ASTM B567-98(2021)

(Test Method)Standard Test Method for Measurement of Coating Thickness by the Beta Backscatter Method

Standard Test Method for Measurement of Coating Thickness by the Beta Backscatter Method

SIGNIFICANCE AND USE

4.1 The thickness or mass per unit area of a coating is often critical to its performance.

4.2 For some coating-substrate combinations, the beta backscatter method is a reliable method for measuring the coating nondestructively.

4.3 The test method is suitable for thickness specification acceptance if the mass per unit area is specified. It is not suitable for specification acceptance if the coating thickness is specified and the density of the coating material can vary or is not known.

SCOPE

1.1 This test method covers the beta backscatter gages for the nondestructive measurement of metallic and nonmetallic coatings on both metallic and nonmetallic substrate materials.

1.2 The test method measures the mass of coating per unit area, which can also be expressed in linear thickness units provided that the density of the coating is known.

1.3 The test method is applicable only if the atomic numbers or equivalent atomic numbers of the coating and substrate differ by an appropriate amount (see 6.2).

1.4 Beta backscatter instruments employ a number of different radioactive isotopes. Although the activities of these isotopes are normally very low, they can present a hazard if handled incorrectly. This standard does not purport to address the safety issues and the proper handling of radioactive materials. It is the responsibility of the user to comply with applicable State and Federal regulations concerning the handling and use of radioactive material. Some States require licensing and registration of the radioactive isotopes.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B567 − 98 (Reapproved 2021)

Standard Test Method for

Measurement of Coating Thickness by the Beta Backscatter

1

Method

This standard is issued under the fixed designation B567; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Terminology

1.1 This test method covers the beta backscatter gages for 2.1 Definitions of Terms Specific to This Standard:

the nondestructive measurement of metallic and nonmetallic 2.1.1 activity—the nuclei of all radioisotopes are unstable

coatings on both metallic and nonmetallic substrate materials.

and tend to change into a stable condition by spontaneously

emitting energy or particles, or both. This process is known as

1.2 The test method measures the mass of coating per unit

radioactive decay.The total number of disintegrations during a

area, which can also be expressed in linear thickness units

suitably small interval of time divided by that interval of time

provided that the density of the coating is known.

is called “activity.” Therefore, in beta backscatter

1.3 Thetestmethodisapplicableonlyiftheatomicnumbers

measurements, a higher activity corresponds to a greater

or equivalent atomic numbers of the coating and substrate

emissionofbetaparticles.Theactivityofaradioactiveelement

differ by an appropriate amount (see 6.2).

used in beta backscatter gages is generally expressed in

4

1.4 Beta backscatter instruments employ a number of dif- microcuries (1 µCi=3.7×10 disintegrations per second).

ferent radioactive isotopes. Although the activities of these

2.1.2 aperture—the opening of the mask abutting the test

isotopes are normally very low, they can present a hazard if

specimen. It determines the size of the area on which the

handled incorrectly. This standard does not purport to address

coating thickness is measured. This mask is also referred to as

the safety issues and the proper handling of radioactive

a platen, an aperture plate, a specimen support, or a specimen

materials. It is the responsibility of the user to comply with

mask.

applicable State and Federal regulations concerning the han-

2.1.3 backscatter—when beta particles pass through matter,

dling and use of radioactive material. Some States require

they collide with atoms. Among other things, this interaction

licensing and registration of the radioactive isotopes.

will change their direction and reduce their speed. If the

1.5 The values stated in SI units are to be regarded as

deflections are such that the beta particle leaves the body of

standard. No other units of measurement are included in this

matter from the same surface at which it entered, the beta

standard.

particle is said to be backscattered.

1.6 This standard does not purport to address all of the

2.1.4 backscatter coeffıcient—the backscatter coefficient of

safety concerns, if any, associated with its use. It is the

a body, R, is the ratio of the number of beta particles

responsibility of the user of this standard to establish appro-

backscattered to that entering the body. R is independent of the

priate safety, health, and environmental practices and deter-

activity of the isotope and of the measuring time.

mine the applicability of regulatory limitations prior to use.

2.1.5 backscatter count:

1.7 This international standard was developed in accor-

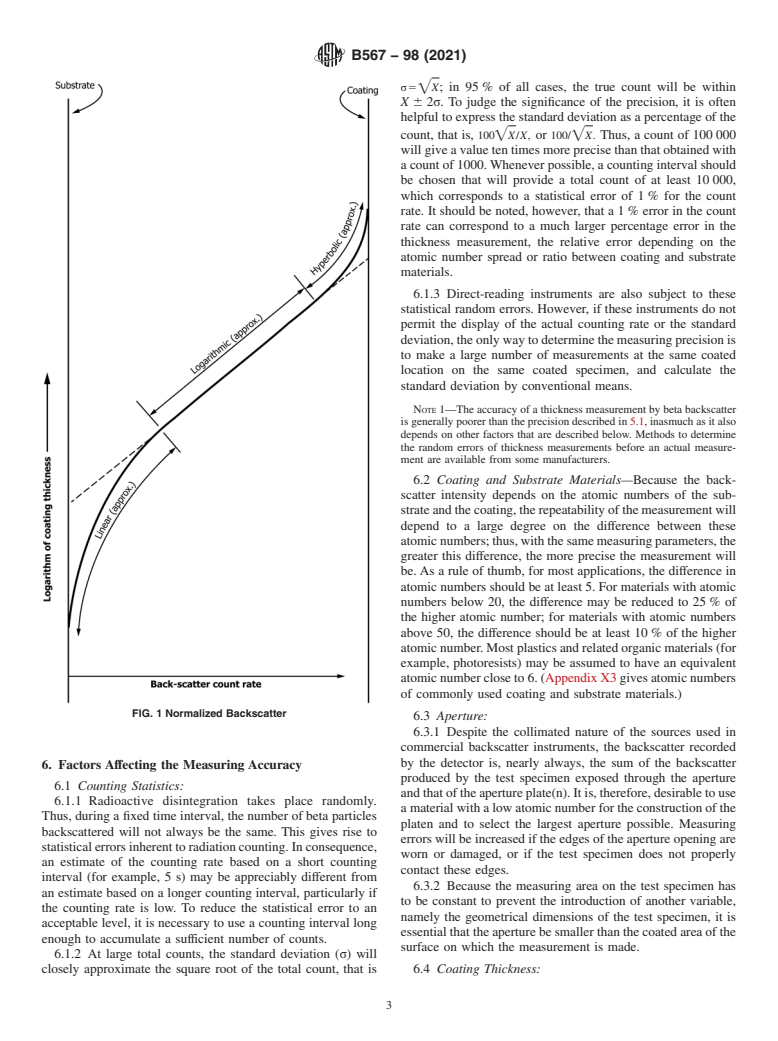

2.1.5.1 absolute backscatter count—the absolute backscat-

dance with internationally recognized principles on standard-

ter count, X, is the number of beta particles that are backscat-

ization established in the Decision on Principles for the

tered during a finite interval of time and displayed by the

Development of International Standards, Guides and Recom-

instrument. X will, therefore, depend on the activity of the

mendations issued by the World Trade Organization Technical

source, the measuring time, the geometric configuration of the

Barriers to Trade (TBT) Committee.

measuringsystem,andthepropertiesofthedetector,aswellas

the coating thickness and the atomic numbers of the coating

1

and substrate materials. X is the count produced by the

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

0

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on

uncoated substrate, and Xs, that of the coating material. To

Test Methods.

obtainthesevalues,itisnecessarythatboththesematerialsare

Current edition approved Apri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.