ASTM B567-98(2021)

(Test Method)Standard Test Method for Measurement of Coating Thickness by the Beta Backscatter Method

Standard Test Method for Measurement of Coating Thickness by the Beta Backscatter Method

SIGNIFICANCE AND USE

4.1 The thickness or mass per unit area of a coating is often critical to its performance.

4.2 For some coating-substrate combinations, the beta backscatter method is a reliable method for measuring the coating nondestructively.

4.3 The test method is suitable for thickness specification acceptance if the mass per unit area is specified. It is not suitable for specification acceptance if the coating thickness is specified and the density of the coating material can vary or is not known.

SCOPE

1.1 This test method covers the beta backscatter gages for the nondestructive measurement of metallic and nonmetallic coatings on both metallic and nonmetallic substrate materials.

1.2 The test method measures the mass of coating per unit area, which can also be expressed in linear thickness units provided that the density of the coating is known.

1.3 The test method is applicable only if the atomic numbers or equivalent atomic numbers of the coating and substrate differ by an appropriate amount (see 6.2).

1.4 Beta backscatter instruments employ a number of different radioactive isotopes. Although the activities of these isotopes are normally very low, they can present a hazard if handled incorrectly. This standard does not purport to address the safety issues and the proper handling of radioactive materials. It is the responsibility of the user to comply with applicable State and Federal regulations concerning the handling and use of radioactive material. Some States require licensing and registration of the radioactive isotopes.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B567 − 98 (Reapproved 2021)

Standard Test Method for

Measurement of Coating Thickness by the Beta Backscatter

Method

This standard is issued under the fixed designation B567; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Terminology

1.1 This test method covers the beta backscatter gages for 2.1 Definitions of Terms Specific to This Standard:

the nondestructive measurement of metallic and nonmetallic 2.1.1 activity—the nuclei of all radioisotopes are unstable

coatings on both metallic and nonmetallic substrate materials.

and tend to change into a stable condition by spontaneously

emitting energy or particles, or both. This process is known as

1.2 The test method measures the mass of coating per unit

radioactive decay.The total number of disintegrations during a

area, which can also be expressed in linear thickness units

suitably small interval of time divided by that interval of time

provided that the density of the coating is known.

is called “activity.” Therefore, in beta backscatter

1.3 Thetestmethodisapplicableonlyiftheatomicnumbers

measurements, a higher activity corresponds to a greater

or equivalent atomic numbers of the coating and substrate

emissionofbetaparticles.Theactivityofaradioactiveelement

differ by an appropriate amount (see 6.2).

used in beta backscatter gages is generally expressed in

1.4 Beta backscatter instruments employ a number of dif- microcuries (1 µCi=3.7×10 disintegrations per second).

ferent radioactive isotopes. Although the activities of these

2.1.2 aperture—the opening of the mask abutting the test

isotopes are normally very low, they can present a hazard if

specimen. It determines the size of the area on which the

handled incorrectly. This standard does not purport to address

coating thickness is measured. This mask is also referred to as

the safety issues and the proper handling of radioactive

a platen, an aperture plate, a specimen support, or a specimen

materials. It is the responsibility of the user to comply with

mask.

applicable State and Federal regulations concerning the han-

2.1.3 backscatter—when beta particles pass through matter,

dling and use of radioactive material. Some States require

they collide with atoms. Among other things, this interaction

licensing and registration of the radioactive isotopes.

will change their direction and reduce their speed. If the

1.5 The values stated in SI units are to be regarded as

deflections are such that the beta particle leaves the body of

standard. No other units of measurement are included in this

matter from the same surface at which it entered, the beta

standard.

particle is said to be backscattered.

1.6 This standard does not purport to address all of the

2.1.4 backscatter coeffıcient—the backscatter coefficient of

safety concerns, if any, associated with its use. It is the

a body, R, is the ratio of the number of beta particles

responsibility of the user of this standard to establish appro-

backscattered to that entering the body. R is independent of the

priate safety, health, and environmental practices and deter-

activity of the isotope and of the measuring time.

mine the applicability of regulatory limitations prior to use.

2.1.5 backscatter count:

1.7 This international standard was developed in accor-

2.1.5.1 absolute backscatter count—the absolute backscat-

dance with internationally recognized principles on standard-

ter count, X, is the number of beta particles that are backscat-

ization established in the Decision on Principles for the

tered during a finite interval of time and displayed by the

Development of International Standards, Guides and Recom-

instrument. X will, therefore, depend on the activity of the

mendations issued by the World Trade Organization Technical

source, the measuring time, the geometric configuration of the

Barriers to Trade (TBT) Committee.

measuringsystem,andthepropertiesofthedetector,aswellas

the coating thickness and the atomic numbers of the coating

and substrate materials. X is the count produced by the

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on

uncoated substrate, and Xs, that of the coating material. To

Test Methods.

obtainthesevalues,itisnecessarythatboththesematerialsare

Current edition approved April 1, 2021. Published May 2021. Originally

available with a thickness greater than the saturation thickness

approvedin1972.Lastpreviouseditionapprovedin2014asB567–98(2014).DOI:

10.1520/B0567-98R21. (see 2.1.12).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B567 − 98 (2021)

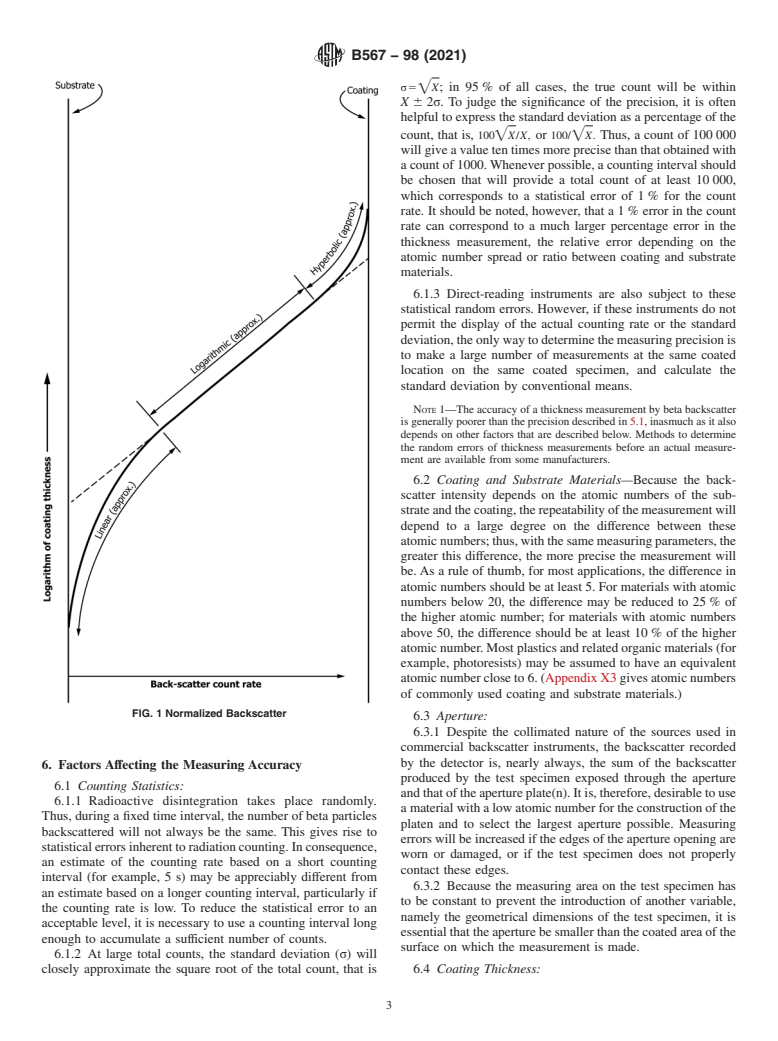

2.1.5.2 normalized backscatter—the normalized 3. Summary of Test Method

backscatter, x , is a quantity that is independent of the activity

n

3.1 When beta particles impinge upon a material, a certain

of the source, the measuring time, and the properties of the

portionofthemisbackscattered.Thisbackscatterisessentially

detector. The normalized backscatter is defined by the

a function of the atomic number of the material.

equation:

3.2 If the body has a surface coating and if the atomic

numbers of the substrate and of the coating material are

X 2 X

sufficiently different, the intensity of the backscatter will be

x 5

n

X 2 X

s 0

between two limits: the backscatter intensity of the substrate

and that of the coating. Thus, with proper instrumentation and

where:

if suitably displayed, the intensity of the backscatter can be

X = count from the substrate,

used for the measurement of mass per unit area of the coating,

X = count from the coating material, and

s

which, if the density remains the same, is directly proportional

X = count from the coated specimen, and each count is for

to the thickness.

the same interval of time.

3.3 The curve expressing coating thickness (mass per unit

Because X is always ≥X and ≤ X , x can only take values

0 s n

area)versusbetabackscatterintensityiscontinuousandcanbe

between 0 and 1. (For reasons of simplicity, it is often

subdivided into three distinct regions, as shown in Fig. 1. The

advantageous to express the normalized count as a percentage

normalized count rate, x , is plotted on the X-axis, and the

n

by multiplying x by 100.)

n

logarithm of the coating thickness, on the Y-axis. In the range

2.1.5.3 normalized backscatter curve—the curve obtained

0≤ x ≤0.35, the relationship is essentially linear. In the range

n

by plotting the coating thickness as a function of x .

n 0.35≤x ≤0.85, the curve is nearly logarithmic; this means

n

that, when drawn on semilogarithmic graph paper, as in Fig. 1,

2.1.6 beta particles—beta particles or beta rays are high-

the curve approximates a straight line. In the range

speed electrons that are emitted from the nuclei of materials

0.85≤ x ≤1, the relationship is nearly hyperbolic.

undergoing a nuclear transformation. These materials are n

called beta-emitting isotopes, beta-emitting sources, or beta

3.4 Radiation other than the beta rays are emitted or

emitters.

backscattered by the coating or substrate, and may be included

in the backscatter measurements.Whenever the term backscat-

2.1.7 coating thickness—in this test method, coating thick-

ter is used in this method, it is to be assumed that reference is

ness refers to mass per unit area as well as geometrical

made to the total radiation measured.

thickness.

2.1.8 dead time or resolving time—Geiger-Müller tubes

4. Significance and Use

used for counting beta particles have characteristic recovery

4.1 The thickness or mass per unit area of a coating is often

times that depend on their construction and the count rate.

critical to its performance.

Afterreadingapulse,thecounterisunresponsivetosuccessive

4.2 Forsomecoating-substratecombinations,thebetaback-

pulsesuntilatimeintervalequaltoorgreaterthanitsdeadtime

scatter method is a reliable method for measuring the coating

has elapsed.

nondestructively.

2.1.9 energy—it is possible to classify beta emitters by the

4.3 The test method is suitable for thickness specification

maximum energy of the particles that they release during their

acceptance if the mass per unit area is specified. It is not

disintegration. This energy is generally given in mega-

suitable for specification acceptance if the coating thickness is

electronvolts, MeV.

specified and the density of the coating material can vary or is

2.1.10 equivalent (or apparent) atomic number— the

not known.

equivalent atomic number of an alloy or compound is the

atomic number of an element that has the same backscatter

5. Instrumentation

coefficient as the material.

5.1 In general, a beta backscatter instrument will comprise:

2.1.11 half-life, radioactive—for a single radioactive decay

(1)aradiationsource(isotope)emittingprimarilybetaparticles

process, the time required for the activity to decrease by half.

having energies appropriate to the coating thickness to be

measured (see Appendix X2), (2) a probe or measuring system

2.1.12 saturation thickness—the minimum thickness of a

witharangeofaperturesthatlimitthebetaparticlestothearea

material that produces a backscatter that is not changed when

of the test specimen on which the coating thickness is to be

the thickness is increased. (See also Appendix X1.)

measured, and containing a detector capable of counting the

2.1.13 sealed source or isotope—aradioactivesourcesealed

number of backscattered particles (for example, a Geiger-

in a container or having a bonded cover, the container or cover

Müller counter (or tube)), and (3) a readout instrument where

being strong enough to prevent contact with and dispersion of

the intensity of the backscatter is displayed.The display, in the

the radioactive material under the conditions of use and wear

form of a meter reading or a digital readout can be: (a)

for which it was designed.

proportional to the count, (b) the normalized count, or (c) the

2.1.14 source geometry—the spatial arrangement of the coatingthicknessexpressedeitherinthicknessormassperunit

source,theaperture,andthedetectorwithrespecttoeachother. area units.

B567 − 98 (2021)

σ5=X; in 95% of all cases, the true count will be within

X 62σ. To judge the significance of the precision, it is often

helpful to express the standard deviation as a percentage of the

count, that is, 100=X/X, or 100/=X. Thus, a count of 100000

willgiveavaluetentimesmoreprecisethanthatobtainedwith

acountof1000.Wheneverpossible,acountingintervalshould

be chosen that will provide a total count of at least 10000,

which corresponds to a statistical error of 1% for the count

rate. It should be noted, however, that a 1% error in the count

rate can correspond to a much larger percentage error in the

thickness measurement, the relative error depending on the

atomic number spread or ratio between coating and substrate

materials.

6.1.3 Direct-reading instruments are also subject to these

statistical random errors. However, if these instruments do not

permit the display of the actual counting rate or the standard

deviation,theonlywaytodeterminethemeasuringprecisionis

to make a large number of measurements at the same coated

location on the same coated specimen, and calculate the

standard deviation by conventional means.

NOTE 1—The accuracy of a thickness measurement by beta backscatter

is generally poorer than the precision described in 5.1, inasmuch as it also

depends on other factors that are described below. Methods to determine

the random errors of thickness measurements before an actual measure-

ment are available from some manufacturers.

6.2 Coating and Substrate Materials—Because the back-

scatter intensity depends on the atomic numbers of the sub-

strateandthecoating,therepeatabilityofthemeasurementwill

depend to a large degree on the difference between these

atomicnumbers;thus,withthesamemeasuringparameters,the

greater this difference, the more precise the measurement will

be.As a rule of thumb, for most applications, the difference in

atomicnumbersshouldbeatleast5.Formaterialswithatomic

numbers below 20, the difference may be reduced to 25% of

the higher atomic number; for materials with atomic numbers

above 50, the difference should be at least 10% of the higher

atomicnumber.Mostplasticsandrelatedorganicmaterials(for

example, photoresists) may be assumed to have an equivalent

atomicnumbercloseto6.(AppendixX3givesatomicnumbers

of commonly used coating and substrate materials.)

FIG. 1 Normalized Backscatter

6.3 Aperture:

6.3.1 Despite the collimated nature of the sources used in

commercial backscatter instruments, the backscatter recorded

by the detector is, nearly always, the sum of the backscatter

6. Factors Affecting the Measuring Accuracy

produced by the test specimen exposed through the aperture

6.1 Counting Statistics:

andthatoftheapertureplate(n).Itis,therefore,desirabletouse

6.1.1 Radioactive disintegration takes place randomly.

amaterialwithalowatomicnumberfortheconstructionofthe

Thus, during a fixed time interval, the number of beta particles

platen and to select the largest aperture possible. Measuring

backscattered will not always be the same. This gives rise to

errorswillbeincreasediftheedgesoftheapertureopeningare

statisticalerrorsinherenttoradiationcounting.Inconsequence,

worn or damaged, or if the test specimen does not properly

an estimate of the counting rate based on a short counting

contact these edges.

interval (for example, 5 s) may be appreciably different from

6.3.2 Because the measuring area on the test specimen has

an estimate based on a longer counting interval, particularly if

to be constant to prevent the introduction of another variable,

the counting rate is low. To reduce the statistical error to an

namely the geometrical dimensions of the test specimen, it is

acceptable level, it is necessary to use a counting interval long

essentialthattheaperturebesmallerthanthecoatedareaofthe

enough to accumulate a sufficient number of counts.

surface on which the measurement is made.

6.1.2 At large total counts, the standard deviation (σ) will

closely approximate the square root of the total count, that is 6.4 Coating Thickness:

B567 − 98 (2021)

6.4.1 In the loga

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.