ASTM D1092-12(2017)

(Test Method)Standard Test Method for Measuring Apparent Viscosity of Lubricating Greases

Standard Test Method for Measuring Apparent Viscosity of Lubricating Greases

SIGNIFICANCE AND USE

5.1 Apparent viscosity versus shear rate information can be useful in predicting pressure drops in grease distribution systems under steady-state flow conditions at constant temperature.

SCOPE

1.1 This test method covers measurement, in poises, of the apparent viscosity of lubricating greases in the temperature range from −54 °C to 38 °C (−65 °F to 100 °F). Measurements are limited to the range from 25 P to 100 000 P at 0.1 s−1 and 1 P to 100 P at 15 000 s−1.

Note 1: At very low temperatures the shear rate range may be reduced because of the great force required to force grease through the smaller capillaries. Precision has not been established below 10 s−1.

1.2 This standard uses inch-pound units as well as SI (acceptable metric) units. The values stated first are to be regarded as standard. The values given in parentheses are for information only. The capillary dimensions in SI units in Fig. A1.1 and Fig. A1.2 are standard.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.3.1 In addition, temperature measuring devices such as liquid-in-glass thermometers, thermocouples, thermistors, or platinum resistance thermometers that provide equivalent or better accuracy and precision, that cover the temperature range for ASTM thermometer 49C, may be used.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1092 − 12 (Reapproved 2017)

Standard Test Method for

Measuring Apparent Viscosity of Lubricating Greases

This standard is issued under the fixed designation D1092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method covers measurement, in poises, of the

ization established in the Decision on Principles for the

apparent viscosity of lubricating greases in the temperature

Development of International Standards, Guides and Recom-

rangefrom−54°Cto38°C(−65°Fto100°F).Measurements

−1 mendations issued by the World Trade Organization Technical

are limited to the range from 25P to 100000P at 0.1s and

−1 Barriers to Trade (TBT) Committee.

1P to 100P at 15000s .

NOTE1—Atverylowtemperaturestheshearraterangemaybereduced 2. Referenced Documents

because of the great force required to force grease through the smaller

−1

2.1 ASTM Standards:

capillaries. Precision has not been established below 10s .

D88Test Method for Saybolt Viscosity

1.2 This standard uses inch-pound units as well as SI

D217Test Methods for Cone Penetration of Lubricating

(acceptable metric) units. The values stated first are to be

Grease

regarded as standard. The values given in parentheses are for

D3244Practice for Utilization of Test Data to Determine

information only. The capillary dimensions in SI units in Fig.

Conformance with Specifications

A1.1 and Fig. A1.2 are standard.

3. Terminology

1.3 WARNING—Mercury has been designated by many

regulatory agencies as a hazardous material that can cause

3.1 Definitions:

central nervous system, kidney and liver damage. Mercury, or

3.1.1 apparent viscosity, n—of a lubricating grease is the

its vapor, may be hazardous to health and corrosive to

ratio of shear stress to shear rate calculated from Poiseuille’s

materials.Cautionshouldbetakenwhenhandlingmercuryand

equation, and is measured in poises (see 10.1).

mercury containing products. See the applicable product Ma-

3.1.2 capillary, n—For the purpose of this test method, a

terial Safety Data Sheet (MSDS) for details and EPA’s

capillary is any right cylindrical tube having a length to

website—http://www.epa.gov/mercury/faq.htm—for addi-

diameter ratio of 40 to 1.

tional information. Users should be aware that selling mercury

3.1.3 shear rate, n—the rate at which a series of adjacent

and/or mercury containing products into your state or country

layers of grease move with respect to each other; proportional

may be prohibited by law.

to the linear velocity of flow divided by the capillary radius,

1.3.1 In addition, temperature measuring devices such as

and is thus expressed as reciprocal seconds.

liquid-in-glass thermometers, thermocouples, thermistors, or

platinum resistance thermometers that provide equivalent or

4. Summary of Test Method

betteraccuracyandprecision,thatcoverthetemperaturerange

4.1 The sample is forced through a capillary by means of a

for ASTM thermometer 49C, may be used.

floating piston actuated by the hydraulic system. From the

1.4 This standard does not purport to address all of the

predeterminedflowrateandtheforcedevelopedinthesystem,

safety concerns, if any, associated with its use. It is the

the apparent viscosity is calculated by means of Poiseuille’s

responsibility of the user of this standard to establish appro-

equation.Aseriesofeightcapillariesandtwopumpspeedsare

priate safety, health and environmental practices and deter-

used to determine the apparent viscosity at sixteen shear rates.

mine the applicability of regulatory limitations prior to use.

Theresultsareexpressedasalog-logplotofapparentviscosity

versus shear rate.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.G0.02 on Consistency and Related Rheological Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2017. Published August 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1950. Last previous edition approved in 2012 as D1092–12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1092-12R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1092 − 12 (2017)

5. Significance and Use

5.1 Apparent viscosity versus shear rate information can be

useful in predicting pressure drops in grease distribution

systems under steady-state flow conditions at constant tem-

perature.

6. Apparatus

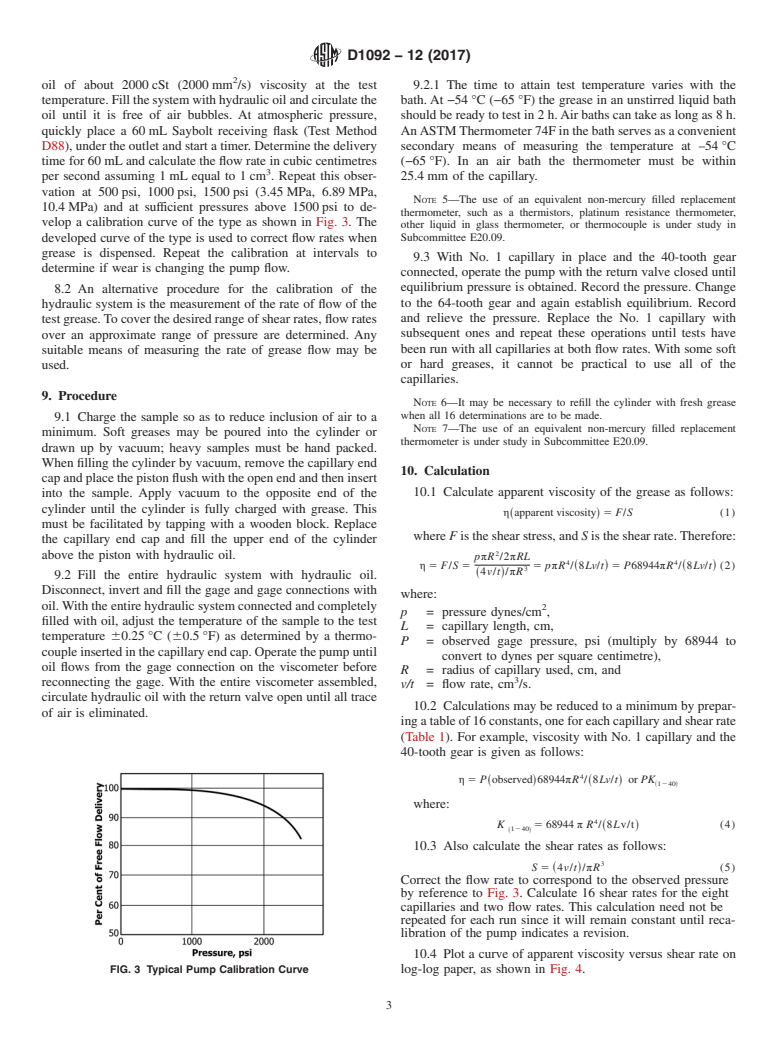

6.1 The assembled pressure viscometer consists of four

major divisions, the power system, the hydraulic system, the

grease system (described in the annex and shown in Fig. 1),

andabathofoptionaldesign.Fig.2isaphotographofthefirst

three divisions as commonly used at room temperature. This

form of the apparatus can be used with a cylindrical insulated

tank178mm(7in.)indiameterand508mm(20in.)deep.The

bathmediummaybekeroseneoralcoholcooledmanuallywith

dry ice. Alternatively the grease system, the grease and

hydraulic system, or all three major divisions can be built into

anyliquidorairbaththatwillcoverthetemperaturerangeand

maintain the grease at test temperature 60.25°C (60.5°F).

7. Sampling

7.1 A single filling of the grease cylinder requires about

0.223kg ( ⁄2lb) of grease which is the minimum size sample.

NOTE 2—It is possible for an experienced operator to complete the 16

single determinations with a single filling. However, some samples reach

FIG. 2 Photograph of Apparatus

the equilibrium pressure slowly, making it advisable to have a sample of

several pounds available.

NOTE4—Itisdesirabletofiltersomegreasesthrougha60-meshscreen

7.2 Generally no special preparation of the sample is nec-

topreventpluggingtheNo.8capillary.Followprudentlaboratorypractice

essary. to keep equipment cleaned and flushed before use.

NOTE 3—The apparatus works the samples to some extent as they pass

8. Calibration and Standardization

through the capillary. Somewhat better precision is obtained if they are

8.1 To calibrate the hydraulic system, remove the grease

previously worked as described in Test Methods D217. Working of some

greases may cause aeration. cylinder and replace it with a needle valve. Select a hydraulic

FIG. 1 Schematic Drawing of Apparatus

D1092 − 12 (2017)

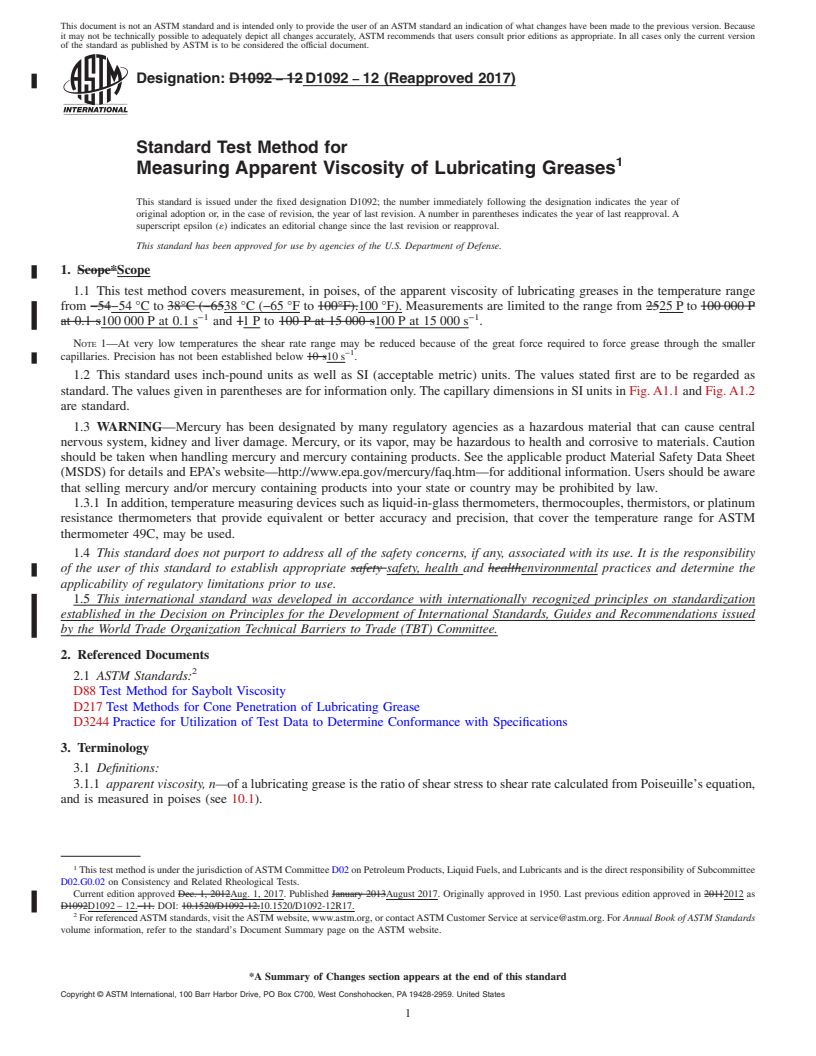

oil of about 2000cSt (2000mm /s) viscosity at the test 9.2.1 The time to attain test temperature varies with the

temperature.Fillthesystemwithhydraulicoilandcirculatethe bath.At −54°C (−65°F) the grease in an unstirred liquid bath

oil until it is free of air bubbles. At atmospheric pressure, shouldbereadytotestin2h.Airbathscantakeaslongas8h.

quickly place a 60mL Saybolt receiving flask (Test Method AnASTMThermometer74Finthebathservesasaconvenient

D88),undertheoutletandstartatimer.Determinethedelivery secondary means of measuring the temperature at –54°C

timefor60mLandcalculatetheflowrateincubiccentimetres (−65°F). In an air bath the thermometer must be within

per second assuming 1mL equal to 1cm . Repeat this obser- 25.4mm of the capillary.

vation at 500psi, 1000psi, 1500psi (3.45MPa, 6.89MPa,

NOTE 5—The use of an equivalent non-mercury filled replacement

10.4MPa) and at sufficient pressures above 1500psi to de-

thermometer, such as a thermistors, platinum resistance thermometer,

velop a calibration curve of the type as shown in Fig. 3. The

other liquid in glass thermometer, or thermocouple is under study in

developed curve of the type is used to correct flow rates when Subcommittee E20.09.

grease is dispensed. Repeat the calibration at intervals to

9.3 With No. 1 capillary in place and the 40-tooth gear

determine if wear is changing the pump flow.

connected, operate the pump with the return valve closed until

equilibrium pressure is obtained. Record the pressure. Change

8.2 An alternative procedure for the calibration of the

to the 64-tooth gear and again establish equilibrium. Record

hydraulic system is the measurement of the rate of flow of the

and relieve the pressure. Replace the No. 1 capillary with

testgrease.Tocoverthedesiredrangeofshearrates,flowrates

subsequent ones and repeat these operations until tests have

over an approximate range of pressure are determined. Any

been run with all capillaries at both flow rates. With some soft

suitable means of measuring the rate of grease flow may be

or hard greases, it cannot be practical to use all of the

used.

capillaries.

9. Procedure

NOTE 6—It may be necessary to refill the cylinder with fresh grease

when all 16 determinations are to be made.

9.1 Charge the sample so as to reduce inclusion of air to a

NOTE 7—The use of an equivalent non-mercury filled replacement

minimum. Soft greases may be poured into the cylinder or

thermometer is under study in Subcommittee E20.09.

drawn up by vacuum; heavy samples must be hand packed.

Whenfillingthecylinderbyvacuum,removethecapillaryend

10. Calculation

capandplacethepistonflushwiththeopenendandtheninsert

10.1 Calculate apparent viscosity of the grease as follows:

into the sample. Apply vacuum to the opposite end of the

cylinder until the cylinder is fully charged with grease. This

η apparentviscosity 5 F/S (1)

~ !

must be facilitated by tapping with a wooden block. Replace

where Fistheshearstress,and Sistheshearrate.Therefore:

the capillary end cap and fill the upper end of the cylinder

above the piston with hydraulic oil.

pπR /2πRL

4 4

η 5 F/S 5 5 pπR /~8Lv/t! 5 P68944πR /~8Lv/t! (2)

~4v/t!/πR

9.2 Fill the entire hydraulic system with hydraulic oil.

Disconnect, invert and fill the gage and gage connections with

where:

oil.Withtheentirehydraulicsystemconnectedandcompletely

p = pressure dynes/cm ,

filled with oil, adjust the temperature of the sample to the test

L = capillary length, cm,

temperature 60.25°C (60.5°F) as determined by a thermo-

P = observed gage pressure, psi (multiply by 68944 to

coupleinsertedinthecapillaryendcap.Operatethepumpuntil

convert to dynes per square centimetre),

oil flows from the gage connection on the viscometer before

R = radius of capillary used, cm, and

reconnecting the gage. With the entire viscometer assembled,

v/t = flow rate, cm /s.

circulate hydraulic oil with the return valve open until all trace

10.2 Calculations may be reduced to a minimum by prepar-

of air is eliminated.

ingatableof16constants,oneforeachcapillaryandshearrate

(Table 1). For example, viscosity with No. 1 capillary and the

40-tooth gear is given as follows:

η 5 P observed 68944πR / 8Lv/t or PK

~ ! ~ !

~1240!

where:

K 568944π R / 8Lv/t (4)

~ !

~ !

10.3 Also calculate the shear rates as follows:

S 5 4v/t /πR (5)

~ !

Correct the flow rate to correspond to the observed pressure

by reference to Fig. 3. Calculate 16 shear rates for the eight

capillaries and two flow rates. This calculation need not be

repeated for each run since it will remain constant until reca-

libration of the pump indicates a revision.

10.4 Plot a curve of apparent viscosity versus shear rate on

FIG. 3 Typical Pump Calibration Curve log-log paper, as shown in Fig. 4.

D1092 − 12 (2017)

TABLE 1 Suggested Data Sheet for Recording Test Results (With Illustrative Test Values)

Sample . . No. 2 Grease Temperature . . 25°C

..

Date. . Nov. 1, 1948 Operator. . R.S.

A B A C

12 3 4 5 6 7

Apparent

Observed Shear Rate, Shear Stress,

K = 68944 Viscosity,

−1

Capillary Gear Pressure, S ,s = dynes per sq

πR /(8Lv/t) n poises,

P, psi (4v/t)/πR cm = n × S

= P×K

1 40 25.5 28.10 716 15 10 740

2 40 38.3 6.83 267 61 16 300

3 40 48.8 3.61 176 120 21 100

4 40 63.5 1.90 120 230 27 800

5 40 96.5 0.89 86 480 41 300

6 40 125 0.58 72.6 755 54 800

7 40 286 0.139 39.8 3 140 125 000

8 40 546 0.0464 25.3 9 320 235 500

1 64 29.5 17.60 520 24 12 470

2 64 45.8 4.27 195 98 19 100

3 64 60 2.26 135.5 195 26 400

4 64 82.3 1.19 97.9 370 36 250

5 64 130 0.556 72.4 770 55 800

6 64 165 0.363 59.9 1 220 73 200

7 64 384 0.087 33.4 5 020 167 500

8 64 720 0.029 20.9 14 900 311 000

A

Values in this column are predetermined.

B

Column 3 times Column 4.

C

Column 5 times Column 6.

FIG. 4 Typical Chart for Apparent Viscosity versus Shear Rate

NOTE 8—Shear stresses also can be calculated by multiplying apparent

11. Precision and Bias

viscosities by their corresponding shear rates. For solving various prob-

11.1 Due to the nature of the results, the precision of this

lems involving the steady flow of greases, shear stress-shear rate relation-

shipsmaybeplottedonappropriatecharts.Instructionsontheuseofthese

test method was not obtained according to RR:D02-1007,

charts are given in the article by Rein and McGahey.

“Manual on Determining Precision Data for ASTM Methods

on Petroleum Products and Lubricants.” The precision of this

test method as determined by statistical examination of inter-

Rein and McGahey, “Predicting Grease Flow in Large Pipes,” NLGI

Spokesman, April 1965. laboratory results is as follows:

D1092 − 12 (2017)

11.2 The data in 11.2.1 and 11.2.2 should be used for ing in different laboratories on identical test material would, in

judging the acceptability of results (95% confidence) accord- the long run, in the normal and correct operation of the test

ing to the concept of precision as given in Practice D3244.

method, exceed the values given in Table 2 only in one case in

11.2.1 Repeatability—The difference between two test

twenty.

results, obtained by the same operator with the same apparatus

11.2.3 Reproducibility of the curve drawing operation var-

under constant operating conditions on identical test material,

ies from 5 to 8 % for the above samples. These data are based

would in the long run, in the normal and correct operation of

upon curve values of apparent viscosity at the six shear rates.

thetestmethod,exceedthevaluesgiveninTable2onlyinone

A separate curve was drawn for each run.

case in twenty.

11.2.2 Reproducibility—The difference between two single

11.3 Bias—Since there is no accepted reference material

and independent results obtaine

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1092 − 12 D1092 − 12 (Reapproved 2017)

Standard Test Method for

Measuring Apparent Viscosity of Lubricating Greases

This standard is issued under the fixed designation D1092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This test method covers measurement, in poises, of the apparent viscosity of lubricating greases in the temperature range

from −54−54 °C to 38°C (−6538 °C (−65 °F to 100°F).100 °F). Measurements are limited to the range from 2525 P to 100 000 P

−1 −1

at 0.1 s100 000 P at 0.1 s and 11 P to 100 P at 15 000 s100 P at 15 000 s .

NOTE 1—At very low temperatures the shear rate range may be reduced because of the great force required to force grease through the smaller

−1

capillaries. Precision has not been established below 10 s10 s .

1.2 This standard uses inch-pound units as well as SI (acceptable metric) units. The values stated first are to be regarded as

standard. The values given in parentheses are for information only. The capillary dimensions in SI units in Fig. A1.1 and Fig. A1.2

are standard.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.3.1 In addition, temperature measuring devices such as liquid-in-glass thermometers, thermocouples, thermistors, or platinum

resistance thermometers that provide equivalent or better accuracy and precision, that cover the temperature range for ASTM

thermometer 49C, may be used.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D88 Test Method for Saybolt Viscosity

D217 Test Methods for Cone Penetration of Lubricating Grease

D3244 Practice for Utilization of Test Data to Determine Conformance with Specifications

3. Terminology

3.1 Definitions:

3.1.1 apparent viscosity, n—of a lubricating grease is the ratio of shear stress to shear rate calculated from Poiseuille’s equation,

and is measured in poises (see 10.1).

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.G0.02 on Consistency and Related Rheological Tests.

Current edition approved Dec. 1, 2012Aug. 1, 2017. Published January 2013August 2017. Originally approved in 1950. Last previous edition approved in 20112012 as

D1092D1092 – 12.–11. DOI: 10.1520/D1092-12.10.1520/D1092-12R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1092 − 12 (2017)

3.1.2 capillary, n—For the purpose of this test method, a capillary is any right cylindrical tube having a length to diameter ratio

of 40 to 1.

3.1.3 shear rate, n—the rate at which a series of adjacent layers of grease move with respect to each other; proportional to the

linear velocity of flow divided by the capillary radius, and is thus expressed as reciprocal seconds.

4. Summary of Test Method

4.1 The sample is forced through a capillary by means of a floating piston actuated by the hydraulic system. From the

predetermined flow rate and the force developed in the system, the apparent viscosity is calculated by means of Poiseuille’s

equation. A series of eight capillaries and two pump speeds are used to determine the apparent viscosity at sixteen shear rates. The

results are expressed as a log-log plot of apparent viscosity versus shear rate.

5. Significance and Use

5.1 Apparent viscosity versus shear rate information can be useful in predicting pressure drops in grease distribution systems

under steady-state flow conditions at constant temperature.

6. Apparatus

6.1 The assembled pressure viscometer consists of four major divisions, the power system, the hydraulic system, the grease

system (described in the annex and shown in Fig. 1), and a bath of optional design. Fig. 2 is a photograph of the first three divisions

as commonly used at room temperature. This form of the apparatus can be used with a cylindrical insulated tank 178 mm (7 in.)

178 mm (7 in.) in diameter and 508 mm (20 in.) 508 mm (20 in.) deep. The bath medium may be kerosene or alcohol cooled

manually with dry ice. Alternatively the grease system, the grease and hydraulic system, or all three major divisions can be built

into any liquid or air bath that will cover the temperature range and maintain the grease at test temperature 60.25° C

(60.5°F).60.25 °C (60.5 °F).

7. Sampling

7.1 A single filling of the grease cylinder requires about 0.223 kg 0.223 kg ( ⁄2 lb) lb) of grease which is the minimum size

sample.

NOTE 2—It is possible for an experienced operator to complete the 16 single determinations with a single filling. However, some samples reach the

equilibrium pressure slowly, making it advisable to have a sample of several pounds available.

7.2 Generally no special preparation of the sample is necessary.

NOTE 3—The apparatus works the samples to some extent as they pass through the capillary. Somewhat better precision is obtained if they are

previously worked as described in Test Methods D217. Working of some greases may cause aeration.

FIG. 1 Schematic Drawing of Apparatus

D1092 − 12 (2017)

FIG. 2 Photograph of Apparatus

NOTE 4—It is desirable to filter some greases through a 60-mesh screen to prevent plugging the No. 8 capillary. Follow prudent laboratory practice

to keep equipment cleaned and flushed before use.

8. Calibration and Standardization

8.1 To calibrate the hydraulic system, remove the grease cylinder and replace it with a needle valve. Select a hydraulic oil of

about 2000 cSt (2000 mm2000 cSt (2000 mm /s) viscosity at the test temperature. Fill the system with hydraulic oil and circulate

the oil until it is free of air bubbles. At atmospheric pressure, quickly place a 60-mL60 mL Saybolt receiving flask (Test Method

D88), under the outlet and start a timer. Determine the delivery time for 60 mL 60 mL and calculate the flow rate in cubic

centimetres per second assuming 1 mL 1 mL equal to 1 cm1 cm . Repeat this observation at 500, 1000, 1500 psi (3.45, 6.89, 10.4

MPa) 500 psi, 1000 psi, 1500 psi (3.45 MPa, 6.89 MPa, 10.4 MPa) and at sufficient pressures above 1500 psi 1500 psi to develop

a calibration curve of the type as shown in Fig. 3. The developed curve of the type is used to correct flow rates when grease is

dispensed. Repeat the calibration at intervals to determine if wear is changing the pump flow.

8.2 An alternative procedure for the calibration of the hydraulic system is the measurement of the rate of flow of the test grease.

To cover the desired range of shear rates, flow rates over an approximate range of pressure are determined. Any suitable means

of measuring the rate of grease flow may be used.

FIG. 3 Typical Pump Calibration Curve

D1092 − 12 (2017)

9. Procedure

9.1 Charge the sample so as to reduce inclusion of air to a minimum. Soft greases may be poured into the cylinder or drawn

up by vacuum; heavy samples must be hand packed. When filling the cylinder by vacuum, remove the capillary end cap and place

the piston flush with the open end and then insert into the sample. Apply vacuum to the opposite end of the cylinder until the

cylinder is fully charged with grease. This must be facilitated by tapping with a wooden block. Replace the capillary end cap and

fill the upper end of the cylinder above the piston with hydraulic oil.

9.2 Fill the entire hydraulic system with hydraulic oil. Disconnect, invert and fill the gage and gage connections with oil. With

the entire hydraulic system connected and completely filled with oil, adjust the temperature of the sample to the test temperature

60.25°C (60.5°F)60.25 °C (60.5 °F) as determined by a thermocouple inserted in the capillary end cap. Operate the pump until

oil flows from the gage connection on the viscometer before reconnecting the gage. With the entire viscometer assembled, circulate

hydraulic oil with the return valve open until all trace of air is eliminated.

9.2.1 The time to attain test temperature varies with the bath. At −54°C (−65°F)−54 °C (−65 °F) the grease in an unstirred liquid

bath should be ready to test in 2 h. 2 h. Air baths can take as long as 8 h. 8 h. An ASTM Thermometer 74F in the bath serves as

a convenient secondary means of measuring the temperature at –54°C (−65°F).–54 °C (−65 °F). In an air bath the thermometer

must be within 25.4 mm 25.4 mm of the capillary.

NOTE 5—The use of an equivalent non-mercury filled replacement thermometer, such as a thermistors, platinum resistance thermometer, other liquid

in glass thermometer, or thermocouple is under study in Subcommittee E20.09.

9.3 With No. 1 capillary in place and the 40-tooth gear connected, operate the pump with the return valve closed until

equilibrium pressure is obtained. Record the pressure. Change to the 64-tooth gear and again establish equilibrium. Record and

relieve the pressure. Replace the No. 1 capillary with subsequent ones and repeat these operations until tests have been run with

all capillaries at both flow rates. With some soft or hard greases, it cannot be practical to use all of the capillaries.

NOTE 6—It may be necessary to refill the cylinder with fresh grease when all 16 determinations are to be made.

NOTE 7—The use of an equivalent non-mercury filled replacement thermometer is under study in Subcommittee E20.09.

10. Calculation

10.1 Calculate apparent viscosity of the grease as follows:

η apparent viscosity 5 F/S (1)

~ !

where F is the shear stress, and S is the shear rate. Therefore:

pπR /2πRL

4 4

η5 F/S 5 5 pπR /~8Lv/t! 5 P68944πR /~8Lv/t! (2)

~4v/t!/πR

where:

where:

p = pressure dynes/cm ,

L = capillary length, cm,

P = observed gage pressure, psi (multiply by 68944 to convert to dynes per square centimetre),

R = radius of capillary used, cm, and

v/t = flow rate, cm /s.

10.2 Calculations may be reduced to a minimum by preparing a table of 16 constants, one for each capillary and shear rate

(Table 1). For example, viscosity with No. 1 capillary and the 40-tooth gear is given as follows:

η5 P observed 68944πR / 8Lv/t or PK

~ ! ~ !

~1240!

where:

K 5 68944 π R / 8Lv/t (4)

~ !

~ !

10.3 Also calculate the shear rates as follows:

S 5 ~4v/t!/πR (5)

Correct the flow rate to correspond to the observed pressure by reference to Fig. 3. Calculate 16 shear rates for the eight cap-

illaries and two flow rates. This calculation need not be repeated for each run since it will remain constant until recalibration

of the pump indicates a revision.

10.4 Plot a curve of apparent viscosity versus shear rate on log-log paper, as shown in Fig. 4.

NOTE 8—Shear stresses also can be calculated by multiplying apparent viscosities by their corresponding shear rates. For solving various problems

D1092 − 12 (2017)

TABLE 1 Suggested Data Sheet for Recording Test Results (With Illustrative Test Values)

Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 2 Grease Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25°C

. .

Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nov. 1, 1948 Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R.S.

A B A C

1 2 3 4 5 6 7

Apparent

Observed Shear Rate, Shear Stress,

K = 68944 Viscosity,

−1

Capillary Gear Pressure, S , s = dynes per sq

πR /(8Lv/t) n poises,

P, psi (4v/t)/πR cm = n × S

= P × K

1 40 25.5 28.10 716 15 10 740

2 40 38.3 6.83 267 61 16 300

3 40 48.8 3.61 176 120 21 100

4 40 63.5 1.90 120 230 27 800

5 40 96.5 0.89 86 480 41 300

6 40 125 0.58 72.6 755 54 800

7 40 286 0.139 39.8 3 140 125 000

8 40 546 0.0464 25.3 9 320 235 500

1 64 29.5 17.60 520 24 12 470

2 64 45.8 4.27 195 98 19 100

3 64 60 2.26 135.5 195 26 400

4 64 82.3 1.19 97.9 370 36 250

5 64 130 0.556 72.4 770 55 800

6 64 165 0.363 59.9 1 220 73 200

7 64 384 0.087 33.4 5 020 167 500

8 64 720 0.029 20.9 14 900 311 000

A

Values in this column are predetermined.

B

Column 3 times Column 4.

C

Column 5 times Column 6.

FIG. 4 Typical Chart for Apparent Viscosity versus Shear Rate

involving the steady flow of greases, shear stress-shear rate relationships may be plotted on appropriate charts. Instructions on the use of these charts are

given in the article by Rein and McGahey.

Rein and McGahey, “Predicting Grease Flow in Large Pipes,” NLGI Spokesman, April 1965.

D1092 − 12 (2017)

11. Precision and Bias

11.1 Due to the nature of the results, the precision of this test method was not obtained according to RR:D02-1007, “Manual

on Determining Precision Data fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.