ASTM C952-02(2009)

(Test Method)Standard Test Method for Bond Strength of Mortar to Masonry Units

Standard Test Method for Bond Strength of Mortar to Masonry Units

SIGNIFICANCE AND USE

These procedures are useful for research into bond strength of masonry. They are not intended to predict the bond strength of commercial masonry construction. The bond strength in commercially built structures is determined by many factors beyond the characteristics of mortar, masonry units, and the procedures of this test method.

Note 1—The crossed-brick couplets method measures a direct tensile strength of the bond between the mortar and masonry unit. It does not determine the flexural strength of the unit mortar assembly. Other test methods may be more appropriate for determining the flexural bond strength between mortar and masonry units. These include Test Method C 1072, Test Methods C 1357, and Test Methods E 518.

SCOPE

1.1 This test method provides two procedures for measuring bond strength of mortar to masonry units: a crossed brick couplet tensile test for evaluating mortar-brick bond strength and a stacked-bond, flexural test for evaluating mortar-concrete block bond strength.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: C952 − 02 (Reapproved 2009)

Standard Test Method for

Bond Strength of Mortar to Masonry Units

This standard is issued under the fixed designation C952; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C1357 Test Methods for Evaluating Masonry Bond Strength

C1437 Test Method for Flow of Hydraulic Cement Mortar

1.1 This test method provides two procedures for measuring

E518 Test Methods for Flexural Bond Strength of Masonry

bond strength of mortar to masonry units: a crossed brick

couplet tensile test for evaluating mortar-brick bond strength

3. Significance and Use

andastacked-bond,flexuraltestforevaluatingmortar-concrete

3.1 These procedures are useful for research into bond

block bond strength.

strength of masonry. They are not intended to predict the bond

1.2 The values stated in inch-pound units are to be regarded

strength of commercial masonry construction. The bond

as standard. The values given in parentheses are mathematical

strength in commercially built structures is determined by

conversions to SI units that are provided for information only

many factors beyond the characteristics of mortar, masonry

and are not considered standard.

units, and the procedures of this test method.

1.3 This standard does not purport to address the safety

NOTE 1—The crossed-brick couplets method measures a direct tensile

concerns, if any, associated with its use. It is the responsibility

strength of the bond between the mortar and masonry unit. It does not

of the user of this standard to establish appropriate safety and

determine the flexural strength of the unit mortar assembly. Other test

health practices and determine the applicability of regulatory

methods may be more appropriate for determining the flexural bond

limitations prior to use. strength between mortar and masonry units. These include Test Method

C1072, Test Methods C1357, and Test Methods E518.

2. Referenced Documents

PREPARATION AND TESTING OF FRESH MORTAR

2.1 ASTM Standards:

C67 Test Methods for Sampling and Testing Brick and

4. Preparation of Mortar

Structural Clay Tile

4.1 Proportion mortar materials by weights equivalent to

C90 Specification for Loadbearing Concrete Masonry Units

volume proportions to be used in prism construction. Use unit

C129 Specification for Nonloadbearing Concrete Masonry

weights for individual materials as given in Specification

Units

C270. Sand shall be permitted to be used in a damp loose

C140 Test Methods for Sampling and Testing Concrete

condition,providedthatmoisturecontentofsandisdetermined

Masonry Units and Related Units

with reference to the oven-dried condition and batch propor-

C270 Specification for Mortar for Unit Masonry

tions are adjusted accordingly. Record weight of ingredients

C780 Test Method for Preconstruction and Construction

(including water) added to the batch of mortar.

Evaluation of Mortars for Plain and Reinforced Unit

4.2 Mix mortar in a mechanical paddle-type mortar mixer.

Masonry

Time periods referenced below are measured from when water

C1072 Test Methods for Measurement of Masonry Flexural

and cementitious materials are combined.

Bond Strength

4.2.1 Add an estimated amount of water to the mortar to

achieve the desired consistency (Note 2). Mix mortar for three

1 minutes and determine consistency. If the desired consistency

This test method is under the jurisdiction of ASTM Committee C15 on

Manufactured Masonry Units and is the direct responsibility of Subcommittee

is specified by flow determine it in accordance with Test

C15.04 on Research. Committee E-6 maintains a continued interest in these

Method C1437. If the desired consistency is specified as initial

practices and will make use of them in the future.

cone penetration, determine it in accordance with Test Method

CurrenteditionapprovedJune1,2009.PublishedJuly2009.Originallyapproved

´1

C780.Onceconsistencyisrecorded,returnthematerialusedto

in 1959. Last previous edition approved in 2002 as C952 – 02 . DOI: 10.1520/

C0952-02R09.

measure the consistency to the mixer. If the consistency is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

within the desired range, continue mixing the batch for an

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

additional two minutes. If the consistency is less than the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. desired range, add water to the batch and mix for one minute

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C952 − 02 (2009)

and determine consistency. Once consistency is recorded, 6. Crossed-Brick Couplets

return the material used to measure consistency to the mixer. If

6.1 Brick—Test specimens consisting of crossed-brick cou-

theconsistencyiswithinthedesiredrange,continuemixingthe

plets may be used to determine:

batch for one minute.

6.1.1 Bond between specified brick and a specified mortar,

NOTE 2—Workable consistency of mortar for concrete masonry con-

6.1.2 Relative bond between different brick and a specified

struction generally requires an initial cone penetration reading of 55 6 5

mortar, or

mm or a flow of 125 6 5 %. Workable consistency of mortar for clay

6.1.3 Relative bond between a specified brick and different

masonry construction generally requires an initial cone penetration

mortars.

reading of 65 6 5 mm or a flow of 135 6 5 %. Optimum consistency for

a specific mortar-unit combination may differ from these values. 6.1.4 In each case, the initial rate of absorption of the brick

shall be determined in accordance withTest Methods C67.The

4.2.2 If after the one-time addition of water the consistency

brick used for couplets shall include the full range of absorp-

is not in the desired range, discard the batch.

tion rates acceptable under the specifications.

4.2.3 If the measured consistency exceeds the desired range

at any time, discard the batch.

6.2 Construction of Test Specimens :

6.2.1 Center the mold on the lower brick of the couplet and

4.3 Immediately after mixing the mortar, determine its

lightly mix a small quantity of mortar on the board by turning

initial cone penetration in accordance with Test Method C780.

over with the spoon.

Determine the cone penetration of the mortar every 15 6 5

6.2.2 Half-fill the mold by sharply dashing into each corner

minutes. If the cone penetration is less than 80 % of its initial

and the center of the mold a small quantity of mortar from the

value, discard the remaining portion of the mortar without

half-filled spoon. Note the time at start of a 1-min interval.

constructing additional mortar joints.

Apply additional mortar by heaping loosely with the spoon

PREPARATION AND TESTING OF BOND STRENGTH

above the top of the mold. Strike off excess mortar with the

TEST SPECIMENS

straightedge, starting on a diagonal across the mold and

working first to one corner and then to the opposite corner of

5. Apparatus

the mold. Remove the mold from the mortar bed.

6.2.3 At the end of the 1-min time interval, place the upper

5.1 Miscellaneous—Brass-covered mortar board 18 in. (457

brick on the mortar bed in a crosswise direction to the lower

mm) square, an 11-in. (279-mm) long mason’s trowel, labora-

brick. Place the frame of the hammer on the top brick with the

tory trowel with straight edges, short handled spoon or scoop

weight of the hammer held in the other hand. Drop the hammer

of ⁄4-cup (0.5-dm ) capacity, steel straightedge 10 in. (254

1 5

in a frame a distance of 1 ⁄2 in. (38 mm).

mm) long, metal mold ⁄2 in. (13 mm) deep with 3 ⁄8-in.

(92-mm) square opening beveled to slope of 0.08 (total 0.04), 6.2.4 Measure and record the extrusion of the mortar on the

top surface of the lower brick. Cut away extruded mortar from

splash board (Fig. 1) with handle 20 in. (508 mm) long and 3

in. (76 mm) wide. all four edges of the mortar bed.

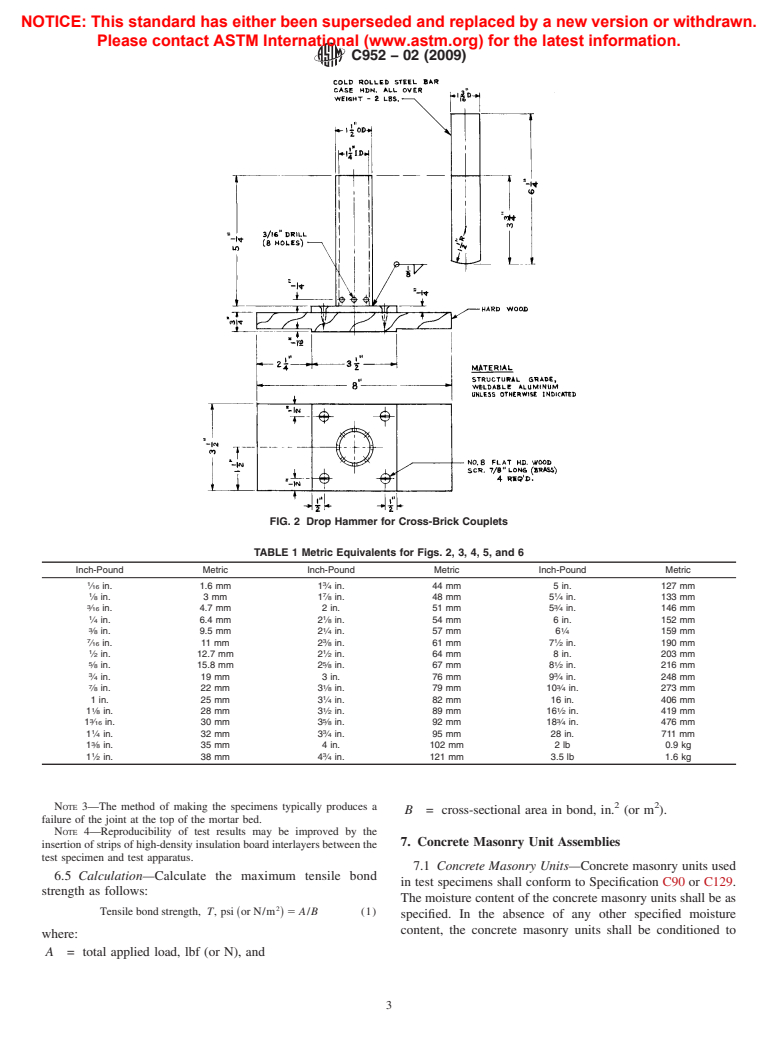

5.2 Drop Hammer for crossed-brick couplets (Fig. 2, Table 6.3 Curing—Promptly enclose the test specimen within an

1). airtight covering. Keep covered for 7 days. Remove the cover

and store until tested. Unless otherwise specified, the specimen

5.3 Drop Hammer for block assemblies (Fig. 3).

shallbestoredinlaboratoryairatarelativehumidityofatleast

5.4 Loading Jigs for crossed-brick couplets (Fig. 4).

50 %.

5.5 Frames (Fig. 5) for testing block assemblies: upper

6.4 Testing—Center the specimen between the upper and

frame fitted with ball bearing mounted 10 in. (254 mm) from

lower tripods and place in the testing machine as shown in Fig.

vertical axis of specimen f

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:C952–91 (Reapproved 1997) Designation:C952–02 (Reapproved 2009)

Standard Test Method for

Bond Strength of Mortar to Masonry Units

This standard is issued under the fixed designation C 952; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Section 13 on Keywords was added editorally in November 1997.

1. Scope

1.1This test method provides two procedures for measuring bond strength of mortar to masonry units: a crossed brick couplet

tensile test for evaluating mortar-brick bonding and a stacked-bond, flexural test for evaluating mortar-concrete block bonding.

1.2

1.1 This test method provides two procedures for measuring bond strength of mortar to masonry units: a crossed brick couplet

tensile test for evaluating mortar-brick bond strength and a stacked-bond, flexural test for evaluating mortar-concrete block bond

strength.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C67 Test Methods offor Sampling and Testing Brick and Structural Clay Tile

C91Specification for Masonry Cement

90 Specification for Loadbearing Concrete Masonry Units

C109Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube Specimens)

129 Specification for Nonloadbearing Concrete Masonry Units

C190Test Method for Tensile Strength of Hydraulic Cement Mortars

C230Specification for FlowTable for Use inTests of Hydraulic Cement 140 Test Methods for Sampling andTesting Concrete

Masonry Units and Related Units

C 270 Specification for Mortar for Unit Masonry

C305Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

780 Test Method for Preconstruction and Construction Evaluation of Mortars for Plain and Reinforced Unit Masonry

C427Test Method for Moisture Condition of Hardened Concrete by the Relative Humidity Method 1072 Test Method for

Measurement of Masonry Flexural Bond Strength

C 1357 Test Methods for Evaluating Masonry Bond Strength

C 1437 Test Method for Flow of Hydraulic Cement Mortar

E 518 Test Methods for Flexural Bond Strength of Masonry

3. Significance and Use

3.1These procedures are useful for research into bonding of masonry. They are not intended to predict the bond strength of

commercial masonry construction. The bonding in commercially built structures is determined by many factors beyond the

characteristics of mortar, masonry units, and the procedures of this test method.

3.1 These procedures are useful for research into bond strength of masonry. They are not intended to predict the bond strength

ThistestmethodisunderthejurisdictionofASTMCommitteeC15onManufacturedMasonryUnitsandisthedirectresponsibilityofSubcommitteeC15.04onResearch.

Committee E-6 maintains a continued interest in these practices and will make use of them in the future.

Current edition approved April 15, 1991. Published June 1991. Originally published as E149–59T. Redesignated C952–76 in 1981. Last previous edition C952–86.

´1

Current edition approved June 1, 2009. Published July 2009. Originally approved in 1959. Last previous edition approved in 2002 as C 952 – 02 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 04.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C952–02 (2009)

of commercial masonry construction. The bond strength in commercially built structures is determined by many factors beyond

the characteristics of mortar, masonry units, and the procedures of this test method.

NOTE 1—The crossed-brick couplets method measures a direct tensile strength of the bond between the mortar and masonry unit. It does not determine

the flexural strength of the unit mortar assembly. Other test methods may be more appropriate for determining the flexural bond strength between mortar

and masonry units. These include Test Method C 1072, Test Methods C 1357, and Test Methods E 518.

PREPARATION AND TESTING OF FRESH MORTAR

4. Preparation of Mortar

4.1Apparatus:

4.1.1Scales, Weights, and Glass Graduatesconforming to 2.1, 2.2, and 2.4 of Test Method C190 except that the scales and scale

weights shall be of suitable capacity.

4.1.2Mixer, Paddle, Mixing Bowl, and Scraperconforming to 2.1 to 2.4, of Method C305 except that the mixer, paddle, and

mixing bowl shall have a capacity of 10 qt (0.01 m ) and the first or slow speed of the mixer shall revolve the paddle at a rate

of 144 6 5 rpm, with a planetary speed of approximately 61 rpm. The second speed shall revolve the paddle at a rate of 258 6

10 rpm, with a planetary motion of approximately 109 rpm.

4.1.3Stop Clock.

4.2Procedure:

4.2.1Weigh or measure the proper quantities of aggregates (Note 1), cementing materials, and water needed for the batch. The

amount of water used shall provide a mortar of wet consistency, and the mortar shall preferably be as wet as can conveniently be

handled with a mason’s trowel.

4.1 Proportion mortar materials by weights equivalent to volume proportions to be used in prism construction. Use unit weights

for individual materials as given in Specification C 270. Sand shall be permitted to be used in a damp loose condition, provided

that moisture content of sand is determined with reference to the oven-dried condition and batch proportions are adjusted

accordingly. Record weight of ingredients (including water) added to the batch of mortar.

4.2 Mix mortar in a mechanical paddle-type mortar mixer. Time periods referenced below are measured from when water and

cementitious materials are combined.

4.2.1 Add an estimated amount of water to the mortar to achieve the desired consistency (Note 2). Mix mortar for three minutes

and determine consistency. If the desired consistency is specified by flow determine it in accordance with Test Method C 1437.

If the desired consistency is specified as initial cone penetration, determine it in accordance with Test Method C 780. Once

consistency is recorded, return the material used to measure the consistency to the mixer. If the consistency is within the desired

range, continue mixing the batch for an additional two minutes. If the consistency is less than the desired range, add water to the

batch and mix for one minute and determine consistency. Once consistency is recorded, return the material used to measure

consistency to the mixer. If the consistency is within the desired range, continue mixing the batch for one minute.

NOTE1—About 400 g of aggregate will provide sufficient mortar for several bond test specimens.

4.2.2Charge the mixing bowl with the measured amounts of aggregate and cementing material. Mix manually with a spoon for

5 s. Insert the paddle into the mixture. Preset the stop clock to 10 s before zero time. Set the mixer at No. 1 (slow) speed,

approximately 144 rpm.

4.2.3Simultaneously start the stop clock and the mixer. Mix for 10 s.

4.2.4At zero time and at a continuing slow speed, add the major portion (approximately 95%) of the mixing water within 10

s. Continue mixing for an additional 10 s.

4.2.5Stop the mixer. Change quickly to No. 2 (fast) speed (about 260 rpm) and resume mixing. Continue mixing for a total of

2 min elapsed time starting from zero time.

4.2.6Stop the mixer. Let the mortar stand in the bowl for 10 min with the bowl covered with a slotted lid, permitting the paddle

to remain in the mortar. Before placement of the lid within the first 15 s of the 10-min waiting period, quickly scrape down into

the batch with a rubber scraper any mortar that may have collected on the side of the bowl.

NOTE2—If the mortar is one that tends to segregate and in which the fines stick to the bottom of the bowl, the paddle may be temporarily removed

and the scraper applied to the extreme bottom of the bowl to bring up such fines as may have adhered to the bowl bottom.

4.2.7Remove the cover, change to No. 1 (slow) speed, and mix for 30 s.Add the remainder of the mixing water during the first

part of this 30-s interval. Stop the mixer, change promptly to No. 2 (fast) speed, and finish by mixing for an additional 30 s.

5.Initial Flow of Mortar

5.1Apparatus—The flow table and flow mold shall conform to the requirements of Specification C230.

5.2Procedure—Immediately after final mixing of the mortar, determine the initial flow of mortar from the bowl in accordance

with 8.3 of Test Method C109 excepting the reference to trial mortars at the end of that section. Discard that portion of the mortar

used to determine the initial flow.

NOTE3—The high flow of some mortars makes it advisable to drop the table less than 25 drops before measuring the flow. When calculating the initial

C952–02 (2009)

flow for 25 drops of such mortars, the measured flow should be increased by adding two percentage points of flow for each drop of the table less than

25.

6.Water Retention of Mortar

6.1Apparatus—WaterretentionapparatusshallconformtotherequirementsfortheapparatusinSection25ofSpecificationC91.

6.2Procedure—Immediately after measuring the initial flow, remix the mortar remaining in the bowl for 15 s; then determine

the flow after suction and the water retention of the mortar in accordance with the requirements of Sections 28 and 29 of

Specification C91.

NOTE4—The number of drops of the flow table shall be the same as that used to determine the initial flow and, excepting that the mortar is not

necessarily tempered to an initial flow of 110% and that the mortar used for determining the initial flow is discarded and not returned to mixing bowl,

the procedure shall be in accordance with the specified requirements.

7.Air Content of Mortar

7.1Apparatus—Measure, straightedge, spatula, and other needed apparatus conforming to 18.1 of Specification C91.

7.2Procedure:

7.2.1Preliminary—Placethemortarremaininginthemixingbowlafterfillingthesuctioncupforwaterretentiontestonamortar

board and use for the fabrication of bond test specimens. After mortar for bond test specimens has been taken from the board,

determine the air content of the mortar remaining on the board.

7.2.2Final—Determine the weight of 400 mL of mortar as specified in 20.1 of Specification C91, except that the mortar is not

necessarily tempered to an initial flow of 110%.

7.3Calculation—Calculate the air content of the mortar in accordance with Section 22 of Specification C91, except that the

specific gravity of the sand (value S in the equation) shall be that of the sand used in the mortar.

8.Compressive Strength of Mortar

8.1Apparatus—Specimenmolds,tamper,trowel,andtestingmachineconformingto3.5,3.8,3.9,and3.10ofTestMethodC109.

8.2Procedure—Preparation of specimen molds and molding of test specimens shall conform to Sections 7 and 8.4 of Method

C109. Fill the molds after determination of the weight of 400 mL of the mortar in accordance with 5.2.2 of this test method.

8.3Storage of Test Specimens—Store mortar cubes in accordance with 11.2.2 of Specification C270. 2—Workable consistency

of mortar for concrete masonry construction generally requires an initial cone penetration reading of 55 6 5 mm or a flow of 125

6 5 %. Workable consistency of mortar for clay masonry construction generally requires an initial cone penetration reading of 65

6 5 mm or a flow of 135 6 5 %. Optimum consistency for a specific mortar-unit combination may differ from these values.

4.2.2 If after the one-time addition of water the consistency is not in the desired range, discard the batch.

4.2.3 If the measured consistency exceeds the desired range at any time, discard the batch.

4.3 Immediately after mixing the mortar, determine its initial cone penetration in accordance with Test Method C 780.

Determine the cone penetration of the mortar every 15 6 5 minutes. If the cone penetration is less than 80 % of its initial value,

discard the remaining portion of the mortar without constructing additional mortar joints.

PREPARATION AND TESTING OF BOND STRENGTH TEST SPECIMENS

9.

5. Apparatus

9.1

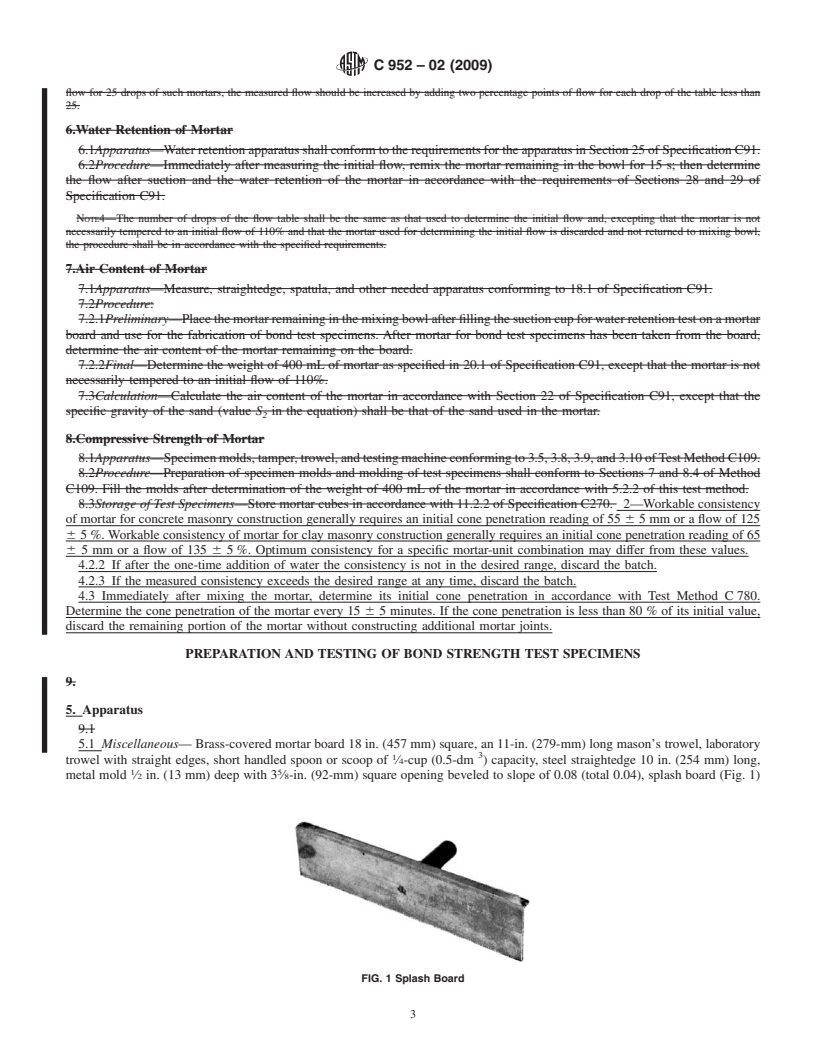

5.1 Miscellaneous— Brass-covered mortar board 18 in. (457 mm) square, an 11-in. (279-mm) long mason’s trowel, laboratory

trowel with straight edges, short handled spoon or scoop of ⁄4-cup (0.5-dm ) capacity, steel straightedge 10 in. (254 mm) long,

1 5

metal mold ⁄2 in. (13 mm) deep with 3 ⁄8-in. (92-mm) square opening beveled to slope of 0.08 (total 0.04), splash board (Fig. 1)

FIG. 1 Splash Board

C952–02 (2009)

with handle 20 in. (508 mm) long and 3 in. (76 mm) wide.

9.2

5.2 Drop Hammer for crossed-brick couplets (Fig. 2, Table 1).

9.3

5.3 Drop Hammer for block assemblies (Fig. 3).

9.4

5.4 Loading Jigs for crossed-brick couplets (Fig. 4).

9.5

5.5 Frames (Fig. 5) for testing block assemblies: upper frame fitted with ball bearing mounted 10 in. (254 mm) from vertical

axis of specimen for eccentric application of vertical load. Fig. .

9.6

5.6 Torque Wrench.

10.

6. Crossed-Brick Couplets

10.1

6.1 Brick—Test specimens consisting of crossed-brick couplets may be used to determine:

10.1.1Bond between specified brick and a specified mortar,

10.1.2Relative bond between different brick and a specified mortar, or

10.1.3Relative bond between a specified brick and different mortars.

10.1.4In each case, the initial rate of absorption of the brick shall be determined in accordance with Section 29 of Methods C67.

For 10.1.1, the brick used for couplets should include the full range of absorption rates acceptable under the specifications. For

10.1.3, absorption rates of the brick should be limited to a range of 15 g.

10.2

6.1.1 Bond

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.