ASTM F3190-21

(Practice)Standard Practice for Heat Fusion Equipment (HFE) Operator Qualification on Polyethylene (PE) and Polyamide (PA) Pipe and Fittings

Standard Practice for Heat Fusion Equipment (HFE) Operator Qualification on Polyethylene (PE) and Polyamide (PA) Pipe and Fittings

SIGNIFICANCE AND USE

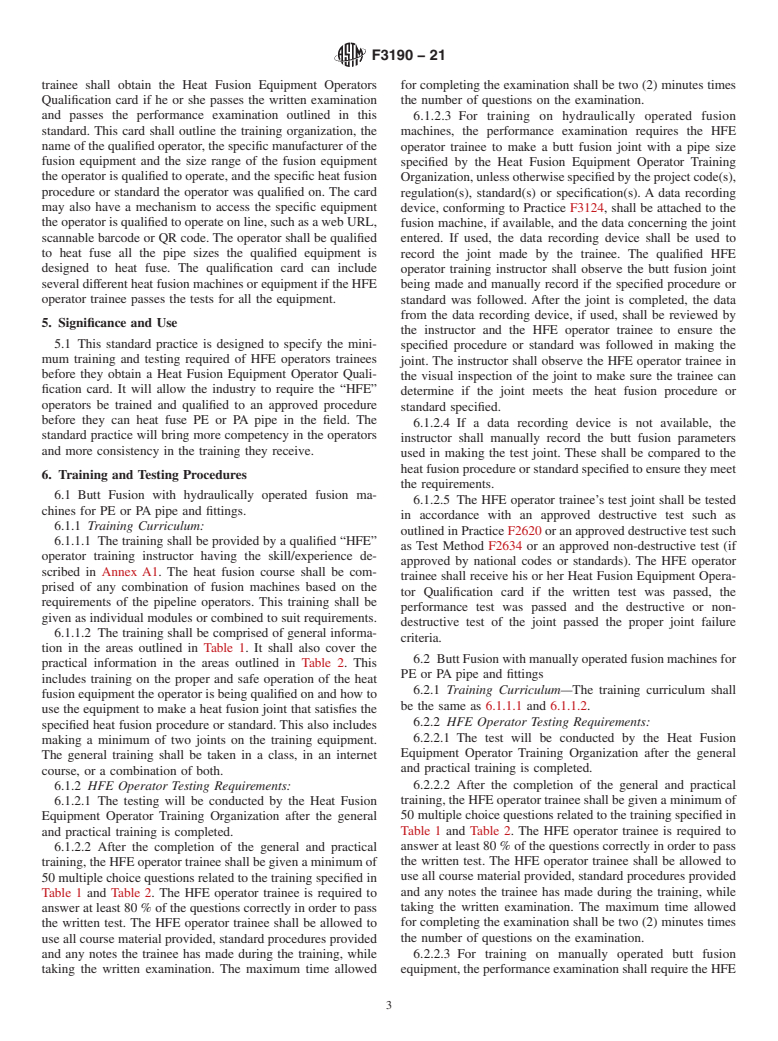

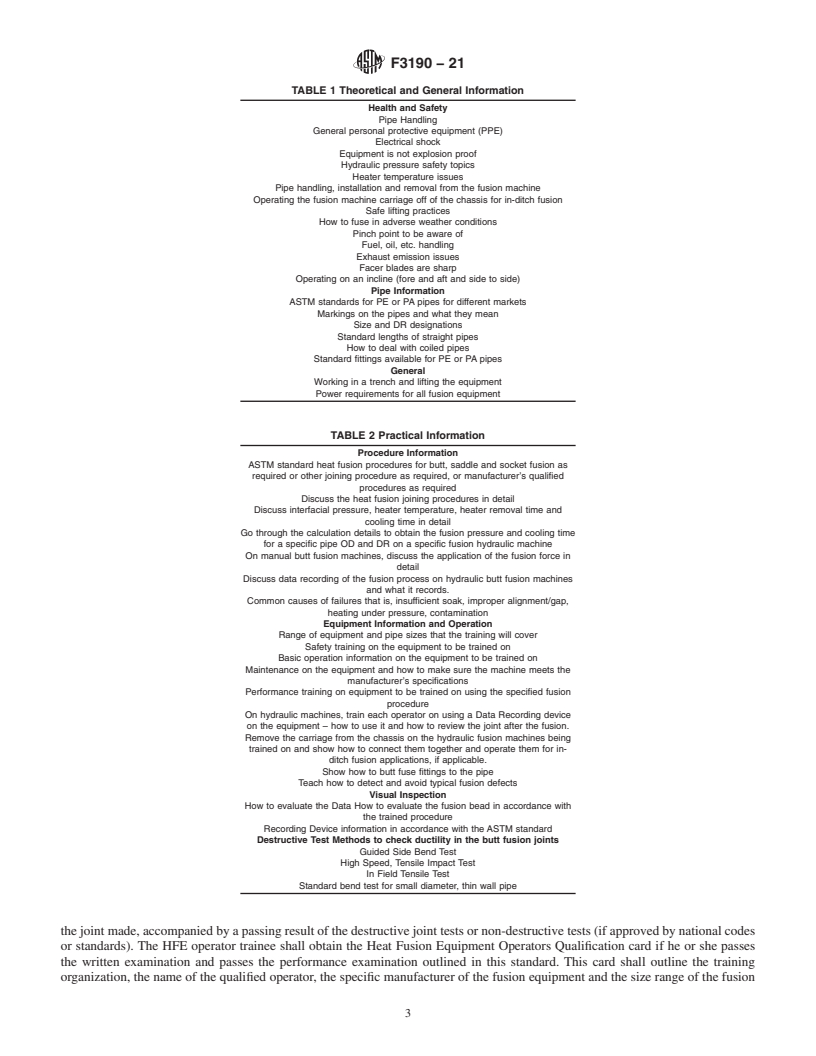

5.1 This standard practice is designed to specify the minimum training and testing required of HFE operators trainees before they obtain a Heat Fusion Equipment Operator Qualification card. It will allow the industry to require the “HFE” operators be trained and qualified to an approved procedure before they can heat fuse PE or PA pipe in the field. The standard practice will bring more competency in the operators and more consistency in the training they receive.

SCOPE

1.1 This practice describes criteria for the training, assessment and qualification of heat fusion equipment (HFE) operators in, but not limited to, a field environment in order to establish and maintain competency in the joining of Polyethylene (PE) and Polyamide (PA) piping systems.

1.2 This HFE operator training and qualification is applicable to heat fusion joining of PE pipe and fittings to other PE pipe and fittings of related polymer chemistry specified in the heat fusion procedures or standards used. It is also applicable to heat fusion joining of PA pipe and fittings to other PA pipe and fittings of the same polymer chemistry specified in the heat fusion procedures or standards used. The heat fusion between PE pipe and fittings to PA pipe and fittings is NOT allowed.

1.3 The HFE operator training and qualification shall be for butt fusion for either PE or PA piping products, using the specific brand and size range of fusion machine to be used by the HFE operator and the heat fusion procedures or standards specified. If the HFE operator trainee requests, the training shall also include saddle and/or socket fusion of PE pipe and fittings of related polymer chemistry specified in the heat fusion procedures or standards used. This standard does not include training on the electro-fusion of these piping products.

1.4 The HFE operator qualification shall be for one specific manufacturer’s fusion machine or a size range of that manufacturer’s hydraulic fusion machines or equipment that all operate in the same manner with the same hydraulic design and controls and the same heater and facer design. For smaller pipe sizes (6 in. and smaller), the qualification can be on a specific fusion machine or a combination of butt, saddle and/or socket fusion machines or equipment.

1.5 The HFE operator qualification shall be on specific heat fusion procedures or standards specified for PE and PA pipes. For PE pipe and fittings, this shall include Practice F2620 or other company or pipe manufacturer’s procedures, or a combination thereof. For PA-11 pipe and fittings, this shall include Plastics Pipe Institute (PPI) Technical Report TR-45 or other company or pipe manufacturer’s procedures. For PA-12 pipe and fittings, this shall include Practice F3372 or other company or pipe manufacturer’s procedures, or a combination thereof. For other PA pipe materials, use other company or pipe manufacturer’s procedures.

1.6 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F3190 −21 An American National Standard

Standard Practice for

Heat Fusion Equipment (HFE) Operator Qualification on

1

Polyethylene (PE) and Polyamide (PA) Pipe and Fittings

This standard is issued under the fixed designation F3190; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* bination thereof. For PA-11 pipe and fittings, this shall include

Plastics Pipe Institute (PPI) Technical Report TR-45 or other

1.1 This practice describes criteria for the training, assess-

company or pipe manufacturer’s procedures. For PA-12 pipe

ment and qualification of heat fusion equipment (HFE) opera-

and fittings, this shall include Practice F3372 or other company

tors in, but not limited to, a field environment in order to

or pipe manufacturer’s procedures, or a combination thereof.

establish and maintain competency in the joining of Polyeth-

For other PA pipe materials, use other company or pipe

ylene (PE) and Polyamide (PA) piping systems.

manufacturer’s procedures.

1.2 This HFE operator training and qualification is appli-

1.6 The values stated in inch-pound units are to be regarded

cable to heat fusion joining of PE pipe and fittings to other PE

as standard. No other units of measurement are included in this

pipe and fittings of related polymer chemistry specified in the

standard.

heat fusion procedures or standards used. It is also applicable

1.7 This standard does not purport to address all of the

to heat fusion joining of PA pipe and fittings to other PA pipe

safety concerns, if any, associated with its use. It is the

and fittings of the same polymer chemistry specified in the heat

responsibility of the user of this standard to establish appro-

fusion procedures or standards used. The heat fusion between

priate safety, health, and environmental practices and deter-

PE pipe and fittings to PA pipe and fittings is NOT allowed.

mine the applicability of regulatory limitations prior to use.

1.3 The HFE operator training and qualification shall be for

1.8 This international standard was developed in accor-

butt fusion for either PE or PA piping products, using the

dance with internationally recognized principles on standard-

specific brand and size range of fusion machine to be used by

ization established in the Decision on Principles for the

the HFE operator and the heat fusion procedures or standards

Development of International Standards, Guides and Recom-

specified. If the HFE operator trainee requests, the training

mendations issued by the World Trade Organization Technical

shall also include saddle and/or socket fusion of PE pipe and

Barriers to Trade (TBT) Committee.

fittings of related polymer chemistry specified in the heat

fusion procedures or standards used. This standard does not

2. Referenced Documents

include training on the electro-fusion of these piping products.

2

2.1 ASTM Standards:

1.4 The HFE operator qualification shall be for one specific

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe

manufacturer’s fusion machine or a size range of that manu-

and Fittings

facturer’s hydraulic fusion machines or equipment that all

F2634 Test Method for Laboratory Testing of Polyethylene

operateinthesamemannerwiththesamehydraulicdesignand

(PE) Butt Fusion Joints using Tensile-Impact Method

controls and the same heater and facer design. For smaller pipe

F3124 Practice for Data Recording the Procedure used to

sizes (6 in. and smaller), the qualification can be on a specific

Produce Heat Butt Fusion Joints in Plastic Piping Systems

fusion machine or a combination of butt, saddle and/or socket

or Fittings

fusion machines or equipment.

F3372 Practice for Butt Fusion Joining of PA12 Pipe and

Fittings

1.5 The HFE operator qualification shall be on specific heat

3

fusion procedures or standards specified for PE and PA pipes. 2.2 PPI Standards:

TR-45 Butt Fusion Joining Procedure For Field Joining of

For PE pipe and fittings, this shall include Practice F2620 or

other company or pipe manufacturer’s procedures, or a com- Polyamide-11 (PA-11) Pipe

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3190 − 16 F3190 − 21 An American National Standard

Standard Practice for

Heat Fusion Equipment (HFE) Operator Qualification on

1

Polyethylene (PE) and Polyamide (PA) Pipe and Fittings

This standard is issued under the fixed designation F3190; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice describes criteria for the training, assessment and qualification of heat fusion equipment (HFE) operators in, but

not limited to, a field environment in order to establish and maintain competency in the joining of Polyethylene (PE) and Polyamide

(PA) piping systems.

1.2 This HFE operator training and qualification is applicable to heat fusion joining of PE pipe and fittings to other PE pipe and

fittings of related polymer chemistry specified in the heat fusion procedures or standards used. It is also applicable to heat fusion

joining of PA pipe and fittings to other PA pipe and fittings of the same polymer chemistry specified in the heat fusion procedures

or standards used. The heat fusion between PE pipe and fittings to PA pipe and fittings is NOT allowed.

1.3 The HFE operator training and qualification shall be for butt fusion for either PE or PA piping products, using the specific

brand and size range of fusion machine to be used by the HFE operator and the heat fusion procedures or standards specified. If

the HFE operator trainee requests, the training shall also include saddle and/or socket fusion of PE pipe and fittings of related

polymer chemistry specified in the heat fusion procedures or standards used. This standard does not include training on the

electro-fusion of these piping products.

1.4 The HFE operator qualification shall be for one specific manufacturer’s fusion machine or a size range of that manufacturer’s

hydraulic fusion machines or equipment that all operate in the same manner with the same hydraulic design and controls and the

same heater and facer design. For smaller pipe sizes (6 in. and smaller), the qualification can be on a specific fusion machine or

a combination of butt, saddle and/or socket fusion machines or equipment.

1.5 The HFE operator qualification shall be on specific heat fusion procedures or standards specified for PE and PA pipes. For PE

pipe and fittings, this shall include Practice F2620 or other company or pipe manufacturer’s procedures, or a combination thereof.

For PA-11 pipe and fittings, this shall include Plastics Pipe Institute (PPI) Technical Report TR-45 or other company or pipe

manufacturer’s procedures. For PA-12 pipe and fittings, this shall include Practice F3372other or other company or pipe

manufacturer’s procedures, or a combination thereof. For other PA pipe materials, use other company or pipe manufacturer’s

procedures.

1.6 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this

standard.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

Current edition approved April 1, 2016May 1, 2021. Published May 2016May 2021. Originally approved in 2016. Last previous edition approved in 2016 as F3190–16.

DOI: 10.1520/F3190–1610.1520/F3190–21

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3190 − 21

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings

F2634 Test Method for Laboratory Testing of Polyethylene (PE) Butt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.