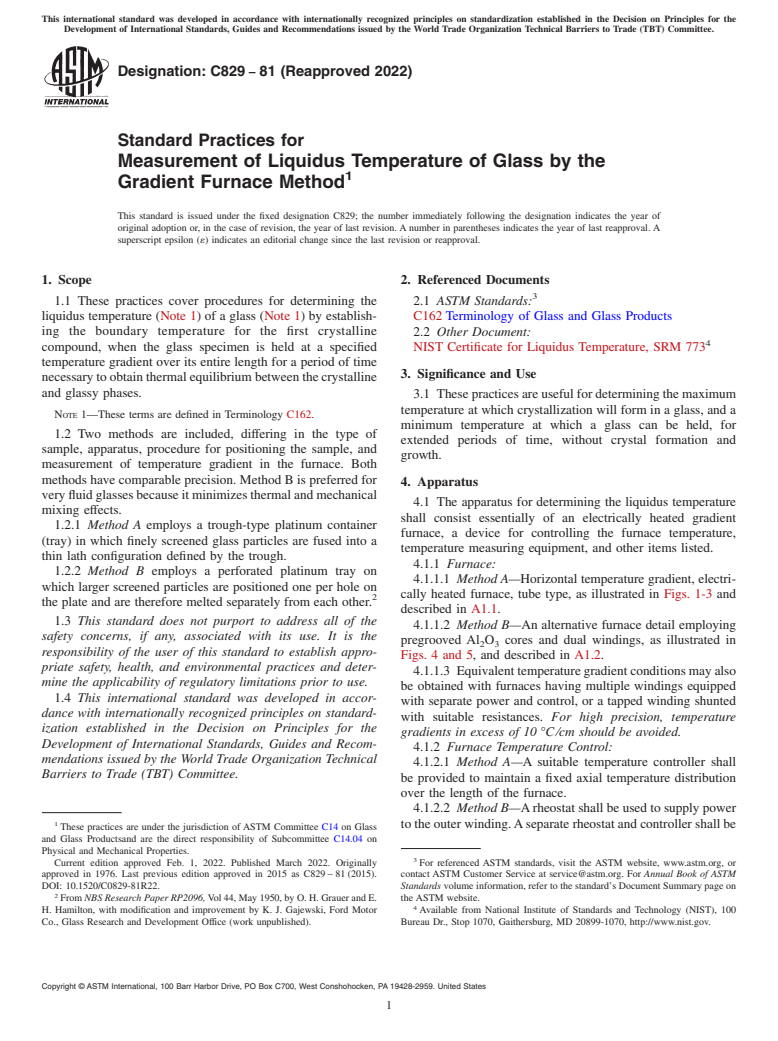

4.1.1.2 Method B—An alternative furnace detail employing

safety concerns, if any, associated with its use. It is the

pregrooved Al O cores and dual windings, as illustrated in

2 3

responsibility of the user of this standard to establish appro-

Figs. 4 and 5, and described in A1.2.

priate safety, health, and environmental practices and deter-

4.1.1.3 Equivalenttemperaturegradientconditionsmayalso

mine the applicability of regulatory limitations prior to use.

be obtained with furnaces having multiple windings equipped

1.4 This international standard was developed in accor-

with separate power and control, or a tapped winding shunted

dance with internationally recognized principles on standard-

with suitable resistances. For high precision, temperature

ization established in the Decision on Principles for the

gradients in excess of 10 °C ⁄cm should be avoided.

Development of International Standards, Guides and Recom-

4.1.2 Furnace Temperature Control:

mendations issued by the World Trade Organization Technical

4.1.2.1 Method A—A suitable temperature controller shall

Barriers to Trade (TBT) Committee.

be provided to maintain a fixed axial temperature distribution

over the length of the furnace.

4.1.2.2 Method B—Arheostatshallbeusedtosupplypower

1

totheouterwinding.Aseparaterheostatandcontrollershallbe

These practices are under the jurisdiction of ASTM Committee C14 on Glass

and Glass Productsand are the direct responsibility of Subcommittee C14.04 on

Physical and Mechanical Properties.

3

Current edition approved Feb. 1, 2022. Published March 2022. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1976. Last previous edition approved in 2015 as C829–81(2015). contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DOI: 10.1520/C0829-81R22. Standards volume information, refer to the standard’s Document Summary page on

2

From NBS Research Paper RP2096,Vol44,May1950,byO.H.GrauerandE. the ASTM website.

4

H. Hamilton, with modification and improvement by K. J. Gajewski, Ford Motor Available from National Institute of Standards and Technology (NIST), 100

Co., Glass Research and Development Office (work unpublished). Bureau Dr., Stop 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.